- Boat Accessories

- Where to Buy

Special until April 30th: 30% off Solvent & Cleaner for the month of April. Use Code APR24 at checkout. *restrictions apply

Free ground shipping in the Continental US for any orders over $150!

Wooden Boat Maintenance Tips...

Wooden boat maintenance tips.

Owning a boat comes with its own set of skills: understanding sealing, unique repairs, and adapting to the challenges that come with interacting with marine life. But a wooden boat comes with a whole other set of challenges. That’s why we’ve put together this guide of the best wooden boat maintenance tips to maintain the quality and luster of your craft.

Keep Your Wooden Boat Dry

When you maintain wood around your home, keeping it dry is intuitive and easy. After all, if you have damp, rotting wood in your roof, you know immediately that you need to take action. With a wooden boat, it can be harder to detect. But it’s no less important to keep your wood dry.

One important thing to keep in mind is that you need to also watch where wet wood is exposed to the air. It’s possible to keep a wood boat in the water and have it not rot—after all, much of it is cut off from the air. But with your boat bilge, for example, the combination of water and ventilation means you need to pay attention.

Every time you sail, remove water from the boat bilge and make sure it’s dry. You might also apply Bilge Cleaner during this time, since you’ll be rinsing and drying out the bilge afterwards.

Consistently Clean Your Wooden Boat

One underrated aspect of the fight against rot is keeping your wood clear of debris and dirt. When dirt gets into areas of your boat, it can attract moisture. No matter how much you might try to clean the exterior of your boat, dirt getting into the interior can lead to moisture and, eventually, rot. This is what you want to avoid.

The easiest way to make sure that this never happens is to ensure that you have a cleaner that adequately cleans boat wood. A good general Boat Cleaner like those available here at BoatLIFE are great places to start, as they can be used anywhere on your boat—even if you’re not cleaning off the wood specifically.

Paint your Boat to Protect It

One of the reasons people choose to paint or varnish their boat isn’t because they know it will look good, but because a layer of paint adds some additional protection for the wood. If you want your boat to be as resistant to rot as possible, giving the exterior a thorough painting or varnish can be a great way to separate the wood from the moisture problems that we’ve talked about here.

You’ll want to be careful about maintenance, however. Watch for cracking in the paint or varnish from the sun. This can lead to fissures, which in turn can expose the wood.

How to Address Rot

Finally, if you do notice that there is rot developing, you can always try a Git Rot kit , which uses capillary action in the dry wood to get deep into the fibers and restore its strength.

Shop BoatLIFE Products

Our top wooden boat maintenance tip is to shop our products from BoatLIFE! If you want more great ways to keep your boat’s wood properly maintained and protected, purchase a few cleaners to keep on hand. We look forward to serving you!

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

Featured Products

Liquid LifeSeal® Sealant 5.2 fl. oz. Clear

Stainless Steel Cleaner 16 fl. oz.

Related blogs, the importance of neutral curing when choosing a boat sealant.

The marine market is seemingly saturated with sealants, making it a hard choice for boaters to navigate uncharted waters. However, […]

Maintaining Your Boat Cover Investment

When choosing a boat cover, there are a number of factors to consider to maintain your boat cover investment. One, […]

Boat Maintenance in a Bucket Now Half Off

In search of the perfect holiday gift for the avid boater in your world? Look no further than BoatLIFE‘s Boat […]

All products proudly made in the usa

- Forum Listing

- Marketplace

- Advanced Search

- All Topics Sailing

- General Sailing Discussions

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Wooden Boat, What does it take to maintain one?

- Add to quote

What does it take to maintain a wooden boat? I love sailing and woodworking but don't think I would ever want a wooden boat, or at least one that lived in the water. I really enjoy looking at them at the wooden boat festivals I have been to though, but somehow have developed a fear of what it would take to fix up and maintain a wooden boat. Some recent posts here got me thinking. Someone with a wood boat wanted a bigger, newer wood boat if he had the money. In another thread someone suggested a wood boat as an alternative to another. In my mind the boat being wood made it a complete other type of beast. In reality, how much more work is owning a wooden boat?

A wooden boat will take every bit of free time that you have and then you will still have a long list of projects you will never get around to. Thats to keep it in Bristol condition of course. If you have the funds to pay someone else to do it the task becomes much much easier. Now if you dont mind your boat having a little character it will still require a lot more work than a fiberglass one, but it will become much more manageable.

MarkCK said: A wooden boat will take every bit of free time that you have Click to expand...

Depends on the shape one would take ownership of a wooden boat. It also depends on what type of wooden boat it is. Mine is all wood, and I would build yet another, and larger. Then again it is cold molded. Go to the wooden boat forum, and you will get an idea of what it takes .......i2f

Wooden boats and how they are built has allot of bearing on how much care they need. There is now.. I'd say in the last 30 years or so.. a growing number of wooden boats that are built and or restored with high end materials. They are best described as being in a state of "arrested" decomposition. Also, there are builders that build hulls in wood and epoxy. some are called cold molded, some are strip planked, which becomes a composite hull, very stable, strong, and rot resistant. Some Old (and new) traditionally built boats are planked.. like the planks on a hardwood or softwood floor only longer.. this is called carvel planking. it is built on purpose to have "gaps" in the seams.. which have cotton or oakum wedged in. the seams were then sealed with tar or putty in the old days, now with high tech caulking. Carvel planking is the most fear producing method of hull planking also.. as it's the kind that needs to "swell" or be kept wet. this type of build also is the worse looking when it drys out from being out of the water. The other type of planking looks like the sides of a house. It's called "lapstrake" the planks were often riveted and screwed along the edges with tar or caulk in between overlaps. On newer boats that look the same many are are being built in what is called "glued lapstrake" and the strakes are made of plywood.. very stable, strong and very beautiful to see when finished with varnish. Cormeum is spot on about how little time his boat needs, because his boat has been well loved and cared for I'm sure. The most important parts to fail in larger wooden boats are, the deadwood, stern post and or stem in the bow. Keel and keel bolts are problems also, Ribs (called timbers) are often easy to repair in the boat. A method called sistering.. about the same as used in building houses. Big old wooden boats are left to rot.. Big old fiberglass boats are left also.. except, everything but the hull rots! Study, research, and look at many many boats before you buy.. often you will find them free. I just found a "free" boat. 23ft full keel 82 years old with carvel planking and iron keel, I won't be adopting her but I'm trying to find a home for her. Anyone should know their limitations when it comes to old boats. glass or wood. So much "stuff" is very costly. Even if the boat itself it well restored or maintained. The cost of sails,spars, rigging, engines, systems, etc are why some people build boats and never finish them.

Having spent the first 25 years of my life around wooden boats, meaning riding in them as a child, then helping my dad work on his and then maintaining my own, my answer is A LOT. For every four months we used our Mahogany Chris Crafts, Constellations and Romers, we/I would spend twice that sanding and varnishing. They sure were beautiful though. If you have a dedicated passion for them, they are great. If you just think they are pretty-look at someone else's..... AR

Wooden Boat, What does it take to maintain one? Passion.

My first boat was a 26' 1928 Chris Craft run about. That was in the early 50s'. All I can say is If you can keep the bottom from dry rotting , then all else is nice like when you stop hitting your head with a hammer. Dick

Wooden boats loosely fall into three categories; 1. There are high maintenance wooden boats, (planked)and then 2. There are lower maintenance wooden boats,(cold moulded), and 3. Cheap or free wooden boats that will break your heart. but one thing they all have in common- all wooden boats require passion. A wooden boat will own YOU, not vice versa. if you have wooden boat stewardship in your heart, and you understand that there are no acceptable shortcuts in a varnish schedule, that you really do need a caulking mallet to properly caulk your boat, if you understand that it takes as long as it takes to take up, then you might be one to carry forth the legacy. A wooden boat will take over a large part of your life, and you will be a better person for it. if you worry about how much time maintenance will require, if you'd rather be sailing than caretaking, if you are a procrastinator who won't fix something until it is well and truly broken/rotten/gone, then you aren't ready for a wooden boat.

Hartley18 said: Wood, steel and 'glass boats all require maintenance: wood simply requires less maintenance, more frequently, than 'glass. Click to expand...

