Home > Resources > Halyards, Sheets, and Lines: A Guide to Choosing and Maintaining Your Sailboat Rigging

Halyards, Sheets, and Lines: A Guide to Choosing and Maintaining Your Sailboat Rigging

11 May 2023

Ask Precision Sails , Hardware , Maintenance , Technical

How to Choose the Right Halyard/Sheet

When choosing a halyard for your sailboat, several factors come into play. These include the weight of the sail, the type of sail, the sailboat’s size, and the expected wind conditions. You should also consider the halyard’s stretch, which affects sail shape and performance. It is essential to choose a halyard that matches the load the sail will have on the line. Low-stretch halyards are ideal for racing and performance sailing, where every fraction of a knot counts.

Some Things to Consider when Choosing a Halyard or Sheet Include:

- Material: The material you choose for your line can affect its strength, durability, and stretch resistance.

- Diameter: The diameter of your halyard or sheet should be appropriate for the load the sail will apply to it and the size of your boat.

- Length: The length of your halyard or sheet should allow you to run your lines wherever they are needed, plus some extra for you to trim and tie off with.

- Attachment: The type of attachment you choose for your halyard or sheet can change depending on how you run your sheets and how the head of your sail is configured.

- Review Your Options: Making a decision about lines can be daunting, luckily Precision Sails has made it easy for you to pick your halyard or sheets by simplifying the process into two groups and pre-selecting the diameter, length, and attachment for your boat and line.

Here is a Quick Guide to Explain Material Choice:

The Precision Cruising series employs high-quality polyester lines, which are a good all-around option for starting and performing well. Polyester halyards and sheets are the most common and suitable for most sizes of sailboats, but they do stretch more than other lines like dyneema, spectra, or stirotex, which can affect sail shape and performance.

To address this, the Precision Performance series focuses on using stronger and stretch-resistant inner cores, making them ideal for racing sailboats that require high precision and tight tolerances. These lines are made of stirotex, which you may recognize by the name of spectra or dyneema. Stirotex is a chemically identical variation. The parent compound in these high-tension lines is HMPE. These lines are the strongest and least stretchy, making them the top choice for high-performance racing sailboats.

How to Maintain Your Halyards, Sheets, and Lines

Proper maintenance of your halyards is crucial for their longevity and reliability. Some tips for maintaining your halyards include:

Maintenance Checklist

- Regular inspection: Check your lines regularly for signs of wear, fraying, or damage.

- Cleaning: Clean your halyards and sheets periodically with soap and water to remove dirt and salt buildup.

- Lubrication: Lubricate your halyards and sheets with a silicone spray or dry lubricant to reduce friction and wear.

- Storage: When not in use, store your lines coiled neatly and out of direct sunlight if you can.

Signs of Wear – How to Inspect Your Lines

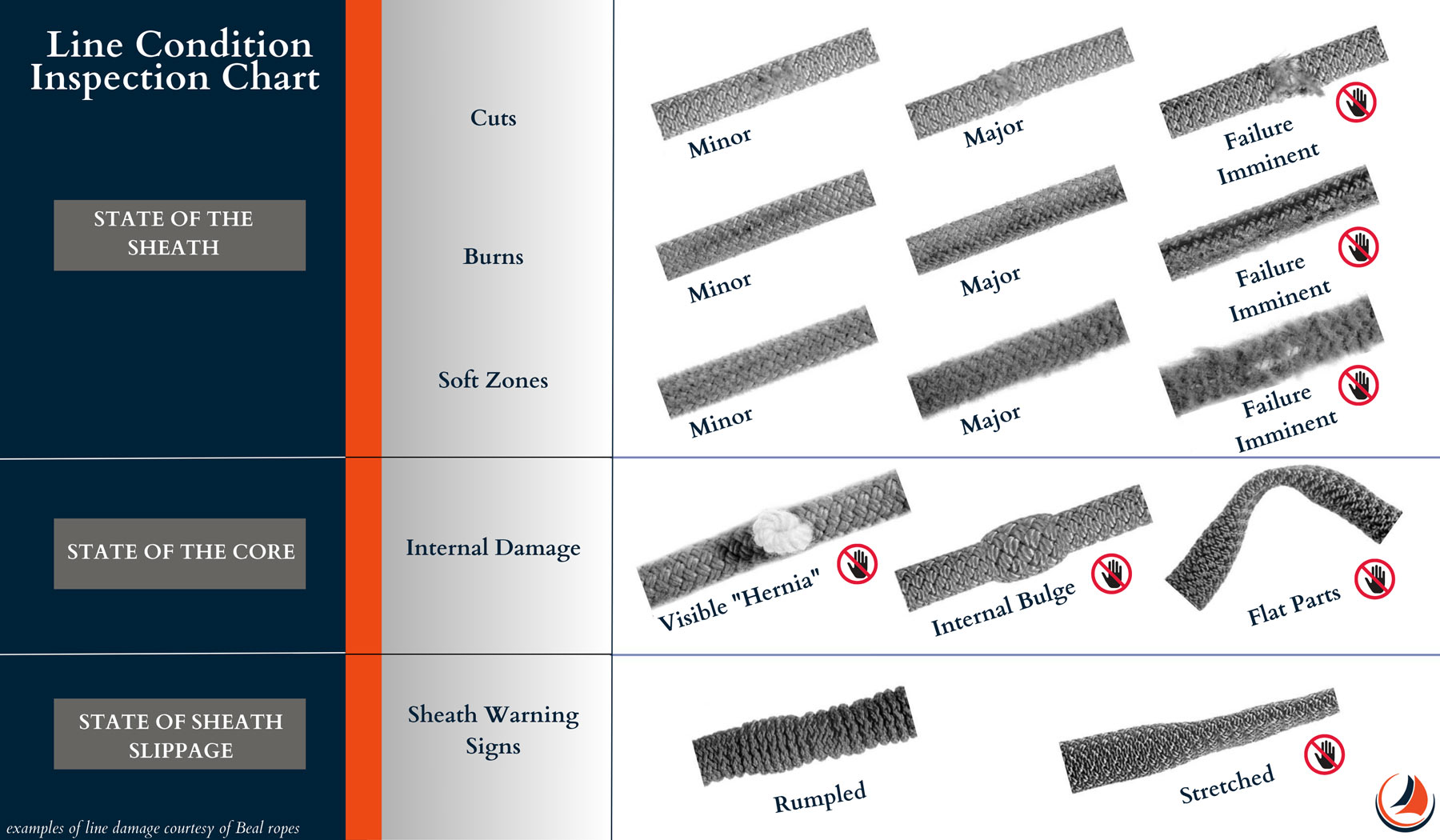

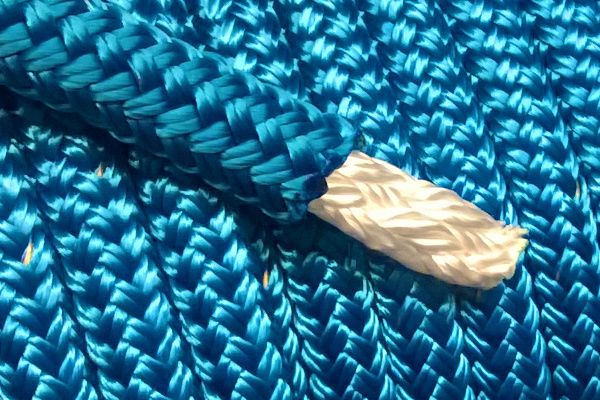

Lines that show obvious signs of deterioration must be discarded and replaced immediately. One of the most apparent and hazardous signs of wear on a line is a cut or damaged sheath that exposes the core. In such cases, it is important to retire the line immediately to prevent any further damage or potential failures.

Other signs may include hardness around the sheath or fuzziness. These signs may be particularly evident near the connection points or any areas of high friction. It’s also important to pay attention to any changes in the handling or feel of the line, as this may indicate internal damage or other issues that require attention.

A way to protect your investment is proper care and cleaning and avoiding the use of harsh chemicals or high-pressure washers, which can damage the fibers. This can be done by soaking them in a bucket of warm water with mild soap or detergent, then rinsing thoroughly and allowing them to air dry. This helps to remove any salt, dirt, or grime that may have accumulated, which can cause premature wear and tear if left unchecked.

A way to visualize this is to envision dirt particles getting trapped between the fibers of the line and causing small tears in the weave. When the line is put under tension, these dirt particles act like miniature saw blades, gradually weakening the line over time and potentially leading to catastrophic failures. Therefore, regular cleaning and maintenance of your lines, including halyards and sheets, is essential to ensure their longevity and reliability and to avoid any dangerous situations while out on the water.

Inspecting Your Lines for Damage

Pro tip: Usage level and proper care is a more important indicator than age

Let’s dispel some common misconceptions about when to retire a sailboat line. For example, some sailors may retire a line based solely on its age, rather than its condition. We want to stress the importance of inspecting lines regularly and retiring them when signs of wear or damage are detected, regardless of their age. Here’s a helpful checklist so you know what to look for on your lines.

Inspection Checklist

- Check for visual signs of wear and tear, such as fraying or abrasions, which can weaken the line and compromise its strength. Be sure to examine the line thoroughly, paying particular attention to any areas of high friction or wear.

- Run your hands along the length of the line, feeling for any hard or soft spots, which can indicate internal damage or wear. If you detect any abnormalities, consider retiring the line or seeking professional advice.

- Look for any signs of UV damage, which can cause the line to degrade over time. This is particularly important for lines that are exposed to sunlight for extended periods.

- Check the diameter of the line, ensuring that it matches the manufacturer’s specifications. Any significant deviations may indicate that the line has been stretched or otherwise damaged.

- Examine the connection points, including splices and knots, ensuring that they are secure and free from any signs of wear or damage.

To recap, lines, halyards, and sheets are an essential component of any sailing vessel, and choosing the right halyard for your boat is a necessary part of outfitting your vessel. Regular maintenance and proper care of your halyards can ensure their longevity and reliability. We hope this article has provided valuable insights into halyards, sheets, and lines, though we understand that it may seem like a lot of information.

If you feel overwhelmed by the amount of information, don’t worry, we have simplified the process of finding the right line for your boat. Simply fill out a form , and we will send you the best fit and our professional opinion based on the type of sailing you plan on doing. If you have any questions, comments, or wish to order lines from our sail consultants, please don’t hesitate to contact us.

FAQ’s

Q: What is a sailboat halyard?

A: Halyards are ropes or lines used to hoist sails, flags, and other equipment on a boat.

Q: What is a sailboat sheet?

A: A sailboat sheet is a line that is attached to the lower corner of a sail and used to control its position relative to the wind. The sheet is usually led through a block or a series of blocks, which allow the sailor to adjust the sail’s angle and trim it for maximum efficiency. In addition to controlling the sail’s position, the sheet also helps to control the sail’s shape and tension, which can affect the boat’s speed and handling.

Q: Can different types of materials be used to make halyards, sheets, and lines?

A: Yes, lines can be made of various materials such as polyester, nylon, stirotex, and dyneema. Each material has its own strengths and weaknesses, and the choice of material depends on the type of sailing and personal preference.

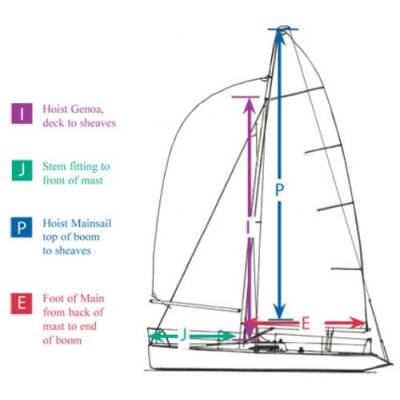

Q: How do I determine the length of halyard I need for my sailboat?

A: It’s important to consult with a sail consultant or experienced sailor to ensure you get the correct length. The length of halyard you need will depend on the height of your mast, the type and size of the sail you will be using, and where you plan on trimming your sails. Calculating the length is more complex than simply taking a guess, not to worry though, we have made it easy. Give us a call or fill out our form to let our system crunch the numbers for you.

Q: How do I know if my halyard or sheets are due for replacement?

A: Look for signs of wear and tear such as fraying, kinking, or stretching. If the line feels stiff or brittle, it may be time to replace it. Additionally, if you notice any damage to the sheave or winch, this may also indicate the need for a replacement. See the checklist above for detailed instructions.

Q: Are there any safety precautions I should take when using halyards and sheets?

A: Yes, it’s important to properly understand how to use a winch and don’t wrap the rope around your arm or fingers. Always be aware of your surroundings and avoid getting entangled in halyards or other lines. It’s also recommended to have a backup halyard in case of failure or emergency situations.

Q: How can halyards affect the performance of a sailboat?

A: The type of halyard used can have an impact on the performance of the sailboat. For instance, a stretchy halyard may cause the sail to lose its shape by releasing the tension on the sail over time, while a stretch-resistant halyard can help the sail maintain its shape in strong winds.

Q: Is it possible to splice or repair a damaged halyard or sheet?

A: It is possible to splice or repair a damaged halyard, depending on the extent of the damage and the material of the halyard. However, it’s essential to have the repair done by a professional or experienced sailor to ensure the halyard’s continued reliability and safety.

Q: How often should I replace my lines?

A: The lifespan of halyards and sheets can vary depending on factors such as usage, exposure to weather, and material. It’s recommended to regularly inspect your lines for wear and tear and replace them as needed. Condition is a much stronger indicator than age. Assuming light use and good condition, some materials like Stirotex have a longer lifespan, other materials may need to be replaced more often. In general, halyards and sheets should be replaced every 3-5 years for optimal safety and efficiency.

Related Posts

Full Battens vs Partial Battens vs 2 Full plus 2 Partial Battens

Full Battens VS Partial Battens At

Precision Sails we are asked every day during our customer quote consultation “Should I choose Full Battens or Partial Battens for my new mainsail?” Whether you are cruising or racing you will need to examine the pros and cons of adding full battens to your main sail.Positive Aspects of Full […]

My Need for Cruising Speed Demands a Great Suit of Sails

My Need for Cruising Speed Demands a Great Suit of SailsI like to sail fast mostly in the heavy winds that Lake Ontario throws.

