production Strider 24

plywood Romany 34

lightweight 14ft Zeta mainhull

Strike 15 trimaran at speed

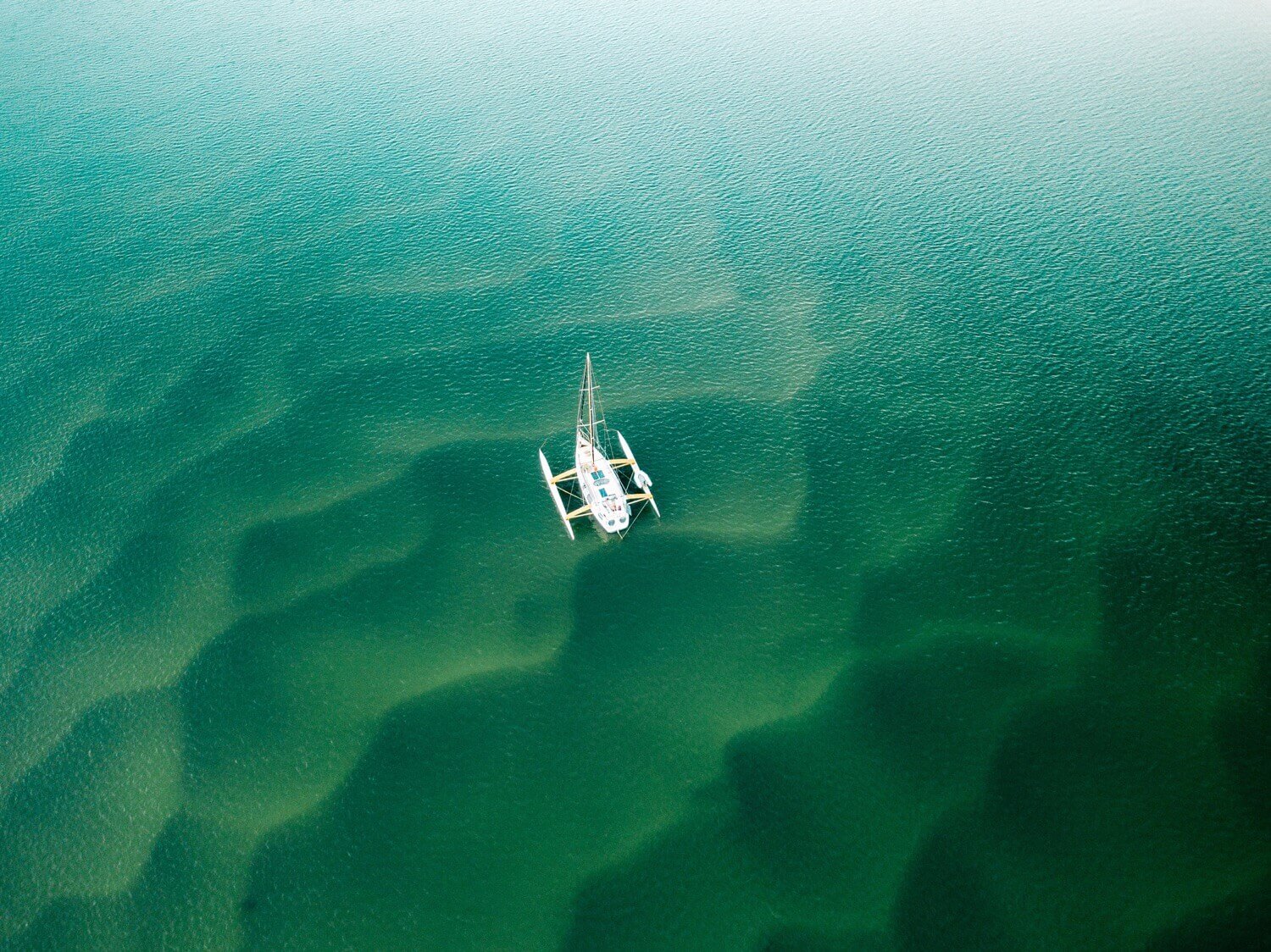

28ft Skoota in British Columbia

10ft 2 sheet ply Duo dinghy

24ft Strider sailing fast

36ft Mirage open deck catamaran

- All Our Designs

- For new visitors

- About Richard Woods

- Useful Articles

- Testimonials

- Plan Updates

- Links to Owners and Suppliers

- Consultancy Service

- Boats for Sale

- Blog and Facebook Posts

- Our Cruising Blog (updated Jan 26th 2020)

- Download Eclipse logbook (300 page pdf)

- Download Newsletters 1992-2002 (pdf)

- Download Year Reviews 2002-14 (pdf)

- Download FAQs (pdf)

- Download Boat Tests (pdf)

Hull Resistance and Hull Shape Comparisons

Introduction

As I've said elsewhere, I only like to design boats that are fun to sail. I also know from personal experience just how much effort is involved in building even the smallest boat. I've found that it is the psychological effort that's particularly hard, especially if you are a home builder building alone in your spare time. I also know that there are other people, like myself, who's keeness to build is not matched by manual dexterity.

So I try to design boats that are straightforward to build. In simple terms, if I can build it then anyone can! To do this I try to keep to simple shapes and use flat panels where ever possible. Flat decks in particular have many advantages. For a start they are easier to walk on, while coming alongside and boarding from a marina pontoon or dinghy is a lot safer. Flat panel hulls may not offer ultimate speed, but to be honest, few cruising sailors need the fastest boat while I've found that most people don't have either the skill or daring to sail a racing boat to its full potential.

You have to remember that a cruising boat, especially, isn't just for sailing. It has to be a practical floating cottage as well. And the design of that often over rules otherwise desirable sailing features. And also remember that boats have to be usable in harbours and marinas. It's not like the "good old days" when Slocum and even the Pardey's first went to sea - with no engines and few marinas or even cruisers. So all cruising boats MUST maneuver reliably under power and be easy to board from both the dock and from a dinghy.

That is one reason why I don't now like canoe sterns. They make boarding so much harder than a boat with transom steps (the acid test I always use - "could my mother get on board?"). Safe maneuvering in a small harbour is another reason I like small boats. I also find a trimaran much harder to handle than a catamaran when coming alongside, as it is so difficult to reach the outrigger bows to fend off, especially when compared to the big wide decks of a catamaran. Successful designs are ones that work in every situation, not just those that sail or motor fast in a straight line.

I always try to visulise what a particular design would be like when sailing to windward at 2am in the rain. Or when reefing. Or of course when drifting downwind on a very hot humid day.

I tend to own a fleet of multihulls. Sometimes I just go for a day sail, sometimes I race for the weekend, and most years I spend a long time living on board (I spent every Christmas living on board a boat from 2001 - 2009). All this experience means that I have personally faced nearly every situation you can meet when sailing and I use that experience in my designs.

Hull Shapes and Performance

In this article I will talk solely about hull shapes in relation to performance. Comfort, seakindliness and load carrying are also major factors affecting hull shapes and will be discussed in more detail in future articles.

People try to simplify hull design and performance predictions, formulae like the Bruce Number and KSP spring to mind. These coefficients rely only on basic sail area, displacement and length dimensions yet purport to give an accurate indicator of performance. It's easy to show that these formulae cannot be relied on if you consider that a Tornado would have the same rating whether it was sailing forwards or backwards! I suspect the latter is slower! Its probably as accurate as predicting car speed from the kerbside weight and engine horsepower. In fact hull design is a hugely complex subject while different sailing conditions require different solutions. For example, inshore boats can have a flatter rocker while offshore cruisers should be more veed forward to prevent pounding when sailing to windward in waves.

Some factors affecting yacht design are based on scientific principles and are unalterable, so always apply, whatever ones basic design philosophy and regardless of cross section shape (ie whether one uses a Deep V or round bilge hull for example). Everything else is just styling or dressing up the same proven concepts in a slightly different way. As with all moving objects, speed is the result of the combination of resistance to movement (drag) and available power. In sailing boats the power is related to the sail area while in simple terms drag comes in two forms - friction drag and wave making drag.

Frictional drag is primarily dependent on the Wetted Surface Area (WSA). Less is always better than more and WSA is the biggest factor affecting lightwind speed. The minimum WSA for a given displacement (or boat weight) is the hemisphere (eg half an orange). A longer, thinner hull has proportionately more WSA and so in light winds suffers from more drag and thus is slower but conversely is significantly faster as the wind gets up. In fact this is one reason why monohulls - which are much more orange like, do well in light winds. Spray also adds to wetted surface, one reason why powerboats have spray rails. Lots of spray makes a boat look as though it is sailing fast, but it is actually very inefficient. As an example, because of their heel and deeply immersed lee outrigger, trimarans make a lot more spray than catamarans. But we usually find that they are actually slower, particularly reaching, than an upright, low spray producing catamaran. Round bilge hulls have the lowest WSA and deep V hulls the most.

Many people think that, because multihulls have relatively thin hulls, wave making drag is non-existent, but in fact, nothing could be further from the truth. The size of waves that a hull makes depends on several factors. The Slenderness Ratio (SLR) or Displacement Length Ratio (DLR) is a measure of the fineness of a hull and is the technically correct coefficient that naval architects use. However, it is easier to visualise the hull waterline length/hull WL Beam ratio (LWL/BWL), so that is more commonly used. That's acceptable, as for a given cross-section shape, the SLR is directly related to LWL/BWL. Higher ratios result in smaller waves. Typically the LWL/BWL ratio will vary from 10:1 for a good cruising boat to 16:1 for a racing boat. (Team Philips has a LWL/BWL ratio of 35:1!) Finer hulls are more efficient at high speeds, but as we've just seen suffer from more WSA and so for normal cruising catamarans in average conditions a ratio of 11:1 - 13:1 seems optimum.