Just for the record I am not shopping for any boat at the moment, let alone a wooden one. I had just found myself rejecting a suggestion of a boat as it was wooden and felt I should know more about them so I could be a better armchair sailor. I plan to build some wooden kayaks some day though. In the meantime thanks for all the info. Also I did not know who of you owned wooden boats, now I have another level of respect for you folks.

Jordan,, I highly recommend CLC boats. Chesapeake Light Craft | Boat Plans, Boat Kit, Kayak Kit, Canoe Kit, Sailboat Kit, Rowboat Kit, Paddleboard Kit, Boat Plan, Boat Kits, Kayak Kits, Canoe Kits, Sailboat Kits, Rowboat Kits, Paddleboard Kits, Boatbuilding Supplies, Boat Gear and Accesso I finally sold my 18ft yak. my son and built them a long time ago. took about a weekend to build one. And that was from plans.. not the kit.

Wow Denise, Very impressive. I have looked at CLC, Pigmy, One Ocean and others for years dreaming of building one. I also have Nick Shades book on strip built boats. I just know I have no place to build one or store it. I also think it would take me more than a weekend to do it, especially from a plans. I even have a couple of sheets of Okume and a few gallons of Raka Epoxy. Wish I had the space.

W/o going into lengthy discussions of the different building techniques, etc... I'll say that IF one acquires a wooden boat of traditional (carvel) construction that is in superb condition and one is dedicated to staying on top of everything that needs attention when it demands attention, then it doesn't take a LOT to maintain a woodie. Coldmolded or composite (strip/coldmolded) boats even less. The problem is a woodie might look great from the dock but down in the bilges it could have all sorts of COSTLY repairs in need of doing. Personally I love woodies but I love sailing just as much or more and while I do enjoy working on them I don't want to be a slave to them. If you think you want to play around w/ a woodie find an old One Design and restore it. I did that years ago. In fact I have a 1955 vintage Lightning in my garage that I haven't finished and have considered selling just to free up the space. (not an advertisement, just a comment!)

I think BLJ makes a very good point... it really depends on what you mean by a wooden boat. Do you mean a traditional wooden boat, like a carvel or lapstrake plank-built boat? Do you mean a stitch and glue plywood boat? A cold-molded boat or a strip laminated boat? The latter two can be very low maintenance, since the wood is epoxy or fiberglass encapsulated. They can also be very long lasting boats, since properly built cold-molded or strip laminated boats are very rigid and don't suffer from the fatigue that fiberglass boats can.

The thing I like about wood is that everything, EVERYTHING can be repaired or replaced. Al it takes is time and a bit of skill or somebody like me and your money if ya don't have the first two elements.

I have had the same wood boat for more than 48 years. I would say the most labor-intensive aspects of the experience over all that time have been keeping up the brightwork and messing with old Graymarine gas engines - activity not limited to wood boats. The latter issue has been corrected with the installation of a diesel. Regarding the former - it could be corrected quite easily with a few quarts of paint, but since the varnish is looking pretty good at the moment I think I'll wait.

- ?

- 174K members

Top Contributors this Month

Boat Reviews

- Aquila Boat Reviews

- Aspen Boat Reviews

- Avalon Boat Reviews

- Aviara Boat Reviews

- Axopar Boat Reviews

- Barletta Boat Reviews

- Bayliner Boat Reviews

- Centurion Boat Reviews

- Charger Boat Reviews

- Cruiser Yachts Reviews

- Formula Boat Reviews

- Fountaine Pajot Reviews

- Freeman Boatworks Reviews

- Galeon Luxury Yachts Reviews

- Intrepid Boat Reviews

- Jupiter Marine Reviews

- Manitou Boat Reviews

- Native Watercraft Reviews

- Phenom Yacht Reviews

- Pursuit Boat Reviews

- Sailfish Boat Reviews

- Sea Ray Boat Reviews

- Sea-Doo Watercraft Reviews

- SeaVee Boat Reviews

- Solace Boat Reviews

- Windy Boat Reviews

- X Shore Boat Reviews

- Yamaha Boat Reviews

- Boats Specs

- Marine Pros

- Boat Insurance

- Boat Warranties

- Boat Transport

- Boat Towing

- Marine Forecasts

Your Ultimate Boating Resource

2024 Pursuit OS 445: An Overview

Boat safety 101: exploring the serenity and adventure of boating, the moment of truth – 6 signs you need a new boat, is it possible to wakesurf on a pontoon boat, 2024 aquila 47 molokai review, 2024 sea-doo switch 13 sport review, 2024 aspen c120 review, what is the proper maintenance for a wooden hull boat.

If you have a wooden hull boat, you know how important it is to properly maintain it. Wooden boats require more upkeep than their fiberglass counterparts, but with the right care, they can last for decades. Here are a few tips for maintaining your wooden hull boat:

1. Keep it dry: Wooden boats need to stay dry, as moisture can cause the wood to rot. When you’re not using your boat, make sure it’s stored in a dry location. If you keep it in the water, use a high-quality cover to protect it from rain and other weather elements.

2. Inspect regularly: Regular inspections are critical for keeping your wooden hull boat in good condition. Check for signs of rot or damage in the wood, and make any necessary repairs right away. You should also inspect the boat’s hardware, such as fittings and fasteners, to ensure they’re secure and not corroded.

3. Clean often: Keeping your boat clean is essential for maintenance. Use a mild soap and water to clean the boat’s exterior regularly. Avoid using harsh chemicals or abrasive cleaners, as these can damage the wood.

4. Refinish periodically: Depending on the age and condition of your boat, it may need to be refinished periodically. Refinishing involves sanding down the boat’s exterior and applying a new layer of finish. This process helps protect the wood and keep it looking like new.

5. Use professional services: If you’re not comfortable performing maintenance tasks yourself, it’s best to seek professional help. There are boatyards and specialists who offer services like refinishing, repairs, and inspections specifically for wooden boats.

By following these tips, you can ensure your wooden hull boat stays in excellent condition for years to come. Remember, proper maintenance is key for preserving the beauty and longevity of your boat.

Related Questions

What type of wood is used for pier pilings, what is the difference between a dock and a floating pier, what is the proper technique for pulling a beginner wakeboarder, what does ‘no wake’ mean on a lake, what is the difference between wash and wake, is wakesurfing possible in the sea, why don’t wooden piers rot, what size wakeboard is needed, how to achieve more pop on a wakeboard, does wake surfing translate to ocean surfing, latest posts, the top 9 reasons to maintain a meticulous boat log, don't miss, our newsletter.

Get the latest boating tips, fishing resources and featured products in your email from BoatingWorld.com!

Eco-Savvy Sailing: Expert Tips for Reducing Fuel Costs and Enhancing Your Boating Experience

Sea safety blueprint: constructing the perfect float plan for your boating adventures, 10 essential tips for fishing near private property, the benefits of using a drift sock: guidance for anglers, lure fishing: secrets for imitating live bait and attracting fish, explore the untapped depths of america’s best bass fishing spots, tackle your catch-and-release adventures with these 6 tips, outboard motor maintenance: tips for keeping your engine in top shape, the essential boat tool kit: tools every boater needs, diy boat building: 8 tips and tricks for building your own vessel, the art of miniature maritime craftsmanship: ship in a bottle, antifouling paints: a guide to keeping your boat shipshape, beginner’s guide to standup paddle boarding: tips and techniques, boating for fitness: how to stay active on the water, kayak safety: how to stay safe on the water, anchoring in a kayak or canoe: how to secure your small boat, 2024 yamaha 222xd review, 2024 sailfish 316 dc review, 2023 seavee 340z review, 2023 centurion fi23 review, gear reviews, megabass oneten max lbo jerkbait review, fortress anchors fx-7 anchoring system review, fortress anchors fx-11 anchoring system review, fortress anchors commando anchor kit review, fortress anchors aluminum anchors review, stay in touch.

To be updated with all the latest news, offers and special announcements.

- Privacy Policy

How To Care For Your Classic Wooden Boat

Coeur Custom > Blog > How To Care For Your Classic Wooden Boat

If you’re the owner of a classic wooden boat , then you know that proper maintenance is key to keeping it in good condition for years to come. Wooden boats require care, and if you’re not familiar with how to properly take care of them, you could end up doing more damage than good. In this blog post, we will discuss some tips and tricks for maintaining your classic wooden boat so that it stays in great shape for years to come!