How to Fold a Sail (Mainsail or Headsail) For safe Storage

Knowing how to fold a sail correctly will make your sails last longer and make them easier to set. Replacement sails are an investment and folding them properly is important to their longevity.

" * " indicates required fields

Currency: GBP

- Worldwide Delivery

Mooring Warps and Mooring Lines

- LIROS 3 Strand Polyester Mooring Warps

- LIROS Braided Dockline Mooring Warps

- LIROS Classic Mooring Warps

- LIROS Green Wave 3 Strand Mooring Warps

- LIROS Handy Elastic Mooring Warps

- LIROS Moorex12 Mooring Warps

- LIROS Octoplait Polyester Mooring Warps

- LIROS Polypropylene Floating Mooring Warps

- LIROS Super Yacht Mooring Polyester Docklines

- Marlow Blue Ocean Dockline

Mooring Accessories

- Mooring Cleats and Fairleads

- Mooring Compensators

- Mooring Shackles

- Mooring Swivels

Mooring Strops

- LIROS 3 Strand Nylon Mooring Strops

- LIROS Anchorplait Nylon Mooring Strops

- Small Boat and RIB Mooring Strops

Mooring Bridles

- V shape Mooring Bridles

- Y shape Mooring Bridles

Mooring Strops with chain centre section

- 3 Strand / Chain / 3 Strand

- Anchorplait / Chain / Anchorplait

Bonomi Mooring Cleats

- Majoni Fenders

- Polyform Norway Fenders

- Dock Fenders

- Fender Ropes and Accessories

- Ocean Inflatable Fenders

Mooring Buoys

Max power bow thrusters.

- Coastline Bow Thruster Accessories

50 metre / 100 metre Rates - Mooring

Mooring information.

- Mooring Warps Size Guide

- Mooring Lines - LIROS Recommended Diameters

- Mooring Rope Selection Guide

- Mooring Warp Length and Configuration Guide

- How to estimate the length of a single line Mooring Strop

- Mooring Ropes - Break Load Chart

- Mooring Compensator Advisory

- Rope Cockling Information

- Fender Size Guide

- Majoni Fender Guide

- Polyform Norway Fender Inflation Guide

Custom Build Instructions

- More Article and Guides >

Anchor Warps Spliced to Chain

- LIROS 3 Strand Nylon Spliced to Chain

- LIROS 3 Strand Polyester Spliced to Chain

- LIROS Anchorplait Nylon Spliced to Chain

- LIROS Octoplait Polyester Spliced to Chain

Anchor Warps

- Leaded Anchor Warp

- LIROS 3 Strand Nylon Anchor Warps

- LIROS 3 Strand Polyester Anchor Warps

- LIROS Anchorplait Nylon Anchor Warps

- LIROS Octoplait Polyester Anchor Warps

- Aluminium Anchors

- Galvanised Anchors

- Stainless Steel Anchors

Calibrated Anchor Chain

- Cromox G6 Stainless Steel Chain

- G4 Calibrated Stainless Steel Anchor Chain

- Lofrans Grade 40

- MF DAMS Grade 70

- MF Grade 40

- Titan Grade 43

Clearance Chain

Anchoring accessories.

- Anchor Connectors

- Anchor Trip Hooks and Rings

- Anchoring Shackles

- Bow Rollers and Fittings

- Chain and Anchor Stoppers

- Chain Links and Markers

50 / 100 metre Rates - Anchoring

Chain snubbers.

- Chain Hooks, Grabs and Grippers

- Chain Snubbing Bridles

- Chain Snubbing Strops

Drogue Warps and Bridles

- Lewmar Windlasses

- Lofrans Windlasses

- Maxwell Windlasses

- Quick Windlasses

Windlass Accessories

- Coastline Windlass Accessories

- Lewmar Windlass Accessories

- Lofrans Windlass Accessories

- Lofrans Windlass Replacement Parts

- Maxwell Windlass Accessories

- Quick Windlass Accessories

Anchoring Information

- How To Choose A Main Anchor

- Anchoring System Assessment

- Anchor Chain and Rope Size Guide

- The Jimmy Green Guide to the Best Anchor Ropes

- What Size Anchor Do I Need?

- Anchor Size Guides

- Anchor Rope Break Load and Chain Compatibility Chart

- How to Choose Your Anchor Chain

- How to Establish the Correct Anchor Chain Calibration?

- Calibrated Anchor Chain - General Information

- Calibrated Anchor Chain Quality Control

- Calibrated Chain - Break Load and Weight Guide

- Galvanising - Managing Performance and Endurance expectation

- Can Galvanised Steel be used with Stainless Steel?

- Windlass Selection Guide

- More Articles and Guides

Stainless Steel Wire Rigging and Wire Rope

- 1x19 Wire Rigging

- 7x19 Flexible Wire Rigging

- Compacted Strand Wire Rigging

- Insulated 1x19 Wire Backstays

Wire Rigging Fittings

- Swaged Terminals

- Swageless Terminals

- Turnbuckles / Rigging screws

- Turnbuckle Components

- Backstay Insulators

- Wire Terminals

Rigging Accessories

- Backing Plates

- Backstay Adjuster and Fittings

- Backstay Blocks

- Pins, Rings and Nuts

- Rigging Chafe Protection

Fibre Rigging

- DynIce Dux Fibre Rigging

- LIROS D-Pro Static Rigging

- LIROS D-Pro-XTR Fibre Rigging

- Marlow Excel D12 MAX 78 Rigging

- Marlow M-Rig Max Rigging

Fibre Rigging Fittings

- Bluewave Rope Terminals

- Colligo Marine Terminals

Dinghy Rigging

- Dinghy Rigging Fittings

- Fibre Dinghy Rigging

- Stainless Steel Dinghy Rigging

Wind Indicators

Guard wires, guardrails and guardrail webbing.

- Guard Rail Fittings

- Guard Rails in Fibre and Webbing

- Guard Wire Accessories

- Guard Wires

Furling Systems

- Anti-torsion Stays

- Headsail Reefing Furlers

- Straight Luff Furlers

- Top Down Furlers

Furling Accessories

- Continuous Furling Line Accessories

- Furling Line Accessories

50 / 100 metre Rates - Wire and Fibre

Standing rigging assistance.

- More Articles and Guides >

- Cruising Halyards

- Performance Halyards

- Dinghy Halyards

Rigging Shackles

- Bronze Snap Shackles

- Captive and Key Pin Shackles

- hamma™ Snap Shackles

- Selden Snap Shackles

- Soft Shackles

- Standard Snap Shackles

- Tylaska End Fittings

- Wichard Snap Shackles

Lashing, Lacing and Lanyards

- LIROS 3 Strand Lashing, Lacing and Lanyards

- LIROS Braided Lashing, Lacing and Lanyards

- Cruising Sheets

- Performance Sheets

- Dinghy Sheets

- Continuous Sheets

- Tapered Sheets

Running Rigging Accessories

- Anti-Chafe Rope Protection

- Barton Sail Handling

- Lazy Jack Sail Handling

- Rodkickers, Boomstruts

- Sail Handling Accessories

- Slab Reefing

Shock Cord and Fittings

Control lines.

- Cruising Control Lines

- Performance Control Lines

- Dinghy Control Lines

- Continuous Control Lines

Classic Ropes

- 50 / 100 metres - Classic

- Classic Control Lines

- Classic Docklines

- Classic Halyards

- Classic Sheets

- LIROS Classic 3 Strand Polyester

50 / 100 metre Rates - Running Rigging

- 50 / 100 metres - Cruising Ropes

- 50 / 100 metres - Dinghy Ropes

- 50 / 100 metres - Lashing and Lanyards

- 50 / 100 metres - Performance Ropes

- LIROS Ropes

- Marlow Ropes

Running Rigging Resources

- Running Rigging Rope Fibres and Construction Explained

- How to Select a Suitable Halyard Rope

- How to select Sheets and Guys

- Dyneema Rope - Cruising and Racing Comparison

- Dinghy Rope Selection Guide

- Rope Measurement Information

- Running Rigging - LIROS Recommended Line Diameters

- Running Rigging Break Load Comparison Chart

- Colour Coding for Running Rigging

- Selecting the right type of block, plain, roller or ball bearing

- Replacing your Furling Line

- Recycling Rope

- Running Rigging Glossary

Custom Build Instructions for Sheets, Halyards, Control Lines

Low friction rings, plain bearing blocks.

- Barton Blocks

- Harken Element Blocks

- Seasure 25mm Blocks

- Selden Yacht Blocks

Wooden Blocks

Ball bearing blocks.

- Barton Ball Bearing Blocks

- Harken Ball Bearing Blocks

- Holt Dynamic Blocks

- Selden Ball Bearing Blocks

Ratchet Blocks

- Harken Ratchet Blocks

- Selden Ratchet Blocks

Roller Bearing Blocks

- Harken Black Magic Blocks

- Selden Roller Bearing Blocks

Clutches and Organisers

- Barton Clutches and Organisers

- Lewmar Clutches

- Spinlock Clutches and Organisers

Genoa Car Systems

- Barton Genoa Sheeting

- Harken Genoa Systems

- Lewmar HTX Genoa Systems

Traveller Systems

- Barton Traveller Systems

- Harken Traveller Systems

Deck Fittings

- Bungs and Hatches

- Bushes and Fairleads

- Deck Eyes, Straps and Hooks

- Pad Eyes, U Bolts and Eye Bolts

Rudder and Transom Fittings

- Pintles and Gudgeons

- Tiller Extensions and Joints

Stanchion Blocks and Fairleads

Snatch blocks.

- Barton K Cam Cleats

- Harken Ball Bearing Cam Cleats

- Holt Cam Cleats

- Selden Cam Cleats

- Spinlock PXR Cleats

Block and Tackle Purchase Systems

- Barton Winches, Snubbers and Winchers

- Coastline Electric Winch Accessories

- Harken Winches, Handles and Accessories

- Karver Winches

- Lewmar Winches, Handles and Accessories

- Winch Servicing and Accessories

Deck Hardware Support

- Blocks and Pulleys Selection Guide

- Barton High Load Eyes

- Dyneema Low Friction Rings Comparison

- Seldén Block Selection Guide

- Barton Track Selection Guide

- Barton Traveller Systems Selection Guide

- Harken Winch Selection Guide

- Karver Winch Comparison Chart

- Lewmar Winch Selection Guide - PDF

- Winch Servicing Guide

Sailing Flags

- Courtesy Flags

- Red Ensigns

- Blue Ensigns

- Flag Accessories

- Flag Staffs and Sockets

- Flag Making and Repair

- Signal Code Flags

- Galvanised Shackles

- Stainless Steel Shackles

- Titanium Shackles

- Webbing only

- Webbing Restraint Straps

- Webbing Sail Ties

- Webbing Soft Shackles

Hatches and Portlights

Sail care and repair.

- Sail Sewing

Maintenance

- Antifouling

- Fillers and Sealants

- Primers and Thinners

- PROtect Tape

Fixings and Fastenings

- Monel Rivets

- Screws, Bolts, Nuts and Washers

- U Bolts, Eye Bolts and Pad Eyes

Splicing Accessories

- Fids and Tools

- Knives and Scissors

General Chandlery

- Barrier Ropes

- Canvas Bags and Accessories

- Carabiners and Hooks

- Netting and Accessories

- Rope Ladders

Seago Boats and Tenders

Chandlery information, flag articles.

- Flag Size Guide

- Bending and Hoisting Methods for Sailing Flags

- Courtesy Flags Identification, Labelling and Stowage

- Courtesy Flag Map

- Flag Etiquette and Information

- Glossary of Flag Terms and Parts of a Flag

- Making and Repairing Flags

- Signal Code Message Definitions

Other Chandlery Articles

- Anchorplait Splicing Instructions

- Antifoul Coverage Information

- Hawk Wind Indicator Selection Guide

- Petersen Stainless - Upset Forging Information

- Speedy Stitcher Sewing Instructions

- Thimble Dimensions and Compatible Shackles

Jackstays and Jacklines

- Webbing Jackstays

- Stainless Steel Wire Jackstay Lifelines

- Fibre Jackstay Lifelines

- Jackstay and Lifeline Accessories

Safety Lines

Lifejackets.

- Children's Life Jackets

- Crewsaver Lifejackets

- Seago Lifejackets

- Spinlock Lifejackets

Buoyancy Aids

Life jackets accessories.

- Lifejacket Lights

- Lifejacket Rearming Kits

- Lifejacket Spray Hoods

Overboard Recovery

- Lifebuoy Accessories

- Purchase Systems

- Slings and Throwlines

Floating Rope

- LIROS Multifilament White Polypropylene

- LIROS Yellow Floating Safety Rope

- Danbuoy Accessories

- Jimmy Green Danbuoys

- Jonbuoy Danbuoys

- Seago Danbuoys

- Liferaft Accessories

- Seago Liferafts

Safety Accessories

- Fire Safety

- Grab Bag Contents

- Grab Bags and Polybottles

- Handheld VHF Radios

- Sea Anchors and Drogues

Safety Resources

- Guard Wires - Inspection and Replacement Guidance

- Guard Wire Stud Terminal Dimensions

- Webbing Jackstays Guidance

- Webbing Jackstays - Custom Build Instructions

- Danbuoy Selection Guide

- Danbuoy Instructions - 3 piece Telescopic - Offshore

- Liferaft Selection Guide

- Liferaft Servicing

- Man Overboard Equipment - World Sailing Compliance

- Marine Safety Information Links

- Safety Marine Equipment List for UK Pleasure Vessels

Sailing Clothing

- Sailing Jackets

- Sailing Trousers

- Thermal Layers

Leisure Wear

- Accessories

- Rain Jackets

- Sweatshirts

Sailing Footwear

- Dinghy Boots and Shoes

- Sailing Wellies

Leisure Footwear

- Walking Shoes

Sailing Accessories

- Sailing Bags and Holdalls

- Sailing Gloves

- Sailing Kneepads

Clothing Clearance

Clothing guide.