The Prismatic Coefficient (Cp) is a measure of the fullness of the ends of a boat, the higher the number the fatter the ends and - surprisingly - the more efficient at high speeds. Intuitively you'd think that a diamond shape would cut through the water best, but that's not actually the case. A high Cp also has the advantage of reducing pitching. But to complicate matters, the lower the SLR the lower the Cp can be. Typically a monohull has a figure around .56, while a properly designed multihull will be about .63. Although such a shape is slower than a lower Cp in light winds that is not a problem as one then has the sail carrying power to add extra sail to compensate. It is when sailing fast in strong winds that you need an efficient hull because you then don't have the stability to carry more sail. As an example a 30' boat with a Cp of .63 will be 1/2 knot faster than one with a Cp of .55 when sailing in 25 knot winds for EXACTLY the same sail area (and crew effort etc). Boats with a low Cp try to race faster by keeping too much sail up and it was these types that often used to capsize 25 years ago. Add in the fact that the high Cp boat won't pitch as much and its clear which is going to be the better boat.

In simple terms the Half Angle of Entry is the angle that the waterlines make to the hull CL at the bow. If it is too low then the boat is wet to sail, and, in extremis, if it is hollow there is a pressure build up further aft which slows the boat. If too fat it is also wet to sail as the bow wave goes vertically up the sides of the boat. All sailors, no matter how skillful, sail slower if they can't see where they are going because they are being blinded by spray! In both cases the correct Cp has to be maintained. So a 10 degree angle seems a good compromise. Vertical bows look fast but its actually very difficult to draw a vertical bow on a hull with both the correct Cp and one that has good reserve buoyancy. Read my articles about the Cape to Rio race to discover what I learnt first hand about the perils of vertical bows!

When I was a design student I took the opportunity to do some tank testing on catamaran models and I investigated the drag from the wave interference between the hulls. I found that this interference caused significant drag at certain speeds - in fact up to 20% when compared to hulls at an infinite spacing. So it's vital to reduce this interference as much as possible. The simplest way is to have a hull spacing wide enough so that the bow waves meet at the stern rather than under the boat. This has the added bonus that there is significantly less bridge deck slamming. In the past designers said that the optimum L/B ratio was 2:1. (In fact they were talking about overall length and beam when obviously it is waterline length and beam that are the crucial measurements.) The reasons given for this ratio were the theories that wider boats would break up and be hard to tack. In practice I've heard that limiting beam had more to do with the width of the boatyard doors! Our Strider Turbo has a LWL of 6.6m and a hull centreline spacing of 4.2m yet I've always thought it was a better sailing boat than the standard Strider. So the general trend is to go as wide as one can. But structural strength is still a problem, even with modern techniques and materials. Wide boats are heavier than narrow ones and that ultimately limits the LWL/BWL ratio to about 2:1 on cruising boats with full bridgedeck cabins.

Turning now to the hull above the waterline, vertical topsides reduce space inside dramatically and in addition are not good news when sailing offshore. As a boat moves in waves so it heaves up and down, causing discomfort and slowing the boat. Flared topsides help counteract this heaving because as the boat sinks the buoyancy picks up more quickly than with vertical topsides. The result is a smoother ride and as a bonus, better load carrying ability for, by the same token, the hull sinks slower so there is less increase in WSA and wavemaking as the boat is loaded. Clearly, freeboard adds to windage and slows the boat. Traditionally yachts had low freeboard because they were large (J Class etc) so people could fit in the accommodation easily regardless of freeboard and it's easy to make a low freeboard yacht look elegant. More importantly, it was hard to make a conventionally caulked and planked boat strong and watertight if it had too many planks (ie too much freeboard). As boats got smaller and as grp took over freeboards had to, and could, increase. Adding a few centimetres (inches) of freeboard adds enormously to interior space and at the same time results in a boat that is drier and more comfortable to sail. Fortunately, in practice I have never found that high freeboard slows the boat down appreciably and certainly not by enough to worry any except the most ardent racer.

Load carrying considerations are an important factor for cruising boats. In general it's natural for people to add weight aft because it is easier to load stores near the companionway than forward. Engines and their associated tanks, generators, a/c units etc are also always aft. So I always try to add extra buoyancy near the stern. That means that when empty the boat will probably float stern up. Too many poorly designed multihulls float stern down and drag their transoms.

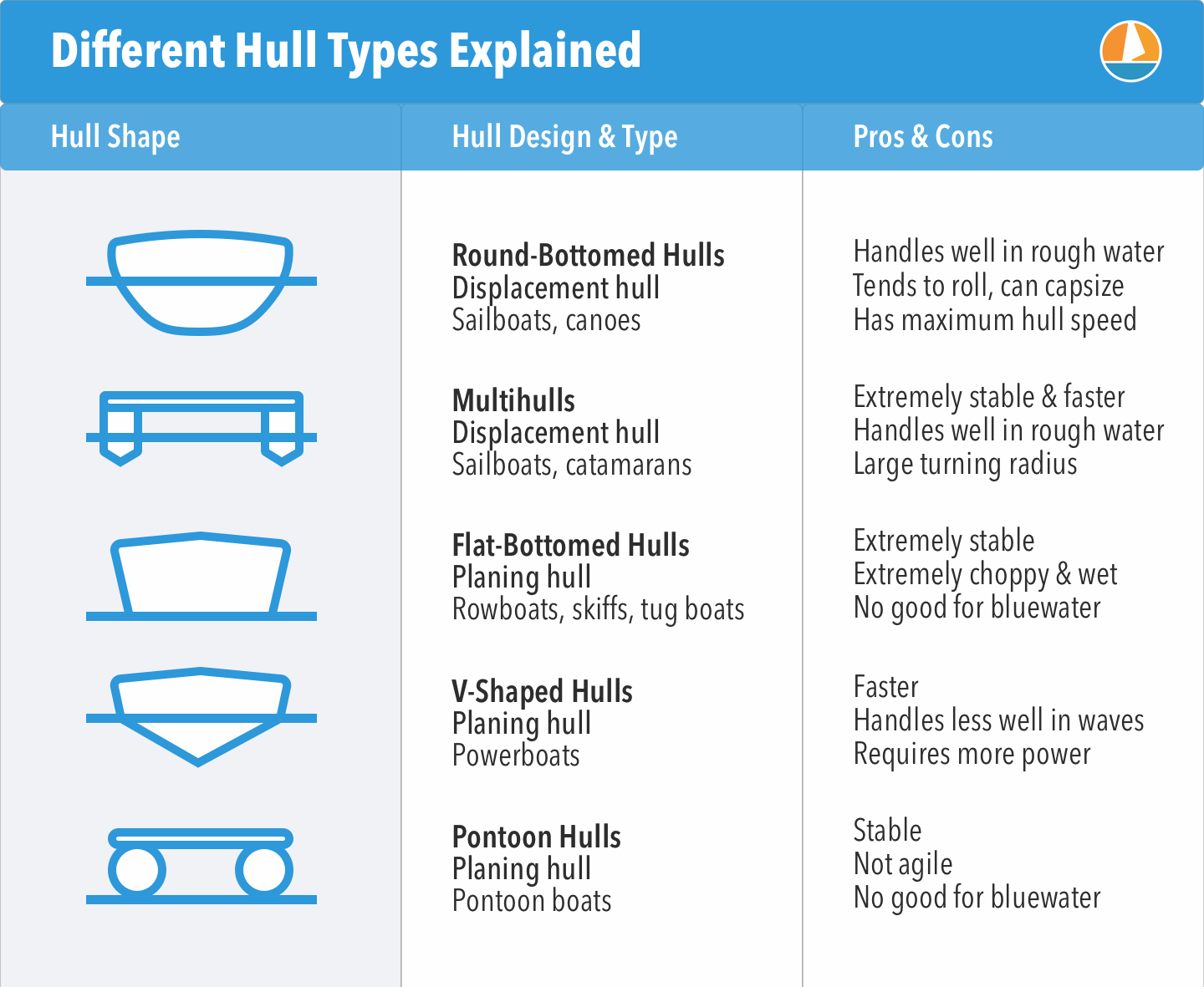

Pros and Cons of popular hull shapes

The deep V is a simple to build hull shape that matches the human body as it is narrow low down and wider high up so it is a good choice if the accommodation is only in the hulls. It can make to windward without keels or boards - just - but it's more maneuverable and makes less leeway with them fitted. Deep V hulls pitch more than any other hull shape, particularly if they have canoe sterns. Hull asymmetry is needed to reduce pitching, a canoe stern is obviously as pointed as the bow so it's bound to pitch more. They have more WSA than any other hull shape so are slow in light winds.

The flat bottom hull is also easy to build and has the added advantage that it is self supporting during building and transport. It needs Veeing forward for offshore sailing or it will pound. Then it becomes a hard chine/single chine hull. Carefully drawn such a shape is a close approximation to a round bilge hull, but without any complicated building.

The round bilge hull is the only hull shape that can be varied over it's length so one get exactly the shape one wants. It has minimum WSA, and so is also the optimum hull shape but it is the slowest to build. A topsides knuckle helps deflect spray, adds interior volume and makes it easy to join flat topsides to the curved bottom. It also makes a nice styling line.

From the start of my design career I have always tried to design balanced, undistorted hulls that sail easily on all points but are not too extreme. However, I have made a few changes to my hull shapes over the years. First I have increased freeboard (in common with most designers, monohull and multihull). I have also increased the centreline spacing and where appropriate, drawn a bigger knuckle. I haven't designed any deep V boats for a long time because of the pitching and light wind speed problems. I have found the flat bottomed or single chine hulls are as simple to build and are more efficient hull shapes.

Finally, I am one of the few designers who use all feasible hull shapes and so can choose the most appropriate one for the intended use. I'm not committed by dogma to any one hull design. The performance differences between different hulls are easy to see, however I have not noticed any practical difference in seaworthiness between them.

The following sketches are typical hull cross sections. Please note, these are not to scale and are not real boats, instead they are just examples of the different hullshapes we use in our designs. (For those not familiar with lines plans: Only half sections are shown. The forward half of the boat is shown to the right, the aft half is to the left of the vertical centreline.)