Keep Your Wooden Boat Clean

When people think of maintenance it is often synonymous with cleaning, and for good reason. A key part of taking care of your classic wooden boat is to keep it clean. You should clean your boat regularly, even if it doesn’t seem dirty. Anything from pollen to bird droppings can damage the wood and affect its appearance, so it’s important to remove them as soon as possible.

The best wooden boats are cleaned regularly for the interior and exterior alike.

Interior Cleaning

Why is cleaning the interior of your wooden boat important? Believe it or not, the cleanliness of the interior plays a major role in the lifespan of your boat. Just like your home, if the interior of your boat is not cleaned regularly it will start to show signs of wear and tear much quicker.

Cleaning the interior of your wooden boat is not as difficult as you may think. Start by removing all of the cushions and taking everything out of storage. Once everything is out, you can vacuum or sweep the floors and wipe down all of the surfaces. If you have a removable carpet, be sure to clean that as well.

After the interior is clean, you can put everything back in its place. Be sure to put the cushions back on last so they don’t get dirty again while you’re working.

Exterior Cleaning

Cleaning the exterior of your wooden boat is just as important as cleaning the interior. The first step is to wash the hull to remove any dirt or other debris that could damage the wood. You can use a pressure washer for this, but be sure to use a low setting so you don’t damage the wood.

Be sure to use a mild marine detergent and avoid using too much pressure.

After the hull is clean, you can move on to cleaning the deck. Start by sweeping off any loose dirt or debris, then use a mild deck cleaner to remove any stains. Be sure to rinse the cleaner off completely in the process.

Engine And Mechanical Maintenance

Another important aspect of taking care of your classic wooden boat is to regularly maintain the engine and other mechanical parts. This includes things like changing the oil, checking the fluids, and making sure all of the moving parts are properly lubricated.

It’s also a good idea to have a professional inspect the engine and other mechanical parts on a regular basis. This will help ensure that everything is in good working condition and catch any potential problems before they become serious.

Dry Docking Your Classic Wooden Boat

One of the best things you can do for your classic wooden boat is to dry dock it regularly. Dry docking is when you remove the boat from the water and allow it to sit on land for some time. This allows you to inspect the hull for any damage and make any necessary repairs.

It’s also a good opportunity to clean the boat from top to bottom, including the hull, deck, and engine.

Dry docking your boat is something that should be done at least once a year, but more often if possible.

Resealing When Necessary

Another important part of taking care of your classic wooden boat is to reseal it when necessary. The sealant helps protect the wood from the elements and keeps it looking its best.

You’ll know it’s time to reseal your boat when you start to see cracks or chips in the existing sealant. Be sure to clean the surface thoroughly before applying the new sealant.

Applying a new coat of sealant is not a difficult task, but it should be done carefully. Be sure to follow the instructions on the product you’re using to ensure the best results.

Coeur Custom: Classic Wooden Boat Restoration

Now that you know how to take care of your classic wooden boat, it’s time to get out there and enjoy it! If you need help with any aspect of restoration or maintenance, be sure to contact Coeur Custom . We specialize in classic wooden boat restoration and can help you keep your boat looking its best. Contact us today to learn more!

Step-By-Step Guide: How to Build a Wooden Sailboat – Complete DIY Tutorial

Alex Morgan

Building a wooden sailboat is a rewarding and fulfilling endeavor that allows you to create your own vessel for sailing adventures. Whether you’re a seasoned sailor or a woodworking enthusiast, constructing a wooden sailboat requires careful planning, attention to detail, and a love for craftsmanship. This comprehensive guide will take you through the step-by-step process of building a wooden sailboat, from choosing the right design and gathering the necessary materials to assembling the framework, building the deck and cabin, and installing the sails and rigging. We will also discuss the finishing touches and regular maintenance required to keep your wooden sailboat in optimal condition for years of enjoyment on the water. Let’s dive into the world of wooden sailboat construction and embark on this exciting journey together.

Key takeaways:

Key takeaway:

- Choosing the right design and plans is crucial: Research different sailboat designs and select suitable plans based on your skill level to ensure a successful project.

- Gather the necessary materials and tools: Pay attention to wood selection and preparation, as well as acquiring the tools and equipment needed for building your wooden sailboat.

- Attention to detail in the construction process is important: Prepare and assemble the framework carefully, focusing on lofting, laying out the keel, constructing the ribs, and the hull structure to ensure a sturdy and reliable sailboat.

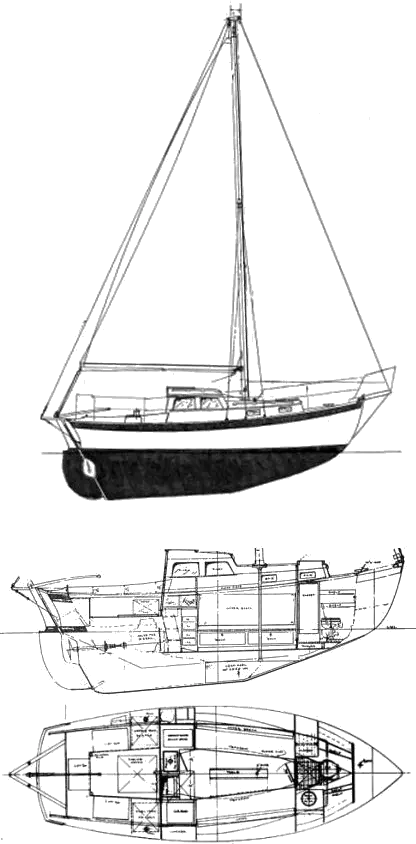

Choosing the Right Design and Plans

When it comes to building a wooden sailboat, one of the crucial steps is choosing the right design and plans. In this section, we’ll take a deep dive into the world of sailboat designs and explore the vast array of options available. From researching different sailboat designs to selecting plans that match your skill level, we’ll guide you through the exciting process of bringing your wooden sailboat dream to life. So, hop aboard and let’s set sail on this exhilarating journey of craftsmanship and adventure.

Researching Different Sailboat Designs

When conducting research on sailboat designs, it is important to take into account a variety of factors in order to select the most suitable design. One of the primary considerations is whether you prefer a monohull or a multihull sailboat. Monohulls are more commonly found and offer superior performance when sailing upwind, whereas multihulls provide both stability and speed.

Another aspect to consider is your level of sailing experience. If you are a beginner, it is advisable to seek out designs that are easier to handle and forgiving. On the other hand, experienced sailors may gravitate towards performance-oriented designs that are ideal for racing or long-distance cruising.

It is crucial to think about how you intend to use the sailboat. Are you looking for a day sailer , a cruiser , or a racing boat ? Each design comes with its own set of distinctive features and characteristics.

Determining the appropriate size of the sailboat is another crucial step, which should be based on the number of people and activities you plan to have on board. You must also decide whether you prefer an open cockpit or an enclosed cabin .

To find the perfect sailboat design that aligns with your sailing goals and preferences, it is imperative to thoroughly research various options and take into consideration all of these factors. By doing so, you will be able to make an informed decision and select the ideal sailboat design.

Selecting Suitable Plans for Your Skill Level

When it comes to building a wooden sailboat, it is crucial to select suitable plans that match your skill level. This is important as it ensures that you have the necessary knowledge and expertise to effectively complete the construction. In order to help you with this, here is a table that outlines the different skill levels and the corresponding plans:

Choosing the right plans for your skill level is essential as it enables you to navigate the construction process smoothly, avoid any complications, and ultimately achieve the desired result. It is crucial to honestly evaluate your woodworking skills and then select plans that align with your abilities. Keep in mind that building a wooden sailboat demands patience , attention to detail , and a willingness to learn and improve your woodworking skills.

As a pro tip, if you are a beginner, it is advisable to start with simpler plans and gradually work your way up to more complex projects. This allows you to gain experience and confidence in your woodworking abilities over time. So always remember to select suitable plans for your skill level and enjoy the process of building your wooden sailboat.

Gathering the Necessary Materials and Tools

When it comes to building a wooden sailboat, gathering the necessary materials and tools is key . In this section, we’ll dive into the exciting world of selecting and preparing the right wood for your sailboat, as well as the essential tools and equipment you’ll need to bring your project to life. So, start sharpening your creativity and let’s sail away into the realm of wooden boat construction!

