Standing Rigging (or ‘Name That Stay’)

Published by rigworks on november 19, 2019.

Question: When your riggers talk about standing rigging, they often use terms I don’t recognize. Can you break it down for me?

From the Rigger: Let’s play ‘Name that Stay’…

Forestay (1 or HS) – The forestay, or headstay, connects the mast to the front (bow) of the boat and keeps your mast from falling aft.

- Your forestay can be full length (masthead to deck) or fractional (1/8 to 1/4 from the top of the mast to the deck).

- Inner forestays, including staysail stays, solent stays and baby stays, connect to the mast below the main forestay and to the deck aft of the main forestay. Inner forestays allow you to hoist small inner headsails and/or provide additional stability to your rig.

Backstay (2 or BS) – The backstay runs from the mast to the back of the boat (transom) and is often adjustable to control forestay tension and the shape of the sails.

- A backstay can be either continuous (direct from mast to transom) or it may split in the lower section (7) with “legs” that ‘V’ out to the edges of the transom.

- Backstays often have hydraulic or manual tensioners built into them to increase forestay tension and bend the mast, which flattens your mainsail.

- Running backstays can be removable, adjustable, and provide additional support and tuning usually on fractional rigs. They run to the outer edges of the transom and are adjusted with each tack. The windward running back is in tension and the leeward is eased so as not to interfere with the boom and sails.

- Checkstays, useful on fractional rigs with bendy masts, are attached well below the backstay and provide aft tension to the mid panels of the mast to reduce mast bend and provide stabilization to reduce the mast from pumping.

Shrouds – Shrouds support the mast from side to side. Shrouds are either continuous or discontinuous .

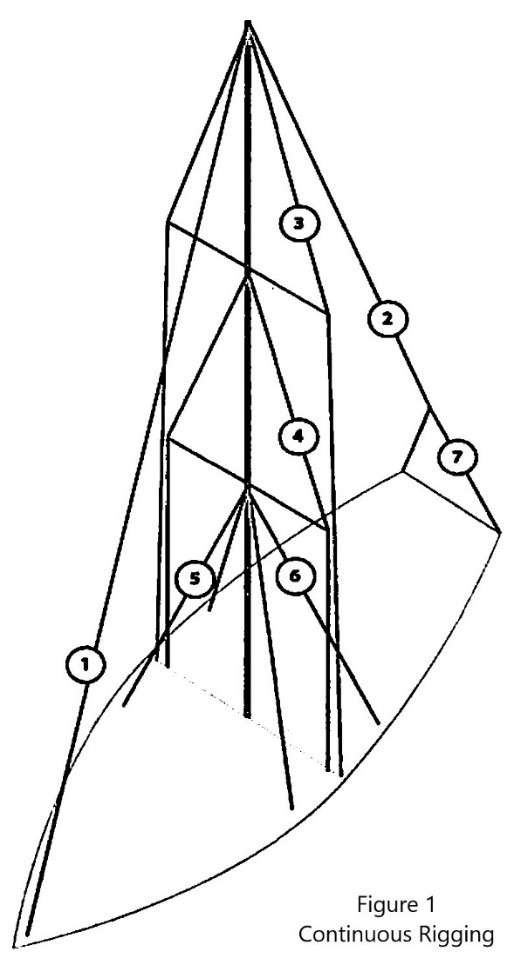

Continuous rigging, common in production sailboats, means that each shroud (except the lowers) is a continuous piece of material that connects to the mast at some point, passes through the spreaders without terminating, and continues to the deck. There may be a number of continuous shrouds on your boat ( see Figure 1 ).

- Cap shrouds (3) , sometimes called uppers, extend from masthead to the chainplates at the deck.

- Intermediate shrouds (4) extend from mid-mast panel to deck.

- Lower shrouds extend from below the spreader-base to the chainplates. Fore- (5) and Aft-Lowers (6) connect to the deck either forward or aft of the cap shroud.

Discontinuous rigging, common on high performance sailboats, is a series of shorter lengths that terminate in tip cups at each spreader. The diameter of the wire/rod can be reduced in the upper sections where loads are lighter, reducing overall weight. These independent sections are referred to as V# and D# ( see Figure 2 ). For example, V1 is the lowest vertical shroud that extends from the deck to the outer tip of the first spreader. D1 is the lowest diagonal shroud that extends from the deck to the mast at the base of the first spreader. The highest section that extends from the upper spreader to the mast head may be labeled either V# or D#.