This is the "Dory" hull used on the Janus and Gypsy as well as the Strike trimaran mainhulls. Note that the Janus does not have a V'eed area forward (as shown) as the bottom is narrow enough to prevent slamming on such a small boat.

This chined hull is used on Flica, Mirage and Romany and is a close approximation to a round bilge hull, but built in flat panels

This is a deep V hull used on Surfsong, Windsong and Mira (deep V version)

This is the chined V hull used on Meander, Rhea and Ondina. If these larger boats had a conventional V hull then either the gunwale or keel panel would have to be very wide so that the hull had the correct displacement. By adding a soft chine the lower hull section can be well flared, while the topsides remain nearer vertical. This hull shape has the added advantage that the hull panel is stiffer and, as each section is smaller, it can be easier to make.

This continuously curving hull shape is used on Wizard, Sango and Wizzer. It has a similar below-waterline shape to a Strider hull (for example) but the bulge in the topsides allows a vertical bow to be drawn while keeping a good flare forward to prevent nosediving. It also adds to the interior room, especially at shoulder level. These hulls can be built in strip planking or foam sandwich but it is harder to build than the small knuckle hull shape.

This "Small Knuckle" round bilge hull is used on Strider, Shadow, Merlin, Gwahir, Skua, Gypsy (round bilge version), Mira (round bilge version), Scylla, Nimbus, Rhea (round bilge version) and Cirrus. This shape is easier to make than the one below. The knuckle is small and is usually made from solid timber (eg 2" x 1"). Even so it has proven effective at reducing spray and slamming. The hull bottom can be double diagonal plywood or strip plank. The topsides of both this hull shape and the one below can be strip plank or sheet plywood. Alternatively both knuckle designs can be built in foam sandwich with a flat panel topside panel.

This is the "Large Knuckle" hull used on the Scorpio, Javelin, Sagitta, Eclipse and Transit. It is the most sophisticated shape I draw, and takes the longest to build. The large flare increases space inside and cuts down on spray. The angle of the hull at the WL is actually higher than on other hull shapes. That means that it sinks relatively slowly as you add weight. A big advantage for cruisers. But it also means the boat doesn't pitch and heave so much, ie vertical movements are reduced. That is because it is (slightly) harder to make the boat sink as it goes through waves. All minor differences but they add up if you are looking for the best all round shape.

Having said that, if you are planning on using LAR keels rather than daggerboards then you will probably be better off with a flat panel hull. There is no point in taking just one part of the overall design to the limit, you have to balance the trade off for the whole boat. So don't fit daggerboards and cheap sails! Makes no sense to me.

- PERFORMANCE TOPICS

Optimising Hull Lines for Performance

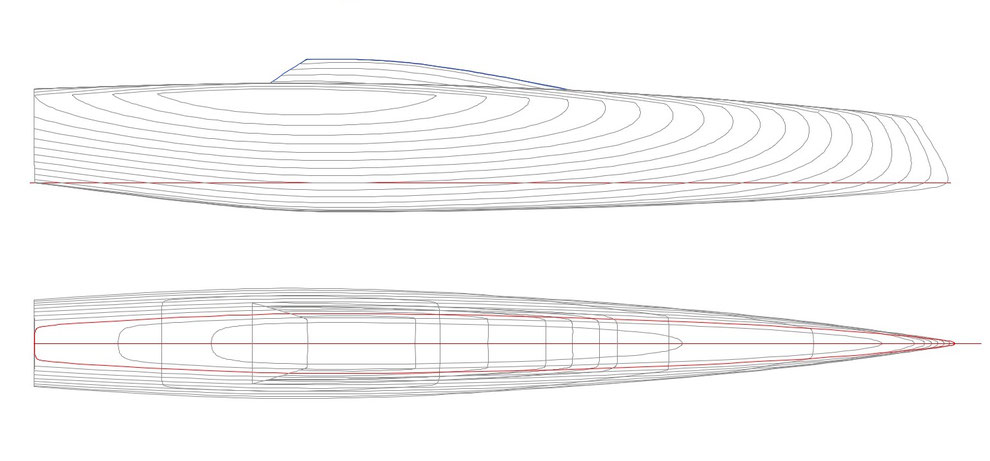

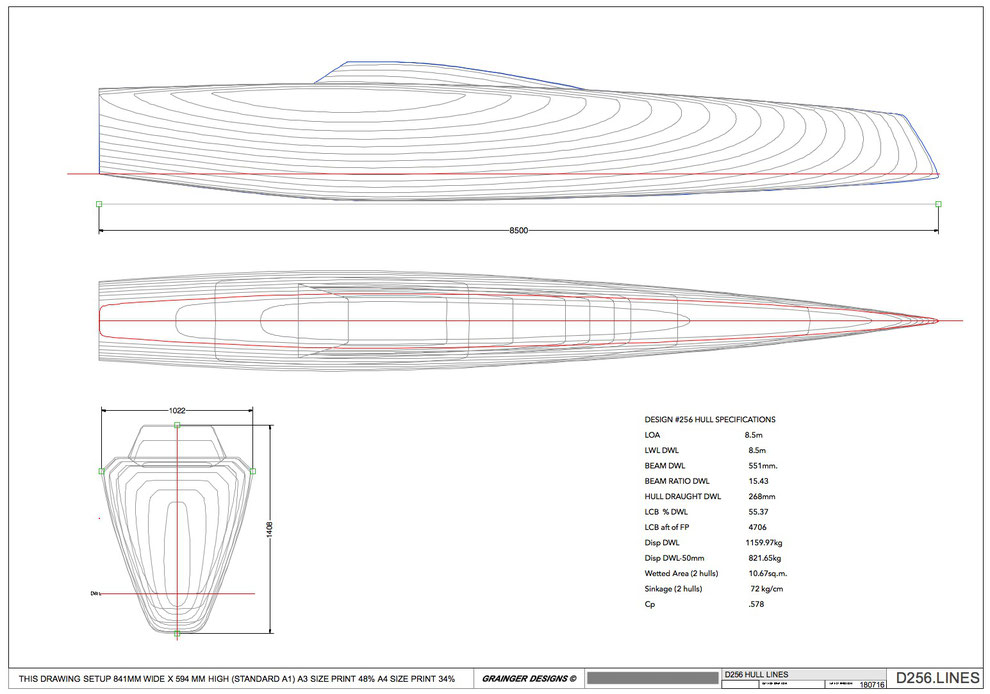

This article was inspired by a question about the rocker line in the new 8.5m cat Design 256 and I want to stick to the point, so we won’t turn it into a book, but I’ll discuss two issues, hull fineness ratio and some aspects of the rocker profile.

When you manipulate the hull form you’re adjusting the lines in three planes, waterplanes (plan view), buttocks (side view including the keel rocker) and the section shapes. So you need to be aware of how the shapes are changing in the other two planes as you manipulate any one of these three, or all three globally as is now possible with computer modelling.

There are two fundamental constants that you start with and don’t change throughout the process. The big one is the displacement or the amount of buoyancy you need.

If you make the hull finer by narrowing the waterlines you have to increase the draft or make the ends fuller to get back to the required displacement number.

If you flatten the rocker line you have to increase the hull width, fill out the ends, or square up the section shapes rather than having a V or rounded V.

The other constant is the longitudinal centre of buoyancy. You really can’t do any meaningful shaping of the hull form until you have settled on the these two constants.

A third number that we can plug in as a constant if we want to is the prismatic coefficient which describes bow much volume there is end the ends relative to the cross section shape in the middle of the boat, but in sailing boats this is of less importance compared to other factors.

The hull lines for Design 256, 8.5m Cat. It's that hump in the rocker line - right under the back of the cabin that brought up the question and is one of the key points discussed here.

Hull fineness.

Fine hulls are fast, but only in the higher speed range. There’s a misconception I come across quite a bit that you can add weight and windage and you’ll still be fast as long as your hulls are fine.

Well you won’t be. Your boat will simply sink to find the new state of equilibrium. If your transoms are submerged you’ll have more drag. If your bridge deck is too close to the water you’ll have slamming. Much better to be conservative with your displacement figure in the design stage than overly optimistic.

And fine hulls have more wetted area so you have more drag in light air where friction resistance is the primary drag factor.

I’ve seen promotional material for catamarans stating that the boat has less wetted area because it has fine hulls. For a given displacement the minimum wetted area is described by a sphere (or a semi sphere in the case of a floating object). The more you stretch it out in length, keeping the displacement constant, the more wetted area you have.

The more you make the section shape into a deep V or a broad U with tight corners, as opposed to a semicircle, the more wetted area you have. Add into the equation finer hulls are slower to tack.

So fine hulls are only an advantage if your boat is light and has enough sail area to ensure you’re travelling at speeds where form resistance is greater than skin resistance.

In my view the advantage of fine hulls is often overrated as it applies to cruising cats.

At the other end of the scale the resistance curve is fairly flat up to about 1:9 which is still quite fast in most conditions. From there the resistance rises steeply as the hull gets fatter and at 1:8 and fatter you’re suffering from some serious form drag.

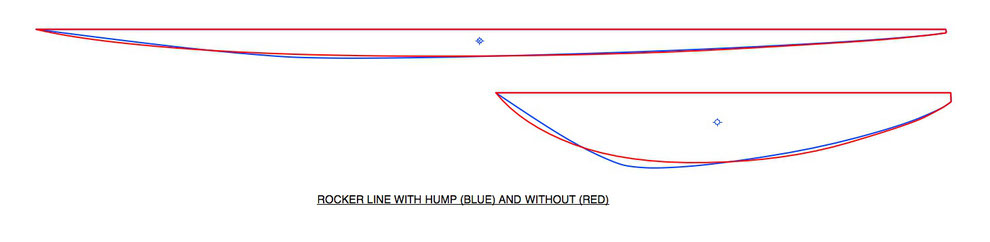

This is the rocker line isolated from the lines plan above (in blue) and and the red line shows a more moderate rocker line that achieves the same buoyancy and maintains the centre of buoyancy in the same position. The bow is to the right.