- What to wear Sailing

- Helly Hansen Mens Jacket and Pant Size Guide

- Helly Hansen Womens Sailing Jacket and Pant Size Guide

- Lazy Jacks Mens and Womens Size Charts

- Musto Men's and Women's Size Charts

- Old Guys Rule Size Guide

- Sailing Gloves Size Guides

- Weird Fish Clothing Size Charts

The Jimmy Green Clothing Store

Lower Fore St, Beer, East Devon, EX12 3EG

- Adria Bandiere

- Anchor Marine

- Anchor Right

- August Race

- Barton Marine

- Blue Performance

- Brierley Lifting

- Brook International

- Brookes & Adams

- Captain Currey

- Chaineries Limousines

- Coastline Technology

- Colligo Marine

- Cyclops Marine

- Douglas Marine

- Ecoworks Marine

- Exposure OLAS

- Fire Safety Stick

- Fortress Marine Anchors

- Hawk Marine Products

- Helly Hansen

- International

- Jimmy Green Marine

- Maillon Rapide

- Mantus Marine

- Marling Leek

- Meridian Zero

- MF Catenificio

- Ocean Fenders

- Ocean Safety

- Old Guys Rule

- Petersen Stainless

- Polyform Norway

- PSP Marine Tape

- Sidermarine

- Stewart Manufacturing Inc

- Team McLube

- Technical Marine Supplies

- Titan Marine (CMP)

- Ultramarine

- Waterline Design

- William Hackett

Clearance August Race Boat Cleaning Kit £26.00

Clearance LIROS Racer Dyneema £55.08

Clearance Folding Stock Anchor £123.25

Clearance LIROS Herkules £0.00

Clearance Barton Size 0 Ball Bearing Blocks - 5mm £10.13

Clearance Marlow Blue Ocean® Doublebraid £18.48

Mooring Clearance

Anchoring clearance, standing rigging clearance, running rigging clearance, deck hardware clearance, chandlery clearance, safety clearance, sheets and halyards selection guide.

23 Nov 2018

A guide to choosing the right replacement running rigging lines

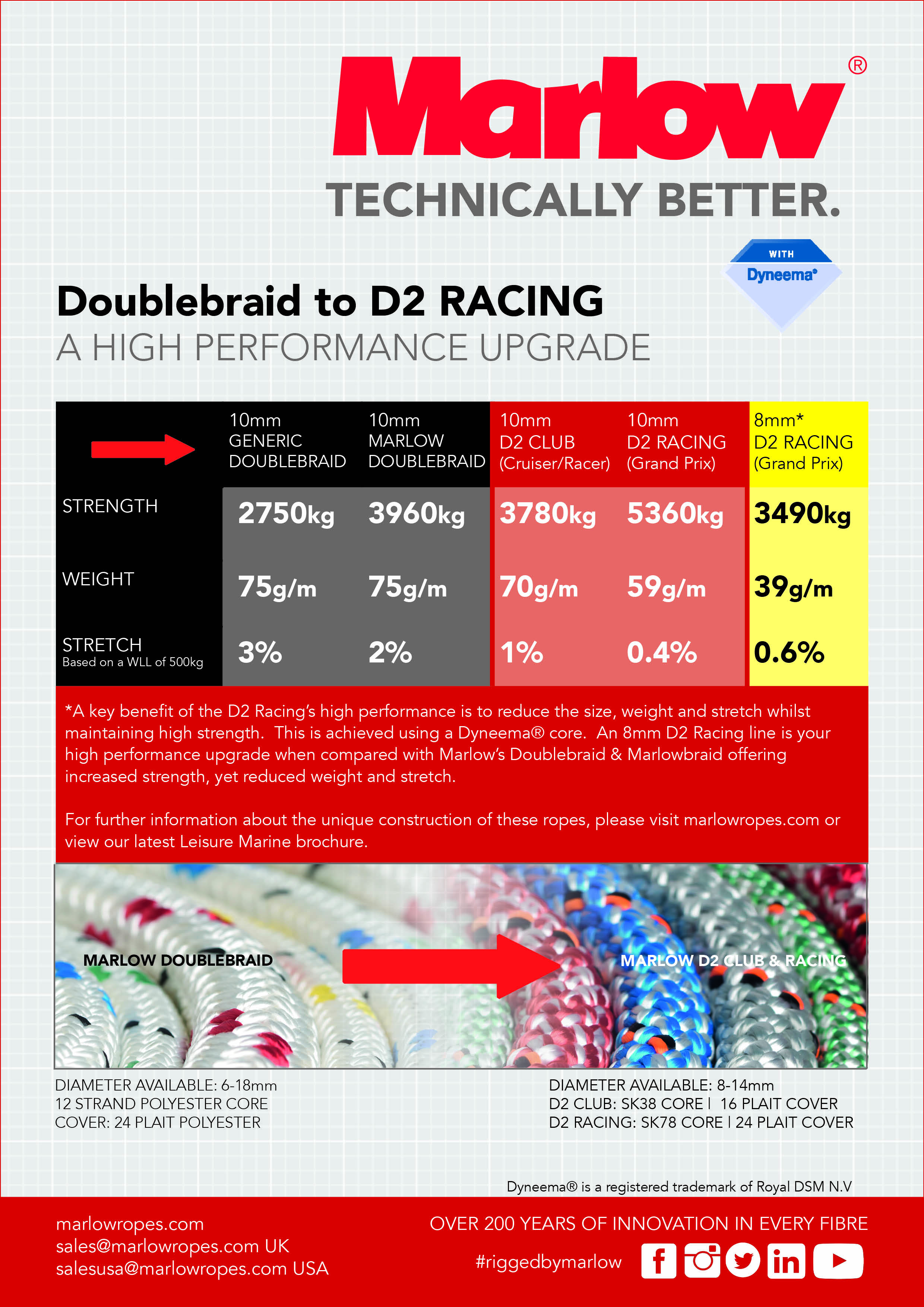

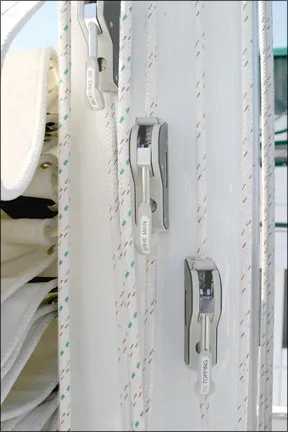

Purchasing replacement lines is often a straightforward process. Especially, if you're happy with the performance of the existing line and can identify what it is. The length can easily be specified by measuring an existing halyard or sheet and can even be guessed fairly accurately, from schematics if you are familiar with your deck layout. The nominal diameter is slightly trickier because different brands use different volumes of fibre to achieve their specifications creating slight variations in comparable ropes. If in doubt, deck hardware is often a good place to check for recommended line diameters.

The difficulty arises when considering an upgrade or you're not entirely sure what you already have on board. At this point, the material to be used, the construction and the diameter of the rope all need to be considered. These factors have a significant influence on the overall cost and performance of your line. This guide aims to help you choose the right line at the right price.

Rope Materials

There are many more fibres available for the truly discerning sailor, however, this article sets out the 5 most common ones found in our product range.

Listed in order from most expensive to most economical, they are Vectran, Dyneema, Technora, Polyester and Polypropylene.

- Vectran is the strongest and most expensive fibre and has very low elongation over time (creep). It is commonly impregnated with a UV stabiliser.

- Dyneema is very nearly equal to Vectran in terms of strength and stretch and is also usually impregnated with a UV protective coating. The price advantage over Vectran makes this a popular choice with rope manufacturers at the upper end of the market.

- Technora has very high abrasion and UV resistance and is commonly blended into the cover/jacket of a braid on braid line.

- Polyester is the most common fibre with excellent UV resistance, good breaking strains and low stretch characteristics. It is available in a bright monofilament fibre and a softer, matt finish, spun yarn. Bright polyester fibres are low stretch e.g. braid on braid bright white polyester. The softer feel, spun yarn has less strength and is slightly stretchier. Spun yarn is typically used for the cover/jacket on e.g. 16 plait matt polyester.

- Polypropylene is the lightest (doesn't absorb water) and cheapest fibre. However, it is stretchy and susceptible to UV.

Rope manufacturers have traditionally used different fibres for the core and the cover, in order to make the most of their relative advantages, but can now produce even better ropes by blending different fibres together, in either the core or the jacket.

Rope Construction

The majority of lines are comprised of a braided core and a braided jacket. The most common cruising lines are 100% polyester (cost effective). The weight of fibre in these lines is usually balanced equally between the cover and the core and can be spliced using the double braid splice.

Marlowbraid is the exception as it has a 3-strand core which slightly reduces stretch for a very modest increase in price. The downside of this construction is that it tends to flatten around sheaves and winches.

N.B. braided lines with a polypropylene core may make a saving but will be reflected in a marked lack of performance particularly with regard to extra stretch where it is not desirable.

The construction of the cover also has a bearing on abrasion resistance. Generally, the covers with a tighter weave or 'more plaits' e.g. 8, 16, 24 or 32 plaits offer a sliding scale of improved wear resistance.

Stronger fibres such as Dyneema or Vectran are required to significantly increase the strength of a line and reduce its stretch. Typically, these fibres are used in the core which is therefore much stronger than the cover. These lines then have to be spliced using the core dependent method which in turn means the weight of fibre in the cover can be reduced.

Cost vs Performance

The cost is directly related to the amount of Dyneema/Vectran content in the finished rope and therefore related to the strength and stretch.

It, therefore, follows that the strongest (and most expensive) line for a given diameter does not have a cover and is 100% 'core'. However, Halyards and sheets still rely on the cover for grip and abrasion resistance in clutches and on winches. The solution is to strip the cover from the core shortly after the winch or clutch. This can only be done with core dependent ropes.

All the fibres mentioned can be blended to produce covers with different properties. Racers may use a polypropylene/Dyneema blend for lightweight sheets or a technora/polyester blend for sheets that get through a lot of work. Cruisers are less likely to have sailing condition specific requirements, so a standard polyester cover heavy enough to give good longevity is usually the best bet.

Choose the right line

The full range of lines supplied by Jimmy Green Marine can cater for both the cruisers and the racers. So we have arranged the lines on a sliding scale to help you decide where to aim. Specifications are based on 12mm lines.

Whether you're a cruiser looking to strengthen up your lines for a more adventurous outing or a racer looking for a better price point Jimmy Green has a line for you.

You can also find further information on the infographic below. The stretch percentages are based on a 500kg working load rather than an ultimate breaking load. This accounts for the difference between the infographic and the table above.

Shop for Sheets and Halyards

Related products

Liros 12mm dynamic plus dyneema - sheets, halyards, control lines, 10mm marlowbraid - sheets, halyards, control lines, 100 metre reel - marlowbraid, liros 14mm herkules - sheets, halyards, control lines, 50 metre cut length - liros classic matt plait polyester, author: jimmy green, you may also like.

Top 5 Sail Control Ropes

Ten tips to help you enjoy winter sailing.

Keyboard_arrow_left guide to tackling a complete re-rig, the decision-making checklist for buying anchor chain keyboard_arrow_right.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Ericson 34-2 Finds Sweet Spot

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Solar Panels: Go Rigid If You have the Space…

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

What Your Boat and the Baltimore Super Container Ship May Have…

Check Your Shorepower System for Hidden Dangers

DIY survey of boat solar and wind turbine systems

What’s Involved in Setting Up a Lithium Battery System?

The Scraper-only Approach to Bottom Paint Removal

Can You Recoat Dyneema?

How to Handle the Head

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Sails, Rigging & Deck Gear

Practical Sailors Guide to Choosing Cost-Efficient Halyard Materials

Practical sailor testers evaluate the many cordage choices available for both furling sail halyards and conventional sail halyards, with a look at the different rope fibers out there and a specific focus on cost vs. line stretch..

Sail performance is directly affected by the type and condition of your halyards. Upgrading your halyards to a low-stretch fiber helps ensure youre getting the sails full power, and it can add life your sails. After testing a sampling of lines from New England Ropes, Novatech Braids, Samson Rope, and Yale Cordage, Practical Sailor found that line stretch decreases significantly as cost increases. And while the very-low- to no-stretch high-tech lines often come with through-the-roof prices, there are low-stretch halyard options available for the budget-minded sailor. This article offers a line cost vs. line stretch analysis and an overview of the fibers available. UV resistance and other factors like abrasion resistance and ease of splicing will be the subject of future tests on these halyard materials.

****

While considerable development continues in the realm of high-tech, high-budget halyards, cruising sailors and club racers face a variety of choices but few new products since our last comprehensive halyard comparison (“For All-Rope Halyards, Its Hard to Beat New England Ropes Sta-Set,” December 1997). One recent addition to the range is VPC, from New England Ropes, which brings the low-stretch, low-creep characteristics of Vectran into an affordable upgrade from polyester double braid. Creep is a fibers taffy-like gradual elongation over time while under a static tensile load, and given how most sailors today are relying on at least one permanently hoisted sail, this factor will likely come into play.

Over the last decade or so, the large production-boat builders have found that more than 80 percent of new-boat buyers are choosing in-mast furling mainsails on boats 30 feet and longer. These boats all have roller-furling headsails, too, so the selection of halyard material is simplified somewhat: The halyards for these sails are rarely handled, so “hand” becomes a less-important quality to consider.

Another attribute, though, becomes more important: durability under load. The working end of the halyard spends its life under tension, bent around a sheave at the masthead. Because the sail remains aloft indefinitely, the halyard is rarely inspected, and must be trusted to perform without supervision throughout a season, or longer, if the boat is sailed year-round. All of these lines, except the Amsteel, have polyester covers, so one can expect similar service lives.

For sailors who have conventional sails and use the halyards on a regular basis, hand remains important. So too does the lines willingness to run free without snagging. And these sailors have plenty of opportunities to inspect the line for wear at its critical points.

Clutch slippage is also a factor. In last years rope clutch test (“ Clutch Play ,” April 2006), we used three of the halyards featured in this comparison. Subjected to 400-pound loads in two of our preferred clutches, the Lewmar D2 (the easiest to bleed) and the Spinlock XAS (the best gripping), Yales Vizzion proved to hold the best (average slippage 3/8-inch), followed by Samson Warpspeed (13/32-inch) and New England Ropes Sta-Set (7/16-inch). We will be looking at all these halyards clutch performance in a future test.

