- Anchoring & Mooring

- Boat Anatomy

- Boat Culture

- Boat Equipment

- Boat Safety

- Sailing Techniques

The Essential Guide To A Jib Sheet

A jib sheet is an essential part of any sailing vessel. It’s a line that connects the jib sail to the cockpit, allowing sailors to control and adjust the sails as they manoeuvre their boats. This blog post will discuss everything you need to know about jib sheets, from how to tie them off to why they matter.

Key Takeaways

- The jib sheet system includes four key components: the clew, track, blocks, and sheets.

- Different types of jib sails, such as the genoa, working jib, and storm jib , have unique pros and cons depending on the weather conditions and sailing needs.

- The jib sheet serves as the central control for adjusting the angle of the sail to the wind and runs through blocks attached to either side of the boat.

- Proper trimming and tensioning of the jib sheet are crucial for maximizing performance and maneuverability.

- Mastering jib sheet techniques can help sailors improve their speed and efficiency while sailing, as well as their control and handling capabilities.

The Anatomy of a Jib Sheet System

The jib sheet system is essential for any sailboat, as it plays a significant role in controlling the sail and manoeuvring the boat. The jib sheet system includes four key components:

The clew is located at the bottom corner of the sail, which joins with the mast and boom. It comprises two parts: an eyelet (or grommet) and a block that slides along the track. The eyelet carries two lines: one from the sail’s top corner (the head) and one from the bottom corner (the clew). These lines are attached with loops or knots on most boats to ensure a secure connection.

The track runs along both sides of the boat, usually on either side of the cockpit. It is made up of several sections that are bolted together. Each section has small slots or grooves which allow you to adjust your clew block position according to your needs while sailing.

The Blocks

Blocks are connected to both ends of your jib sheet line so they can slide along your tracks as you adjust your sail trim . Blocks come in different types and sizes depending on their purpose; some will be used for heavy-duty applications, while others may only be used for light-duty purposes such as adjusting your clew block position when sailing downwind .

Blocks are designed with strong materials like stainless steel or aluminium to withstand even harsh conditions while sailing. They also feature multiple pulleys, which help reduce friction as they slide along your tracks while you adjust your sails. This makes it much easier to change quickly during tricky sailing conditions when time is at a premium!

The sheets connect everything together – they attach directly to the blocks and give you direct control over your sail’s trimming action. The sheets will typically consist of either rope or webbing material depending on their use – rope is better suited for heavier loads. In comparison, webbing offers more flexibility for lighter loads but requires more care when handling due to its delicate nature. In addition, sheets can be “dyneema”, an ultra-lightweight material specifically designed for high-performance racing boats where every ounce counts!

Each type of jib sail has its advantages and disadvantages, so it’s essential to understand what type will work best for a specific situation. Some common types include:

The genoa is among the most commonly used types of jib sails. It is typically larger than other jibs and provides more power in lighter winds. The genoa also offers increased manoeuvrability and agility in tight spaces due to its greater size. One downside to using a genoa jib is that they can be difficult to tack, especially if you’re working with a stiffer sail material like dacron or laminate.

Working Jib

Working jibs are much smaller than genoas and designed for heavier wind conditions. They offer better performance in strong winds but are less agile than their larger counterparts. Working jibs can be easier to tack than genoa sails due to their smaller size, making them ideal for sailors who want more control over their boat in high winds. However, they provide less power in lighter winds than the larger genoa sails .

Storm Jibs

Storm jibs are some of the smallest jib sails explicitly designed for use during stormy weather conditions. They offer excellent manoeuvrability and stability even when facing powerful gusts while still being relatively easy to handle, thanks to their small size. Storm jibs provide less power than other jib sails, so they should only be used when necessary due to inclement weather conditions or strong gusts that would otherwise make sailing difficult or dangerous .

What is a Jib Sheet?

A jib sheet is a line (rope) attached to the clew of the jib sail , a triangular sail located at the front of a sailboat and extending back to the cockpit, where crew members can adjust it from. The jib sheet serves as the central control for adjusting the angle of the sail to the wind.

A jib sheet is a line that runs from the clew of the jib sail to one or two winches on either side of the boat . The purpose of this line is to hold the sail in place while also allowing you to adjust its trim as needed. Depending on the type of boat, the jib sheet may be attached to both port and starboard winches. This allows you to adjust each side independently to set up your sails for different conditions.

There are two types of jib sheets: a single sheet or a two-part split sheet. Both sheets come together at the tiller and are adjusted by pulling on one or both ends in unison. The goal of adjusting the jib sheet is to trim the sail so that it catches more wind, which will help propel your boat forward faster and more efficiently. They are typically made from low-stretch rope such as Dacron or Vectran.

The term “sheet” comes from an old nautical term for a rope; most sailors are familiar with sheet ropes used for sails, but many don’t realise that it’s also used for other purposes — such as mooring lines or anchor lines! The critical difference between these uses and what makes them all “sheet ropes” is that they are typically used for tension rather than lifting or hauling applications.

How Does It Work?

When setting up your jib sheet, it’s essential to ensure that it has enough slack to allow the sail to move freely with wind shifts and gusts. If there isn’t enough slack in the line, then friction will cause the sail to become less efficient and create drag which can slow down your boat. Too much slack can also create problems because your sail won’t remain properly trimmed when sailing upwind . It takes some practice and experience before you get a feel for how much slack should be in your jib sheet at any given time.

The jib sheet runs through blocks (pulleys) attached to either side of the boat, allowing sailors to adjust the angle of attack by pulling on either side of the line. By pulling on one side while letting out slack on another, sailors can change which direction their sails are pointing relative to the wind and their intended course. This helps them maximise their speed and manoeuvrability in any given situation.

In addition to adjusting for wind direction, sailors use jib sheets to trim their sails for maximum efficiency and power output. By adjusting both sides evenly and simultaneously, sailors can achieve full power without worrying about over-trimming or creating too much heeling pressure on one side of the boat. This gives them greater control over their boat’s speed and performance in different conditions.

Trimming The Jib Sail

Trim your jib sail by adjusting the pressure on your jib sheet. Pulling on the sheet will create more tension in the sail, which will cause it to become fuller and, therefore, more power efficient. To reduce tension, ease off on the sheet until it is pulling evenly across both sides of the boat. This will allow for maximum performance in light wind conditions. It’s important not to overtighten or under-tighten your jib sheets, as this can also impact your boat’s performance.

Tension Your Jib Sheet

In addition to trimming your sails with a jib sheet, you must also ensure they are tensioned correctly. This means ensuring that both ends are equally tight and pulling in opposite directions. This helps prevent wear on both ends of the rope over time and provides proper control over your sails when sailing. If one side is too loose or too tight compared to its counterpart, it can throw off your boat’s handling capabilities and cause instability.

Change Course With The Jib Sheet

Finally, using a jib sheet allows you to easily change course while sailing without having to tack or gybe manually each time you need to turn around or adjust direction slightly. Pull down on one side while pushing on the other until you reach your desired order or heading. It’s essential to keep going quickly once you’ve got this point; otherwise, you may turn back in unwanted circles!

Increasing Speed

When it comes to increasing speed, jib sheets play an important role. Adjusting your sails to catch more wind allows you to move faster and move more efficiently than before. The key is knowing when to shorten your sheets or trim them in closer, so they don’t flog (flap) in the wind. Each boat is different depending on its size and shape, so practice makes perfect for getting it right for maximum speed.

Improving Manoeuvrability

Correctly set jib sheets help you turn quickly and smoothly when sailing close-hauled. This requires skilful use of your tiller/wheel and adept control of your jib sheets by pulling them in or letting them out as necessary while turning. This will give you more control over how tight of a turn you can make while staying within a comfortable range for your vessel’s design.

How Do I Tie Off My Jib Sheet?