In the image lower right I've squashed it up and increased the height to make the difference in the lines more obvious.

The difference in the two lines is quite subtle, but races are often won or lost by seconds.

Rocker Profile

So if we’re looking for low wetted area we would want a rocker profile that was even and rounded, relatively deep in the middle and rising smoothly to the surface at each end. But this would give us a low prismatic which is not ideal in the higher speed range, and it’s not ideal for pitch damping which in my view is the critical design factor that is often underrated.

Pitching is slow. It destroys the airflow in your sails and the flow around the hulls, and your performance is suffering from slamming loads.

The single most effective way to counter pitching is with asymmetry in the water planes. You can achieve that in the with a fine bow and broad transom. Or you can achieve it with V sections forward and a flattened U shape aft. Or you can achieve it in the profile view with a very straight run forward and a bump in the aft sections. A flatter rocker line is better for resisting pitching than an evenly curved one with deeper draft in the middle.

The final result is a combination of all three of these factors.

On a cat like Design 256 the weight is concentrated well aft so we need to get buoyancy well aft.

The kink you see in the rocker profile helps to do this. It also helps to keep the rocker straight for most of its length and smooth the water flow exiting the hull aft at higher speeds, possibly promoting some planing effect.

If we had a more even rocker line we would slightly reduce the wetted area, but we would increase the pitching and the water would exit the hull aft at a steeper angle, increasing form drag in the higher speed range.

How much of a bump can you put in there without creating a flow separation, and how damaging would that flow separation be? I really don’t know. The way all of these factors interplay in the various conditions we sail in is very complex.

Ultimately a lot of this work is gut feel nurtured by experience, observing things in nature and most importantly experimenting and trying new ideas.

Is the new Groupama AC45 a breakthrough that will influence the form of racing catamarans into the future? I don’t think anyone has a computer that can answer that. We have to wait and see.

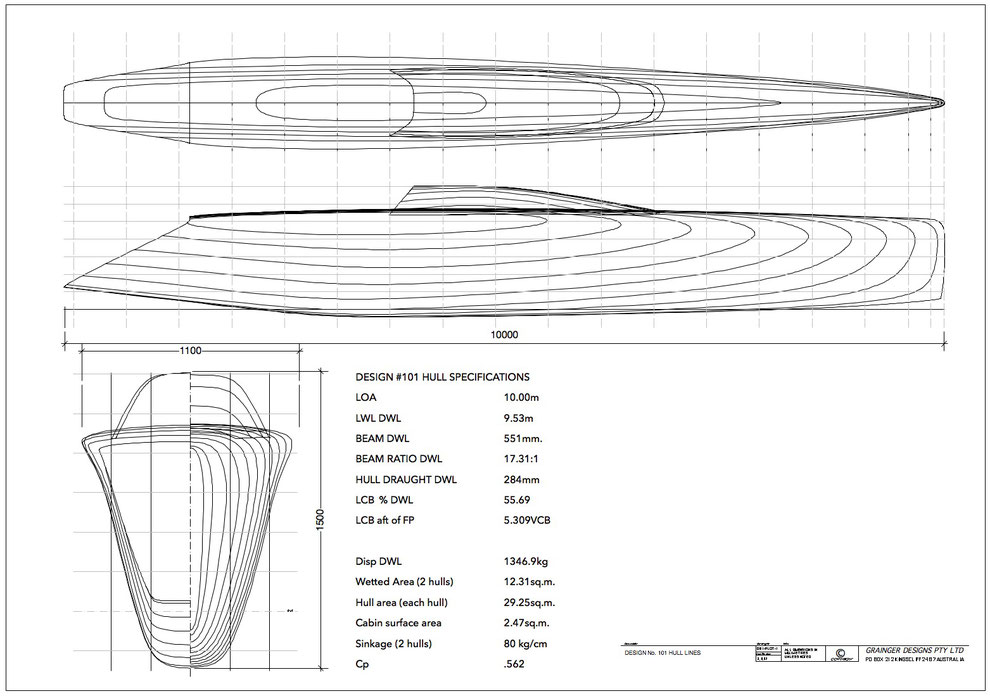

Symmetric and non symmetric water-planes. The blue line with grey fill is the DWL from the design above. As is typical with modern cat hulls the bow is long and fine, the stern is full and rounded. This is the asymmetry that has a damping effect on pitching. The red line on the other hand is more like you would see on a double ended monohull and quite a few multihulls have also used this shape in the past. It's quite symmetric about the pitch axis and does not have good pitch resistance.

The hull lines of the new 8.5m Sports Cat Design 256

Mad Max , Previously Carbon Copy . She was designed in 1997 but she's the current (2016) title holder of the Australian Multihull Chamionships (2 successive years) and the fastest inshore racing boat in Australian waters.

Join the Newsletter

- Scroll to top

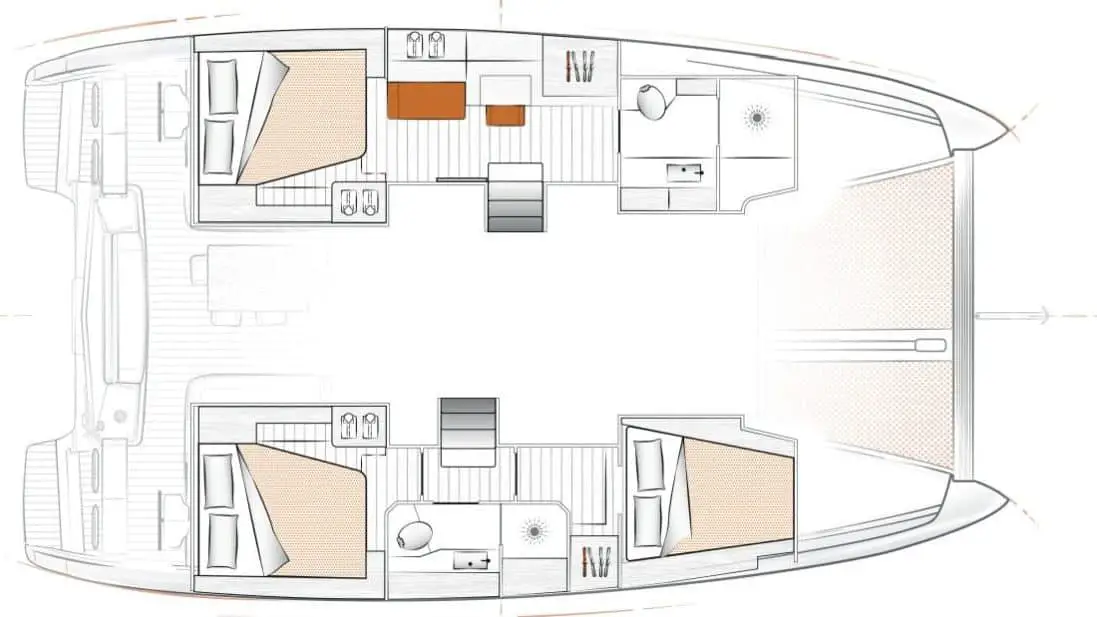

How To Create the Perfect Cruising Catamaran Layout

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

More than ever before, sailing fans are gaining an interest in catamaran layouts and designs that define performance. Many others are also looking into either buying a cruising catamaran or designing and building one. While building a catamaran is no piece of cake, this article shows you how to create the perfect cruising catamaran layout.

To create the perfect catamaran layout, carefully consider factors like a good hull design, optimal helm station placement, boat stability, and adequate load-carrying capacity. Excellent galley positioning, ease of handling, and spacious living and sleeping quarters are also crucial.

The modern cruising catamaran is a far cry from the simple Polynesian double canoe of old. That’s because structural innovations and new composite materials have resulted in multihulls with impressive cruising abilities. Keep reading to learn more about exceptional catamaran layouts.

The Changing Trends in Catamaran Designs

The early cruising catamaran designs resulted in boats that could sail much faster than traditional sailing boats. In addition, they could glide with ease in shallow waters and required less wind and crew. Unfortunately, these cruising cats were heavy, had small, cramped interiors, and boasted somewhat challenging handling abilities.

Today’s cruising catamarans are different. They boast the utmost comfort, high speeds, and the safety of a well-designed cruising yacht. They are also more exciting, visually appealing, deliver the smoothest of rides, and sport more spacious interiors.

Have a look at the below video showcasing the top ten cruising catamarans:

Features To Look Out for in Catamaran Design Layouts

Cruising catamaran designers understand what most sailors look for in a cruising vessel. They, therefore, design cruising multihulls that address these pertinent issues and more. Some of the features you might want to consider having in your dream boat include the following:

- Responsive performance. Outstanding performance allows for pleasurable cruising and ensures your safety since you have more options during difficult weather.

- Excellent load-carrying ability . This allows you to have an extended cruising vacation or ocean crossing.

- Boat stability . Go for lightweight, robust construction, which results in a lot of buoyancy.

- A low center of gravity for smooth rides and enhanced performance. Centering weight around a low center of gravity improves the overall sailing quality, reduces pitching movement and reduces the risk of capsizing .

- Adequate bridgedeck clearance to reduce slamming and provide better performance in rough conditions. A high bridgedeck also means less noise and slapping action from the waves hitting the boat bottom, thus ensuring a quieter, smoother ride.

- Comfortable sailing. To enjoy a quality life on board, you need comfort while at sea. Thus, elements like gentle movement, no creaks or groans, no bridgedeck slamming, and minimal pitching are essential for quality, peaceful and restful sleep.

Now that you know what a cutting-edge catamaran features, let’s look at how to create the perfect cruising catamaran layout.