Regardless of sail type or deck gear, one factor always affects the choice of line for any halyard, and that is stretch. When the goal is to get the best performance out of a sail, its halyard should stretch as little as possible when it comes under additional load from a freshening breeze or sailing closer to the wind. When a halyard stretches, it allows the sail fabric to move aft. The draft of the sail moves with it. This results in the driving force rotating aft, creating more heeling moment and more weather helm. The boat is sailing less efficiently than it could, and you may be forced to reef earlier than you otherwise would.

As its fabric pulls aft, a sail on a mast track will scallop between the slides, and horizontal wrinkles will form at the slides. Apart from looking unseamanlike and making life less pleasant aboard, this also puts uneven stress on the sail fabric, which could&emdash;depending on how much sailing you do under these conditions&emdash;shorten its useful life.

So, heres another reason to renew your halyards, and perhaps even upgrade them: to save wear and tear on your sails.

Ironically, a cruising-boat owners budget is often expended on comforts and electronics, while the sails, which one would suppose are the boats reason for existing in the first place, get short shrift. When it finally comes time to specify the halyards and running rigging, the pot is empty. Ultimately, for the sake of a hundred dollars saved on a halyard, the owner never sees the full performance he paid for in his new sail.

For an average boat in the mid-30-foot range, a new mainsail can cost from $2,000 upward, and the premium for a “performance” mainsail over a basic Dacron model starts at about $500. Anyone investing that much would be well advised to hoist it on a halyard that does it justice. For about $100 over the cost of a basic polyester double braid, halyard stretch can be reduced by 75 percent, and the sail will be better able to deliver its promised performance.

By the same token, if you have an aging sail thats rather stretchy along the luff, you could eke another season or two out of it while you save up for a new one by spending a couple of hundred dollars on a less stretchy halyard. The halyard you bought will still be good for the new sail a few years down the road.

Another benefit of a low-stretch halyard is that it reduces effort in the cockpit. Trim-conscious sailors will find they have to make fewer adjustments to the halyard to keep the draft where they want it.

How We Tested

For this article, we looked exclusively at the cost/stretch aspect of new halyards. The Stretch to Cost Table on page 14 shows quite dramatically how great the benefit is for an additional investment that is really quite small, relative to the cost of a new sail. While we specifically looked at a main halyard, the results apply equally to a jib halyard for the same reasons.

For our comparison, to keep the math simple, our hypothetical test boat was somewhere around 35 feet, with a mainsail luff length of 40 feet. Running the halyard back to the cockpit, we assumed 50 feet of line between the winch and the head of the fully hoisted sail. Again for simplicity, we assumed a halyard load of 1,000 pounds, which is a reasonable maximum to expect the mainsail to exert on it&emdash;after that, its time to reef. (Once reefed, stretch resistance becomes even more important on a conventional sail, because the exposed halyard is now longer by the depth of the reef. When a luff-furling sail is reefed, adjusting halyard tension is pointless.)

For each sample of cordage we examined, we took the manufacturer-supplied stretch characteristics and calculated the stretch in inches that would result from our 1,000-pound load acting on the 50-foot standing part of the halyard. To simplify the pricing, we assumed buying 100 feet of line to provide an ample tail in the cockpit and enough extra length to allow “freshening the nip” a few times over the halyards life.

Our baseline rope was double-braid polyester, 7/16-inch in diameter. This kept our assumed 1,000-pound load at no more than 15 percent of the lines average breaking strength. A smaller diameter would probably suffice in the real world, but it would stretch more, precisely the opposite of what were trying to achieve.

The resulting graph of inches of stretch plotted against cost produced a dramatic curve, from which its quite obvious that the first $100 you spend over the basic polyester double-braid halyard buys a significant reduction in stretch. We should note that the values used for stretch are interpolated from data provided by the manufacturers in their literature or on their websites. While they may not be precise, we are confident that they reliably illustrate the argument. We intend to do our own testing on all of these lines, including stretch, to be reported on in a future issue.

The prices used in the graph are the lowest prices we found for each product. While researching these, we were reminded of how important it is to shop around. The price sources we used, and they are by no means exhaustive, appear in the “PS Value Guide Halyards” at left.

Learning the Ropes

The fibers commonly used in the products we studied are polyester, ultra-high-molecular weight polyethyline (UHMPE, sometimes written UHMWPE), para-aramids, and liquid-crystal polyester polyarylate (LCP). Polyolefin (polypropylene) is also used to add bulk to some fiber combinations.

This side of the Atlantic, polyester is usually known by its Dupont trade name, Dacron. It is inexpensive (relatively), has good tensile strength, and resists degradation by UV light, but it has a low Youngs Modulus (meaning, its stretchy). Compared to 7×19 stainless-steel wire, which was commonly used in the past for halyards, its very stretchy.

UHMPE comes under two common brand names, Spectra and Dyneema. Each of these has variants, but thats beyond the scope of this article. UHMPE has high strength and low stretch, which in combination with its generally good resistance to UV makes it well suited to halyards.

Para-aramids include Kevlar, Technora, and Twaron, variations on a molecular theme from different manufacturers. They exhibit similar strength to UHMPE at a lower price, but the trade-off is theyre not totally happy bending, they don’t perform well under abrasion, and they don’t stand up to sunlight as well. In sailing applications, they are usually found protected by a covering of some sort, except when they are the protection&emdash;against the heat generated when highly loaded lines are blown off a winch.

Vectran is the only LCP found in marine rope. It has high strength, low stretch, and better abrasion resistance than the para-aramids. It is far less susceptible to creep that UHMPE, and for that reason, it is useful when under standing loads. It, too, needs protection from UV.

Polyolefin, sometimes listed as MFP, is an inexpensive fiber used to bulk up small volumes of high-tech fibers to increase diameter and improve “hand.” It is basically polypropylene, and used by itself, appears in ski-tow ropes and on life-saving equipment. Its light, and it floats, but it doesn’t stand up to UV light.

Plotting Price vs. Stretch

Plotting cost against stretch using the same 1,000-pound load on a range of ropes produces a very clear picture of what youre buying. (For loads other than our 1,000 pounds, scaling up or down should produce the same relationship between stretch and cost.) You can almost halve the stretch by simply upgrading from 7/16-inch Sta-Set to the same size in Sta-Set X. Going up another level (see rope list) halves the stretch again, even with a reduction to 3/8-inch diameter to reduce cost. As stretch approaches zero, cost goes through the roof, but thats of little consequence even to the serious club racer, because several choices lie within a reasonable price point.

One way to use the graph would be to pick a maximum cost youd be comfortable with and look at the individual plots to the left of that number. Youll find that some of them are higher-tenacity material at smaller diameters. We figured 5/16-inch (8 millimeters) is as small as is comfortable to handle. Depending on your boats current winches, rope clutches, and sheaves, these may not work for you.

We included one single-braid line, Amsteel, simply for comparison. If youre tempted to go that route, you should consult a rigger about covering it so that it can lock properly in stoppers.

UV resistance and other factors like abrasion resistance and ease of splicing will be the subject of future tests on these halyard materials.

Conclusions

When it comes to making your decision, you will have to take into account factors beyond dollars and stretch&emdash;nothings simple. And until we do further testing, any definitive recommendations would be premature. Nonetheless, using the accompanying tables you should be able to find a good halyard that best meets your requirements and budget.

First: What size and type of line do you currently have? If this is original equipment, the entire halyard system may have been designed around it, from the masthead sheaves to the turning blocks at the base of the mast, to the clutch on the cabin top. Before electing to go down a size, or even two, in line diameter, you need to be sure this wont trigger a cascade of modifications necessary to accommodate it.

If you had wire, you will have to change the masthead sheaves to suit any synthetic line (and those sheaves are probably due for replacement anyway). Sheaves grooved for wire will make short work of a synthetic replacement. The higher high-tech lines, such as the 12-strand, single-braid Dyneema or Spectra (Amsteel, for example), work best under high loads in a sheave with a flatter-profile groove. The line flattens, reducing the difference in tension between the inner and outer fibers. Double-braid lines, which are the most suited to cruisers and casual racers anyway, are less fussy.

Going down a size in diameter will help your halyard systems efficiency by reducing internal friction as it turns around the now relatively larger sheaves. Most rope manufacturers specify a sheave-to-line-diameter ratio of 8:1 for optimal performance, but you rarely see this in many production-boat setups.

Going down two sizes, from 7/16-inch to 5/16-inch, will certainly get you into the high-tech material within your budget, but you may not get the stretch savings you hoped for. Also, you may find your stoppers wont accommodate the line.

Check the range of sizes your clutch or stopper will handle. If it will accommodate a size smaller than your present halyard, you can move up to a higher tenacity fiber core for better performance and down in diameter, and still gain the low-stretch advantage.

If you have permanently hoisted sails, you might want to look at a low-creep fiber for the halyards. This usually means a Vectran blend, and therefore more expense, but you wont suffer from gradual loss in luff tension as the season goes by. Because your sail is either all the way up or off the boat, the fall of the halyard, the part that would be hung on the mast or wherever when the sail is up, doesn’t have to be high-tech. A good rigger will be able to combine a single-braid standing part with a cover-only tail, saving both weight aloft and money.

Make sure you make both the tail and standing part long enough to permit freshening the nip a few times. Where the halyard sits on the masthead sheave, it will wear, and it will be exposed to ultraviolet (UV) light. Regular inspection, and cutting off and replacing the splice once in a while should prevent an untimely failure.

All of the lines discussed here can be spliced, but their differing constructions will dictate just what type of splice to use. Splice required is listed in the Value Guide, with additional information available on the manufacturers websites. Most of the suppliers also offer splicing services, and depending on line size and splice complexity, $15 to $30 seems like a bargain when measured against frustration most of us part-time riggers will suffer should we attempt the job ourselves.

- Practical Sailor Halyard Lines Value Guide

- Stretching Dollars

- Splice-Ability

RELATED ARTICLES MORE FROM AUTHOR

So why is the plot of price vs. strech included?

Where are the “accompanying tables” ?

To Karen- The tables are in the Also With this Article links at the bottom. To Darrell- Your pricing guide is really out of date. APS does not exist anymore. Hall Spars does not appear to sell line. DR Marine does not sell Portland Braid. The prices seem way out of date. Novabraid Polyspec was extremely hard to find online which raises concerns about it. I found it from The Chandlery Online for $1.69/ft.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

40-Footer Boat Tours – With Some Big Surprises! | Boat Tour

Electrical Do’s and Don’ts

Bahamas Travel Advisory: Cause for Concern?

Island Packet 370: What You Should Know | Boat Review

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Boat Sailor

Halyard sailing: unlocking the secrets to smooth sailing.

Ahoy there, fellow sailing enthusiasts! Today, I’m excited to dive deep into the world of halyard sailing, a crucial aspect of sailing that often goes overlooked. As someone who has spent countless hours on the water, I can vouch for the significance of a well-maintained halyard system in optimizing your sailing experience. So, hop aboard as we hoist the sails and explore the ins and outs of halyard sailing!

Introduction to Halyard Sailing

As you embark on your sailing journey, understanding the fundamentals of halyards becomes paramount. These seemingly ordinary ropes play a pivotal role in raising and lowering sails, directly impacting your vessel’s performance and safety. But fear not, we’re here to guide you through the enchanting realm of halyard sailing!

Understanding Halyards

What are halyards.

Halyards are ropes or lines used to hoist and lower sails, allowing you to harness the wind’s power and set your course. These ropes are the unsung heroes that transform the still canvas into billowing sails, propelling your boat forward.

Types of Halyards

There are various halyards available, each catering to different sailing needs. From wire halyards to modern synthetic lines, understanding their unique characteristics empowers you to make informed choices.

Materials Used for Halyards

The choice of halyard material can significantly impact its strength, durability, and performance. We’ll explore the pros and cons of different materials, helping you decide what suits your sailing style best.

Importance of Proper Halyard Setup

Safety and Performance

A well-maintained halyard system ensures not only a smooth sailing experience but also enhances your safety on the water. We’ll delve into the relationship between halyards and safety, so you can navigate with confidence.

Avoiding Wear and Tear

Halyards are subject to wear over time due to constant use and exposure to the elements. By understanding how to minimize wear, you can prolong their lifespan and save on replacement costs.

Enhancing Sail Control

Efficient halyard handling allows for precise sail control, empowering you to adapt to changing weather conditions and achieve optimal performance. Let’s unravel the secrets of harnessing the wind’s full potential.

Choosing the Right Halyard for Your Sailboat

Consider the Boat Type

The type of boat you own plays a vital role in determining the appropriate halyard. Whether you’re cruising on a monohull or flying on a catamaran , we’ve got you covered.

Sailing Conditions

Adapting to varying weather conditions demands the right halyard choice. Discover how to match halyards to different wind strengths and sea states, ensuring a pleasurable sail in all circumstances.

Sail Material and Size

The type of sails you use influences the halyard’s requirements. We’ll explore the connection between sail material, size, and halyard selection to optimize your sailboat’s performance.

Maintaining and Inspecting Halyards

Regular cleaning and lubrication.

Proper halyard maintenance involves regular cleaning and lubrication to prevent dirt buildup and maintain smooth operation. Learn the best practices for keeping your halyards in top-notch condition.

Identifying Signs of Wear

Vigilance is key to spotting early signs of halyard wear. We’ll walk you through common indicators, ensuring you catch any issues before they escalate into a larger problem.

Replacing Halyards

When the time comes to bid farewell to your trusty halyards, having a seamless replacement process can get you back on the water swiftly. We’ll provide guidance on when and how to replace aging halyards.

Best Practices for Halyard Handling

Raising and lowering sails.

Mastering the art of raising and lowering sails ensures a safe and efficient sailing experience. Discover techniques to execute these maneuvers effortlessly.

Preventing Tangles and Snags

Tangled halyards can quickly turn a leisurely sail into a frustrating affair. Unravel the mysteries of tangle prevention and maintain a stress-free sailing journey.