You must tie off your jib sheet correctly because incorrect knots can cause sailing problems. Once you’ve chosen your knot, it’s time to attach it to the jib sheet. Begin by looping one end of the rope through itself and then looping it around the clew of your jib sheet (the clew being at the bottom corner of your sail). Pull both ends tightly and tie them together using whichever knot you choose. Make sure you pull tight before securing it with a stopper knot or a half hitch so the knot won’t come undone while sailing.

Finally, you can use a snap shackle to attach the jib sheet to its designated position on your boat’s rigging system. This will ensure that everything stays where it should be during rough weather or high winds.

For any sailor looking to take their skills up a notch, there’s no substitute for time on the water. And when it comes to improving performance and manoeuvrability out at sea, honing your jib sheet techniques is key: Trimming the sail, tensionally getting things just right – even changing direction with ease; mastering these elemental art forms will surely set you apart!

Where should you avoid anchoring a boat?

Dragging anchor: what you need to know, related posts, whisker pole sailing rig: techniques and tips, reefing a sail: a comprehensive guide, sail trim: speed, stability, and performance.

- Cookie Policy

- Privacy Statement

© 2023 TIGERLILY GROUP LTD, 27 Old Gloucester Street, London, WC1N 3AX, UK. Registered Company in England & Wales. Company No. 14743614

Welcome Back!

Login to your account below

Remember Me

Retrieve your password

Please enter your username or email address to reset your password.

Add New Playlist

- Select Visibility - Public Private

No products in the cart.

Sailing Ellidah is supported by our readers. Buying through our links may earn us an affiliate commission at no extra cost to you.

A Full Guide to The Jib Sail And How To Use It

Most cruising boats today have a sail plan consisting of at least three sails: A mainsail, a headsail, and a light-wind sail.

The Jib sail (along with its sister, the Genoa) is one of the most widely used headsails on modern sailboats in combination with a larger mainsail. It is very versatile and easy to use in different configurations throughout most weather conditions.

In this article, I want to explain the Jib in detail and talk a bit about how it works and how we rig and trim it to get the most performance out of the boat. I’ll also show you each part of the sail and its materials before explaining how it differs from other headsails like the Genoa .

Finally, I’ll finish with some tips on maintaining the sail properly to make sure it last as long as possible.

Well, shall we get started?

What is a Jib sail, and what do we use it for?

The Jib is a triangular sail that does not overlap the mainsail. It is typically between 100% and 115% of the foretriangle size and is commonly seen on modern vessels with fractional rigs.

The foretriangle is the triangular area formed by the mast, deck, and forestay. Learn more terms here .

Like other headsails, the Jib is usually rigged on a furling system attached to the forestay , making it easy to operate. The Jib can also be rigged with a self-tacking system, making upwind sailing easy for you, whether you want to cruise solo or with your friends.

How the Jib works on a sailboat

The Jib provides a sail area forward of the mast, allowing the boat to be steered and balanced effectively.

The curved shape of the sail creates a pressure differential. The outer, more convex side (leeward side) has a lower pressure than the inner, concave side (windward side). This pressure differential generates lift, which translates into forward propulsion, much like how an airplane wing produces lift.

How to rig a Jib

You can rig the Jib on either a furling system or directly to the forestay. Most modern sailing boats are equipped with a furling system, which is a long sleeve that runs from the top of the mast down to the bow and attaches to a drum on the bottom and a swivel on the top.

Take a closer look at this step-by-step process on how to rig the Jib to sail onto a furling system:

- Feed the Jib’s luff into the track on the furler’s sleeve with the top of the sail first and connect the head ring on the sail to the chackle on the swivel.

- Attach the Jib halyard to the swivel and hoist the sail up.

- When the sail is hoisted almost all the way to the top, you attach the sail’s tack to a shackle on the top of the drum.

- Put the halyard on a winch and winch it tight.

- Now you have to manually roll up the sail around the forestay and tie on the two sheets to the clew of the sail.

- Lead the two sheets on each side of the vessel’s side decks through the sheet cars, turn blocks, and back to the winches.

- Now that the sail is furled away, we need to tie the furling line onto the drum. You have to figure out how the furling line attaches, as it differs from system to system.

- Once the furler line is attached to the drum, ensure that it can wrap itself up freely.

- Pull the sail back out using one of your sheets and monitor that the furling line wraps on nicely.

- Leed the furling line through the blocks and funnels, through the jammer , and leave it next to the winch.

- Furl the sail away again using the furling line and ensure that the sheets run freely as you monitor your sail getting wrapped nicely around the forestay.

- Secure the furler line jammer and tidy up your two sheets. Make sure to secure the sheets around the winches.

So, you see now why most boats use furling systems? It is easy! Many larger sailboats even have electrical furlers, removing the need for the furling line.

How to use, reef, and trim a Jib

To use the Jib, you wrap the furler line around the winch, open the jammer, and pull on either of the sheets, depending on which tack you are sailing on. You should hold on to the furler line to prevent the sail from unfurling itself uncontrollably, especially in strong winds. Trying to catch it if it starts running can injure your hands, so be careful! I’m speaking from experience here; burned hands are “No bueno.”

You can now unfurl the entire sail or a part of it. Once the full sail, or the amount you desire, is out, adjust your car position and tighten the sheet.

How to reef a jib

You do the opposite as the above to reef the sail or furl it back in.

Ease off the working sheet, but keep it on the winch. At the same time, pull in on the furler line either manually or on the winch. Remember to move the cars forward and re-tighten the sheet if you are reefing away only a part of the Jib.

How to trim a jib

Adjusting the sheet cars and sheet tension is important to obtain an optimal sail shape in the Jib. Finding this balance is what we call sail trim . I’m not going too deep into sail trim here, as it is a topic for itself, which will require a separate article,.

But here is a rule of thumb:

You want the leech and foot of the sail to form an even “U” shape on any point of sail . When sailing upwind, you usually move the car aft. When bearing off the wind, you move the car forward.

The goal is to apply even tension on both the foot and the leech. When you reef the sail, you’ll also want to move the car forward to adjust for the reduced sail area. Sailing downwind doesn’t require the same fine-tuning as upwind sailing.

Four tips for sailing upwind:

- Winch up the jib sheet until the leech stops fluttering and the foot has a nice, even “U” shape.

- You must move the sheet car forward if the foot is tight and the leech flutters.

- Move the sheet cars aft if the leech is tight and the foot flutters .

- If the wind increases and the boat starts to heel excessively, you can either ease off the sheet or adjust your course more head to wind.

You should play around and experiment with sail trim, as every boat behaves differently. Trimming sails is an art that takes time to master. Staysails, Jibs, and Genoas are trimmed the same way, but the car positions will be different due to their size and shape differences. Once you learn how to trim a Jib, you’ll be able to trim any headail and even a storm jib or a spinnaker.

Sailing with more than one Jib

Sailing with multiple jib sails can be beneficial on longer downwind passages. Most furling systems have two tracks, allowing you to have two Jibs on the same furler, making this setup easy to reef. You can do the same with Yankees and Genoas, depending on what you have available in your boat.

Some sailboats have two or more forestays, allowing them to have two individually furled Jibs. This is usually called a cutter rig. Most Cutter rigs, however, use a Staysail on the inner forestay and a Yankee sail on the outer, but this versatile rig allows you to experiment with many setups.

Exploring the different parts of the Jib

Head: The head is the top corner of the Jib. It typically has a ring in the top corner that attaches to the Jib halyard or the top swivel for furling systems.

Leech: The leech is the aft part of the rib, located between the clew and head.

Luff : A Jib’s luff is the front part between the tack and head. Jibs can be equipped with luff foam to help maintain their shape when partially reefed on a furler.

Clew : The clew is the aft lower corner of the jib where the sheets are attached.