Build a Larger-Sized Catamaran

The early catamarans ranged between 36-42 feet (10.9-12.8m). At the time, this appeared to be a good size in terms of safety and ease of handling. However, the boats were heavy, and the additional drag and displacement adversely affected their performance and windward ability.

It’s now possible to make the new generation catamarans lighter, larger, and more spacious with excellent power-to-weight features. The current trend is larger-sized catamarans in the 45-50 feet (13.7- 15.2) range. Composite engineering and technologically advanced equipment such as furling systems, electric winches, and autopilot make it easier for a smaller crew to sail larger boats with confidence. And to do so without compromising safety or stability.

Get the Best Catamaran Hull Design

A cruising catamaran’s performance depends on three main aspects; its length, the sail area, and the boat’s weight. Long boats are generally fast. A light boat with more sail area is also faster than a heavier boat with less sail area. In other words, you can make a multihull faster by making it longer, lighter, or adding more sail.

However, there are exceptions to this rule; a boat with too much sail area is more likely to capsize if there are brisk winds. Also, if the boat’s design makes it too light, it’ll be unable to handle much punishment, while a hull design that’s too slim would make the vessel incapable of carrying any significant loads. But that’s not all; if the boat is too long or too large, it’ll become grossly exorbitant. Narrow hull shape might also mean smaller cabins.

Nonetheless, these three factors alone are not enough to determine a cruising catamaran’s performance. While faster boats boast finer hulls, the wetted surface area tends to increase as fineness increases; thus, fine hulls end up becoming less fast in low wind speeds. Also, very wide hulls mean a reduction in actual performance.

The Prismatic Coefficient (Cp), a measure of how full the ends of the hull get, is the most essential design hull shape factor for any catamaran. A high Cp equals high speeds, although you can still use a lower Cp if you have fine hulls. Nevertheless, the key to a good Catamaran design is a higher Cp for fast sailing.

To achieve a high Cp, there are several things you can do:

- Fit bulb bows . Unfortunately, the bulb bows tend to slam in a seaway when you do this.

- Have an extensive planning aft section . However, this can increase the wetted surface area, WSA and lead to additional challenges.

- Flatten out the hull rocker and add a bustle aft. This helps to add displacement aft.

Build Convertible Main Living Spaces

The open cockpit is now a thing of the past. Instead, pioneering designers for catamaran manufacturers like Nautitech, Gunboat, and Catana now replace traditional-style salons, cockpits, and cabins with spacious indoor and outdoor living spaces. The concept involves merging separate saloon and cockpit areas with duplicate lounge spaces and the use of hard-wearing composite materials.

You can also design the cabin to suit your preferences. You may decide to add a cabin or remove one, add a bathroom, have the forward berth in the hull or on the wing deck.

- The design enhancements boost usable space while opening up the living areas.

- It reduces time and costs for interior maintenance and cleaning.

- Large windows bring in more light, increasing visibility.

- Luxurious, spacious, and airy owners’ cabins provide more comfortable living space.

Bulkhead Helm Stations vs. Twin Stern Steering

Many catamaran owners have traditionally preferred bulkhead steering. This helm position remains popular, but twin stern steering positions come with more advantages since they provide greater sails visibility. The twin stern positions are also best suited for racing or day sailing since they often lack adequate protection for extended cruising.

Exposed helms are not ideal for a long ocean passage. Go for a safe, secure, and well-protected helm station that provides good visibility and comfortable space for long watches. Again, it’s best to have all control lines at the helm to establish a static control station. Also, have all push-button-controlled winches, instruments, windlass, and autopilot prominently located inside the cockpit.

- Twin stern steering positions give you a better view of the sails

- You get a better feel for overall sailing conditions.

- Twin stern steering positions lack the necessary protection for extended cruising.

Go for the Flybridge Design

The flybridge design is appealing because it offers excellent visibility, more comfort, and additional entertainment and lounging space for everyone on board. Unfortunately for smaller boats – those below 50 feet (15.24m), there is minimal protection from the elements. As such, you might want to consider adding enclosures to offer protection. The flybridge, thus the helm, remains cut off from the vessel, which makes communicating with the crew a challenge.

- It provides great visibility.

- It offers comfortable spacing.

- It might be unsafe to move from the cockpit to the flybridge in bad weather.

- It isn’t easy to communicate with the crew.

Daggerboards vs. Fixed Keels

Average cruising catamarans typically utilize fixed keels while high-performance cats have daggerboards . Fixed keels allow you to beach your catamaran easily, and your hull remains intact if a collision occurs. While you lose some angle when sailing upwind, you gain more interior space in the hulls that you can put to good use.

Daggerboards are essential in a performance cruising catamaran since they guarantee that the boat delivers good upwind sailing, including during difficult situations. During long passages, they allow you to point better upwind though the drawback is that they consume much interior space within the cruising catamaran’s hulls.

Since flying on foils ( hydrofoils ) isn’t that practical on cruising catamarans, designers of larger-sized boats have also come up with modified daggerboards. These daggerboards produce lift and prevent leeway, too, thereby improving performance significantly, as seen with the Catana 59’s curved daggerboards. These foil-like daggerboards lift the boat ever so slightly upon reaching higher speeds, making it feel less heavy and much faster.

At the end of the day, calculating the performance of a boat sailing in a wide range of varying seas and winds might not be easy – despite a daggerboard or fixed keel configuration. This is because upwind speed depends not only on the sails’ quality but also windage and the height of the bridgedeck beyond the water.

- The design innovations -curved daggerboards and hydrofoils- improve catamaran performance significantly.

- Daggerboards enable you to access otherwise inaccessible anchorages.

- Daggerboards take up hull space in the hulls of your vessel.

Galley Up vs. Galley Down

Galley layout are becoming more and more important as more people, including families, start sailing regularly. While at sea, your galley needs to be a safe place, well-ventilated, and functional. Everything should be well-thought-out for the sailor’s comfort, including handholds to make it safer to move around the boat.

While the galley location can either be up the bridgedeck or down in the hull, galley up appears to be the most popular trend. This makes the galley the focal point of both the living space and entertainment areas.

If you have a family, this placement is ideal since you make your meals from the galley and get to spend most of your time here. Many cruising families and couples prefer this arrangement and find separating the galley down the hull unappealing. Besides, carrying hot food up and down the staircase is unsafe.

Still, galley down is ideal for charter boats since it offers a private cooking area and uses up hull space efficiently.

- Having the galley on the bridgedeck is ideal for families and cruising couples.

- Placing the galley on a similar level with the serving area and cockpit is safer and less tiring.

- There’s better ventilation on the bridgedeck, making for comfortable cooking.

- There’s less kitchen privacy galley up.

- On smaller catamarans, this layout can impact the size of the saloon seating area significantly.

Production Catamaran vs. Custom

The choice of either a production catamaran or a custom design might seem pretty straightforward. Production catamarans from major brands come backed by proven designs, dependable construction, solid warranties, and many years of experience. The catamarans are easy to service, source for parts, and most – particularly the owner’s versions – hold on to their value, making them much easier to resell.

On their part, custom boats are fantastic in that you can tailor them to your exact needs. However, they might be more challenging to maintain or service. That’s because of parts unavailability and lack of construction knowledge.

Choose Quality Construction Materials

The best quality materials to use on your catamaran are both light and robust. While carbon fiber is great, plywood, plywood/epoxy, and strip-cedar are excellent materials too. What’s more, they are also affordable, so you don’t have to get too hung up on cutting-edge building materials. What matters is build quality; thus, a well-built plywood catamaran boat can last as long as a boat made from more high-tech materials.

Combining various materials also helps combat some of the issues that plague plywood boats in terms of resale value. At times, the design tends to make the boats appear pretty dated.

- Plywood and strip-cedar materials are affordable and provide excellent build quality.

- Plywood boats may have a lower resale value than those built with modern materials.

Consider Ease of Handling

An important factor in handling a cruising catamaran is deck layout. Most cruising catamarans sailed short-handed , so if your boat has one helm, all lines should run back here to allow for a static control station for the entire boat.

The other essential element is visibility from the helm. The 360 degrees of visibility while maneuvering, docking, or underway is crucial to your boat’s safety, as well as life and property. As such, you should be able to view both bows, or at least the pulpits and sterns, while standing at the helm. If not, you may have challenges handling the boat due to blind spots.

Consider the Load Carrying Capacity

A well-designed catamaran is enjoyable to sail in all weather conditions. It’s also much easier to handle than a monohull because of its widely spaced twin engines. But when you immerse extra hull depth, the vessel gets sluggish and moves slower, maneuvering in tight spots or when docking becomes more challenging. Furthermore, the hull submersion reduces bridge deck clearance, leading to hull slamming.

To allow for adequate load carrying capacity, you need a design that provides a generous displacement. This helps to ensure that you maintain reasonable bridge deck clearance even when fully loaded. It also allows you to avoid digging big holes in the water as you drag your transoms.

Displacement refers to the amount of buoyancy designed into the hulls, which essentially means that your boat will cruise better if its weight is less than your designed displacement.

Note that an overloaded catamaran not only loses out on performance but eventually, on safety too. To counter this, choose a lightweight catamaran with hulls bearing cored construction and interiors made of lightweight materials.

Remember, when you go cruising, you will need to carry fuel, extra water, supplies, equipment, and amenities, translating into thousands of extra pounds. Therefore, try and avoid the following design errors to ensure that your catamaran has an adequate load-carrying capacity:

- Avoid putting in place too much accommodation space.

- Avoid building a heavy boat ‐ use low-tech construction materials.

- Avoid installing inboards in a small boat.

- Lightly constructed catamarans perform faster and carry more weight.

- Cored construction makes for a strong and stiff catamaran, thus enabling good performance.

Final Thoughts

A well-designed cruising catamaran is a joy to behold. Today’s modern technological advancements mean that you can buy or build a light but strong cruising catamaran. And as you can see from this article, there are many excellent cruising catamaran layouts that you can choose from.