A sailboat’s standing rigging is generally built from wire rope, rod, or occasionally a super-strong synthetic fibered rope such as Dyneema ® , carbon fiber, kevlar or PBO.

- 1×19 316 grade stainless steel Wire Rope (1 group of 19 wires, very stiff with low stretch) is standard on most sailboats. Wire rope is sized/priced by its diameter which varies from boat to boat, 3/16” through 1/2″ being the most common range.

- 1×19 Compact Strand or Dyform wire, a more expensive alternative, is used to increase strength, reduce stretch, and minimize diameter on high performance boats such as catamarans. It is also the best alternative when replacing rod with wire.

- Rod rigging offers lower stretch, longer life expectancy, and higher breaking strength than wire. Unlike wire rope, rod is defined by its breaking strength, usually ranging from -10 to -40 (approx. 10k to 40k breaking strength), rather than diameter. So, for example, we refer to 7/16” wire (diameter) vs. -10 Rod (breaking strength).

- Composite Rigging is a popular option for racing boats. It offers comparable breaking strengths to wire and rod with a significant reduction in weight and often lower stretch.

Are your eyes crossing yet? This is probably enough for now, but stay tuned for our next ‘Ask the Rigger’. We will continue this discussion with some of the fittings/connections/hardware associated with your standing rigging.

Related Posts

Ask the Rigger

Do your masthead sheaves need replacing.

Question: My halyard is binding. What’s up? From the Rigger: Most boat owners do not climb their masts regularly, but our riggers spend a lot of time up there. And they often find badly damaged Read more…