Wood Selection and Preparation

Incorporating the provided keywords naturally in the provided text:

1. Conduct research on the different types of wood used in boatbuilding, such as mahogany , teak , or oak . This will help you make an informed decision regarding the most suitable wood for your sailboat.

2. Determine the specific requirements of your sailboat design in order to guide your wood selection process. Each design may have different needs and preferences when it comes to the type of wood to be used.

3. Take into consideration the durability and resistance to rot of the wood options available. This is crucial to ensure the longevity and overall quality of your sailboat. Choosing a wood that can withstand exposure to water and other elements is essential.

4. Look for straight , dry , and defect-free wood. This will contribute to the structural integrity of your sailboat. Any defects or irregularities in the wood may compromise its strength and performance.

5. Calculate the amount of wood needed based on the specific design and measurements of your sailboat. This will help you estimate the quantity of wood required for the construction process.

6. Mill or cut the wood into the required dimensions and shapes as outlined in the sailboat design. This step is crucial for achieving the desired structure and appearance of your sailboat.

7. Prior to assembly, it is important to sand the wood surfaces thoroughly. This will remove any rough edges or splinters, ensuring a smooth and safe finish.

8. Apply a protective coating or sealant to the wood in order to prevent water damage. This will help preserve the wood and extend its lifespan .

By following these steps, you can ensure that the wood selected and prepared for your sailboat construction is suitable and of high quality.

Tools and Equipment Needed for the Project

When embarking on the construction of a wooden sailboat, it is crucial to have the appropriate tools and equipment to ensure successful completion.

To accurately measure and obtain precise alignment and dimensions, essential measuring tools such as a tape measure , combination square , and level are indispensable.

For shaping wooden components, cutting tools like a circular saw or table saw , jigsaw , and hand saw are necessary.

Joinery tools, including a chisel set , mallet or hammer , and drill with different-sized bits, are vital for smoothly joining parts together.

To achieve a polished finish, sanding and finishing tools such as sandpaper with varying grits, sanding blocks , and a random orbital sander are crucial.

Additionally, brushes and rollers are required for the application of finishes.

When it comes to safety, it is imperative to prioritize the use of safety goggles , ear protection , a dust mask , and work gloves to ensure personal protection during the construction process.

When selecting tools and equipment, it is essential to invest in high-quality items that are specifically designed for the tasks involved in wooden sailboat building.

By doing so, not only will efficiency be maximized, but the overall quality of the finished boat will also be greatly enhanced.

Preparing and Assembling the Framework

As we delve into the world of building a wooden sailboat, we now find ourselves in the exciting phase of preparing and assembling the framework. In this section, we’ll discover the essential steps that go into setting up the lofting and laying out the keel , as well as the intricacies of constructing the ribs and hull structure. Get ready to immerse yourself in the hands-on process of bringing this magnificent vessel to life!

Setting Up the Lofting and Laying Out the Keel

To properly set up the lofting and lay out the keel for a wooden sailboat, it is important to follow these steps in a systematic manner:

- Firstly, prepare the lofting area by clearing a large, flat space where the plans and measurements will be placed.

- Next, securely attach the keel stock to the lofting platform, making sure it is both level and aligned with the boat’s centerline.

- Using battens, rulers, and pencils, transfer the measurements and lines from the boat plans onto the lofting platform.

- Ensure the accuracy of the waterlines, buttock lines, and other reference lines on the lofting platform by drawing them according to the measurements provided in the boat plans.

- Utilizing the dimensions indicated in the plans, measure and mark the positions of the keel, stem, and transom on the lofting platform.

- Thoroughly examine and adjust all lines and measurements to guarantee their accuracy.

- Identify the locations where any additional frames, bulkheads, or structural elements will connect to the keel, by marking them accordingly.

- Prior to proceeding, double-check all marks and measurements to ensure their accuracy.

The process of setting up the lofting and laying out the keel is an integral step in the construction of a wooden sailboat. It serves as the foundation and reference points for the boat’s overall structure. It is crucial to pay close attention to detail and maintain accuracy throughout the build. By following these steps, you will be on your way to constructing your very own wooden sailboat.

Constructing the Ribs and Hull Structure

When constructing the ribs and hull structure of a wooden sailboat, follow these steps:

– Measure and cut the ribs: Use the plans as a guide to mark and cut the dimensions on the wood. Cut the ribs accurately.

– Attach the ribs to the keel: Position and attach the cut ribs evenly along the keel using marine epoxy and screws.

– Install chines and stringers: Attach the chines to the bottom edge of the boat and install the stringers along the sides for strength.

– Attach the planking: Cut and fit planks to cover the rib and stringer structure, securing them tightly.

– Reinforce the joints: Apply epoxy and fiberglass tape over the joints to strengthen the structure.

– Shape the hull: Use tools to shape and smooth the hull, paying attention to fairing for optimal hydrodynamics.

– Apply a protective finish: Coat the hull and ribs with marine-grade varnish or epoxy for durability.

– Perform a thorough inspection: Check for defects, cracks, or imperfections and make necessary repairs before moving forward.

The process of constructing wooden sailboats has evolved over time, combining traditional techniques with modern materials and tools. Craftsmanship, attention to detail, and an understanding of wood’s properties are still essential in constructing the ribs and hull structure. This blend of artistry and engineering ensures sailboats can withstand the demands of the sea while providing a smooth and enjoyable sailing experience.

Building the Deck and Cabin

Let’s dive into the exciting world of building a wooden sailboat! In this section, we’ll focus on the crucial element of constructing the deck and cabin. Get ready to explore the process of creating the deck framework and adding those essential interior features . From laying the foundation to crafting a cozy cabin space , we’ll uncover the key steps and considerations for bringing your wooden sailboat to life. So, grab your tools and let’s set sail on this exhilarating construction journey !

Creating the Deck Framework

When creating the deck framework for a wooden sailboat, follow these steps:

- Measure and mark the desired deck size and shape on the boat’s frame.

- Cut and shape the wooden planks or panels to match the marked measurements.

- Align the planks or panels horizontally across the frame, ensuring they are straight and evenly spaced.

- Secure the planks or panels to the frame using screws or nails, ensuring tight fastening.

- Add additional support beams or joists underneath the deck for added strength and stability.

- Sand the deck surface to create a smooth and even finish.

- Apply a weather-resistant sealant or paint to protect the deck from moisture and UV damage.

- Install necessary features or fixtures on the deck, such as hatches, cleats or railings.

Pro-tip: Enhance the deck’s strength and durability by adding epoxy or marine adhesive between the joints before securing the planks or panels.

Installing the Cabin and Interior Features

When building a wooden sailboat, it is important to pay attention to every step, including the installation of the cabin and interior features. To install these features, follow the following steps:

1. First, measure and cut the materials for the cabin walls, floor, and ceiling.

2. Next, securely fit the cabin walls in place.

3. Then, attach the floorboards to the cabin base using screws or nails.

4. Align and install the cabin ceiling.

5. If desired, add insulation for extra comfort.

6. Attach interior features such as cabinets, storage compartments, and seating areas.

7. Install windows and hatches to allow for natural light and ventilation.

8. Properly wire the cabin for electricity, ensuring that lights and outlets are installed and functioning.

9. Finish the interior by sanding and applying a protective coat of varnish or paint.

10. Ensure that all installations meet safety standards.

Precision and attention to detail are key when installing the cabin and interior features of a wooden sailboat. By carefully measuring, cutting, and fitting each component, you can ensure a secure fit. It is important to optimize the layout and functionality of the interior features to create a comfortable living space with ample storage. The addition of windows and hatches will enhance comfort and enjoyment by providing natural light and ventilation . If electricity is needed, proper wiring is essential to ensure necessary lighting and power outlets. Finishing the interior with a protective coat of varnish or paint will not only enhance aesthetics but also provide durability.

Remember, the goal is to create a cozy retreat for sailors, so it is important to put in the necessary effort to install the cabin and interior features correctly.

Installing the Sails and Rigging

Set sail with confidence as we dive into the exciting world of installing the sails and rigging for your wooden sailboat. Discover the key considerations in choosing the perfect sails and master the art of setting up and adjusting the rigging. With expert tips and tricks , this section will equip you with the knowledge to navigate the waters with ease and experience the thrill of sailing your wooden masterpiece .