Tack : The tack is the lower, forward corner of the Jib. The tack is connected to a furler drum on the forestay on most sailboats. Vessels using traditional hank-on headsails connect the tack to a fixed point on the bow.

Foot : The foot of the Jib is the bottom portion of the sail between the clew and the tack.

Telltales: Telltales are small ropes, bands, or flags attached to the front of the Jib’s leech to help us understand how the wind affects the sail and allow us to fine-tune the trim for optimal performance.

Commonly used materials for the Jib

The most common material used for Jib’s today is Dacron woven polyester, followed by CDX laminate due to the relatively affordable price. Continuing up the range, we find woven hybrids like Hydranet, Vectran, Radian, and other brands.

Then, we have advanced laminates with Aramids, carbon, kevlar, and more exotic materials. At the top of the spectrum, we find the latest technology in DFi membrane sails like Elvstrøms EPEX or North Sails 3Di, which comes at a premium price tag.

These days, however, modern technology has given us warp-oriented woven cloth, which is becoming a popular option due to its increased ability to keep shape over time without stretching as much as traditionally cross-cut dacron sails. ProRadial, made by Contender and Dimension Polyant, is a good example. North Sails has an excellent article that goes in-depth on sail materials.

The difference between a Jib and a Genoa

The difference between a Jib and a Genoa is that the Jib is a headsail that does not overlap the mainsail, while the larger Genoa is designed to overlap the mainsail. While the smaller Jib is excellent at pointing upwind and easier to handle, the larger Genoa excels on any points of sail with the wind behind the beam.

Genoas are usually larger than 115% of the foretriangle , with sizes ranging from 120% to 150%. They are often used on yachts with masthead rigs and smaller mainsails but are also common on fractional rigs.

How to Maintain and Care for Your Jib Sail

Good maintenance and care of your Jib will ensure optimal performance and minimize wear and tear. Check out these tips on how to maintain and protect your Jib:

- Rinse the Jib with fresh water regularly and leave it up to dry before packing it away. Proper drying will prevent moisture and mildew.

- Give the sail a service once a year. Check for any damaged seams and repair them if necessary. If there are any chafing marks, reinforce the sail with patches on chafe points and add shafe guards to the equipment it rubs against.

- Protect the sail from UV rays by keeping it packed away when not in use. A furling Jib can be protected by adding a UV strip to the foot and leech.

I also wrote an article on how to make sails last longer .

Final Words

We have talked a lot about the Jib’s features and how it works in this article. I recommend you to head out and set sail to get some experience and play around with your sails. If you don’t have a boat, chat around in your nearest marina; someone will for sure bring you along for a sail. I know I would.

Remember to experiment with sail trim and practice tacking and maneuvering the vessel with the sail on both the port and starboard sides.

If you still have questions, check out the frequently asked questions section below or drop a comment in the comment field. I’ll be more than happy to answer any of your questions!

PS: Explore more sails in my easy guide to different types of sails here .

FAQ – The Jib Sail Explained

When to use a jib sail.

The Jib is an excellent sail for most conditions, especially when cruising at any angle towards the wind. The Jib has a benefit over the Genoa in strong winds as it is easier to handle, and its smaller size makes it more effective than a reefed Genoa when sailing to windward.

Can you sail with just the Jib?

It is possible to sail with just the Jib alone, and it works exceptionally well downwind on deep angles where the mainsail usually would have blocked off the wind.

Can you sail upwind with just the jib?

It is possible to sail upwind with just the Jib, but most sailboat owners prefer to balance their boats by flying their mainsail combined with theiJib when sailing to windward.

What is the difference between a Genoa and a Jib?

The Genoa is different from a Jib sail as it is larger and overlaps the mainsail, whereas the Jib is smaller and does not overlap the mainsail.

Sharing is caring!

Skipper, Electrician and ROV Pilot

Robin is the founder and owner of Sailing Ellidah and has been living on his sailboat since 2019. He is currently on a journey to sail around the world and is passionate about writing his story and helpful content to inspire others who share his interest in sailing.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

× You are using an outdated browser. Please upgrade your browser to improve your experience.

We Ship Worldwide! | FREE SHIPPING! for US Continental orders over $99. Click for details.

Shopping Cart

Your cart is currently empty..

FREE SHIPPING! for US Continental orders over $99 click for details

Sailboat Main, Genoa and Spinnaker Sheets

A Sheet Line in sailing is the line that controls the direction of the sails. It is connected to the the sail's clews. Find mainsheets, jib sheets, genoa sheets and spinnaker sheets for your type of sailing, wether it is cruising, performance or racing.

MAURIPRO Sailing, your direct access to Sailboat Main, Genoa and Spinnaker Sheets and all your other sailing and boating needs.

Copyright © 2024 MAURIPRO Sailing LLC.

Everything You Need To Know About Sailboat Jibs

If you’re considering entering the world of sailing or are a beginner at having your own boat, then there are several terms you will need to know and understand to get the most out of your new pastime.

One of these terms that you may have heard, especially concerning sailboats, is a jib. But what is a jib?

A jib is a type of sail that is found on sailboats (see also ‘ Two-Mast Sailboat Types ‘) and understanding what they are and what they do is very important. That’s why we’ve taken the time to write this article to tell you everything you need to know about sailboat jibs.

Let’s get started!

What Is A Sailboat Jib?

A sailboat job is a headsail that is found on sailboats. It’s a triangular sail that is found forward of your mast. It’s typically not as large and has less of a sail area than your mainsail but it is still important to sailing.

Most sailboats that have a single mast will usually have a jib and you’ll find this between the bow and the mast. Jibs are fixed on a stay, which can be a wire, rod (see also ‘ Rod (Unit Of Measurement) Length Compared To Fishing Rod ‘), or rope, and they run forward from the mast to the deck or bowsprit.

A jib is just one of many different types of headsails.

Do Sailboats Need A Jib?

You might be asking yourself that as your sailboat has a mainsail, does it even need a jib? This is a common question asked by many sailors, especially on windy days when the mainsail can get a good force behind it.

The answer is that you probably don’t need the jib to sail and your sailboat will be able to sail without it. However, if you don’t hoist the jib, you will reduce the amount of your sail area by up to 50 percent.

We would recommend that you hoist the jib if you feel you need to. If it’s a windy day and you have the wind at your back, then the mainsail may be all you need and you can leave the jib.

On typical days that have average amounts of wind, most sailors will choose to hoist both the mainsail and the jib and will reef them whenever it is deemed necessary.

We consider this to be the best option and as you become more experienced with sailing, you will find deciding when and where to hoist the jib will become an easier decision to make.

Trimming The Jib

Before we look at trimming the jib, let’s take a little time to define what we mean.

What Is Trimming In Sailing?

When we talk about trimming a jib, or any other sail, we are referring to the process by which sails are controlled.

Sails have lines known as “sheets” attached to them, and when we adjust the tension of these lines to move the sail, this is known as trimming.

How To Trim A Jib

The jib on a sailboat is usually controlled by using two jib sheets that are positioned on either side of the mast. Using two separate sheets makes moving and manipulating the jib easier as you can adjust it from either side.

If there was only one sheet, you would need to constantly reposition the sheet to the appropriate side.

When the wind is to your port side, you will manipulate your jib by adjusting the tension of the starboard side sheet and vice versa. When you adjust the starboard jib sheet, remember to secure it on the winch and free the port side jib sheet to get the best movement.

Is It Possible For A Sailboat To Have Multiple Jib Sails?

Yes, it’s perfectly possible for a sailboat to have more than one jib sail. However, remember that not all headsails are jibs, so some sailboats might have a jib and other types of headsails as well.

Although multiple jibs aren’t unheard of, it’s more likely that an American sailboat will only have one. The most popular cruising sailboat in the States is the single-mast sloop and these typically only have one jib.

Next time you’re at a harbor or on the waves and have the opportunity to see other sailboats, it’s more likely that the sailboats around you will only have one jib.