Coiling and Storing Halyards

A well-coiled halyard is a sailor’s best friend. Learn how to coil and store halyards properly, preventing tangles and extending their lifespan.

Upgrading Halyard Systems

Modern halyard technologies.

The world of sailing continues to evolve, and halyard technology is no exception. Explore the latest innovations that can take your sailing experience to the next level.

Benefits of Upgrading

Upgrading your halyard system can be a game-changer, but understanding the benefits is crucial before making the investment. We’ll discuss the advantages that come with modernizing your halyards.

Cost-Effectiveness

Is upgrading halyards worth the investment? We’ll weigh the costs against the benefits, helping you make an informed decision based on your sailing needs.

Troubleshooting Halyard Issues

Empower yourself with DIY halyard fixes that can save you time and money. Discover quick and easy solutions to common halyard challenges.

When to Seek Professional Help

While some issues can be tackled on your own, others may require professional expertise. Know when it’s time to call in the experts for halyard-related matters.

Enhancing Performance with Halyard Tuning

Tuning for different conditions.

Adapting your halyard setup to different wind and sea conditions can optimize your boat’s performance. Learn how to fine-tune your halyards for any sailing scenario.

Improving Sail Shape

Halyard tension plays a vital role in achieving the desired sail shape. Unlock the secrets of sail shape optimization for maximum speed and efficiency.

Optimizing Speed and Efficiency

Halyard tuning directly affects your boat’s speed and overall efficiency.

Tips for Halyard Care and Longevity

Protecting halyards from uv damage.

UV rays can take a toll on halyard strength and integrity. Discover how to shield your halyards from the sun’s harmful effects.

Avoiding Overloading

Overloading halyards can lead to premature wear and failure. Learn how to distribute loads properly and ensure your halyards stand the test of time.

Storing Halyards Properly

Proper halyard storage during offseason is crucial for their longevity. We’ll guide you through the best practices for storing halyards when they’re not in use.

Frequently Asked Questions

What’s the lifespan of a typical halyard.

Halyard lifespan can vary depending on several factors, such as material, usage, and maintenance. Generally, a well-maintained halyard can last anywhere from 3 to 10 years. Regular inspections and timely replacements can prolong their lifespan.

Can I use a rope halyard for my large sailboat?

Using a rope halyard for a large sailboat is possible, but it’s crucial to choose the right type of rope and ensure it has adequate strength to handle the loads. Consider the sail’s size, boat type, and sailing conditions before making a decision.

How do I know if my halyards need replacement?

Signs of wear, such as fraying, discoloration, or stiffness, may indicate that it’s time to replace your halyards. Additionally, if you notice reduced performance or difficulty in raising or lowering sails, it’s best to inspect the halyards thoroughly and consider replacement.

Can I use the same halyard for different sails?

While it’s possible to use the same halyard for different sails, it may not always be ideal. Different sails often have unique requirements in terms of tension and halyard length. It’s recommended to have dedicated halyards for each sail to ensure optimal performance.

How often should I inspect my halyards?

Regular inspections are essential to catch any signs of wear or damage early on. It’s advisable to inspect your halyards before and after every sailing season, and also periodically throughout the sailing season, especially after experiencing rough weather conditions.

Michael Thompson

Embarking on a lifelong love affair with the sea, I found solace and exhilaration in the art of sailing. From navigating treacherous waters to harnessing the wind's untamed power, my passion has evolved into a mission to inspire others. Join me on a voyage of discovery as we explore the vast horizons of sailing's timeless allure.

More to Explore

Sailing Apparel: Essential Gear for Smooth Sailing

Sail Boat Trailers: Your Guide to Safe and Convenient Transportation

Sail Boat Decor: Enhancing Your Nautical Oasis

Sailboat Parts Explained: Illustrated Guide (with Diagrams)

When you first get into sailing, there are a lot of sailboat parts to learn. Scouting for a good guide to all the parts, I couldn't find any, so I wrote one myself.

Below, I'll go over each different sailboat part. And I mean each and every one of them. I'll walk you through them one by one, and explain each part's function. I've also made sure to add good illustrations and clear diagrams.

This article is a great reference for beginners and experienced sailors alike. It's a great starting point, but also a great reference manual. Let's kick off with a quick general overview of the different sailboat parts.

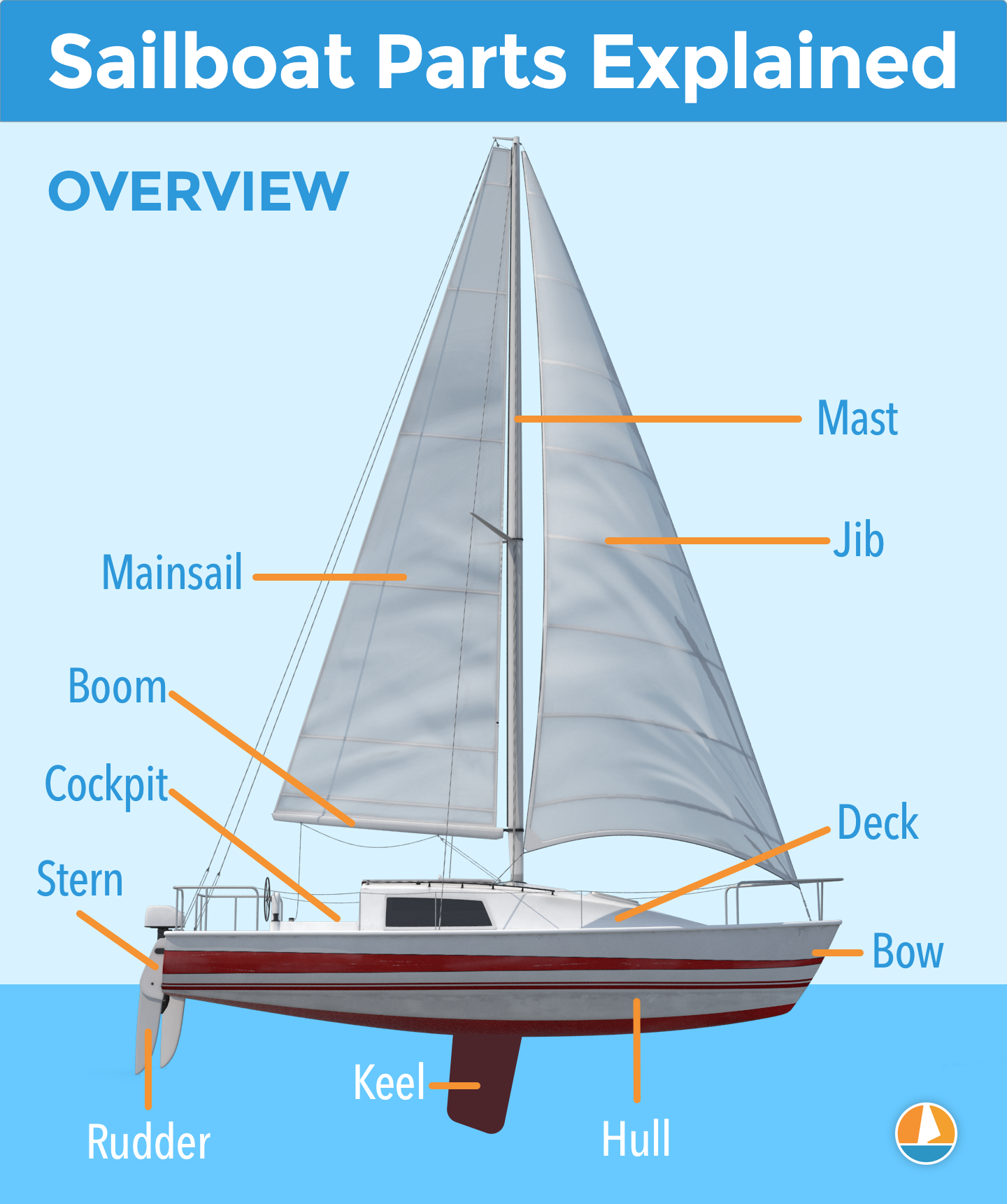

General Overview

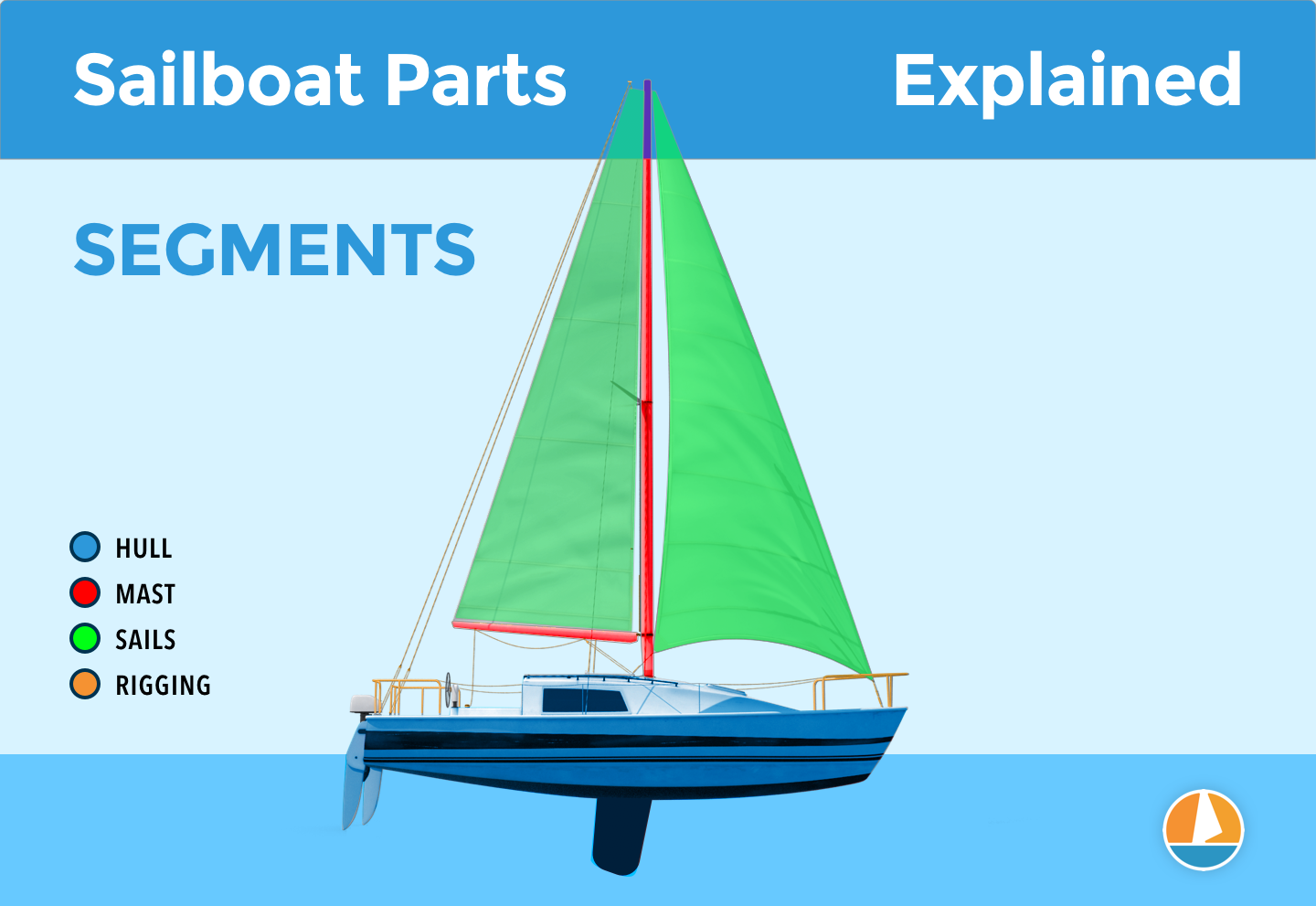

The different segments

You can divide up a sailboat in four general segments. These segments are arbitrary (I made them up) but it will help us to understand the parts more quickly. Some are super straightforward and some have a bit more ninja names.

Something like that. You can see the different segments highlighted in this diagram below:

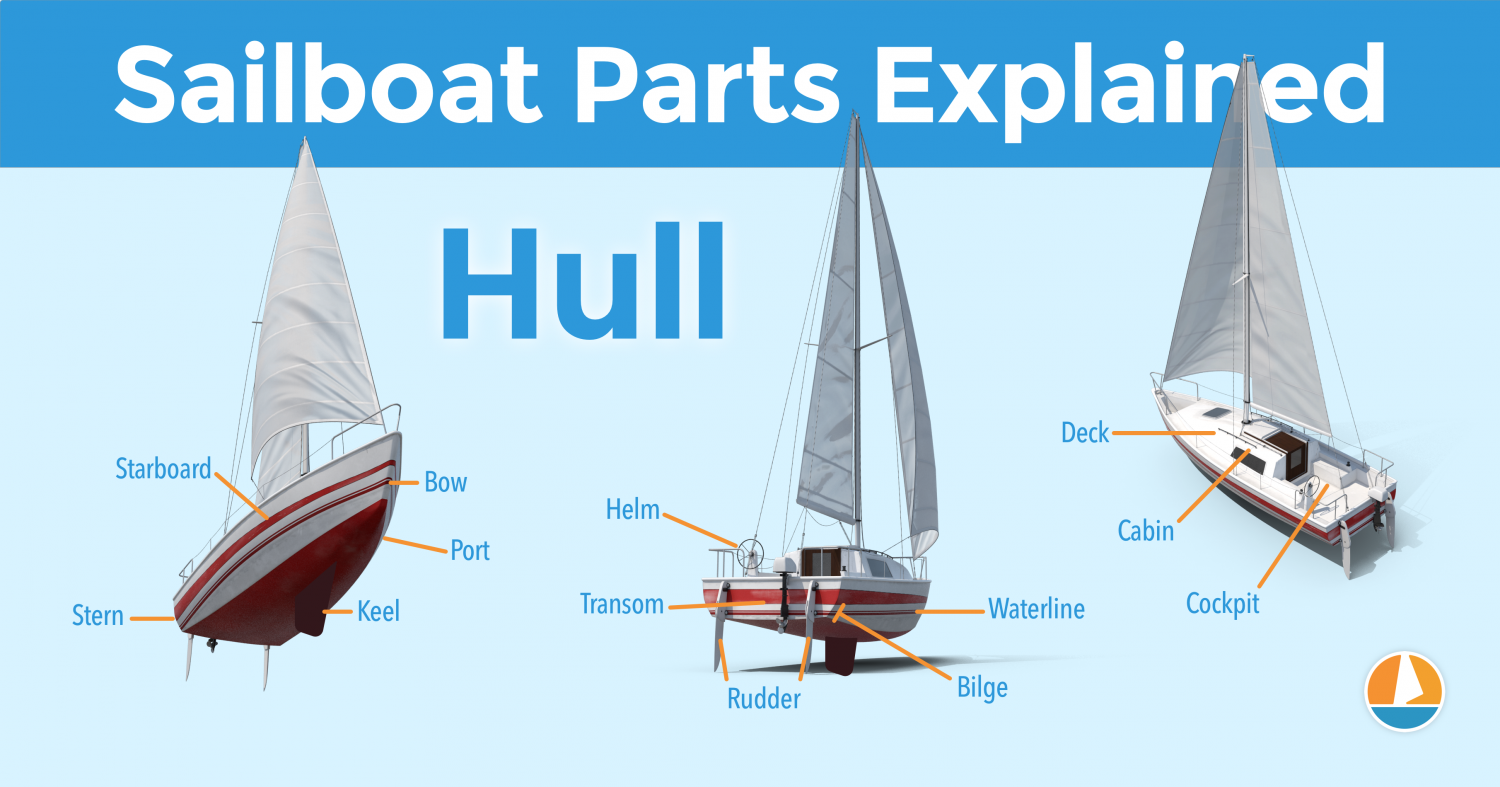

The hull is what most people would consider 'the boat'. It's the part that provides buoyancy and carries everything else: sails, masts, rigging, and so on. Without the hull, there would be no boat. The hull can be divided into different parts: deck, keel, cabin, waterline, bilge, bow, stern, rudder, and many more.