Choosing the Right Sails

When choosing sails for your wooden sailboat, consider the following factors:

– Type of sailing: Determine if you plan to cruise , race , or do both. Different sails are designed for specific purposes.

– Boat size: The size of your sailboat determines the size and number of sails you need. Larger boats require bigger sails , while smaller boats may need fewer and smaller sails .

– Wind conditions: Consider the typical wind conditions in your sailing areas. Different sails perform better in light winds , heavy winds , or various wind conditions.

– Sail material: The material of the sails affects durability and performance. Material choices include Dacron , laminate , and nylon . Each material has different trade-offs between longevity, performance, and cost.

– Reefing options: If you sail in varied or unpredictable wind conditions, choose sails with reefing options. Reefing allows you to adjust the sail area for stronger winds, improving control and safety.

– Manufacturer reputation: Research sail manufacturers for their reputation and reliability. Read reviews, seek recommendations, and consider warranty and customer support.

By considering these factors, you can make an informed decision when choosing sails for your wooden sailboat. Remember, the right sails greatly impact your sailing experience, so take your time and choose wisely.

Setting Up and Adjusting the Rigging

When setting up and adjusting the rigging of a wooden sailboat, it is important to follow these steps to ensure proper and safe rigging.

To start, attach the mast to the deck using a mast step or mast partner for stability and support. This will provide the foundation for the rigging.

Next, secure the standing rigging , which includes the shrouds and stays , to the mast. This will help distribute the forces from the sails and ensure the stability of the mast.

Connect the forestay to the bow of the sailboat. This will keep the mast in line and control the position of the headsail.

To counteract forces from the headsail and maintain rigging tension, attach the backstay to the stern of the boat.

Use turnbuckles or rigging screws to adjust the tension in the standing rigging. This will ensure proper alignment and support of the mast.

Install the running rigging , including halyards and sheets , to control the position and tension of the sails.

Before and during sailing, it is important to regularly check the tension in the rigging to ensure performance and safety.

Make any necessary adjustments to the rigging during sailing in order to optimize the shape of the sails and enhance the performance of the boat.

By following these steps, you will be able to properly set up and adjust the rigging of your wooden sailboat, allowing for safe and enjoyable sailing experiences.

Finishing Touches and Maintenance

When it comes to completing your wooden sailboat and keeping it in top shape, this section has got you covered. We’ll dive into the art of applying exquisite finishes to the hull and deck, giving your sailboat a stunning appearance. And don’t worry, we won’t neglect the nitty-gritty details of regular maintenance and care, ensuring your wooden vessel remains seaworthy for years to come. So, let’s get ready to add those finishing touches and keep your sailboat sailing smoothly !

Applying Finishes to the Hull and Deck

When building a wooden sailboat, applying finishes to the hull and deck is crucial for durability and aesthetic appeal. Here are the steps to follow:

1. Prepare the surfaces: Sand down rough spots, fill in cracks and imperfections, and ensure a smooth and clean surface.

2. Choose the right finish: Consider the type of wood and desired look. Varnish provides a glossy and traditional appearance, while paint offers different colors and styles.

3. Apply the primer: Enhance adherence and create an even surface for the final coat by applying a primer.

4. Apply the finish: Use a brush or roller to apply the chosen finish coat to the hull and deck. Follow the manufacturer’s instructions for drying times and application techniques.

5. Allow for drying and curing: Follow the manufacturer’s instructions for drying and curing to ensure the finish is fully set and provides maximum protection.

6. Inspect and touch up: After drying, inspect the hull and deck for missed spots or imperfections. Touch up any areas that require additional finish for a seamless and polished look.

By following these steps and applying finishes properly, you can protect and enhance the hull and deck of your wooden sailboat, ensuring it looks beautiful and lasts for many years.

Regular Maintenance and Care for Your Wooden Sailboat

Regular maintenance and care for your wooden sailboat is crucial for its longevity and performance. Here are the steps to follow:

1. Inspect the hull and deck for damage like cracks or rot. Promptly repair any issues to prevent further damage.

2. Clean the boat regularly with mild detergent and freshwater to remove dirt, salt, and grime that can accumulate over time.

3. Apply a protective coating to the hull and deck using marine-grade varnish or paint to prevent water penetration and protect against UV damage.

4. Check the rigging and sails for wear or damage. Replace worn-out lines or rigging components for safe sailing.

5. Inspect wooden components such as the mast, boom, and rudder for rot or decay. Replace or repair as necessary to maintain structural integrity.

6. Keep the interior of the sailboat clean and dry to prevent mold and mildew growth. Use a dehumidifier if needed.

7. Regularly check and maintain the boat’s systems , including electrical, plumbing, and navigation equipment. Address any issues promptly.

8. Store the wooden sailboat in a suitable location, such as a covered boat dock or boatyard, when not in use. Protect it from extreme weather conditions.

Pro-tip: Establish a regular maintenance schedule and keep a detailed record of all maintenance and repairs. This will help you stay organized and ensure your wooden sailboat remains in optimal condition.

Some Facts About How To Build A Wooden Sailboat:

- ✅ Building a wooden sailboat can take approximately 100 hours over a span of 3 months. (Source: Instructables)

- ✅ A wooden sailboat can cost around $1,000 to build. (Source: Instructables)

- ✅ The boat is typically built from 4×8 sheets of plywood and measures 8 feet in length. (Source: Instructables)

- ✅ Various tools such as a pull-saw, table saw, router, sander, and drill are needed for building a wooden sailboat. (Source: Instructables)

- ✅ Fiberglass cloth, epoxy resin, screws, and other materials are used to reinforce and waterproof the wooden sailboat. (Source: Instructables)

Frequently Asked Questions

1. how long does it take to build a wooden sailboat.

Building a wooden sailboat typically takes about 100 hours spread over approximately 3 months.

2. What materials are needed to build a wooden sailboat?

To build a wooden sailboat, you will need 4×8 sheets of plywood, epoxy resin, oak plywood, various tools (such as a pull-saw, table saw, router, etc.), fiberglass cloth, screws, fasteners, and other supplies like glue, clamps, and mixing cups.

3. How much does it cost to build a wooden sailboat?

The estimated cost of building a wooden sailboat is around $1,000, including the materials and tools needed for the project.

4. Can I learn to build a wooden sailboat if I have no prior experience?

Yes, building skills can be learned gradually, and mistakes can be avoided along the way. With patience and guidance from boat building plans, even beginners can successfully build a wooden sailboat.

5. How long is the wooden sailboat described in the reference?

The wooden sailboat described in the reference is an 8-foot long pram, featuring classic lines and made from 4×8 sheets of plywood.

6. Can I launch the wooden sailboat in any body of water?

Yes, the wooden sailboat is designed to be light enough to fit in a small pickup truck or be rolled to a local lake on a dolly, making it suitable for various bodies of water.

About the author

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

The history of sailing – from ancient times to modern adventures

History of Sailing Sailing is a time-honored tradition that has evolved over millennia, from its humble beginnings as a means of transportation to a beloved modern-day recreational activity. The history of sailing is a fascinating journey that spans cultures and centuries, rich in innovation and adventure. In this article, we’ll explore the remarkable evolution of…

Sailing Solo: Adventures and Challenges of Single-Handed Sailing

Solo Sailing Sailing has always been a pursuit of freedom, adventure, and self-discovery. While sailing with a crew is a fantastic experience, there’s a unique allure to sailing solo – just you, the wind, and the open sea. Single-handed sailing, as it’s often called, is a journey of self-reliance, resilience, and the ultimate test of…

Sustainable Sailing: Eco-Friendly Practices on the boat

Eco Friendly Sailing Sailing is an exhilarating and timeless way to explore the beauty of the open water, but it’s important to remember that our oceans and environment need our protection. Sustainable sailing, which involves eco-friendly practices and mindful decision-making, allows sailors to enjoy their adventures while minimizing their impact on the environment. In this…

Hylan & Brown – Boatbuilders – Brooklin, Maine – Building and Restoring Classic Wooden Boats

The cost of wooden boat maintenance.