What Material Are Jib Sails Made From?

Historically, jib sails were made of organic materials that had a canvas feel to them, such as cotton.

Traditionally, they’ve been made from materials such as cotton, hemp, and other plant material that have similar properties. A mix of these materials was usually made to get the best mix of strength and durability.

In modern times, synthetic fibers and fabrics have become more common and have largely replaced the more traditional canvas materials.

This is largely because synthetic fibers have several advantages over their organic counterparts. They’re often lighter and stronger, for example, as well as being more durable and able to resist water.

Let’s look at some of the most popular materials used for jib sails.

This is one of the most common materials used for sails. Most modern jib sails are made from polyester that is woven into a blend with other synthetic materials.

The most common type of polyester used in sails is Dacron and this is because it has many inherent properties that make it perfect for sailing.

Dacron doesn’t stretch, has excellent UV resistance, and is also cheap to manufacture, making it a low-cost option.

Dacron sails have become popular because they will last for several years without the need for much maintenance, they’re reliable, and they’re cost-effective.

This is another synthetic material that is commonly used for sails. It shares many characteristics with polyester as it is also inexpensive and durable.

It’s more lightweight than polyester and is ideal for sailboats such as spinnakers that work best with lighter sails.

Nylon isn’t perfect, however, and it can be too stretchy for some sail applications. It also reacts to and can be damaged by certain chemicals, so some people prefer to avoid nylon sails.

Kevlar is an extremely strong and heat-resistant synthetic fiber that has a wide application of uses beyond sailing. Its tightly woven structure means that it is commonly used for personal armor, as well as firefighter uniforms and motorcycle safety clothing.

When comparing the strength-to-weight ratio of Kevlar and steel, Kevlar is five times stronger. It resists stretching and won’t be damaged by even the worst conditions.

All of this makes Kevlar a very expensive material compared to polyester and nylon. For many sailboats, this cost is prohibitive and Kevlar sails are usually only used on expensive ships such as luxury yachts and racing sailboats.

What Are The Parts Of A Jib?

Now that we know more about what a jib is, what it’s used for, and what it’s made from, let’s look at a jib in closer detail.

Jibs have many different parts and mounting points, so if you’re going to sail with one it’s important that you know what they all are and what their purposes are.

Thankfully, many of these parts and terms are similar to what you’ll find on a mainsail so you may already know most of them.

This is the horizontal section that you will see running across the base of the sail. You can usually identify it quite easily because it normally has a reinforced strip of material to prevent it from fraying or becoming damaged.

It’s an easy term to remember because the foot is at the bottom, just as it is with many other items and living things.

You will find the clew at the bottom of the jib. It’s at the aft (back) section of the sail’s foot and is also easy to identify. Most clews will have a metal grommet at the clew.

If you imagine a jib sail in your mind, you should have the image of a triangle that has a straight side and bottom that meet at a right angle. The clew is at this 90-degree angle.

If we keep the image of our triangular jib in our minds, the leech is the long straight section that is placed parallel to the mast. It begins at the clew, found at the 90-degree angle at the bottom, and runs to the very top of the sail.

The orientation of the leech on the jib always follows the direction of the mainsail. The leech is always on the aft part of the sail.

As the foot of the jib is at the bottom, it only follows that the head is at the top. The head of a jib sail is the very top of the triangle and is also usually the smallest of the three angles. This is also easy to identify as, like the clew, it will have a grommet.

We learned that the leech is the part of the jib that is parallel to the mast (see also our article on sailboat masts ) and is the aft part of the sail. In contrast, the luff is the forward part of the sail and is also the longest edge.

It’s the slanted edge that runs from the head of the sail down to the forward end.

The clew is at the corner of the jib where the foot and leech meet. The tack is found directly forward of this and is the opposite corner of the foot, where the foot and luff meet.

The tack, clew, and head, all have provisions so that the jib can be rigged.

Usually, headsails like jibs are hoisted and rigged without being supported by wood, metal, or carbon poles. Known as spars, these poles are fixed and used to support the mainsail but many sailboats don’t use them for jibs.

Instead, sailboat owners decide to use jib booms to support their jib. These can be used to extend bowsprits or improve off-wind sailing. They’re similar to mainsail booms and work in very similar ways.

A jib boom is mounted to the forward part of a bowsprit and pivots from the pedestal. It can be used when projecting the sail but there are other methods for this too, such as using a spinnaker instead.

Not every sailor is a fan of jib booms, however. Some find that they don’t offer many benefits when it comes to windward sailing and choose to avoid them.

They can also take up additional room on the bow and come with the same hazards as a mainsail boom. Whether you choose to use a jib boom or not will be a matter of personal preference.

Final Thoughts

Jibs are a type of headsail that is often seen on sailboats. We hope this guide to jibs has answered all of your questions. Happy sailing!

Related Posts:

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

+31 20 419 64 12

- Lijnenspecialist

- Deutsch

Every sailor has different demands for a main sheet, jib sheet and spinnaker sheets. The most important factors are low stretch, grip and smoothness. PremiumRopes has a wide range of sheets with grip fibers for every type of boat. If you are a racer or performance sailor choose a sheet with Dyneema® fibers or Stirotex. If you are a cruiser, a polyester sheet often will do. Choose a sheet with grip fiber if you handle the sheet without winch.

Application: Sheet, Halyard

High quality polyester line double braided with grip fiber (Cordura). Core is 16 strands braided HT Polyester. Unique cover with a mix of HT Polyester and Cordura fiber, providing an unmatched grip, soft feel and durability. Specially developed for sheets and control lines.

Application: Halyard, Sheet, Control line

This rope has a top quality high tenacity polyester core combined with a smoothly braided polyester cover. This rope will ensure excellent grip and makes it ideal for halyards/ sheets and control lines.

The Eco Cruiser is the shining result of our continuous development efforts combined with our sustainability goals. This rope is completely made from recycled plastics. An all-round braided rope from rPet yarns. It is a complete and balanced rope and can therefore be used for various applications. For example, halyards and sheets, but in the thinner diameters also extremely suitable as a trim line.

This high quality performance regatta rope, has a Stirotex grade 12 coated core and 24 braid HT Polyester cover. Features: Suitable for splicing and tapering, very low stretch, light weight, great durability, stronger than steel. Especially suitable for halyards and sheets.

The Eco Cup is the first high performance rope within our Eco Ropes range. We wanted to developed a good rope for performance sailing and combine this with our sustainability goals. This unique rope provides optimal performance due to its strength, UV resistance, low stretch and abrasion resistant cover.

This top quality high performance regatta rope, has a core made of coated Dyneema® SK78 fibers and 24 braid HT Polyester cover. Features: Suitable for splicing and tapering, very low stretch, light weight, great durability. Excellent for halyards.

This ultra high performance regatta rope, has a core made of coated Dyneema® Sk78 fibers and special cover. The cover is a mix of HT Polyester and special fiber, providing an unmatched grip, soft feel and durability. Other features: Suitable for splicing and tapering, very low stretch, light weight. Excellent for control lines, sheets and spi-halyards

This is an high-performance regatta rope and has a core of coated Stirotex fibers. The Technora/polyester cover is suitable for big winches and works very well in clutches. This rope is suitable for splicing and tapering.

- Stirotex 3 items

- Dyneema® SK78 2 items

- Polyester 2 items

- rPET 1 item

- Technora 1 item

- Grip Fiber 1 item

- Polyester 4 items

- rPET 2 items

- 3 mm 2 items

- 4 mm 5 items

- 5 mm 6 items

- 6 mm 6 items

- 7 mm 2 items

- 8 mm 8 items

- 10 mm 8 items

- 12 mm 7 items

- 14 mm 6 items

- 16 mm 3 items

- 18 mm 1 item

- Minimal 5 items

- Low 3 items

- Motor Yacht 2 items

- Classic yacht 1 item

- Sailing Yacht 8 items

- Cruising Yacht 5 items

- Racing Yacht 7 items

- Dinghy 8 items

- Antracite Grey 1 item

- Beige 3 items

- Black 7 items

- Blue 6 items

- Green 6 items

- Navy Blue 1 item

- Orange 4 items

- Red 7 items

- Silver 4 items

- White 4 items

- Yellow 4 items

Premium Ropes

The best place to buy ropes and rigging for your sailing boat. Ropes and steel wire ropes for industry and architecture. We ship worldwide.