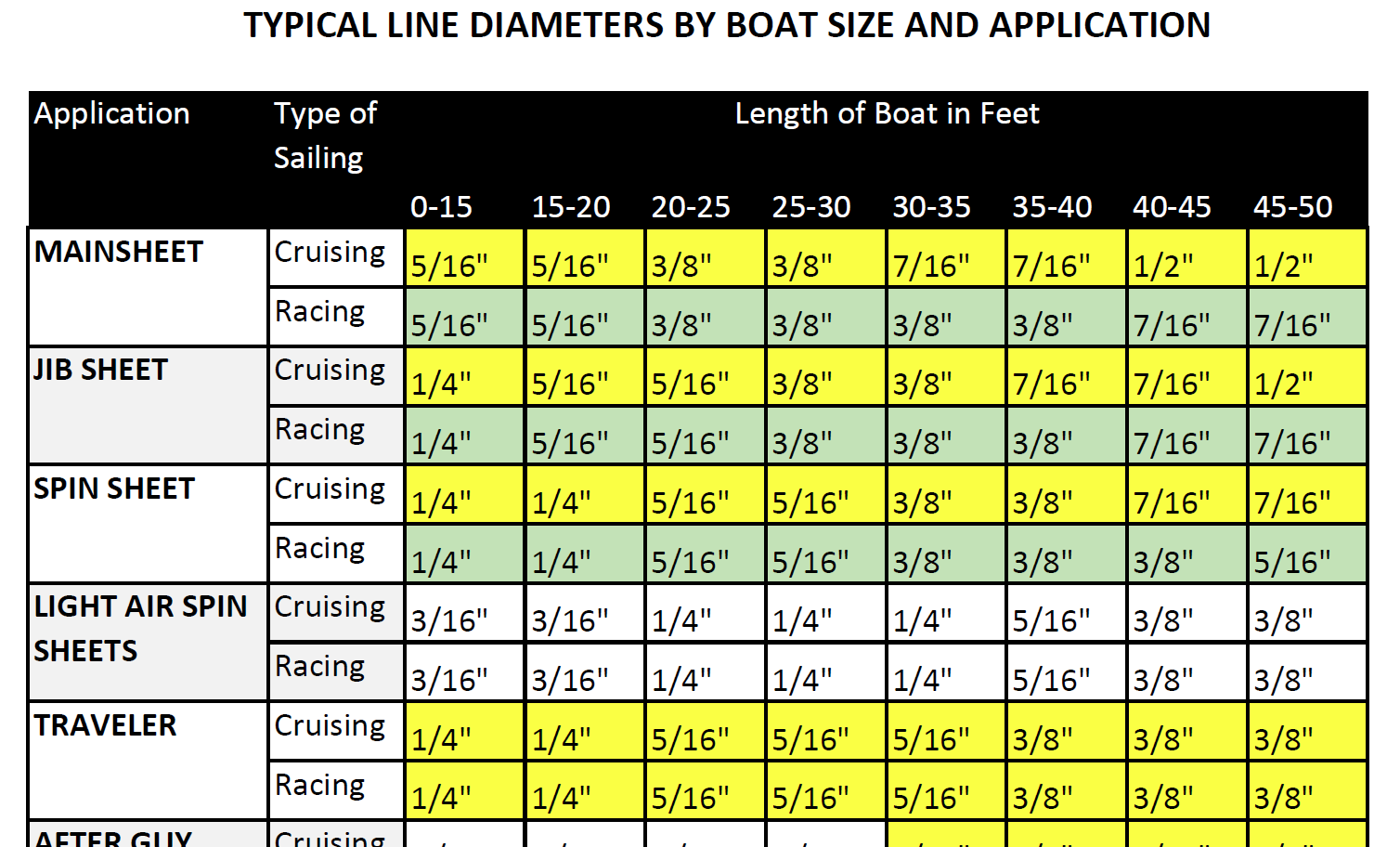

Selecting Rope – Length, Diameter, Type

Question: Do you have guidelines for selecting halyards, sheets, etc. for my sailboat? From the Rigger: First, if your old rope served its purpose but needs replacing, we recommend duplicating it as closely as possible Read more…

Spinlock Deckvest Maintenance

Question: What can I do to ensure that my Spinlock Deckvest is well-maintained and ready for the upcoming season? From the Rigger: We are so glad you asked! Deckvests need to be maintained so that Read more…

Succesfully added to Request List!

- Search for:

- BSI Fiber Rigging

- BSI Rod Rigging

- Compact Strand Dyform Wire

- OS Wire Equipment

- Accessories

- Deck Filler

- Kick service

- Main Sheet – Easymatic

- Flush Hatches

- Lowline Hatches

- Offshore Hatches

- Flush Portlight

- Spare Parts

- Rigging service programme

- Certified Service Centres

- Dealer and service

BSI service

BSI’s service and refit program is based upon a worldwide network of highly respected and experienced rigging companies and service technicians.

REPLACE THE OLD, Leaky deck hatch

SPECIALIst Equipment For your yacht

BSI Group provides you with a unique selection of specialist equipment for cruising, racing, and super yachts from the most dedicated brands in the business.

BSI rigging

Made by sailors, for sailors.

Trusting Mother Nature to carry you safely across the seven seas is a lot easier with top of the line components on board.

Specialist maritime equipment We design, manufacture and market specialist equipment for cruising, racing, and super yachts. Our goal is, and has always been, best-in-class products with the strength to handle anything a raging sea can throw at them, without compromising control or speed.

EXCELLENCE ONBOARD

BSI Group provides you with Specialist Equipment for Cruising, Racing, and Super Yachts from some of the business’ most dedicated brands – all under one sail.

REFIT AND REPAIR

Refit BSI’s service and refit program is based upon a worldwide network of highly respected and experienced rigging companies and service technicians.

Repair Replace the old leaky deck hatch with a new, tight and modern one. Wear, sand and water have left their mark on the old deck hatch so now is the time to change it.

- BSI Rigging

BSI Rigging is a leading player in the yacht rigging industry supplying to OEM yards, private superyacht customers and leading mast manufacturers. The rod, wire and fibre range and associated hardware offer customers a broad range of solutions to meet their standing rigging needs. Our rigging range includes the following products.

The best-in-class rod rigging products with the strength to handle all a ranging sea and the elements can throw at them. BSI standing rod rigging and fittings are designed and manufactured in house on BSI’s own CNC machines.

BSI fibre rigging is a high-performance solution for standing rigging saving weight aloft whilst providing s sound solution, available in a number of materials made to the highest grade suitable for the specific yacht and mast.

OS high quality wire rigging, and fittings for privately owned boats in addition to supplying to many leading production boat yards. BSI offer full traceability and strict quality control on all products with guaranteed value for money.