Wood versus Fiberglass

Why would you want a wooden boat? Well, why would you want a hand made mahogany dining room table? Because you chose it or had it made to match your taste, because of the warmth and elegance it brings to your life, because of the pride you feel at the craftsmanship it embodies. A fiberglass dining room table simply would not do!

How many times have we heard it: “Wooden boats are so beautiful, I’d love to have one if only the maintenance didn’t cost so much”. In all honesty there are significant costs involved in having a boat professionally stored and maintained. But the pervasive misconception is that fiberglass boats cost less.

Are fiberglass boats really so cheap to maintain? The answer is yes, if what you want to do is to neglect your boat. There is no denying that fiberglass can withstand a shocking amount of neglect. But if you want to keep your fiberglass boat looking it’s best, it will cost you.

If you take two equivalent boats, one fiberglass and one of traditional wood construction, both the same age, both with an equal amount of brightwork, and both kept in true yacht fashion, their maintenance costs will be virtually identical.

About the only difference in the maintenance program between these two boats will be in finishing the topsides, a small part of a yacht’s total maintenance bill. A traditionally built boat will require a fresh coat of paint every year or two, while a fiberglass one will need waxing every year or “Awlgrip” every 4 to 6 years. In the long run, these three options will come to very nearly the same cost, especially if your topsides sustain the occasional scratch or ding.

To be fair we should mention that for this equation to be true, a wooden boat must be stored and maintained at a yard that has knowledge and experience in the care of wooden boats. That does not necessarily mean a more expensive yard, but it does mean that wooden boat owner’s must be more selective about where their boats are stored and maintained. In New England it is not hard to find a yard that can properly care for a wooden boat. Outside of New England it can be harder. For this and other reason we sometimes recommend cold molded construction for boats that will reside in Mid Atlantic or Southern areas.

As for longevity, we have done several first restorations of traditionally built wooden boats that were 60 to 80 years old. Many fiberglass yachts have needed restoration at half that age. The reality is that a properly maintained wooden boat can last 100 years, and still look beautiful for your great grandchildren. You can’t say the same for fiberglass boats – they just haven’t been around long enough to prove it.

Go to our Storage and Maintenance Page .

- In the Shop

- SWAN POINT GARVEY – 15′ Flat Bottomed Sailing Skiff

- SOMBRERO – 50′ Low Impact Long Distance Cruiser

- EVE, 26’ Electric Launch

- SELKIE, 23′ Daysailer

- BERET – Low-Impact Coastal/River Cruiser

- TUVA II – Long Range Cruiser

- Sketch Book – Bowler Variants

- ALBURY BROTHERS RUNABOUT

- BEN GARVEYS

- BOWLER (+Kit)

- HIRD ISLAND ELECTRIC SKIFF

- OONAGH (+Kit)

- POINT COMFORT 23

- POINT COMFORT 18 (+Kit)

- PRETTY MARSH

- Swan Point Garvey

- BEACH PEA (+Kit)

- BENJAMIN RIVER PEAPOD (+Kit)

- CHESAPEAKE CRAB SKIFF

- COQUINA – N. G. Herreshoff

- LITTLE CRAB (+Kit)

- RUBY SLIPPER – 23’3″ Daysailer

- WESTPORT SKIFF

- Frequently Asked Questions

- Custom Designs

- Design Blog – OCH

- LILY PAD – 26′ Cruiser

- SCOUT – 43′ Cruiser

- AUK – PC23 Electric

- 14ft BEN GARVEY

- POINT COMFORT 18

- DELIVERANCE

- POSTHASTE IV

- ZEPHYR and SUZANNA

- LIGHT BREEZE

- Four HANDY BILLY launches

- HUNNY – 43′ “Chummy” Rich Downeast Cruiser

- SARDINE – A garvey designed and built by Harry Bryan.

- Maintenance

- 30′ JIAN LING – Knarr Sloop – $12,000

- Now Hiring!

- Merchandise

- Clean Energy

- Articles and Guides

Wooden Boat Care and Maintenance

30th mar 2023 by samantha wilson.

There are basically three options for care and maintenance:

- Dry dock your boat every winter and have a shipwright or boatyard maintain it

- A combination of the two above approaches. Tackle the more basic stuff yourself whilst leaving the more complex jobs for a professional boatyard or shipwright

For those considering the second or third options, below are details of some of the basic care and maintenance tasks which could be undertaken by any capable enthusiastic amateur DIYer.

How to varnishing a wooden boat

Correct surface preparation is the key to a satisfactory varnishing job..

- Remove the old varnish using a paint stripper or a heat gun. Sanding, as well as being labour intensive, can also result in removing some of the wood unnecessarily.

- Any stains can be removed by using oxalic acid or household bleach. However, ensure you neutralise after treating as failure to do so will result in poor varnish adhesion.

- Use a hoover to remove any dust.

Applying the varnish

- Plan the area you are varnishing . A square foot at a time is a manageable method. Use a reflected light source or wear polarised glasses to see where you have varnished and where you haven’t reached yet.

- Thin the first coat by half . A thinner coat will cure far faster and make it easier to sand sooner.

- The following day use 180-240-grit sandpaper and sand carefully taking care not to cut into the varnish.

- The most important factor in the subsequent coats is achieving a glass finish . Ensure your varnish flows by thinning it to avoid tearing or dragging. Don’t worry if it’s too thin, just make the next coat slightly thicker. The further down the can of varnish you get, the more you’ll have to thin as some of the solvents within the varnish will have evaporated. Try and deliver an even brushstroke by simply gliding across the surface rather than digging in with the bristles. Work fast and avoid going back over previous brushstrokes.

Levelling off

- Give the varnish time to dry to let any brushstrokes “level off”.

- Don’t varnish on a hot sunny day. The varnish will dry too quickly and won’t level off satisfactorily. Ideally, varnish on a cooler overcast day with little or no wind.

- Aim to apply one coat per day. This allows plenty of time for the varnish to cure and level off.

Mirror finish

- Once you’ve put eight or nine coats on you’re ready to achieve a mirror finish.

- Wait two or three days for the varnish to harden.

- Flatten with 320 wet & dry paper in a sanding block. Lubricate well with soapy water.

- Wash dust off and tag rag. A simple tag rag can be made by using an old t-shirt dipped in white spirit with a few drops of varnish dropped onto it and then wrung out.

- Thin the varnish as much as you can to make a “wiping varnish”. The varnish will level better and dry faster.

- Quickly apply the final coat of wiping varnish and leave it alone. Do not be tempted to go back over an area.

- By the next day you should have achieved a mirror finish.

Most forms of wood rot encountered by the sailor are caused by fungus although it’s often erroneously misnamed dry rot. The fungus needs three things in order to survive; moisture, oxygen and a warm environment. Bare wood absorbs moisture which then in turn attracts the fungus. Another major factor in eliminating rot is good ventilation. Adequate air-circulation prevents dampness, hence why open boats are less susceptible to damp than closed cabin boats. However, all types of wooden boats are at risk of rot especially when they are not in use.

The type of wood used in the construction is also a factor- softer and faster growing woods attract more rot than older growths. There are many products on the market that treat rot effectively.

Chances are your boat will spend as much time, if not more, in storage than in use. This is a vital factor in the care of any boat, but of particular importance for a wooden craft. Take careful note of the following factors in good storage;

- Wooden craft left afloat at sea suffer less rot than those in fresh water.

- If you keep your boat on the beach or in a yard, then ensure they’re raised off the ground by at least a few inches.

- Don’t leave your boat over long wet grass or under leaf shedding trees.

- Don’t leave your boat near any old wooden structure that may be harbouring rot-hungry spores.

- Open the drain plug to allow any bilge to drain.

- Raise one end higher than the other to help rain water clear.

- If kept indoors, ensure the wood isn’t allowed to dry out too much.

- Check periodically and let some airflow circulate through the interior.

- Check your varnish and paint and treat accordingly.

A good quality canvas cover can effectively protect your boat from rain, sun, leaves, twigs and even bird dropping. Covers should be used in a way that allows air to circulate and let any moisture escape. Leave the ends open. Keep any cover clear of the wood by using a simple framework. Covers made from a breathable canvas material are the best type to use but avoid darker colours which may absorb heat in a hotter climate, drying out the wood excessively. Always check your cover for wear and tear and repair or replace if necessary. Use grommets and lines to hold the cover in place but ensure they are anchored to the ground and not the boat itself.