However, whichever layout you decide on needs to fit your sailing needs and purposes to ensure you remain comfortable and safe while at sea. Above all, ensure that you go for a vessel that you can handle with ease in all weather conditions.

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their "home marina" and sailing will be somewhat...

Did You Know That We Offer Contract to Closing Services? Click Here to Find Out More.

Need Marine Financing? Apply Here With Our Partner, First Approval Source

- Catamaran Interviews

- Catamaran Reviews

- Buying Advice

- Selling Advice

- Woods Design Advice

- Americat 3014

- Balance 526

- Bali 40 Catspace

- Beneteau Blue II

- Broadblue 346

- Broadblue 38 Prestige

- Broadblue 385

- Broadblue 435

- Broadblue 46

- Catalac 10M

- Catalac 11M

- Catalac 12M

- Catalac 900

- Catana 42 S

- Chris White 48 Voyager

- Chris White 55

- Corsair F28 R

- De Villiers

- Dolphin 460

- Endeavour 30

- Endeavour 35 Victory

- Endeavour 36

- Endeavour 44

- Endeavour 44 TrawlerCat

- Fortuna 36 Island Spirit

- Fortuna 401 Island Spirit

- FP 32 Maldives

- FP 35 Tobago

- FP 37 Antigua

- FP 38 Athena

- FP 39 Fidji

- FP 40 Lavezzi

- FP 40 Lucia

- FP 40 Summerland MY

- FP 41 Lipari

- FP 42 Astrea

- FP 42 Venezia

- FP 43 Belize

- FP 44 Helia

- FP 44 Orana

- FP 46 Bahia

- FP 46 Casamance

- FP 48 Salina

- FP 56 Marquises

- FP 57 Sanya

- FP 60 Eleuthera

- FP Saona 47

- Gemini 3000

- Gemini 3200

- Gemini 3400

- Grainger 420 Mystery Cove

- Hirondelle 7M

- Lagoon 37 TPI

- Lagoon 42 TPI

- Lagoon 43 PC

- Leopard 39 PowerCat

- Leopard 45 Classic

- Leopard 47 PowerCat

- Leopard 51 PowerCat

- Leopard 53 PowerCat

- Maine Cat 30

- Maine Cat 41

- Matrix 450 Vision

- Matrix 760 Silhouette

- Maverick 400

- Maverick 420

- Maverick 440

- Nautitech 40

- Nautitech 442

- Nautitech 46 Open

- Nautitech 47

- Outremer 40

- Outremer 45

- Outremer 50 Standard

- Outremer 55

- Privilege 37

- Privilege 39

- Privilege 42

- Privilege 43

- Privilege 435

- Privilege 45

- Privilege 465

- Privilege 48 Transcat

- Privilege 482

- Privilege Serie 5

- Prout 31 Quest

- Prout 33 Quest

- Prout 34 Event

- Prout 35 Snowgoose

- Prout 37 Snowgoose

- Prout 37 Snowgoose Elite

- Prout 38 Manta

- Prout 39 Escale

- Royal Cape 45

- Royal Cape 530 Majestic

- Royal Cape Majestic 500

- Sailcraft 30 Iroquois

- Sailcraft 32 Comanche

- Sailcraft 35 Cherokee

- Sailcraft 41 Apache

- Sailcraft 44 Apache

- Wildcat 350

- Seawind 1000

- Seawind 1160

- Seawind 1200

- Seawind 1260

- Seawind 1600

- Solaris 36 Sunrise

- Solaris 36 Sunstar

- St Francis 44

- St Francis 48

- St Francis 50

- Stealth 11.8

- Heavenly Twins 26

- Ocean Twins 38

- Voyage 380 Maxim

- Voyage 400 Norseman

- Voyage 430 Norseman

- Voyage 450 Cabriolet

- Voyage 47 Mayotte

- Wharram 38 Tiki

- AMI 320 Renaissance

- Woods 22 Wizard

- Woods 35 Banshee

- Woods 35 Flica

- Woods 36 Scylla

- Woods 36 Vardo

- Woods 38 Transit

- Woods 40 Meander

- Xquisite X5

- Xquisite X5+

Catamaran Construction – Hulls, Laminates, and Composites

- Post author By BJ Porter

- Post date October 15, 2020

- 3 Comments on Catamaran Construction – Hulls, Laminates, and Composites

It’s a given that catamarans are more sensitive to weight and loading than monohulls. Catamaran builders strive to build the lightest boats they can without sacrificing strength and stiffness, and have adapted new building techniques and materials to meet this target. Cutting weight allows more passengers and gear without sacrificing performance.

And the marketing materials reflect it–they load every review and website with polysyllabic technical jargon describing the design and production choices each builder made to deliver the best boat they can.

But when you’re reading a brochure and you come across phrases like “ hand laid bidirectional GRP ” or “ vacuumed bagged e-glass with vinylester resin over a Divinycell core ” do you know what that really means?

All modern production catamarans are made with “FRP” construction (for Fiber Reinforced Polymer). Composites aren’t new–it’s just using materials together to strengthen the whole assembly. Straw was added to bricks centuries ago, and steel reinforced concrete is a staple of construction over the last century. For boats, it’s the use of stranded fibers and cured resins which make FRP different.

The term “FRP” doesn’t get into the technical detail of which fibers and which plastics, and how they’re put together to build your hull. There’s a wide variety of fiber types which can be stranded, woven, chopped or sprayed in a varied of patterns then combined with several types of resins to make hulls with different characteristics.

Some FRP techniques produce lighter, stronger shapes, while others are quicker to build and less expensive to produce. The choice of technique is a function of many factors, from the number of hulls and parts to be built, the type of parts, the budget for the project, and many design specific requirements for weight and strength.

1. FRP Basics

The principle behind all FRP construction is the same – you lay our fibers in the shape you need, then saturate them with resin, removing all the air and voids you can. Resin is left to cure, then the piece is ready to finish and use.

The reality is more complex, since building a boat isn’t like making a flat board or a simple door. You’ve got a complex shape with a designed set of curves to build. “Tooling” is the set of shapes to make the boat parts; molds to cover with fiberglass to get the right shapes.

That’s what makes FRP so effective – you can make almost anything out of it. But to do so requires a lot of choices about what you need for the project at hand.

There isn’t a “best” all around material or technique choice for all jobs, and sometimes a lower cost technique or easier to work with material may be the better solution to the problem.

A. Fiber types

Fiber choices in the last few decades have expanded past the glass fibers used in the first mass produced boats in the 1960s. FRP construction wasn’t new even then, they built the first composite boats using modern fiberglass in the 1940s.

The major fibers used in marine construction fall into three categories – glass, aramids, and carbon. The primary differences are in the strength to weight ratios of the fibers, durability, elasticity, and cost. Some construction may use blends of fiber types to combine performance characteristics.

Glass – the most common material still, because of its low cost and versatility. The most common variety used in GRP (Glass Reinforced Polymer) is “E-glass” which refers to its strand size and mineral content. Other grades have different and sometimes better mechanical properties, but may be more expensive and less appropriate for boat building use. Fiber sizes run 10 to 25 microns for E-glass, though other grades may be smaller.

Brands like Leopard, Lagoon, and most higher production volume builders use E-glass.

Aramids – this includes brand names like Kevlar, Technora and Twaron. They have higher tensile strength than E-glass, and resistant abrasion and punctures. Kevlar is a common choice for bullet proof body armor, and can built a tough, lightweight hull. The materials can be difficult to work with, as it is very tough to cut the cloth. It is often blended with carbon fiber or other materials – Catana is known for using Twaron blends in hull construction.

Carbon – the ultimate in lightweight, strong construction material. Carbon fiber is the most expensive fiber, and is available in a variety of weights, grades and strengths. Fibers are smaller than glass – down to 5 Micron.

The lightest, most expensive hulls are made from carbon, but a catamaran builder may use carbon in places other than the hull to add strength and stiffness. Carbon boards, rudders, and reinforcing structures can enhance performance without driving the price of the boat beyond reach. Carbon is the fiber of choice for many custom builds, racing cats, and Gunboat.

B. Mats, Strands, Roving, Direction, and Weights

Fibers are woven into matting and cloth for construction. Depending on the application, different weights of cloth and cloth patterns and weaves may be more appropriate for the job.

Cloth weight refers to the weight per square yard (or meter) of the cloth. A square yard of nine ounce cloth weighs nine ounces. The heavier the cloth, the stronger it is in a laminate.

Fibers carry loads along their length, so cloth weaves have directionality to their strength. Most builders use several layers of cloth with different orientations to give good universal strength to hulls. Specific FRP applications with strict load-path requirements may have more unidirectional fiber layering – for example, a chainplate manufactured from carbon fiber may use unidirectional fiber.

Cloth – fiberglass cloth is commonly used on outer layers of composites. Cloth may have unidirectional or bidirectional strength. Bidirectional cloths have maximum load strengths in two perpendicular directions. Variations on weaves like a modified twill allow a more flexible cloth for better shaping around complex molds.

Mat – is omnidirectional strands of fiber compressed into a cloth. This is often held together with a resin soluble glue, which makes mat great at conforming to mold shapes without folding and bunching as it collapses when wetted. Because the strands do not align, fiber strength is the same in all directions.

Woven Roving – a heavier cloth made from larger bundles of strands. Woven roving allows for quicker buildup of material and strand weight.

Most FRP layups include multiple layers of different cloth and mat. Finished layers may be finer cloth over courser cloth, over woven roving and mat.

Three primary resins are in common use in marine construction – polyester , vinylester , and epoxy . All resins have materials safety concerns and require care in their use and handling.

Polyester is the least expensive and requires breathing protection because of the VOC emission (Volatile Organic Compounds…nasty, smelly fumes). It doesn’t have good bonding/gluing capability, and should only be used with glass fibers for structural building. Some polyester resins are referred to as “isophthalic” resins.