BSI offer a service programme backed by a global network of dealers and service agents. All boats rigged by BSI have a history log to enable refit plans to fit within a yachts schedule.

news & events

Stay updated.

BSI at St Barths Bucket 2024

METS 2023 – 12.540

Beagle V #FollowTheRig 20+ Year Service

Back-to-Back Regatta Wins for BSI Rigged Nakupenda

- OYS Rigging

- Gori Propeller

- Easy products

- Moonlight products

- Jefa Steering

- Hundested Propeller

- OMS – Ocean Marine Systems

- Fjordagervej 34-36 DK-6100 Haderslev T: +45 7322 2222 E: [email protected]

Username or email address *

Password *

Remember me Log in

Lost your password?

Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: 187fc7f7-4902-11ef-90c7-586f91fcdd89

Powered by PerimeterX , Inc.

standing rigging

- rope and line

- cams, cleats and clutches

- head sail gear

- roller furling

- main sail control

- mast hardware

- eye straps and pad eyes

- fairleads and bulls eyes

- anchor and docking

- miscellaneous hardware

- Alexander Roberts

- My Wishlist

- Customer Service

- Order Tracking

- Your Account

- Store Policies & Info

- Privacy Policy

- Helpful Links

- Payment Methods

Shopping Cart: 0 Items

JIB FURLING GEAR

- CDI Flexible

- Furling Accessories

- Racing Foils

- Whisker and Spinnaker

MAIN SAIL FURLING and REEFING

- Boom Furlers

- Reefing and LazyJacks

MAIN SAIL TRACK SYSTEMS

Standing rigging.

- Swage Terminals and Toggles

- Turnbuckles

- Backstay Adjusters

- Inner Forestay Tools...

- Miscellaneous Hardware

- Measuring Guide

- Hardware and Wire

RUNNING RIGGING

- Rope Clutches

- Cam and Standard Cleats

- Pad Eyes, Eye Straps

- Rachet, Snatch, Wire

- Halyard Lift

- Accessories

- rigid vangs

- tackle vangs

GROUND TACKLE

Mast climbing.

- ATN Top Climber

RADAR MOUNTS AND REFLECTORS

Welcome to rigging only.

Our www.riggingandhardware.com shop on line site is now open for business. We now have most manufacture's parts up and running. Pricing is current on the riggingandhardware.com site. Pictures and selection guides are rather lacking at this time but we are working on them and will be loading more product and manufacturers asap. As always, don't hesitate to contact us with any questions or to place an order at [email protected] or call (508) 992-0434.

Our Mission

- We now stock and swage wire up to 5/8 diameter for sailboat standing rigging and architectural wire projects. Larger sizes are available.

- We now stock and swage wire up to 5/8 diameter for standing rigging and architectural projects. Larger sizes are available.

- Metric wire and swage fittings are available for standing rigging applications. We are able to provide swaged standing rigging assemblies as well as mechanical terminals (assembled or you assemble) to meet your needs at an affordable cost. Current stock is 8-10-12mm. Note the bulk of these fittings will have imperial pin and thread dimensions.

Return Policy

Customer comments.

- We thank you and your staff for your help and advise. We are enjoying sailing more with the furler. M.&R. G., Chicago

- All arrived safely and perfectly on time. The lifelines are almost too pretty to put on the boat and it's a damn pretty boat. The shrouds and backstay are superb and a perfect fit. If anyone ever wants a referral about Rigging Only tell them to contact me. R. A. , Curator, N. C.

- Just a quick note to tell you how grateful I am. The order was waiting for me when I arrived as promised. All the parts were of top quality and the prices were more than reasonable. I am recommending the services and products of Rigging Only to all my fellow charter captains of the Virgin Islands Charter League. Capt. G. F. USVI

- Due to your excellent quality, service, and prices on my previous order I would like to get a price quote and estimated turnaround time for replacing my current standing rigging... B. S. Gurnee, IL.

- Got them on time! Many Thanks! C. S. Lacombe, LA

Contact Information

Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

Rigging wire size

Discussion in ' Boat Design ' started by CBTerry , Nov 24, 2018 .

CBTerry Better, is the enemy of good enough.