I'll show you those specific parts later on. First, let's move on to the mast.

Sailboats Explained

The mast is the long, standing pole holding the sails. It is typically placed just off-center of a sailboat (a little bit to the front) and gives the sailboat its characteristic shape. The mast is crucial for any sailboat: without a mast, any sailboat would become just a regular boat.

I think this segment speaks mostly for itself. Most modern sailboats you see will have two sails up, but they can carry a variety of other specialty sails. And there are all kinds of sail plans out there, which determine the amount and shape of sails that are used.

The Rigging

This is probably the most complex category of all of them.

Rigging is the means with which the sails are attached to the mast. The rigging consists of all kinds of lines, cables, spars, and hardware. It's the segment with the most different parts.

The most important parts

If you learn anything from this article, here are the most important parts of any sailboat. You will find all of these parts in some shape or form on almost any sailboat.

Okay, we now have a good starting point and a good basic understanding of the different sailboat parts. It's time for the good stuff. We're going to dive into each segment in detail.

Below, I'll go over them one by one, pointing out its different parts on a diagram, listing them with a brief explanation, and showing you examples as well.

After reading this article, you'll recognize every single sailboat part and know them by name. And if you forget one, you're free to look it up in this guide.

On this page:

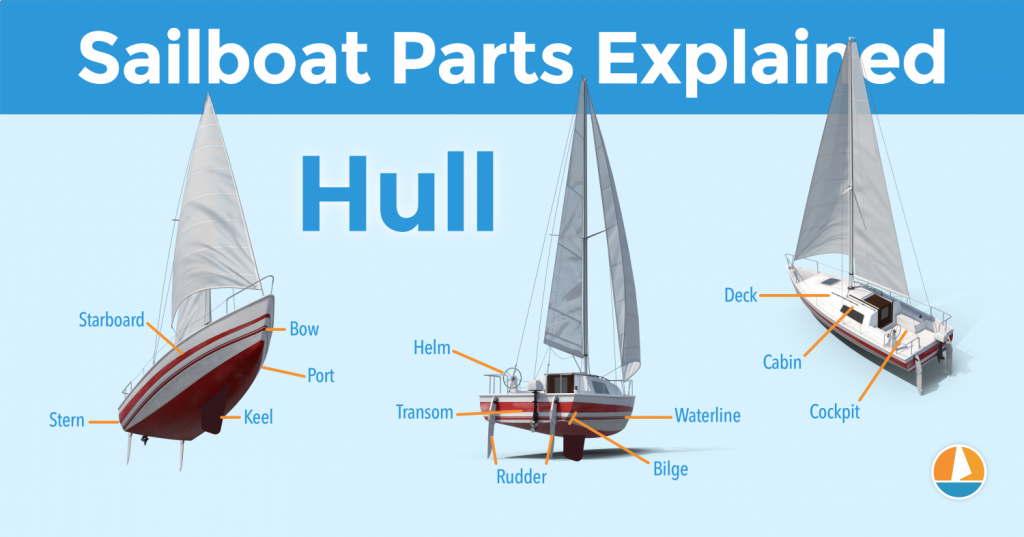

The hull is the heart of the boat. It's what carries everything: the mast, the sails, the rigging, the passengers. The hull is what provides the sailboat with its buoyancy, allowing it to stay afloat.

Sailboats mostly use displacement hulls, which is a shape that displaces water when moving through it. They are generally very round and use buoyancy to support its own weight. These two characteristics make sure it is a smooth ride.

There are different hull shapes that work and handle differently. If you want to learn more about them, here's the Illustrated Guide to Boat Hull Types (with 11 Examples ). But for now, all we need to know is that the hull is the rounded, floating part of any sailboat.

Instead of simply calling the different sides of a hull front, back, left and right , we use different names in sailing. Let's take a look at them.

The bow is the front part of the hull. It's simply the nautical word for 'front'. It's the pointy bit that cuts through the water. The shape of the bow determines partially how the boat handles.

The stern is the back part of the hull. It's simply the nautical word for 'back'. The shape of the stern partially determines the stability and speed of the boat. With motorboats, the stern lies deep inside the water, and the hull is flatter aft. Aft also means back. This allows it to plane, increasing the hull speed. For sailboats, stability is much more important, so the hull is rounded throughout, increasing its buoyancy and hydrodynamic properties.

The transom is the backplate of the boat's hull. It's the most aft (rear) part of the boat.

Port is the left side of a sailboat.

Starboard is the right side of a sailboat

The bilges are the part where the bottom and the sides of the hull meet. On sailboats, these are typically very round, which helps with hydrodynamics. On powerboats, they tend to have an angle.

The waterline is the point where the boat's hull meets the water. Generally, boat owners paint the waterline and use antifouling paint below it, to protect it from marine growth.

The deck is the top part of the boat's hull. In a way, it's the cap of the boat, and it holds the deck hardware and rigging.

Displacement hulls are very round and smooth, which makes them very efficient and comfortable. But it also makes them very easy to capsize: think of a canoe, for example.

The keel is a large fin that offsets the tendency to capsize by providing counterbalance. Typically, the keel carries ballast in the tip, creating a counterweight to the wind's force on the sails.

The rudder is the horizontal plate at the back of the boat that is used to steer by setting a course and maintaining it. It is connected to the helm or tiller.

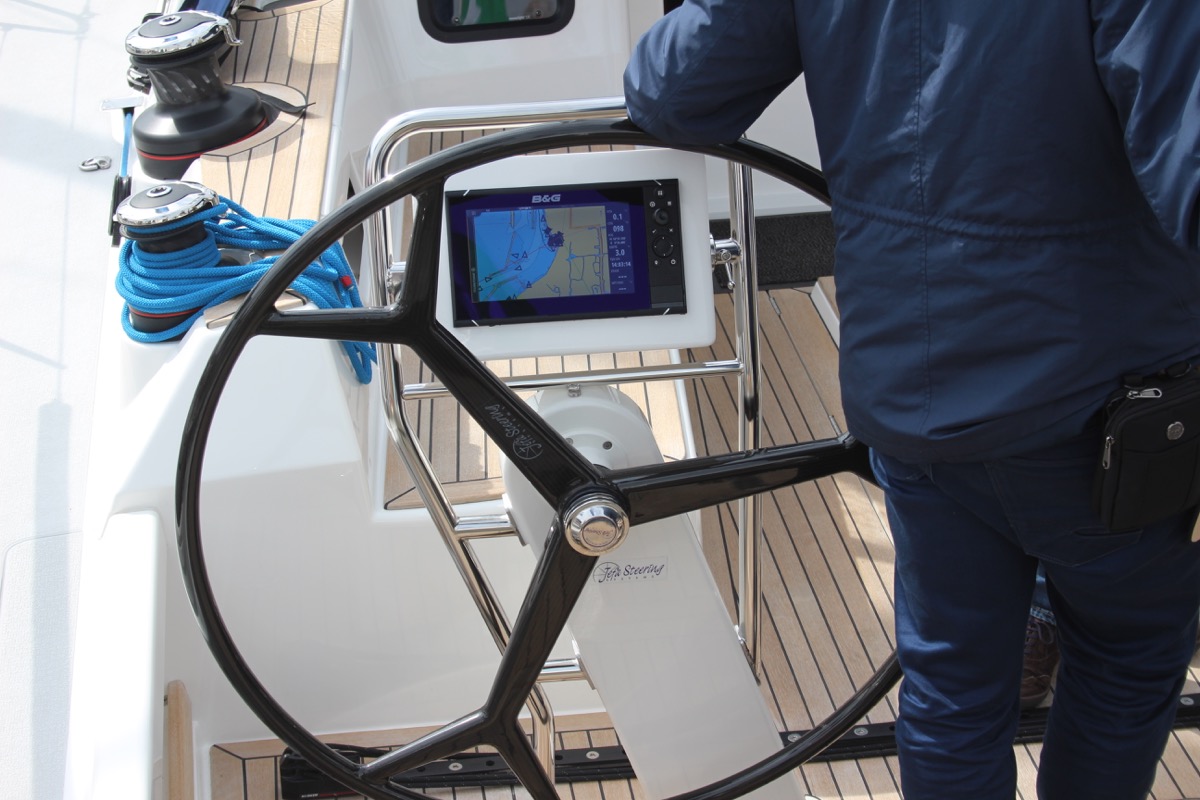

Tiller or Helm

- The helm is simply the nautical term for the wheel.

- The tiller is simply the nautical term for the steering stick.

The tiller or helm is attached to the rudder and is used to steer the boat. Most smaller sailboats (below 30') have a tiller, most larger sailboats use a helm. Large ocean-going vessels tend to have two helms.

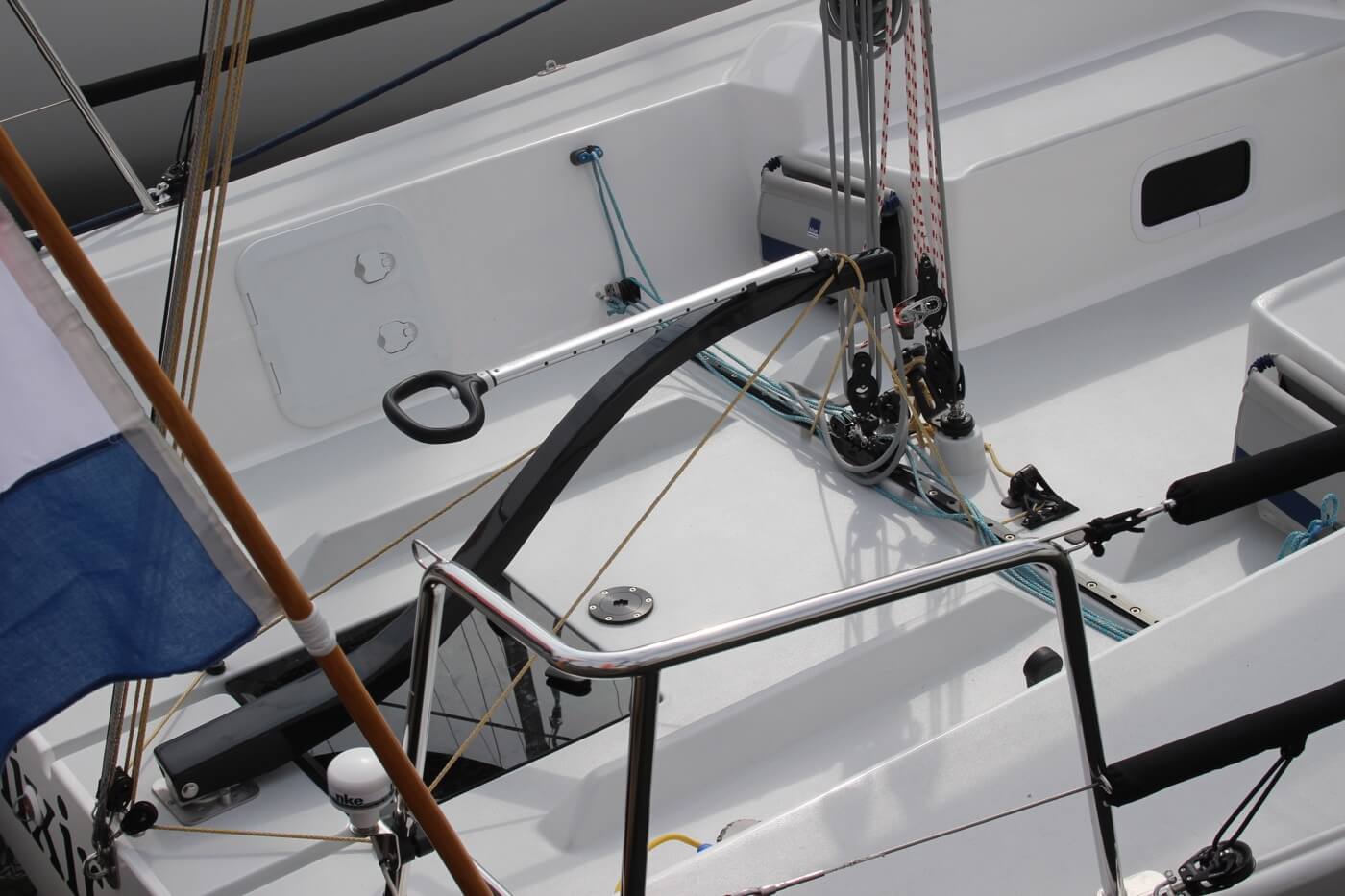

The cockpit is the recessed part in the deck where the helmsman sits or stands. It tends to have some benches. It houses the outside navigation and systems interfaces, like the compass, chartplotter, and so on. It also houses the mainsheet traveler and winches for the jib. Most boats are set up so that the entire vessel can be operated from the cockpit (hence the name). More on those different parts later.