Keep on top of any repairs

Make a habit of routinely checking your boat for any wear and tear. Touch up any damaged varnish and treat any areas of rot before they spread. Pay particular attention to areas of wear such as the coamings where fenders or mooring lines may have rubbed. Check your mooring lines for wear and replace if necessary. If you have any chaffing caused by being dragged up a beach then fix some metal rubbing strips to the bottom of the keel.

Lighter coloured boats reflect the sun which helps to extend the life of any protective paints. Darker colours may result in shortening the life of the paint and even any caulking. The deck of your boat has a hard life so pay attention to its care and maintenance. Repair or replace any cracked deck boards to avoid rot from trapped water, especially with plywood decks. If unchecked it will spread by capillary action and could affect larger and less accessible areas of timber.

Don’t forget items such as spars and oars. Store them out of the sun and touch up any areas of wear. Grease any oar leathers to help prolong their life and make rowing far easier. Any boat kept on the water should have its anti-fouling paint renewed annually to deter borers and marine growth. Check any running and rigging. Also, check any blocks for signs of stress especially on boats with large sail areas.

The more time you spend on caring for your boat when you’re not using it, the less time you will lose to breakages and breakdowns when you are using it. In short, look after your boat and it’ll look after you!

Where to keep your classic wooden boat

Costings based on a 25ft classic yacht:

- $2,000-$5,000 depending on location for a marina berth. Secure, staffed with shore power and water usually available. The most expensive option.

- $500-$1,000 Drying, or mud berth. Boat either floats or rests in the mud dependent on tide.

- $200 apx. Swinging mooring. Moored to a stout buoy anchored to the sea-bed. To access your boat, you’ll need a dinghy or water-taxi service.

- Free Keep it at home on a trailer. Freedom to sail wherever you can drive

Written By: Samantha Wilson

Samantha Wilson has spent her entire life on and around boats, from tiny sailing dinghies all the way up to superyachts. She writes for many boating and yachting publications, top charter agencies, and some of the largest travel businesses in the industry, combining her knowledge and passion of boating, travel and writing to create topical, useful and engaging content.

More from: Samantha Wilson

Related Articles and Guides

6th Dec 2023

Boat Inspection Checklist: How to Inspect a Boat Before Buying

28th Nov 2023

Sea Trial: Costs, Checklist and More

1st Nov 2023

Types of Marine Surveys: Pre-Purchase, Condition and Damage Survey

27th Oct 2023

The Top 15 Questions You Should Ask When Buying a New or Used Boat

- Explore Rightboat

- Boats for Sale

- Boating Articles

- Buyers Guide

- About RightBoat

- Sell Your Boat

- Boat Selling Advice

Enter your email to keep up to date with the latest news

Join for free

Sign up now for free and discover how easy it is to keep up to date with THE latest boats for sale. Find your right boat, and tailor your voyage to finding your next boat.

Benefits of becoming a member:

- Set up tailored alerts

- Personalise your experience

- Download full specifications and broker details

- Keep tabs on your favourite boats

Are you a broker? Join as a Broker

Rightboat - join for free.

Do you have an account already? Login

Save this search

Save your search and receive new boats in your email..

You can unsubscribe from your alerts whenever you like. By pressing the button you accept the Legal Terms and conditions

Sailboat Cleaning and Maintenance: A Step-by-Step Guide

Sailboats are a fantastic investment for those who enjoy spending time on the water. Not only are they a lot of fun to use, but they also provide a unique way to explore the world and escape from the stresses of daily life. However, like any other investment, sailboats require regular maintenance and cleaning to ensure they stay in good condition and continue to perform at their best.

In this blog post, we’ll provide a detailed guide on how to clean your sailboat and how to keep it well-maintained. Whether you’re a seasoned sailor or a beginner, these tips will help you keep your sailboat looking and functioning its best.

Table of Contents

A Step-by-Step Guide for Cleaning and Maintaining your sailboat

Step 1: clean the deck.

The first step in cleaning your sailboat is to wash down the deck. This will remove any dirt, grime, or debris that has accumulated over time. To do this, use a mild soap and water solution and a soft-bristled brush to scrub the deck. Be sure to pay extra attention to areas that are prone to buildup, such as around the cleats and in the corners.

Step 2: Clean the Hull

Next, move on to the hull of your sailboat. The hull is one of the most important parts of the boat, and keeping it clean will help maintain its appearance and performance. To clean the hull, use a mild soap and water solution and a soft-bristled brush. Start from the bow of the boat and work your way towards the stern, being sure to scrub in a circular motion to remove any buildup or stains.

Step 3: Clean the Windows and Hatches

The windows and hatches on your sailboat are important features that provide natural light and ventilation. To clean these areas, use a solution of vinegar and water, or a specialized window cleaner. Apply the solution to the surface and use a soft cloth to gently scrub away any dirt or grime. Be sure to rinse thoroughly with clean water to prevent streaks.

Step 4: Clean the Sails

The sails are one of the most important components of your sailboat, and keeping them clean and in good condition is essential for optimal performance. To clean your sails, use a mild soap and water solution and a soft-bristled brush. Scrub the sails in a circular motion to remove any dirt or buildup, being sure to pay extra attention to areas that are prone to staining.

Step 5: Clean the Hardware

The hardware on your sailboat, such as the cleats, winches, and fittings, is important for both appearance and functionality. To clean these areas, use a mild soap and water solution and a soft-bristled brush. Scrub the hardware in a circular motion to remove any dirt or grime, being sure to pay extra attention to areas that are prone to rust.

Step 6: Maintain the Paint

The paint on your sailboat is important for both appearance and protection against the elements. To maintain the paint, wash it down regularly with a mild soap and water solution. If the paint is starting to fade or become discolored, consider applying a fresh coat of paint to keep it looking its best.

Step 7: Protect the Wood

If your sailboat has any wooden components, such as teak decks or trim, it’s important to protect them from the elements. To do this, clean the wood regularly with a mild soap and water solution and apply a protective finish to keep it looking its best.

Step 8: Check and Maintain the Rigging

The rigging on your sailboat is important for more ensuring the safety of your boat and its passengers while out on the water. Regularly inspect the rigging for any signs of wear or damage, such as frayed lines or rust on the hardware. If you notice any issues, have them repaired by a professional immediately. Additionally, be sure to adjust the rigging as needed to ensure it remains tight and secure.

Step 9: Store Your Sailboat Properly

When not in use, it’s important to store your sailboat properly to protect it from the elements and prevent damage. If possible, store your sailboat in a covered area, such as a boathouse or covered slip. If this is not possible, invest in a quality boat cover to protect the exterior from rain, wind, and sun.

By following these steps, you can keep your sailboat looking and functioning its best for years to come. Regular cleaning and maintenance is essential for maintaining the appearance, performance, and safety of your boat, and investing the time and effort to do so will be well worth it in the end. Happy sailing!

Key Takeaways:

- Clean the deck, hull, windows and hatches, sails, and hardware regularly to maintain their appearance and performance.

- Maintain the paint, protect the wood, and inspect and adjust the rigging regularly.

- Store your sailboat properly when not in use to protect it from the elements and prevent damage.

Answers to Frequently Asked Questions About Cleaning your Sailboat

Best thing to clean a boat with.

The best thing to clean a boat with depends on the type of material the boat is made of and the type of dirt or grime you are trying to remove. Here are some common materials and the best cleaning products to use:

- Fiberglass : A mild soap and water solution or a specialized fiberglass cleaner can be used to clean the surface of a fiberglass boat.

- Metal : A solution of vinegar and water can be used to clean metal components on a boat. For rust, use a specialized rust remover.

- Sails : A mild soap and water solution can be used to clean sails. For tough stains, consider using a specialized sail cleaner.

- Teak Wood : Use a mild soap and water solution to clean teak wood. For long-term protection, apply a teak oil or sealant.

- Upholstery : For upholstery, use a mild soap and water solution or a specialized fabric cleaner.

It’s always a good idea to check the manufacturer’s recommendations and test a cleaning solution in an inconspicuous area before using it on the entire boat. Additionally, always use a soft-bristled brush and rinse thoroughly with clean water to prevent streaks or damage to the boat’s surface.