So I am rerigging my hunter 30, having just rejoined the cherubini owners cult. The wires are quarter inch in diameter. I am going to be replacing the stainless steel rigging with galvanized wire and turnbuckles, 7x19 with thimbles etc. I read several different minimum breaking strength Notions regarding 1/4 inch 1 by 19 stainless steel. Does anyone have a guess as to what minimum breaking strength wire might have been specced for the late 70s? Or, conversely, has standing rigging wire gotten stronger for a given diameter since the late 70s? I am currently looking at a 5/16 galvanized wire with a minimum breaking strength of 8900 pounds which is substantially more than the 6900 lb that is supposedly the industry standard, though rigging only claims their wire is substantially stronger in 1/4 inch diameter ( I understand that suggested working load is different than minimum breaking strength). Why am I in galvanized? Because it's far less expensive and when the wire does corrode it is much easier to see and it tends not to sneak up on a person like stainless crevice corrosion does. Oh, did I mention rerigging the whole boat for about $240 in materials? Once again, is it likely that, through the manufacturing process or better alloying, that quarter inch stainless steel is stronger than was the norm back in the late 70s?

JSL Senior Member

The attached is about 40 years old but might be start. Go back to your supplier and see if he can help. Keep in mind that 7 x 19 will stretch a bit more than 1x19

Attached Files:

Wire rigging strengths(1973).jpg.

DIY sails, rigging, daggerboards for kayak - reasonable expectation for sailing to weather?

Gas Tank Rigging Advice/Grounding? 1977 18' V-Hull

Rigging WHY NOT? Junk Riggs and proas, a Balkan story....

Article - Preliminary Rigging Arrangement Design for Non-Specialists (TheNavalArch)

Sourcing mast and rigging for an 11 metre Catamaran

Ketch standing rigging resources

Can Modern Sail & Rigging Tech Improve a Ketch Rig?

Older fiberglass Lightning Class Running Rigging

Biplane Rig running rigging

Poor Mans Rigging Strain Gage

- No, create an account now.

- Yes, my password is:

- Forgot your password?

COMMENTS

A sailboat's standing rigging is generally built from wire rope, rod, or occasionally a super-strong synthetic fibered rope such as Dyneema ®, carbon fiber, kevlar or PBO. 1×19 316 grade stainless steel Wire Rope (1 group of 19 wires, very stiff with low stretch) is standard on most sailboats. Wire rope is sized/priced by its diameter which ...

BSI Rigging is a leading player in the yacht rigging industry supplying to OEM yards, private superyacht customers and leading mast manufacturers. The rod, wire and fibre range and associated hardware offer customers a broad range of solutions to meet their standing rigging needs. Our rigging range includes the following products.

Stainless steel wire rope, in the sailing world, generally comes in 4 construction types: 1 x 19, 7 x 7, 7 x 19 (pictured left), and 1 x 19 Dyform or Compact Strand (pictured right). Standard 1 x 19 stainless steel wire is primarily used in standing rigging and now (within the last 10 years or so) also lifelines.

Marine Grade 316 stainless steel 1x19 wire is generally the wire rope of choice for Yacht Rigging on Cruising Yachts. Compact Stranded stainless steel wire offers enhanced performance for racing or extended cruising. Marine Grade stainless steel 7x19 wire offers a flexible option for running rigging. Break Load Comparison Chart by Wire ...

Standing Rigging for cruising yachts is mainly produced from a smooth, stiff and strong 1 x 19 construction. Compacted Strand 1 x 7 and 1 x 19 are used for enhanced performance. 7 x 19 is a flexible wire construction for use where the wire needs to turn corners e.g. around a block or sheave. Jimmy Green Marine offer a comprehensive range of ...

Our 1x19 wire from KOS is a high quality 316 stainless steel wire rope most commonly used for standing rigging, although becoming more and more popular for lifelines as well. Features. 316 Stainless Steel. Stiff and Low Stretch. Highly Polished for Marine Use. One Strand Consisting of 19 Wires. WS02. 1/16" Wire Dia, 1 x 19 Wire.

West Marine's selection of boat rigging hardware encompasses all the most respected brands, including FSE Robline, Loos, New England Ropes, Ronstan, Samson Rope, Alexander Roberts, Alps Wire Rope, C. Sherman Johnson, Schaefer, Suncor and Edson Marine to name a few. Of course, for hard or complicated jobs, experienced professionals at West ...