Vinylester is chemically similar to a hybrid of polyester and epoxy, and performs best with fiberglass. It shouldn’t be used in high strength applications with carbon or aramid fibers. It has some adhesive qualities which polyester lacks, it shrinks less during curing, and has better impact resistance.

The added strength of vinylester coupled with increased water resistance makes it an attractive option for many catamaran builders. It costs less than epoxy, but still has better performance than polyester.

Epoxy is the most expensive, but is three times the strength of the others. It offers the best adhesion and the only resin for building structural elements with carbon and aramid. It resists water intrusion better than the other resins, resists blisters, emits no VOCs, and shrinks less. The major drawback is it is more brittle if it takes an impact.

While epoxy is “the best” in terms of strength and ease of building, there are many applications where other resins are appropriate. Budget is a big driver – a boat made from E-Glass doesn’t need epoxy resin, and considerable cost savings to meet a construction price target may drive the choice.

They can build quality boats from all material combinations, but price and performance will drive materials choices to keep some boats more affordable.

2. Cored Construction

What’s the best way to make fiberglass strong? To a point, you can make it thicker. As it gets thicker, it gets heavier. A hollow shape can take more compressive load than a solid one of the same weight, and the same principle applies to fiberglass construction.

Consider an I-Beam used in building construction. It has the same strength (or more) as a solid rectangular beam of similar mass. The compressive load on the beam is supported by the outside edges of the material, the metal in the middle doesn’t contribute much to the strength. So we can remove metal to get the “I” shape while still keeping those sides rigid, making a lighter girder with less material.

The same principle applies to cored construction with fiberglass. Making a sandwich of two layers of fiberglass with a light core between them allows for the greater strength with weight savings.

There are drawbacks – the biggest risk is damage which breaks the skin, which can let water into the core. Earlier cored construction used materials prone to saturation and rot if they got wet. Some builders opt to do cored construction above the waterline and solid below to minimize some of these risks.

But the advantages in weight savings and increased stiffness offset the drawbacks, and there may be a few other side effects like sound and temperature insulation. Like resins and fibers, core materials offer distinct advantages, disadvantages and price points.

Most builders have adopted a hybrid approach, building solid hulls below the waterline, and cored hulls and decks above. This gives a balance of weight and safety.

A. Balsa Core

Balsa is light and inexpensive. The first cored construction used balsa, but it has the disadvantage of being wood. As a natural material, if it gets wet it can rot and break down. Builders use “end grain” balsa – shorter cross cut sections – to prevent wicking of water if there is an intrusion.

B. Foam Core

Closed cell foam cores give good strength to weight savings while minimizing water intrusion. If you get water in the core, it won’t spread very far. Divinycell is a popular PVC foam core, though there are several choices with different densities and compressive strengths.

Some foam cores are not suitable for heat treatment, but infused or vacuum bagged boats like the Outremer and PDQ do well with it.

C. Honeycomb

Honeycomb cores are often the most expensive, but also give some of the best strength to weight ratios. Honeycombed cells made from resin cured aramid papers are some of the best, but also among the most costly. They offer good stiffness, but can be hard to shape. Aluminum and other resin-infused papers are other core materials builders can choose from.

3. Construction and Resin

When building a hull, there are optimal ratios of fiber to resin saturation for target strength and weight. Too little resin and you may not have enough strength (or worse, voids and gaps), and too much, and you’re just adding weight without adding strength. Resins are also a significant material cost in building the boat, so over application not only increases weight but adds cost.

There are many ways to assemble the cores, fibers and resins to build a finished laminate hull – we’re addressing the most common in boat building. Each approach has strengths and limitations, and an impact on the bottom-line cost to build the boat. Any voids or air pockets in the laminate can be disastrous; these techniques have been developed to increase saturation and reduce the risk of voids.

A. Hand Layup / Open Molding

As the name implies, this is the application of resin by hand to cloth as it’s laid into a mold. Wetting is done with a brush, and the laminate is rolled out to remove any air pockets and voids. This is the simplest way to lay up fiberglass, but also the least precise and consistent and will use the most resin.

Skilled craftsmen have built some of the finest vessels in the world this way. Though it’s more popular with monohulls, which are less sensitive to weight, many catamarans built with hand layups on open molds are still out cruising and performing well.

B. Spraying

Using chopped-strand fiber mixed with resin, a “chopper gun” can spray the mixture into a mold to lay down the composite. A consistent thickness can be difficult, but this is a low cost construction technique which makes a very resin-rich laminate. Using sprayed fibers gives lower strength in all directions compared to meticulously laid down mat and bi-directional cloth. But it is a quick technique popular with mass produced, smaller boats.

It is an excellent technique for parts with complex geometry where weight is not an issue, but you will not see it often in catamaran construction. It’s heavy with resin without any resultant increase in strength.

C. Vacuum Bagging (Wet layup)

When an open molded component has been laid up and wetted with resin, vacuum bagging takes the process a step further. After the wetting is complete, air tight plastic bagging is secured around the wetted area, and the air is pumped out of the bag. The vacuum pulls excess resin out and collapses air pockets.

The goal is to get thorough wetting and produce as strong a laminate as possible without excess resin. Knysa and Leopard are two builders that use vacuum bagging on their hulls to reduce weight.

D. Resin Infusion

For resin infusion the cloth, matting and core is laid in place dry, then sealed in an air-tight bag. A vacuum pump attaches to one side of the bag, and on the other a feed for resin. The vacuum sucks the air out of the dry cloth stack, then pulls the resin through the stack, infusing and wetting it.

Resin infusion, when done right, gives the lightest, strongest laminates with no voids and the minimum resin weight for maximum strength. SCRIMP is a variant of the resin infusion process used by some builders, including TPI which build many early Lagoon cats.

E. Pre-preg

Using pre-preg (for “Pre Impregnated”) cloth for your laminating gets rid of the resin bucket. They manufacture cloth with a partially catalyzed resin pressed into it, then it’s chilled or frozen to stop the curing process. There is no need for seperately mixed resins, and there’s no worry your resin might “go off” and harden before you’re done wetting the cloth. Instead, the cloth is assembled, vacuumed, then heated to kick off the curing process.

There are both advantages and disadvantages to using pre-preg for your laminate work. The big disadvantage is the cost; it is most expensive material to use. You also need to chill and store the cloth until you need it, though some can be at room temperature for a couple of weeks without kicking off. And you need an oven which requires some clever tricks if you’re building a forty or fifty foot boat.

But the strength to weight ratio will always be perfect. High tech honeycomb cores are best suited to pre-preg lamination, and without racing against resin cure times, you can ensure perfect cloth placement and precise layout in the build process.

The primary use for pre-preg in boating is high performance race boats. With catamarans, pre-preg may be used high load parts, like Gunboat does for foils and rudders.

4. Industry Examples

Across the catamaran building industry you’ll find almost all the above techniques and materials used, though some are less common. You aren’t likely to find chopped strand sprayed layups in ocean going cats, and hand layups can lead to heavier hulls than weight sensitive catamaran designers prefer. Most manufacturers have moved to vacuum bagging or resin infusion, with a few of the highest end boats using pre-preg for key components.

Built by Robertson & Caine in South Africa, the hull material is vacuum bagged, end-grain balsa-cored E-glass with polyester.

Hand laid, bagged vinylester over an Airex foam core in the hulls.

Earlier Prout catamarans like the Snowgoose 34 featured hand laid solid FRP hulls and decks. Over time they switched to foam or balsa cores for decks and above the waterline.

Older PDQ boats were made from vacuum bagged vinylester – solid below the waterline and cored with CoreCell foam above the waterline and in decks. Newer PDQ models switched to epoxy resin.

All glass is vacuum bagged. Below the waterline is solid E-glass and vinylester. The rest is unidirectional, bidirectional, and triaxial cloths over a Nida-Core polypropylene honeycomb core with isophthalic and vinylester resins.

The Gemini cats are built with a solid hand layup of woven roving and fiberglass mat and polyester resin. Decks are cored with end grain balsa. The Gemini 3200 introduced vinylester resin into the layup to prevent blistering.

Older Lagoons were SCRIMP infused vinylester with and end grain balsa core above the waterline and in the decks.

Newer Lagoon catamarans use polyester and vinylester resins, also infused with balsa cores above the waterline and solid below.

With a carbon fiber inner skin, Catana also uses Twaron aramid fibers in the sandwiched hull over a foam core.

Fontaine Pajot

Primary hull construction is resin-infused vinylester with a balsa cored hull and deck.

Beneath the waterline, Outremer uses a single layer, solid vinylester laminate for safety. The hulls and deck are vinylester with a Divinycell foam core. They stiffen certain components with carbon for rigidity and durability.

Gunboat hulls are epoxy infused carbon fiber with a Nomex honeycomb core. They build dagger boards and other high load components with pre-preg carbon.

- Tags Buying Advice

By BJ Porter

Owner of Hallberg Rassy 53; world explorer.

3 replies on “Catamaran Construction – Hulls, Laminates, and Composites”

Excelent. Thank you for this I learned allot. Johan

Very straight forward information. Thankyou for doing this.

Damn…What an Amazingly Informative Article. *Cheers*

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Hull Hydrodynamics and Design

2.1 Resistance Components on a Hull

Since the main objective of this project involves investigating the resistance of a hull and how it is affected by the introduction of hydrofoils, it is important to understand the components of this hydrodynamic resistance. Additional components will be added with the addition of the lifting foils and the interaction between the hulls and foils will also need to be accounted for. These will be discussed in chapter 3.

2.1.1 Viscous Resistance

The first and most obvious resistance comportent is the visco 3 resistance resulting from the hull skin friction and viscous pressure drag. Viscous resistance is^ç pendent on Reynolds number and so for equivalent scaling of the model we would require Reynolds similaijify.

2.1.2 Form Resistance

Another component is the form resistance. This resistance component results from the shape of the hull as the fluid is forced to change direction (and speed as a result) in order to travel around the hull. This is modelled by simply adding a form factor (1+k) to the viscous resistance, which is roughly equivalent to the average increase in speed required to travel around the hull.