Most larger boats have some sort of roofed part, which is called the cabin. The cabin is used as a shelter, and on cruising sailboats you'll find the galley for cooking, a bed, bath room, and so on.

The mast is the pole on a sailboat that holds the sails. Sailboats can have one or multiple masts, depending on the mast configuration. Most sailboats have only one or two masts. Three masts or more is less common.

The boom is the horizontal pole on the mast, that holds the mainsail in place.

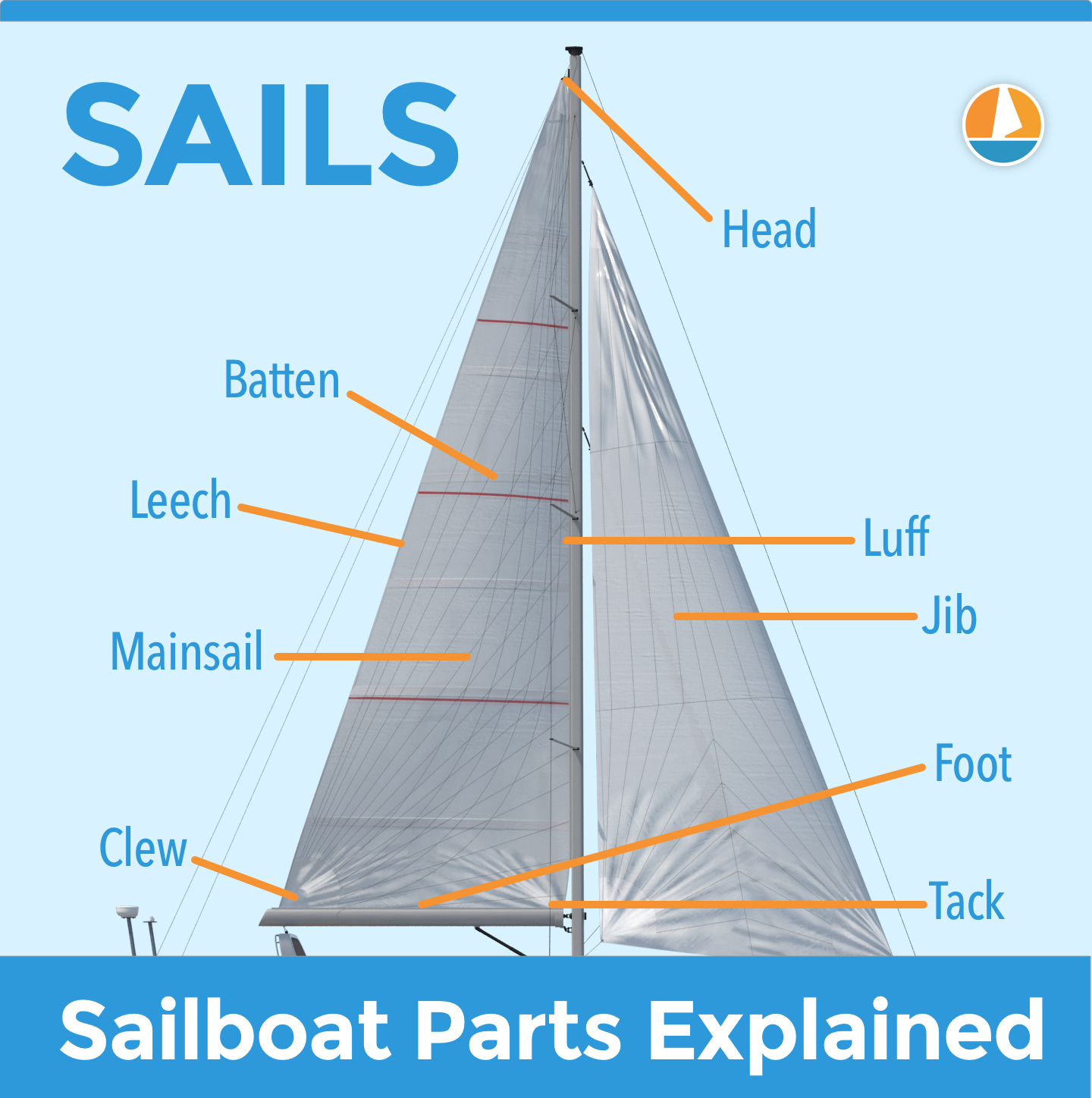

The sails seem simple, but actually consist of many moving parts. The parts I list below work for most modern sailboats - I mean 90% of them. However, there are all sorts of specialty sails that are not included here, to keep things concise.

The mainsail is the largest sail on the largest mast. Most sailboats use a sloop rigging (just one mast with one bermuda mainsail). In that case, the main is easy to recognize. With other rig types, it gets more difficult, since there can be multiple tall masts and large sails.

If you want to take a look at the different sail plans and rig types that are out there, I suggest reading my previous guide on how to recognize any sailboat here (opens in new tab).

Sail sides:

- Leech - Leech is the name for the back side of the sail, running from the top to the bottom.

- Luff - Luff is the name for the front side of the sail, running from the top to the bottom.

- Foot - Foot is the name for the lower side of the sail, where it meets the boom.

Sail corners:

- Clew - The clew is the lower aft (back) corner of the mainsail, where the leech is connected to the foot. The clew is attached to the boom.

- Tack - The tack is the lower front corner of the mainsail

- Head - The head is the top corner of the mainsail

Battens are horizontal sail reinforcers that flatten and stiffen the sail.

Telltales are small strings that show you whether your sail trim is correct. You'll find telltales on both your jib and mainsail.

The jib is the standard sized headsail on a Bermuda Sloop rig (which is the sail plan most modern sailboats use).

As I mentioned: there are all kinds, types, and shapes of sails. For an overview of the most common sail types, check out my Guide on Sail Types here (with photos).

The rigging is what is used to attach your sails and mast to your boat. Rigging, in other words, mostly consists of all kinds of lines. Lines are just another word for ropes. Come to think of it, sailors really find all kinds of ways to complicate the word rope ...

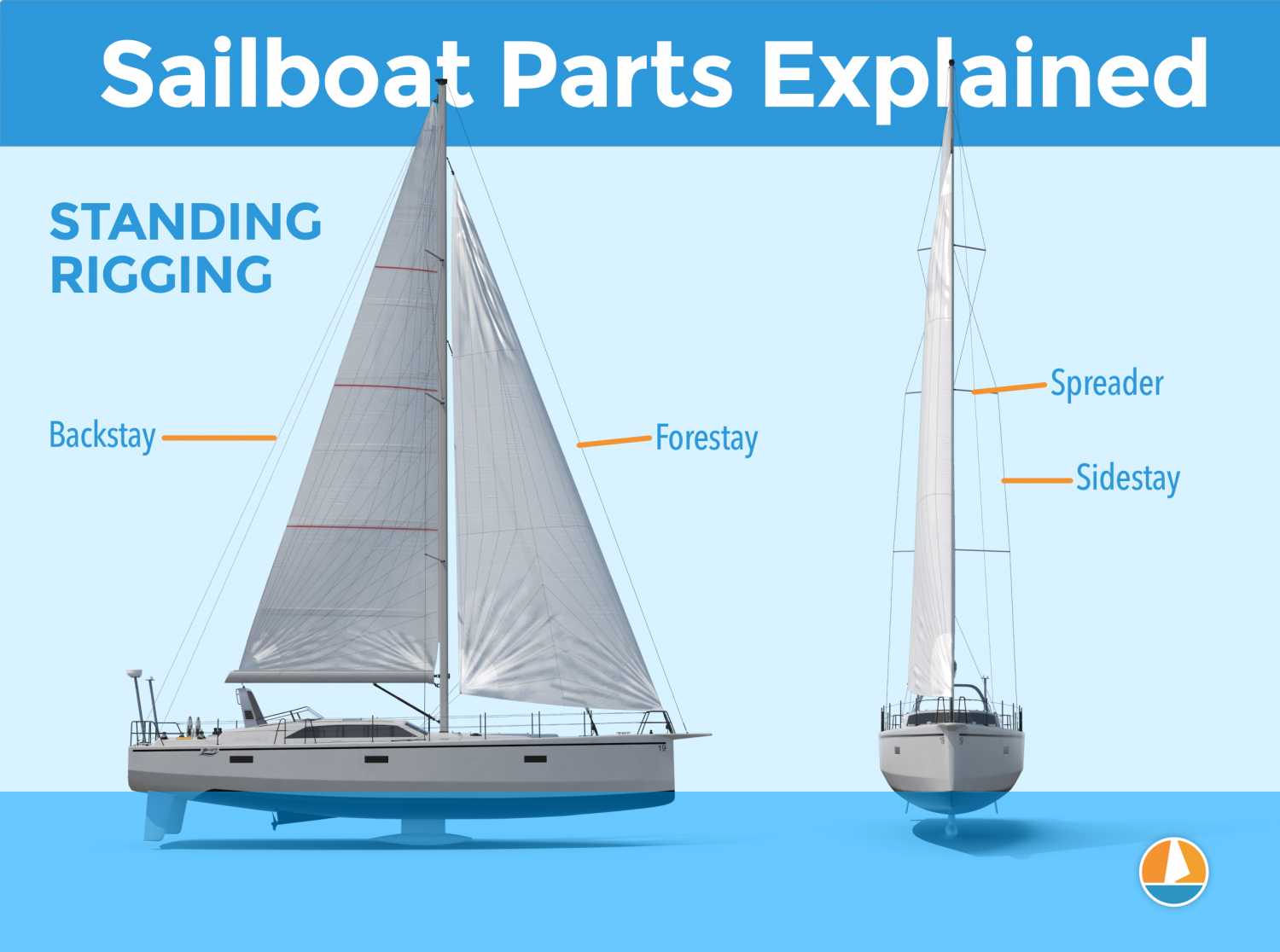

Two types of rigging

There are two types of rigging: running and standing rigging. The difference between the two is very simple.

- The running rigging is the rigging on a sailboat that's used to operate the sails. For example, the halyard, which is used to lower and heave the mainsail.

- The standing rigging is the rigging that is used to support the mast and sail plan.

Standing Rigging

Here are the different parts that belong to the standing rigging:

- Forestay or Headstay - Line or cable that supports the mast and is attached to the bow of the boat. This is often a steel cable.

- Backstay - Line or cable that supports the mast and is attached to the stern of the boat. This is often a steel cable.

- Sidestay or Shroud - Line or cable that supports the mast from the sides of the boat. Most sailboats use at least two sidestays (one on each side).

- Spreader - The sidestays are spaced to steer clear from the mast using spreaders.

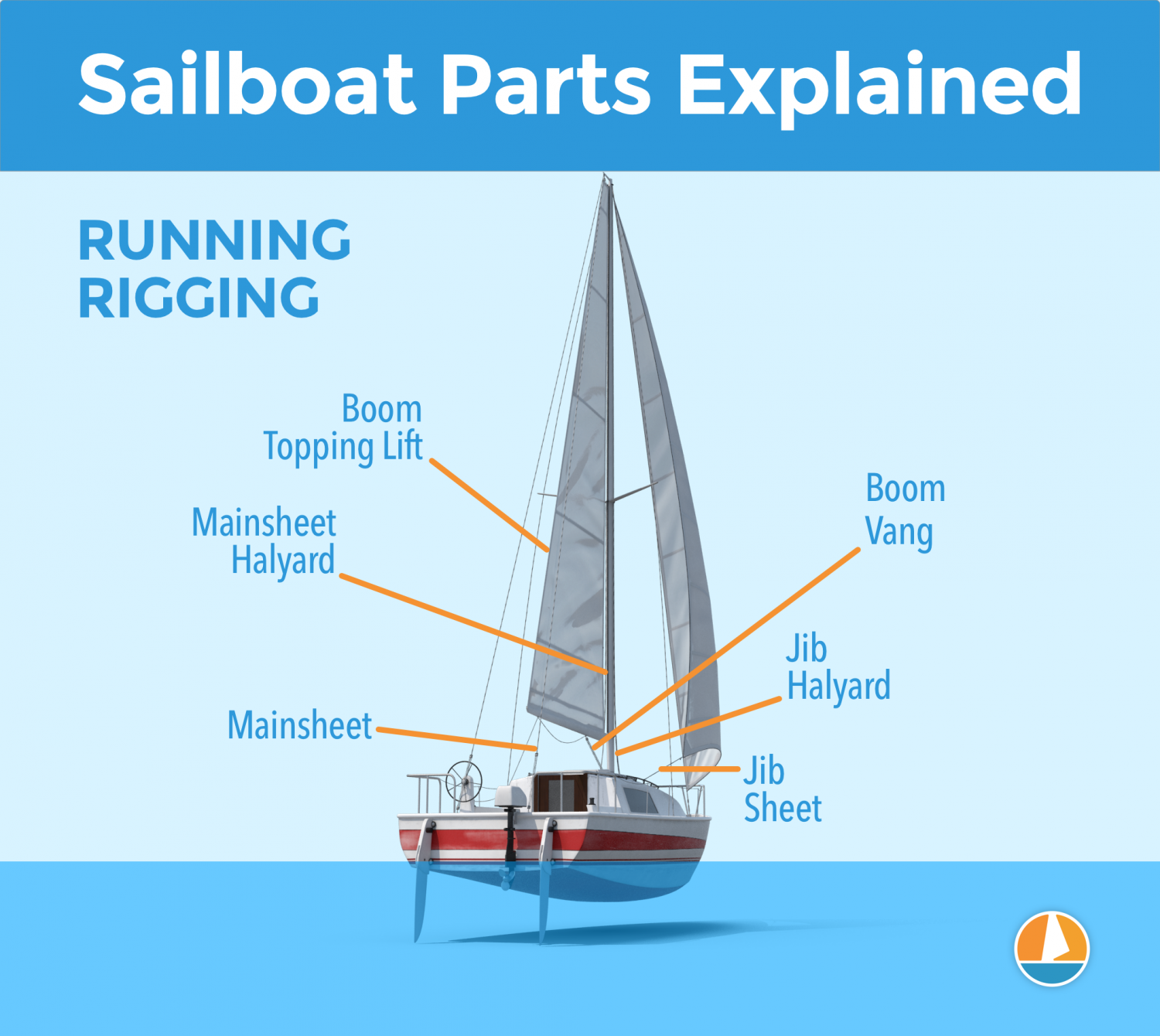

Running Rigging: different words for rope

Ropes play a big part in sailing, and especially in control over the sails. In sailboat jargon, we call ropes 'lines'. But there are some lines with a specific function that have a different name. I think this makes it easier to communicate with your crew: you don't have to define which line you mean. Instead, you simply shout 'mainsheet!'. Yeah, that works.