What Is Good For Cleaning Your Vessel That Does Not Harm Lakes Or Rivers

When cleaning your vessel, it’s important to use cleaning products that are environmentally friendly and won’t harm lakes or rivers. Some of the best cleaning products for cleaning your vessel that are eco-friendly and safe for the environment include:

- Biodegradable Soap : Biodegradable soap is a gentle cleaning solution that can be used on all types of boats. It is made from natural ingredients that break down quickly in the environment and won’t harm aquatic life or vegetation.

- Baking Soda : Baking soda can be used as a gentle abrasive cleaner for removing dirt, grime, and stains from the boat’s surface. Simply mix with water to create a paste, and use a soft brush to scrub the surface.

- White Vinegar : White vinegar is a natural, eco-friendly cleaning solution that can be used to clean and deodorize various parts of the boat. Mix with water to create a solution and use a cloth or spray bottle to clean.

- Lemon Juice : Lemon juice is a natural degreaser and can be used to clean grease and oil from the boat’s surface. Simply mix with water and use a cloth to clean.

- Castile Soap : Castile soap is a natural, plant-based soap that can be used for cleaning various parts of the boat. It is gentle and biodegradable, making it a safe and environmentally friendly option.

Remember to always rinse the boat thoroughly with clean water after cleaning to prevent any residual cleaning products from entering the water. Additionally, avoid using cleaning products that contain harsh chemicals, such as bleach or ammonia, as these can harm aquatic life and the ecosystem.

Household Products To Clean Boat

There are many household products that can be used to clean a boat, including:

- White Vinegar : White vinegar is a natural cleaning solution that can be used to clean and deodorize various parts of the boat. Mix with water to create a solution and use a cloth or spray bottle to clean.

- Olive Oil : Olive oil can be used to clean and protect the boat’s exterior, especially if it has a gelcoat finish. Simply apply a small amount of oil to a cloth and use it to polish the surface.

- Cornstarch : Cornstarch can be used to clean and polish fiberglass surfaces. Simply mix with water to create a paste and use a soft brush to scrub the surface.

Remember to always rinse the boat thoroughly with clean water after cleaning to prevent any residual cleaning products from entering the water. Additionally, always test a cleaning solution in an inconspicuous area before using it on the entire boat to avoid any damage or discoloration.

How To Clean A Fiberglass Boat

Cleaning a fiberglass boat requires a gentle approach to avoid damaging the surface. Here is a step-by-step guide on how to clean a fiberglass boat:

- Rinse the Boat : Rinse the boat with a hose or pressure washer to remove any loose dirt or debris. This will help prevent scratches when you wash the boat.

- Mix Cleaning Solution : Mix a cleaning solution using a mild soap and water or a specialized fiberglass cleaner. Avoid using harsh chemicals, such as bleach or ammonia, as they can damage the surface of the fiberglass.

- Apply Cleaning Solution : Apply the cleaning solution to the boat using a soft-bristled brush or sponge. Start from the top and work your way down, paying extra attention to areas with heavy dirt or grime.

- Scrub the Surface : Gently scrub the surface of the boat, working in small sections. Be sure to rinse the brush or sponge frequently to prevent the spread of dirt and grime.

- Rinse the Boat : Rinse the boat thoroughly with clean water to remove all the cleaning solution and dirt. Use a hose or pressure washer for best results.

- Dry the Boat : Allow the boat to air dry or use a clean, dry cloth to remove any water droplets. Avoid using towels or sponges that can leave lint or scratch the surface.

It’s always a good idea to check the manufacturer’s recommendations and test a cleaning solution in an inconspicuous area before using it on the entire boat. Additionally, it’s important to clean your boat regularly to keep it in good condition and prevent damage from build-up of dirt and grime.

Boat Cleaning Hacks

Here are some useful boat cleaning hacks to make the process easier and more efficient:

- Use a Pressure Washer : A pressure washer is a powerful tool that can quickly remove dirt and grime from the boat’s surface. Just be sure to use a low-pressure setting to avoid damaging the fiberglass.

- Duct Tape for Stains : Duct tape can be used to remove stubborn stains from the boat’s surface. Simply wrap the tape around your fingers, sticky side out, and gently rub the stain. Repeat as necessary until the stain is removed.

- Aluminum Foil for Chrome : Aluminum foil can be used to clean chrome parts on the boat. Simply crumple a piece of foil into a ball and use it to scrub the surface. The foil will remove rust and tarnish, leaving the chrome looking shiny and new.

- WD-40 for Rust : WD-40 is a multi-purpose lubricant that can also be used to remove rust from metal parts on the boat. Simply spray the rust with WD-40, let it sit for a few minutes, and then scrub with a wire brush. Repeat as necessary until the rust is removed.

- Use a Car Wax : Car wax can be used to protect the boat’s surface and keep it looking shiny. Simply apply the wax according to the manufacturer’s instructions, and buff with a clean, dry cloth.

These hacks can help make cleaning your boat easier and more efficient. However, it’s still important to use the proper cleaning solutions and techniques to avoid damaging the boat’s surface. And always follow the manufacturer’s recommendations for cleaning and maintenance.

What can I use to clean my sailboat?

To clean your sailboat, you can use a combination of cleaning solutions and tools, such as:

- Mild soap and water : A mixture of mild soap and water is a safe and effective cleaning solution for removing dirt and grime from the boat’s surface.

- Specialized boat cleaner : There are many specialized boat cleaners available that are designed for specific cleaning tasks, such as removing bird droppings, algae, or tough stains.

- White vinegar : White vinegar is a natural cleaning solution that can be used to clean and deodorize various parts of the boat. Simply mix with water to create a solution and use a cloth or spray bottle to clean.

- Lemon juice : Lemon juice is a natural degreaser and can be used to clean grease and oil from the boat’s surface. Simply mix with water and use a cloth to clean.

- Soft-bristled brush : A soft-bristled brush can be used to scrub the boat’s surface without causing damage. Use it to apply the cleaning solution and remove dirt and grime.

- Microfiber cloths : Microfiber cloths are gentle on the boat’s surface and absorb dirt and grime effectively. Use them to clean and dry the boat after rinsing.

- Hose or pressure washer : A hose or pressure washer can be used to rinse the boat thoroughly and remove any remaining cleaning solution or dirt.

It’s important to follow the manufacturer’s recommendations for cleaning and maintenance, and always test a cleaning solution in an inconspicuous area before using it on the entire boat to avoid any damage or discoloration.

How do I clean my sailboat sails at home?

Here are the steps for cleaning your sailboat sails at home:

- Remove the sails from the boat : Before cleaning the sails, remove them from the boat and lay them flat on a clean surface.

- Brush off dirt and debris: Use a soft-bristled brush to remove any dirt and debris from the sails.

- Mix a cleaning solution : Mix a cleaning solution using mild soap and water, or use a specialized sail cleaner.

- Apply the cleaning solution : Using a soft-bristled brush or a spray bottle, apply the cleaning solution to the sails. Scrub the sails thoroughly, paying special attention to any stained or discolored areas.

- Rinse the sails : Rinse the sails thoroughly with a hose or pressure washer to remove any remaining cleaning solution or dirt.

- Dry the sails : Lay the sails flat in a well-ventilated area to air dry. Avoid drying them in direct sunlight, as this can cause the sails to shrink or become discolored.

- Store the sails properly : Once the sails are dry, fold them neatly and store them in a dry, protected area.

It’s important to always follow the manufacturer’s recommendations for cleaning and maintaining your sailboat sails, and to avoid using harsh chemicals or abrasive materials that can damage the sails. Regular cleaning and maintenance will help extend the life of your sails and keep them looking and performing their best.

Can I pressure wash my sailboat?

Yes, you can pressure wash your sailboat, but it’s important to use the proper pressure setting to avoid damaging the boat’s surface.

Fiberglass boats are typically pressure washed using a low-pressure setting of around 1,000-1,500 psi. This will remove dirt and grime without causing damage to the gelcoat. If you’re unsure about the pressure setting to use, consult the boat’s manufacturer or a professional boat cleaner for guidance.

It’s also important to avoid aiming the pressure washer directly at any delicate or sensitive areas, such as seals, electrical components, or fittings. And, always be sure to wear eye protection and avoid using a pressure washer near anyone else.