2.1.3 Wave Resistance

The next component is wave resistance. This resistance component results from the additional energy required to create the waves resulting from the hull travelling through the water. These waves may be divided into the following categories - diverging (from bow and stern) and transverse waves. For equivalent scaling, Froude similarity is required. Note: fluctuations in wave resistance are as a result of both interference of the bow and stern wave system (as discussed by Bertram [Ber02]) and the wave interference of the two demi-hulls to be discussed in Chapter 2.1.9)

2.1.4 Spray Resistance

This resistance component is a result of the energy required to produce the spray. It is however expected that since the given hull shape is semi-displacement and the speed range is not very high, this is not expected to be a very large component.

2.1.5 Interference Resistance due to foils

This is the added resistance due to interference of the boundary layers of the hull and foils where they join. This is discussed in section 3.2.4 where the low pressure above the foil creates a downward suction on the hull, which in turn cancels some of the lift generated by the foils. In terms of hull resistance, the reduced pressure and associated increase in flow in the gap between the hull and foils would result in an increase in viscous resistance. This may be factored by a change in the form factor on the hull due to foils. Since only a percentage of the hull is affected and at speeds where the effect is strong, the hull will be elevated from the water substantially, this is not expected to be large, but may account for errors in assuming minimal interference between hull and foils.

The wave interference of the foils and hull niay be pMisidtereo as acting on either the hydrofoils or the hull. It is a function of speed and positioning of foils. Migjiotte [Mig9^] indicates that these effects are both significant but no means of determining them theoretically or empirically are available.

2.1.6 Heel Resistance

This is simply the change in resistance (primarily wave and viscous) due to heel. An empirical equation describing the coefficient of resistance and its corresponding formula is found in Larsson et al. [LE02] however this is for a monohull, which behaves very differently to a catamaran. The main difference is that for a catamaran, the WSA is remarkably reduced with heel as the one hull emerges from the water, thus reducing the viscous resistance. It is however interesting to note that from the formula, the effect of heel resistance increases with the square of the Froude number. It must also be borne in mind that heel has other implications also as the force vector on the sail gains a vertical component with heel. Normally this is assumed to cancel with the upward component on rudders and daggerboards [LE02] but with the addition of lifting foils there is an increase in sideward component due to the heel angle and a righting moment due to the free surface effects.

2.1.7 Induced Resistance

Normally this resistance is associated with hydrofoils and is explained in more detail in chapter 3.2.1. If the hull is thin, it may be thought of as a symmetric hydrofoil of low aspect ratio, operating in the vertical plane. If there is an angle of attack or leeway angle on the hull, there will be a resulting side force and induced resistance. Since the effective aspect ratio and area of the hull are relatively small, the daggerboards and rudders will offer most of the resistance to leeway, and induced resistance on the hull is expected to be very small.

2.1.8 Resistance due to Submerged Transom

Transom sterns have several advantages, the most important being that the wetted area (and hence viscous resistance) is less than that of a hull with a streamlined stern while still producing an equivalent wave pattern. [DD97]

When the transom of the hull is submerged at low speeds, the flow does not separate cleanly off the transom and therefore produces a large stern wave due to the sudden change in flow direction. At higher speeds, the velocity pressure of the flow under the transom is sufficient for separation resulting in 'smooth' flow off the stern and reduced resistance (see figure 2.1 below). This means.that the LCG may be placed further aft for high speeds, but the transom must be preferably in Ii tie with the water level for low speeds.

Doctors et al. [Doc98] quantified the speed at vhich flow off the submerged transom becomes 'cleanly separated' in terms of a Froude number based on depth of the transom below the static waterline (d). This critical Froude number is defined as follows...

2.1.9 Resistance due to Interference between Demihulls

• Induced resistance on hulls due to asymmetric flow around demi-hulls This results from the flow over the two demihulls affecting one another. This effect is a function of Froude number and separation distance. As described by Couser et al. [CWM97] the flow about the demi-hulls centrelines is not symmetric resulting in a relative angle of attack and in turn a side force and induced drag force resulting on each hull (lift and induced drag as described above). The side forces on either hull cancel one another out. However, the induced drag on both demi-hulls acts in the same direction and therefore they add. It is logical to assume (as demonstrated by [CWM97]) that the greater the separation distance and the lower the speed, the less of an effect this has. It was also noted that even for smaller separation distances and narrow hulls (high effective aspect ratio) the resulting induced drag coefficient is much smaller than the drag coefficient for the demi-hulls alone and may therefore be ignored. This is again supported by [CMAP97] who states that the side force on the demihulls decreases rapidly with increasing separation while the drag remains relatively constant. This implies induced drag is not significant. The generation of side force is however significant and may be required for structural calculations. It was also noted that this side force is almost always outwards however for small separations the venturi effect may dominate over the impinging bow wave effect and cause

, suction between the hulls.

Wave and viscous interference between demi-hulls i—

Figure 2.2 a) Graph of interference factor (t) vs Froude (Fr) number taken from IM91

The wave patterns of the two demihulls may also affect each other depending on speed (Fr) and separation distance. A further effect is that asymmetric flow around the demi-hulls effects the viscous flow i.e. boundary layer formation. Referring to [IM91], this type of interference resistance is a function of separation distance and Froude number. The results of [IM91] show that wave interference causes large fluctuations in wave resistance below Fr = 0.5 and a virtually constant and small interference factor above Fr = 0.6. This effect is diminished with increasing separation. Referring ahead to Chapter 2.8, the Froude number (FrL) range of the hull which was ultimately designed as our representative hull (RH1) is 0 -1.06. This corresponds to the range examined by [IM91].

Alternatively Turner et al. [TT68] provide a series of results from model testing to determine parameters affecting interference drag. The dependence on separation distance and Froude number is again shown and the following graph uses the data presented in [TT68]. It shows that at FrL ~ 0.27 and 0.33 there is minimum interference and at (B-2b)/L = 0.266 (same as RH1 - see 2.8) there are large fluctuations in interference with Froude number. These fluctuations are greatly reduced at higher separations.

2.2 Stability

Included in the main objective of this thesis is that the hydrofoil support system that is used in the final result will provide stable support throughout the given speed range. It is therefore important to consider the effect that the introduction of a hydrofoil support system will have on the stability of the sailing catamaran.

2.2.1 Pitch stability (Porpoising and Pitchpole)

As mentioned in chapter 1, pitch stability tends to be a problem for sailing catamarans due to the elevated thrust position and the fine demi-hull bows which offer very little buoyancy and planing effects to resist a forward pitching motion.

With the addition of the lifting foils, the COD would be lowered thus increasing the pitching moment arm between the thrust force and the hydrodynamic resistance. On the other hand the addition of the foils should reduce the resistance so it is unclear whether the pitching moment will be increased or reduced for a particular speed, depending on the positioning of the foils. What is clear is that the higher the hulls are raised by the lifting foils, the greater the angle at which pitchpole occurs. In addition to that the lifting foils should increase the speed of the boat for a given condition so these two factors will increase the severity of the pitchpole if it were to occur on foil support.

The terminal velocity of a conventional sailing catamaran is determined by the speed at which the large pitching moment has lowered the bows sufficiently so that the deck starts to flood. This results in an unstable condition where the bows dig in completely and the boat pitch-poles.

Porpoising is a dynamic instability caused by the combined oscillations of boat pitch and heave, which either remains constant (not a comfortable ride) or increasing in amplitude (Risk of pitch-pole). The general rule for avoiding porpoising is to reduce the trim angle i.e. to move the COG forwards - counter trim by stern. For the case of a hydrofoil-supported boat, the hydrofoils act as natural dampeners for pitch and heave and so this instability may be avoided by careful balancing of the hydrofoils. Given the elevated position of the thrust force which will always tend to trim the bow down, it is unlikely that this will be a problem for sailing catamarans unless excessive lift is being produced on the hydrofoils which 'overpowers' the dampening of the free surface effects.

Since the dagger-boards (to which the main foil is attached) are found amidships the percentage of the lift force created by the aft foils is dependent on how far aft of^ainidships the COG is positioned. Ideally one would desire an even distribution of load on the foils fc jr. good pitch ¡stability. The COG however is fairly dependent on the construction of the boat - particularly wdeffi inboard engines and water and fuel tanks are mounted. Practically it is found to be close to 45%, which implies veiy poor distribution of load.

2.2.2 Yaw Stability

Yaw stability is defined as the ability for an object to remain 'pointing' in the direction in which it is travelling. In terms of boats, it is defined as the tendency to resist rotation about the vertical axis (z-axis, as defined in naval architecture). Another definition [Ber02] is - "the ability to move straight ahead in the absence of external disturbances at one rudder angle"

Yaw stability is achieved by one simple criterion- The COG remains in front of the CLR. This may be illustrated by a dart or arrow. When travelling through the air in the conventional direction, it is easily seen that it remains yaw stable and the reverse can be said about a dart or arrow travelling backwards.

Most sailing catamarans are designed with the daggerboards amidships and rudders near the stern and the COG not far aft of amidships. As a result the CLR is usually well aft of the COG. The only condition where yaw instability is likely is when the boat begins to pitchpole so that the CLR is moved forward significantly. This is a case of pith instability in any case. The effect of hydrofoils of yaw stability is not likely to be significant if the foils are attached to the rudders and daggerboards but a canard foil at the bow would shift the CLR forward, thus increasing the likelihood of yaw instability.

2.2.3 Sudden Loss in Foil Lift

The problem with foils as they near the surface is that of ventilation. This will be discussed in more detail in chapter 3 but in short, results in a sudden loss in lift. This would result in the section of boat supported by the ventilated foil dropping suddenly. This would increase the hull resistance at that point and may result in either yaw or pitch instability, depending on which foil becomes ventilated.

2.2.4 Other Aspects on Stability