Running rigging consists of the lines, sheets, and hardware that are used to control, raise, lower, shape and manipulate the sails on a sailboat. Rigging varies for different rig types, but since most sailboats are use a sloop rig, nearly all sailboats use the following running rigging:

- Halyards -'Halyard' is simply the nautical name for lines or ropes that are used to raise and lower the mainsail. The halyard is attached to the top of the mainsail sheet, or the gaffer, which is a top spar that attaches to the mainsail. You'll find halyards on both the mainsail and jib.

- Sheets - 'Sheet' is simply the nautical term for lines or ropes that are used to set the angle of the sail.

- Mainsheet - The line, or sheet, that is used to set the angle of the mainsail. The mainsheet is attached to the Mainsheet traveler. More on that under hardware.

- Jib Sheet - The jib mostly comes with two sheets: one on each side of the mast. This prevents you from having to loosen your sheet, throwing it around the other side of the mast, and tightening it. The jib sheets are often controlled using winches (more on that under hardware).

- Cleats are small on-deck hooks that can be used to tie down sheets and lines after trimming them.

- Reefing lines - Lines that run through the mainsail, used to put a reef in the main.

- The Boom Topping Lift is a line that is attached to the aft (back) end of the boom and runs to the top of the mast. It supports the boom whenever you take down the mainsail.

- The Boom Vang is a line that places downward tension on the boom.

There are some more tensioning lines, but I'll leave them for now. I could probably do an entire guide on the different sheets on a sailboat. Who knows, perhaps I'll write it.

This is a new segment, that I didn't mention before. It's a bit of an odd duck, so I threw all sorts of stuff into this category. But they are just as important as all the other parts. Your hardware consists of cleats, winches, traveler and so on. If you don't know what all of this means, no worries: neither did I. Below, you'll find a complete overview of the different parts.

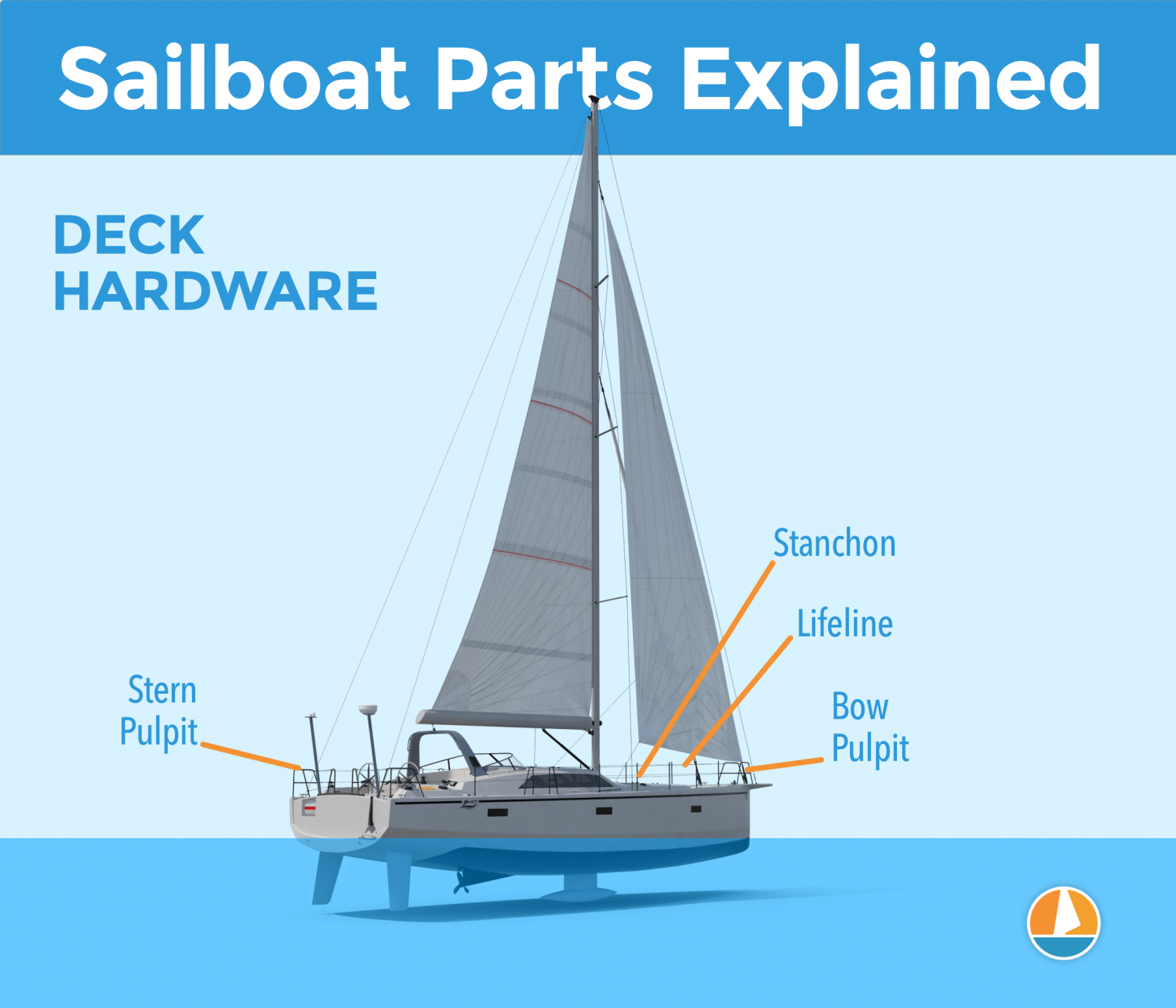

Deck Hardware

Just a brief mention of the different deck hardware parts:

- Pulpits are fenced platforms on the sailboat's stern and bow, which is why they are called the bow pulpit and stern pulpit here. They typically have a solid steel framing for safety.

- Stanchons are the standing poles supporting the lifeline , which combined for a sort of fencing around the sailboat's deck. On most sailboats, steel and steel cables are used for the stanchons and lifelines.

Mainsheet Traveler

The mainsheet traveler is a rail in the cockpit that is used to control the mainsheet. It helps to lock the mainsheet in place, fixing the mainsails angle to the wind.

If you're interested in learning more about how to use the mainsheet traveler, Matej has written a great list of tips for using your mainsheet traveler the right way . It's a good starting point for beginners.

Winches are mechanical or electronic spools that are used to easily trim lines and sheets. Most sailboats use winches to control the jib sheets. Modern large sailing yachts use electronic winches for nearly all lines. This makes it incredibly easy to trim your lines.

You'll find the compass typically in the cockpit. It's the most old-skool navigation tool out there, but I'm convinced it's also one of the most reliable. In any way, it definitely is the most solid backup navigator you can get for the money.

Want to learn how to use a compass quickly and reliably? It's easy. Just read my step-by-step beginner guide on How To Use a Compass (opens in new tab .

Chartplotter

Most sailboats nowadays use, besides a compass and a map, a chartplotter. Chartplotters are GPS devices that show a map and a course. It's very similar to your normal car navigation.

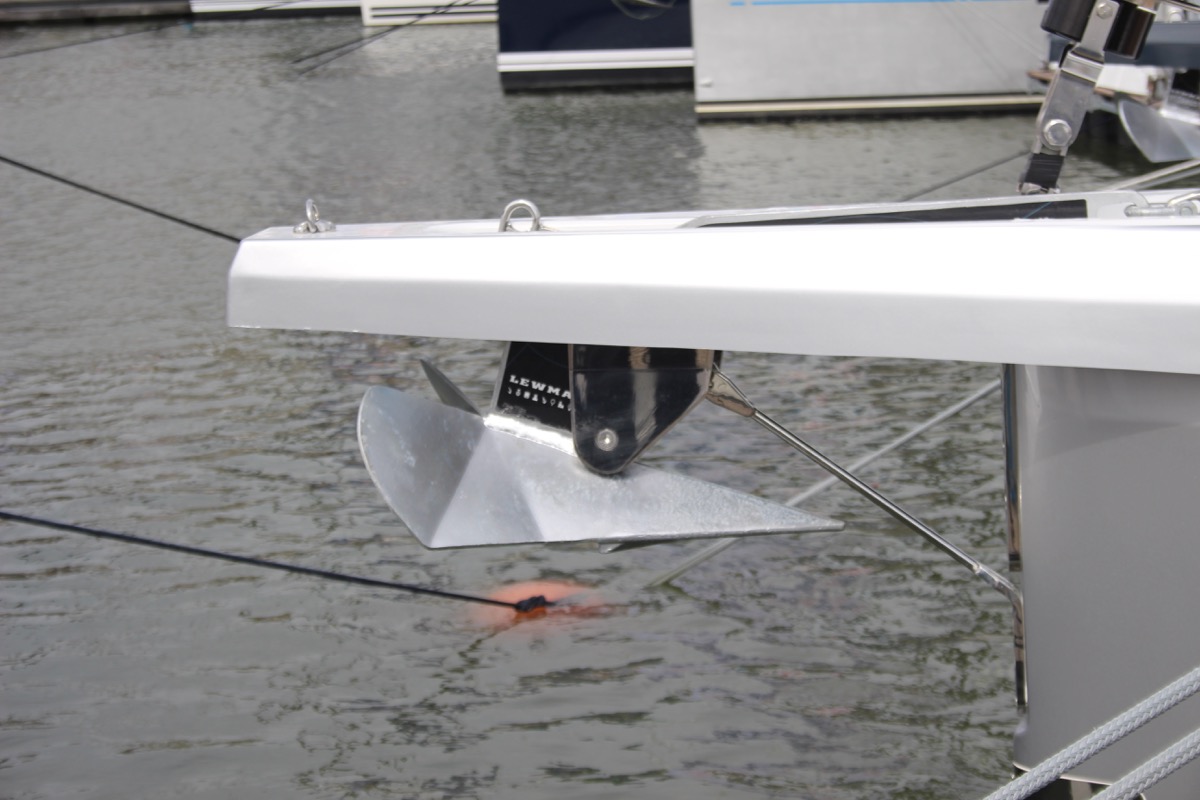

Outboard motor

Most sailboats have some sort of motor to help out when there's just the slightest breeze. These engines aren't very big or powerful, and most sailboats up to 32' use an outboard motor. You'll find these at the back of the boat.

Most sailboats carry 1 - 3 anchors: one bow anchor (the main one) and two stern anchors. The last two are optional and are mostly used by bluewater cruisers.

I hope this was helpful, and that you've gained a good understanding of the different parts involved in sailing. I wanted to write a good walk-through instead of overwhelming you with lists and lists of nautical terms. I hope I've succeeded. If so, I appreciate any comments and tips below.

I've tried to be as comprehensive as possible, without getting into the real nitty gritty. That would make for a gigantic article. However, if you feel I've left something out that really should be in here, please let me know in the comments below, so I can update the article.

I own a small 20 foot yacht called a Red witch made locally back in the 70s here in Western Australia i found your article great and enjoyed reading it i know it will be a great help for me in my future leaning to sail regards John.

David Gardner

İ think this is a good explanation of the difference between a ”rope” and a ”line”:

Rope is unemployed cordage. In other words, when it is in a coil and has not been assigned a job, it is just a rope.

On the other hand, when you prepare a rope for a specific task, it becomes employed and is a line. The line is labeled by the job it performs; for example, anchor line, dock line, fender line, etc.

Hey Mr. Buckles

I am taking on new crew to race with me on my Flying Scot (19ft dingy). I find your Sailboat Parts Explained to be clear and concise. I believe it will help my new crew learn the language that we use on the boat quickly without being overwhelmed.

PS: my grandparents were from Friesland and emigrated to America.

Thank you Shawn for the well written, clear and easy to digest introductory article. Just after reading this first article I feel excited and ready to set sails and go!! LOL!! Cheers! Daniel.

steve Balog

well done, chap

Great intro. However, the overview diagram misidentifies the cockpit location. The cockpit is located aft of the helm. Your diagram points to a location to the fore of the helm.

William Thompson-Ambrose

An excellent introduction to the basic anatomy and function of the sailboat. Anyone who wants to start sailing should consider the above article before stepping aboard! Thank-you

James Huskisson

Thanks for you efforts mate. We’ve all got to start somewhere. Thanks for sharing. Hoping to my first yacht. 25ft Holland. Would love to cross the Bass Strait one day to Tasmania. 👌 Cheers mate

Alan Alexander Percy

thankyou ijust aquired my first sailboat at 66yrs of age its down at pelican point a beautifull place in virginia usa my sailboat is a redwing 30 if you are ever in the area i wouldnt mind your guidance and superior knowledge of how to sail but iam sure your fantastic article will help my sailboat is wings 30 ft

Thanks for quick refresher course. Having sailed in California for 20+ years I now live in Spain where I have to take a spanish exam for a sailboat license. Problem is, it’s only in spanish. So a lot to learn for an old guy like me.

Very comprehensive, thank you