- About us | Meet the team

- Sales conditions

- Return shipments

- Shipping costs

- Cookie Consent

- Testimonials

More inspiration

Company Info

Surinamekade 6 1019 BV Amsterdam The Netherlands

[email protected]

+ 31 20 419 64 12

52°22'12" - 4°53'43"

Chamber of Commerce: 68330626

Send us a message via Whatsapp

What’s a Sailboat Jib? (A Comprehensive Guide)

Are you an experienced sailor looking to learn more about your sailboat? Or are you a beginner looking for a comprehensive guide to help you get started? If so, you’ve come to the right place! In this article, we’ll discuss the basics of sailboat jibs and how they help you sail smoothly and efficiently.

We’ll cover what a jib is, the purpose of a jib, the different types of jibs available, how to rig and trim a jib, the benefits of using a jib, and some tips for setting and trimming a jib.

Whether you’re a beginner or an experienced sailor, let’s get started learning more about sailboat jibs!

Table of Contents

Short Answer

A sailboat jib is a triangular sail that is set at the front of a sailboat.

It is usually attached to the forestay, a cable that runs from the bow of the boat to the mast.

The jib helps to balance the mainsail and increases the sailboat’s ability to sail close to the wind.

The jib is often the smallest sail on a sailboat and is often used for light air sailing.

What is a Sailboat Jib?

A sailboat jib is an essential part of any sailing vessel’s rig.

A jib is a triangular sail that is set at the front of the boat, usually between the mast and the bow.

It is the second most important sail on a sailboat and is typically used to help the boat turn and maneuver more efficiently.

The jib is an important part of a sailboat’s rig and is often used in combination with the mainsail to maximize the boat’s performance.

The jib is usually the first sail to be set up.

It is attached to the forestay, a line that runs from the bow of the boat to the mast.

The jib is adjusted to the desired angle and is held in place by a series of blocks that allow it to be adjusted to different angles.

The jib is also connected to the mast by a halyard, which is a rope that is used to raise and lower the sail.

The jib is an important part of sailing because it allows the boat to turn more efficiently.

The jib provides extra lift and power to the boat, which can be used to turn the boat more quickly and to increase the speed of the boat.

The jib also helps to balance the boat, allowing it to sail more smoothly and easily.

The jib also helps to improve the boat’s performance in light winds.

A boat with a jib will be able to sail in much lighter winds than a boat without one.

This is because the jib acts as a sort of “wing” that is able to catch the wind, allowing the boat to move forward even in light winds.

In conclusion, a sailboat jib is an essential part of any sailing vessel’s rig.

It is an important sail that helps to increase the boat’s performance, turning ability, and speed.

The jib also helps to balance the boat and allows it to sail in lighter winds.

A sailboat is not complete without a jib, and understanding how to properly rig and manage a jib is essential for any sailor.

What is the Purpose of a Jib?

The purpose of a jib is to provide an additional source of power and lift as a sailboat moves through the water.

Unlike the mainsail, which is a large, open-ended sail attached to the mast, the jib is a triangular sail that is set at the front of the boat, usually between the mast and the bow.

This helps to make the boat more maneuverable and provides additional power in lighter winds or upwind sailing.

The jib also provides additional lift, which reduces the amount of drag created by the mainsail.

This can help a sailboat achieve higher speeds or sail closer to the wind.

Additionally, the jib can be used to balance the boat in different conditions, such as when sailing upwind or when beating into a strong wind.

In essence, the jib is an important part of a sailboat’s rig and is often used in combination with the mainsail to maximize the boat’s performance.

Types of Sailboat Jibs

When it comes to sailboat jibs, there are several different types that you can choose from depending on your needs. The most common types of sailboat jibs are: Genoa jibs, cutter jibs, overlapping jibs, and non-overlapping jibs.

Genoa jibs are the largest type of sailboat jib and are often used on larger sailboats.

They are typically used in combination with a mainsail to help maximize the boat’s performance.

Genoa jibs provide the most power and are usually used in light to moderate wind conditions.

Cutter jibs are a type of jib that is designed for smaller sailboats.

They are typically used in combination with a mainsail to help the boat maneuver more efficiently.

Cutter jibs are usually used in moderate to strong winds and offer less power than Genoa jibs.

Overlapping jibs, as the name suggests, overlap with the mainsail when deployed.

These sails are usually used in light-moderate winds and provide more power than cutter jibs.

Non-overlapping jibs, also known as headsails, are the most common type of jib used on sailboats.

These sails are usually used in moderate to strong winds and provide the most power when compared to the other types of jibs.

Finally, there are also asymmetrical spinnakers, which are specialized sails that are designed to help the boat reach higher speeds.

These sails are typically used in combination with a mainsail and jib to help the boat reach maximum speed.

Asymmetrical spinnakers are usually used in moderate to strong winds and provide the most power when compared to the other types of jibs.

No matter what type of sailboat jib you choose, you’re sure to enjoy the increased performance that it provides.

With the right combination of mainsail and jib, you’ll be able to maximize your boat’s performance and have a great day on the water.

How to Rig a Jib

Rigging a jib is an important step in ensuring a successful sailing experience.

It requires some knowledge of sailing terminology and techniques, but once the basics are understood, it can be done quickly and efficiently.

The first step in rigging a jib is to select the appropriate size for your sailboat.

The size of the jib should be based on the size of your boat and the type of sailing you plan to do.

For example, a larger jib will be more effective when sailing in strong winds, while a smaller jib is better suited for lighter winds.

Once you have determined the size of the jib, you can begin the rigging process.

First, attach the jib halyard, which is the line used to hoist the sail, to the head of the jib.

Next, attach the jib sheets, which are the lines used to control the trim of the jib, to the clew of the jib.

Finally, attach the jib tack, which is the line used to attach the jib to the bow of the boat, to the bow.

Once the jib is rigged, you can begin to adjust the trim of the sail.

To do this, you will need to adjust the tension on the jib sheets.

If the tension is too loose, the jib will not be able to fill with wind properly and you will lose power.

On the other hand, if the tension is too tight, the sail will be over trimmed and you will sacrifice performance.

Finally, you can adjust the angle of the jib in relation to the wind to maximize the power of the sail.

This is known as jibing, and it involves adjusting the angle of the sail in relation to the wind so that the wind is hitting the sail at the optimal angle.

This will maximize the power of the sail and help you turn more efficiently.

Rigging a jib is an important part of sailing, and when done correctly, it can make a huge difference in your sailing performance.

With a little knowledge and practice, you can quickly and easily rig your jib to maximize the power of your sailboat.

How to Trim a Jib

When it comes to sailing, the jib is an important part of the boats rig.

It is a triangular sail set at the front of the boat, usually between the mast and the bow.

The jib helps the boat turn and maneuver more efficiently, and is often used in combination with the mainsail to maximize the boats performance.

But before you can use the jib to its full potential, you need to know how to trim it properly.

Trimming a jib is a delicate process, as the sail needs to be adjusted in order to capture the right amount of wind.

To do this, you will need to adjust the angle of the sail relative to the boat, as well as the tension of the sail itself.

The angle of the sail should be adjusted so that it is parallel to the wind direction.

As the wind direction changes, so should the angle of the sail.

In order to adjust the tension of the sail, you will need to use the jib sheet.