Sailboat and yacht standing rigging of the highest quality, swage and mechanical terminals, rigging supplies and cable. Checkout View Cart (0) (508) 992-0434. Toggle navigation. ... mechanical wire terminations. swage wire terminations. turnbuckles. backstay adjusters, hydraulic and manual. adjusters. toggles. inner forestay. running backstays ...

Update your boat's reliability by selecting high-quality stainless steel boat rigging hardware and sailboat running rigging gear designed expressly for the harsh marine environments. Types of Rigging Hardware Available. Standing Rigging: Includes wire ropes, terminals, turnbuckles, and toggles.

The Rigging Loft Inc was established in 1984 to provide sailboat rigging, yacht hardware and provide on site hands on, quality rigging services to sail makers, boat yards and boat builders in South Eastern Massachusetts. ... We now stock and swage wire up to 5/8 diameter for sailboat standing rigging and architectural wire projects. Larger ...

The most common problems found on cruising yachts relate to rigging that is too slack, particularly the shrouds. A frequent misunderstanding between owners and boatyards is that on re-stepping the rig few yards will tune it unless specifically asked to do so. This means a huge number of cruising boats sail to windward with the lee shrouds slack ...

So I am rerigging my hunter 30, having just rejoined the cherubini owners cult. The wires are quarter inch in diameter. I am going to be replacing the stainless steel rigging with galvanized wire and turnbuckles, 7x19 with thimbles etc. I read several different minimum breaking strength Notions regarding 1/4 inch 1 by 19 stainless steel.

Mega Yacht Mooring. Commercial/Cruise Ship Mooring. RIGGING BREAKING STRENGTHS Please find below typical rigging breaking strengths for many marine stainless steel, rope, rod and Kevlar&re rigging applications. ... Type 316 1X7 Compact Strand Stainless Wire Rigging mm. lb. kg. mm. lb. kg. 2.5. 1518. 690. 3.5. 2975. 1350. 3. 2200. 1000. 4. 3925 ...

Run your fingers up and down the last metre of wire above or below the swage, feeling for deformities; if the wire is not uniform the chances are that one of the individual wires has broken, even ...

The strength, minimal elongation, excellent corrosion resistance and general performance of KOS 1x19 construction stainless steel wire are suitable for most sailing yachts. High Performance Compact strand Wire is also available to custom build online. Jimmy Green Marine source stainless steel 1x19 wire rope up to and including 12mm diameter ...

We end up selling mostly complete rigging sets using swage fittings. When discussing options with our customers we can really only justify the additional cost of mechanical fittings when the boat is going to endeavor on high mileage journeys. This way the wire can be replaced, the fittings inspected, and re-used with new cones (wedges).

When it comes to reliable and sturdy fishing rod holders and T-bars, look no further than Hill's Wire Forms and Boat Rigging. We take pride in delivering top-quality products, fostering long-lasting relationships with our customers, and offering our goods at friendly prices.

Stainless Steel Wire - Stranded, 45 lb (20 kg) test, .018 in (0.46 mm) dia, Bright, 30 ft (9.2 m), use for US1M, V32, Soling 1 Meter & Victoria Class $5.49 Out of Stock

Shop By Category. Anchor & Mooring. Anchoring. Anchors; Anchor Kits; Anchor Rope; Anchor Winches; Bow Rollers & Bollards; Chain & Shackles; Sea Anchors; Mooring & Docking

For artists, writers, gamemasters, musicians, programmers, philosophers and scientists alike! The creation of new worlds and new universes has long been a key element of speculative fiction, from the fantasy works of Tolkien and Le Guin, to the science-fiction universes of Delany and Asimov, to the tabletop realm of Gygax and Barker, and beyond.

A residential and industrial region in the south-east of Mocsow. It was founded on the spot of two villages: Chagino (what is now the Moscow Oil Refinery) and Ryazantsevo (demolished in 1979). in 1960 the town was incorporated into the City of Moscow as a district. Population - 45,000 people (2002). The district is one of the most polluted residential areas in Moscow, due to the Moscow Oil ...

Lyubertsy Tourism: Tripadvisor has 1,975 reviews of Lyubertsy Hotels, Attractions, and Restaurants making it your best Lyubertsy resource.

What time is it in Elektrostal'? Russia (Moscow Oblast): Current local time in & Next time change in Elektrostal', Time Zone Europe/Moscow (UTC+3). Population: 144,387 People