This is a line that connects the jib to the boat and is used to adjust the sails tension.

By releasing or tightening the jib sheet, you can adjust the amount of tension on the sail, allowing it to capture the right amount of wind.

When it comes to trimming the jib, it is important to remember that the sail needs to be adjusted in order to maximize the boats performance.

Adjusting the angle of the sail and the tension of the sail will help you capture the right amount of wind and will ensure that you are getting the most out of your boat.

With a little practice and patience, you can become an expert at trimming a jib.

Benefits of Using a Jib

A sailboat jib can be an incredibly useful addition to your boats rigging.

It helps the boat turn more efficiently, allowing the boat to be maneuvered with greater precision.

The jib also adds stability in windy conditions, helping to reduce the risk of capsizing.

Additionally, a jib will provide additional power while sailing, allowing you to make quicker progress, particularly in light winds.

Finally, having a jib can help to reduce the stress on your mainsail, extending its life and reducing the need for frequent repairs.

In addition to providing more power, a jib can also be used to adjust the course of the boat.

For example, when sailing close-hauled (on a close reach with the wind coming from directly ahead), the jib can be used to increase the boats speed and turn it more quickly.

This is especially useful when tacking or jibing.

Using a jib also helps to reduce drag on the boat, allowing it to move faster and more efficiently.

This is especially important for racers, who need to maximize their boats performance in order to gain an edge over their competitors.

Finally, using a jib can help to reduce the overall weight of the boat, making it easier to maneuver and store.

This is especially useful for smaller boats, which may not have enough room to store a large mainsail.

Tips for Setting and Trimming a Jib

When it comes to sailing, a well-executed jib can make or break the success of the voyage. Setting and trimming the jib is essential for the boat to reach its full potential on the water. Here are some tips for setting and trimming a jib:

1. Before setting the jib, make sure the boat is properly balanced by adjusting the traveler and outhaul. This will help to ensure the jib is set correctly.

2. When setting the jib, make sure to keep the jib sheet tensioned and the jib luff taut. This will help to ensure the jib is properly aligned with the wind and the boat will move forward efficiently.

3. When trimming the jib, make sure to adjust the sheet tension to keep the jib luff taut. This will help to maintain the jibs alignment with the wind and maximize the boats performance.

4. When sailing in light winds, it can be beneficial to use a smaller jib to reduce drag. This will help to keep the boat moving forward in light conditions.

5. Lastly, it is important to remember to furl the jib in strong winds. This will help to reduce the sail area and keep the boat under control in heavy winds.

These tips should help sailors to get the most out of their jib when sailing.

With the right setup and trim, a jib can be an essential part of a successful sailing voyage.

Final Thoughts

A sailboat jib is an important part of a sailboat’s rig and can help to maximize the boat’s performance.

It is a triangular sail that is typically set between the mast and the bow.

It is important to understand the purpose of a jib, the different types of jibs available, and how to rig and trim a jib.

With knowledge of these basics, sailors will be able to make the most out of their sailboats jib and enjoy a more efficient sailing experience.

So, start sailing with more confidence and get to know your jib today!

James Frami

At the age of 15, he and four other friends from his neighborhood constructed their first boat. He has been sailing for almost 30 years and has a wealth of knowledge that he wants to share with others.

Recent Posts

When Was Banana Boat Song Released? (HISTORICAL INSIGHTS)

The "Banana Boat Song" was released in 1956 by Harry Belafonte. This calypso-style song, also known as "Day-O," became a huge hit and remains popular to this day for its catchy tune and upbeat...

How to Make Banana Boat Smoothie King? (DELICIOUS RECIPE REVEALED)

To make a Banana Boat Smoothie King smoothie at home, start by gathering the ingredients: a ripe banana, peanut butter, chocolate protein powder, almond milk, and ice. Blend the banana, a scoop of...

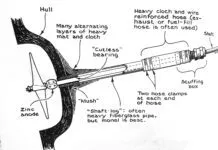

How to Attach Jib Sheets With a Soft Shackle

- Snowboarding

- Scuba Diving & Snorkeling

Form a Loop in the Single Jib Sheet

Tom Lochhaas

Jib sheets attach to the aft-most corner of the jib (the clew) and run back to the cockpit on both sides of the boat. The jib sheets are used to trim the sail in or ease it out. Consider using a soft shackle to tie your jib sheets to the sail.

On most sailboats, jib sheets are usually attached to the clew in one of two ways:

- When two individual sheets are used, both are often tied to the clew with a bowline . This knot can easily be untied when the sail is changed, but the two large bowlines form a big, heavy mass that can cause injury if it strikes you while wrestling with a flailing sail in the wind.

- When a single line is used, a metal shackle is often placed in a loop of the line at its center point, for shackling the lines to the clew. This also means a dangerous hard object that can injure a crew in the head or eye.

But There’s a Better Way

A better solution is to use a soft shackle made with the single jib sheet itself, whipping line, and a short, extra piece of line. This extra piece should be the same diameter as the sheet.

Here's How to Begin

First, form a loop at the center of the single line to be used as jib sheets. It should be about a foot in diameter. Whip the line firmly to maintain the loop.

Form Another Loop in a Short Piece of Line

With a second short piece of line, form another loop that passes through the jib sheet loop. Whip the ends together to maintain the loop.

Insert the Jib Sheet Loop Through the Clew

Insert the jib sheet loop through the sail’s clew.

Pass the Smaller Loop Through the Jib Sheet Loop

Finally, pass the ends of the smaller loop through the end of jib sheet loop, as shown. Then pull the jib sheet to cinch the knot tight.

There are a few advantages of using a soft shackle. It’s lighter and less bulky (and therefore safer) than a metal shackle. It’s also easier to tie and untie with sail changes, and less expensive.

- How to Use Roller Furling

- Learn How to Sail a Small Sailboat – 1. The Parts of the Boat

- How to Tack a Sailboat

- Simple Reefing System for Sailors

- When to Adjust Sailboat Sails for Stronger Winds

- How to Rig a Preventer Line

- Control Your Tiller Without a Tiller-Tamer

- How to Use a Mainsheet Traveler

- A Step-By-Step Guide to Tying and Using a Prusik Knot

- 4 Friction Knots for Climbers

- Your Essential Rappelling Equipment

- How to Make Your Own Jug Band Instruments

- Saltwater Fishing Tips for Freshwater Fishing Enthusiasts

- How to Build a Skateboard Quarter Pipe Ramp

- The Five Basic Parts of a Scuba Diving Regulator

- The History of Inline Skate Development

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Maine Cat 41 Used Boat Review

CS 30 Used Boat Review

Hinckley 49 Used Boat Review

Island Packet 31 Used Boat Review

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Thinking Through a Solar Power Installation

How Does the Gulf Stream Influence our Weather?

Can You Run a Marine Air-Conditioner on Battery Power?

Master the Sailing Basics: Never Stop Learning the Little Things

How to Mount Your Camera on Deck: Record Your Adventures with…

Un-Stepping the Mast for America’s Great Loop

Headsails and Spinnakers: How to Explain Their Functions to a Beginner

Sinking? Check Your Stuffing Box

The Rain Catcher’s Guide

How to Change Your Engine Mounts

Keeping Water Clean and Fresh

Vinyl Boat Lettering DIY Application and Repair

Those Extras you Don’t Need But Love to Have

Three-Model BBQ Test

Alcohol Stoves— Swan Song or Rebirth?

Womens Foul-Weather Gear

Preparing Yourself for Solo Sailing

How to Select Crew for a Passage or Delivery

Preparing A Boat to Sail Solo

Chafe Protection for Dock Lines

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

- Sails, Rigging & Deck Gear

- Safety & Seamanship

A Foolproof (and Simple) Way to Set Jib Leads

An excellent, surprisingly simple way to set jib leads is to use jib luff telltales as a guide. This technique applies to all types of headsails-genoas as well as working jibs-and produces good sail shape, good speed, good pointing ability, and good sailor satisfaction. Heres a description based on my text in the new third edition of The Annapolis Book of Seamanship.

First, every jib should have three yarn telltales at equal intervals up and down the luff, on both sides of the sail. Put them one-quarter, one-half, and three-quarters of the way between the tack and the head. They should be 4″-12″ long, depending on the size of the jib and boat and the eyesight of the sail trimmers and steerers, and placed so they wont easily tangle around the headstay. They can be taped to the sail or sewn into the luff with a knot in the yarn on either side so it wont blow away. Some sails have little windows in the luff for viewing the windward and leeward telltales at the same time; here the telltales should be different colors-traditionally green for starboard and red for port.

Most sailors know that jib telltales are extremely helpful when trimming sails and sailing close-hauled by the luff of the jib. Telltales, as their name suggests, tell the tale of the wind stream. They show how the wind is flowing across the sail, and slightly anticipate the bubbling in the jibs luff (which may not happen on modern stiff sailcloth until the sail has lost a lot of wind). Most of the time, when the telltales on both sides of the sail stream aft, with the windward ones lifting occasionally, the sails trimmed just right. The worst thing is to permit the telltales on the leeward side of the sail to droop. This means the sail is stalled, with no airflow from luff to leech. The cause usually is over-trimming, so ease the sheet. If the windward telltales lift all the time, the sail is eased too far so trim it a little.

Telltales also are a key indicator for setting jib leads. Sail on a close-hauled or close-reaching course with the sails trimmed correctly. When the boats up to speed, slowly head up. If all three telltales on the windward side of the luff simultaneously lift up (break) at the same angle, the lead is set correctly fore and aft.

But if the top telltale lifts first, wind is being spilled aloft and the leech is twisted off too far. That means the lead is too far aft and should be moved forward a little. If the bottom telltale lifts first, the leech is too tight because the lead is too far forward. Keep experimenting. Try one lead position at a time until all three windward telltales mimic each other, breaking at the same time. The correct lead position on one side should be the right one on the other side, too, unless (as sometimes happens) the holes in the track are not arranged similarly. (A safety caution: loads on jib sheets can build dramatically, even on smaller boats, so don’t adjust leads until after you tack.)

On a reach, as the sheet is eased the upper leech will twist off and spill wind, so for best performance move the lead forward a little until the telltales break at the same time (this may not be successful with a tall, narrow high-aspect ratio jib, whose upper leech may never look right on a reach).

This system is valuable in heavy weather. Then, instead of harnessing the wind as effectively as possible by making sails more powerful, youll want to spill wind by depowering the sails. If the boat is overpowered and heeling uncomfortably, decrease the heeling force by spilling wind aloft. To do this, move the lead back one or two holes from optimum, leaving the top telltale, or even the top two telltales, lifting early. In a gusty wind you can get through a puff by sailing on the leech-easing sheets until all three windward telltales are lifting, the sails luff is luffing, and the only full part of the jib is aft.

In very light wind, you may find you get better speed by moving the lead a hole forward of optimum, making the sail more full.

By concentrating on the jib telltales along with the speedometer (or GPS VMG readout), while paying attention to your performance relative to nearby boats, youll find that youll sail a little faster.

More important, I think, youll gain a more intimate and satisfying connection with the boat and the environment. Such harmony between sailor and boat cannot be duplicated in any other relationship between a human and an object (which is why we give names to our boats, but not our automobiles or computers). A great boating writer of an earlier generation, Alfred F. Loomis, once described a skilled skipper this way: I noticed how much at union with his boat this sailor was-stretched at ease, one arm thrown carelessly along the tiller, head just showing above the gunwale, and face uplifted so that his eyes commanded the luff of the sail.

May we all be so in tune with our vessels.

-John Rousmaniere

Flare Practice As we reported in the March 1999 issue, pen-type flare launchers are not particularly difficult to use. On the other hand, we don’t think that the operation any of them is so intuitive that instructions arent required. In an emergency situation, particularly if its dark, one shouldnt have to stop, read and comprehend instructions.

Worse would be trying to launch a flare without the proper procedure.

Aerial flares can be frightening things to use for the first time. They can be quite loud and very smoky. At the least you should familiarize yourself with the flares you choose. If possible, and this is apt to take some negotiation with your local US Coast Guard station, arrange to practice-fire an out-dated flare or two.

While its illegal to fire a red aerial flare over the water in a non-emergency situation without express permission from the USCG, its not against the law to shoot off a white one, and Orion meteors, Skyblazers, andparachute flares from Ikaros and Pains Wessex are available in white. Unfortunately, the parachute flares are too expensive for most of us to consider purchasing for practice. And, while the USCG permits the firing of white flares, its not a practice that they encourage.

We spoke to a Coast Guard representative who told us that observers tend to take the attitude that a flare is a flare, regardless of color, and white flares generate just about as much search-and-rescue activity as do red ones. He suggested that sailors practice-fire on land. When we mentioned the possibility of setting fire to a house, the answer was, Well, there is that.

Some Coast Guard Auxiliary Flotillas, were told, arrange for group practice firings of out-dated flares. If your local group can’t help you, the Fourth of July is a useful, and traditional (if not quite legal), time for such training exercises.

Heaven help the poor soul whose boat actually is sinking during the rockets red glare of the Fourth!

-Richard Greenhaus

Most Popular Boat Names We get a kick out of this, honestly. Each year, BOAT/U.S. surveys its owners and arrives at a list of the most popular boat names. It strikes us as a sort of reflection of society as a whole. Are we metaphysical this year? Competitive? Environmentally aware?

In 1999, the surprise winner was Misty, which BOAT/U.S. said came out of nowhere. Second place was Flying Cloud, followed by Serenity, Irish Wake, Wind Dancer, Seas the Day, Odyssey, Gypsea, Luna Sea and Osprey. Gone are perennial favorites Escape, Obsession and Fantasea.

RELATED ARTICLES MORE FROM AUTHOR

How to mount your camera on deck: record your adventures with diy innovations, leave a reply cancel reply.

Log in to leave a comment

Latest Videos

Hunter Legend 35.5 – Behind the Curtain

Whipping Line On Your Sailboat

Hallberg Rassy 42 – Behind the Curtain

The ICW – The Easiest Way – Sail to the Sun...

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

The Boat That Stays With You

Performance 2:1 jib sheet-1/4″x21′-dyneema blended single braid (2 required)

$ 25.20

Description

Additional information.

- Reviews (0)

These Jib Sheets are sold individually , just in case you lose one and want to replace just one. High tech, long lasting Dyneema braid, already cut to length for the 2:1 jib sheets. Please note: the color of the jib sheet may vary.

| Weight | 1 lbs |

|---|---|

| Dimensions | 3 × 4 × 5 in |

There are no reviews yet.

Your review *

Name *

Email *

You may also like…

Standard 2:1 jib sheet-1/4×21′-trophy braid (white)(2 required)

Jib Sheet – 2:1 purchase kit with standard 1/4 sheets complete (Ronstan blocks)

Jib sheet – 2:1 spliced twisted prestretch bridle only with Ronstan blocks

Jib sheet – 2:1 purchase kit with performance 1/4″ sheets complete (Ronstan blocks)

Please feel free to call us, 8-4 eastern, mon-fri..

Flying Scot Inc.| 800-864-7208 | 301-334-4848 | [email protected]

- How-To Guide

- How-To-Video

- Meet The Builders

- Photo Gallery

Store Pages

- Hardware & Fasteners

- Accessories

- Hull, Rudder, Centerboard & Deck Fittings

- Spars and Standing Rigging

- Racing Items

- Running Rigging

- Come See Us

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Help with Jib sheet size/length

- Thread starter Charisma

- Start date Jun 1, 2010

- Hunter Owner Forums

- Ask A Hunter Owner

Hi all, can someone please give me the length and size of the standard Jib sheets for a H26. There used to be a link to the H26 manual on line. But it is not working and my manual is on the boat, 2 hours away. Thanks Chris

Planing factors You did not say what jib size you need it for so assume the smallest and it should work for all the larger ones. As a geeral rule, use the length of the boat for jib sheets. That gives you enough to have the lazy sheet go around the mast and still have the other end in the cockpit. I'd go with 26'

Thanks Bill, as far as I know the h26, being a B&R comes with only the one size jib. I will order 52 ft. Do you have any recommendations as to the thickness or kind of line to order? Thanks Chris

I think 52 feet will be more than enough. New England Sta Set or Samson XLS would be plenty and 3/8 would be good for handling unless your hardware requires a smaller size. PS: There is a handy line calculator on this site.

Here ya go! Jib Sheets are normally 1.5 x boat length. http://shop.sailboatowners.com/cordage/detail-rigsimple.htm?requiredfields=bid&next=list&bid=1824

Thanks Guys

One more quick question should I allow more for a furler as opposed to regular hanked on?

If you go with that recommended length (way long IYAM unless you have like a 150) you'll have plenty to use on a furler. Note: this is not hi-tech line so having extra is no big deal. Better to be a little long than too short. The only extra amount needed for a furler vs hank-on is a couple of wraps of sheet line when furled.

DianaOfBurlington

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

- Forum Listing

- Marketplace

- Advanced Search

- All Topics Sailing

- General Sailing Discussions

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Best knot for jib sheets

- Add to quote

What's the best knot for attaching the jib sheets to the jib clew? Can someone point me to a source that shows how to tie it? Thanks!

The Bowline (pronounced bow-lynn) is the classic knot for this purpose. Superstrong yet easy to untie. If you don't already know it I would suggest that you practice it until you get it down so that it will be second nature when it comes time to make a sail change in dicey conditions. I used to keep some line on the back of my toilet for this purpose, much to the dismay of my better half. Google Image Result for http://cache.eb.com/eb/image?id=63127&rendTypeId=4

CBinRI said: ...time to make a sail change in dicey conditions. I used to keep some line on the back of my toilet for this purpose, much to the dismay of my better half. CB... You can make sail changes from your toilet!?!? Paul Sorry, but I just couldn't resist! Click to expand...

Just watch Jaws over and over again...its the scene when they are on the Orca right before the Shark pops up and Martin is trying to tie that exact knot... But on a serious note the bowline is the most common way and is useful in many more applications on a sailboat.

Try this site: Grog's Boating Knots Index

best knot is no knot; try a larks head

If the Lark's Head is the same one I know I would worry that when the sheets are slack they might come loose. The lark's head I know uses the tension on over turned loop that has a line through it with a stopper know in the end. When slack the loop can work loose.

I tie more bowlines than any other knot. On my ski boat I use them to tie the ski ropes on and they never fail. they are also easy to untie.

I find the concerns about lark's heads interesting. Joe, there is basically no way a lark's head can come undone, even if the loop completely loosens up. The only way is for the free ends of both sheets to be passed through the loop. As for the strength of the knot, not sure what you mean by that. Knots do weaken the line they're tied in; maybe that's what you're referring to. If so, I don't know how much a lark's head reduces the strength of the line, but bowlines are one of the worst knots for strength. They reduce the breaking load to about 60% of the untied line's breaking load. Anybody have data on lark's heads? Edit: I just realized a lark's head can fail if only one of the free ends passes through the loop... which I suppose could happen if you only ever apply load to one of the free ends, or if the first time the sheet is loaded up, the lark's head hasn't really been made snug yet. Hm!

AdamLein said: I find the concerns about lark's heads interesting. Joe, there is basically no way a lark's head can come undone, even if the loop completely loosens up. Click to expand...

In my experience it is unusual for anyone to use anything other than a bowline for jib sheets. But I could be wrong. And if I ever wanted to do a quck sail change with no knot, as has been proposed, wouldn't I have to pull 50' of line (my boat is 41') through the clew, or am I missing something?

Big boat alternatives I was just looking for an answer to this same question, I did not realize there was a current thread, I posted over at in this seamship thread Considering the larks head when you have two seperate sheets, as I see it the problem is that the knot can lock for one way pull. But if you are putting a larks head in in the middle, you have uneven pull, and that worries me on a larger boat, the forces are so high, it seems like it might slip. The bowline is tried and true, but the knots are hanging up in our tacks and with a small crew in a race, we can't stand that delay. Anyway, since I already have two lines and I want to eliminate knots it looks like I need to splice an eye in the end. So far so good. I also looked at the Attaching Jibsheets article. Then the options are: 0) Bowline (tried and true) 1) larks head (possibly hard to undo) 2) Tylaska Spool Shackles 3) Tylaska J-Shackles 4) EquipLite Connectors (too expensive!) Any thoughts on these? It seems like the spool shackles might be a good compromise. Has anyone used these for genoa sheets on a larger (40'+) boat?

I know conventional wisdom uses the bowline, an excellent knot, for jib sheets, and I do if I need to be able to untie the sheet and re-tie to the next jib. Otherwise, I prefer the buntline hitch. This knot is a bit less prone to snagging on the way past obstacles such as the stays, but has the fault of jamming under load, it will not shake out, but can be a problem to untie. an example Buntline Hitch

I will probably go with the bowline since I know the knot and others have had success with it. However, this site attaching ropes to grommets suggests a double-fishermen's knot.

kwaltersmi said: I will probably go with the bowline since I know the knot and others have had success with it. However, this site attaching ropes to grommets suggests a double-fishermen's knot. Click to expand...

Right. That's the one I've used before with one long continuous jib sheet. But what if there are two separate jib sheets, one for starboard and one for port? Then I think the best (or most popular) knot would be the bowline for each sheet.

I had the same concern re: a larks head slipping when loaded, but since it was mentioned here previously I noticed that the Tartan 40 I crew on is rigged that way. We've never had a problem even though the owner is loath to reef the 150 roller furling genny even when we're defintely overcanvassed. I use bowlines on my boat currently, but I will seriously consider going with a larks head when I need to replace my genny sheets since you need a single long sheet to use a larks head. From what I've seen I think the larks head works fine for boats with roller furling that don't change sails ofter (or at all), but is probably is not the way to go if you frequently change headsails.

Actually, I use a lark's head on my current boat with hank-on headsails and it works fine, no problems changing sails. But I've got a pending deal on a bigger boat with roller furling for the headsail and two separate sheets, thus the question.

It depends on the jib setup, if you use a furling jib most of the time, a continuous jib sheet, port to Stbd with a larks head at the center will be best, almost no weight flapping around. If you do a lot of sail changes bowlines would be more convenient. Avoid shackles, they can really hurt someone.

I've never known a racer (in any league) or a single sailing school to use or suggest anything besides bowlines for the jib/genny. Anyone who wants to do it differently is welcome to, but not on my watch. "but the knots are hanging up in our tacks" I think we've all had that happen. It means one or more of several things are wrong: Wrong size line (too heavy), wrong size loops (too large), or wrong timing on the tacks. Time it wrong, and the lines will always hang up. Change the timing and the line tension when the knots are flying past things--and they will hang instead of pass. Working on the timing and line handling during the tack pretty much can always solve the hanging problem.

I should have pointed out, I haven't raced much, and neither have my wife or kids, I like the larks head because for the most part, I use the same 150 headsail on a furler, and it keeps the weight down at the clew. In the event something gets hung up on the foredeck, and the jib is flagging, there's less to get hit with. respectfully, Joe.

delan said: I should have pointed out, I haven't raced much, and neither have my wife or kids, I like the larks head because for the most part, I use the same 150 headsail on a furler, Click to expand...