- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

- Best Marine Electronics & Technology

Monthly Maintenance: Aluminum Corrosion

- By Steve D’Antonio

- Updated: May 15, 2017

To better understand corrosion, check out a galvanic-series chart. It organizes metals from most noble (most corrosion-resistant, or cathodic) to least noble (least corrosion-resistant, or anodic). Depending on the source, the series might be organized with cathodic metals either at the top or bottom; the version included in the American Boat and Yacht Council Standards establishes the most-cathodic metals at the bottom, where the kings of corrosion resistance (graphite, platinum and titanium, among others) reside. At the top end of the series, the most corrosion-prone metals (magnesium, zinc and aluminum) will be found. The chart is available online with a simple search for “galvanic series.”

Aluminum is among the most corrosion-prone metals. This might seem counterintuitive in that aluminum is ubiquitous in the world of boatbuilding, and is used for everything from spars and outboards to deck hardware and even complete vessels. In fact, it’s also used as a sacrificial anode, which is telling. Aluminum, of which there are many alloys, is a metal of many contradictions.

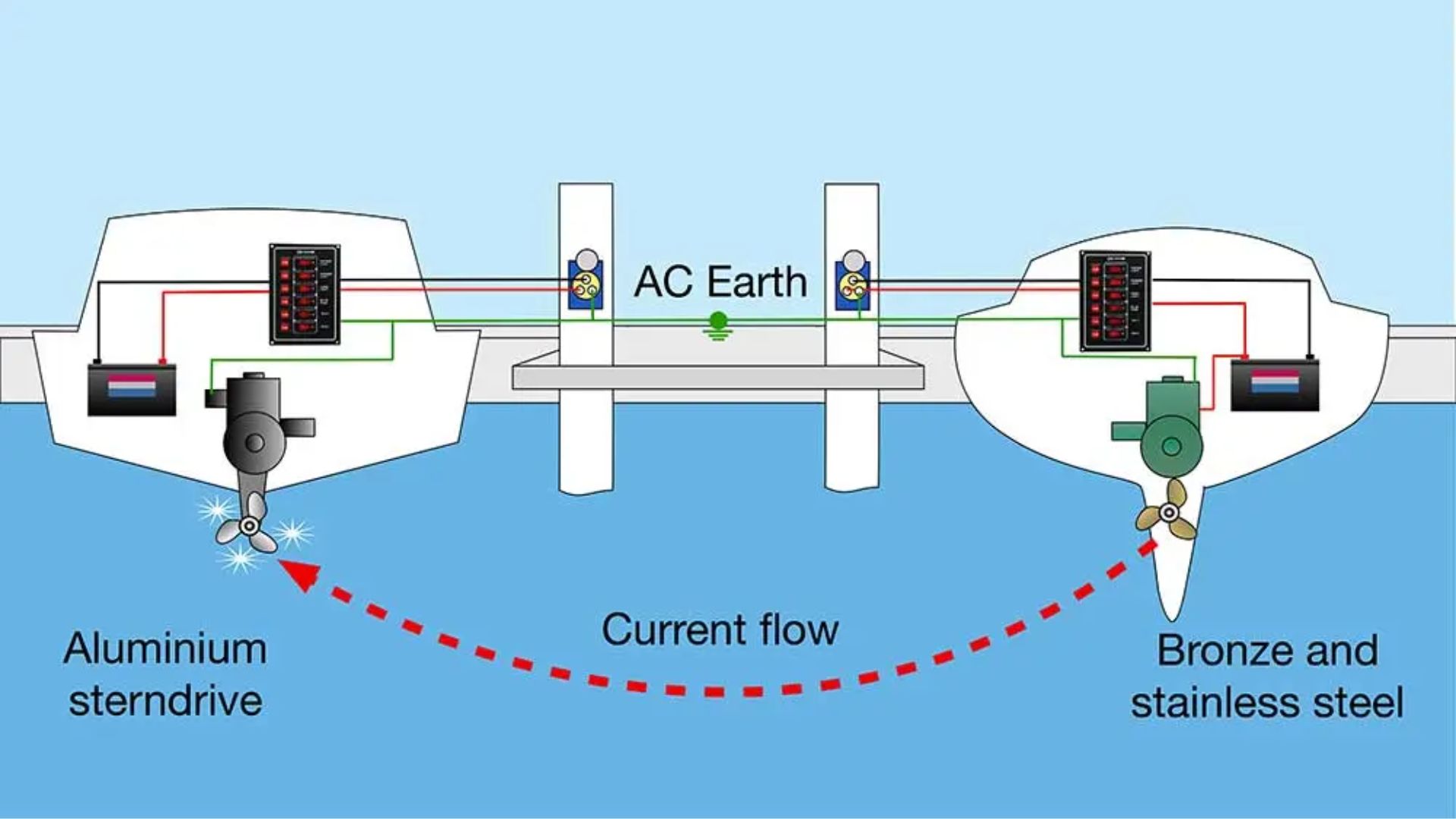

Aluminum most commonly falls prey to two types of corrosion: galvanic and poultice. Galvanic corrosion occurs when aluminum is placed in contact with another metal, establishing a galvanic cell; this can happen either directly or via a wire or other electrical connection, with both being immersed in an electrolyte. That’s straightforward enough, but a host of details are worthy of discussion in order to understand how this works.

Virtually every other metal — with the exception of zinc and magnesium — is more noble than aluminum, and as such they all will cause aluminum to corrode at varying rates when the two are in contact. The farther the other metal is away from aluminum on the galvanic series, the more rapidly the aluminum will corrode. Therefore, while stainless steel will cause aluminum to corrode when the two are in contact under these conditions, the rate is not especially quick, and as such, the two are considered compatible. On the other hand, copper and copper alloys, including brass and bronze, are located farther away from aluminum in the series, and are therefore far more harmful; they are considered entirely incompatible with aluminum. Installing a bronze sail track, for instance, directly on an aluminum spar, would be considered a serious corrosion error.

The electrolyte mentioned earlier is typically seawater; however, fresh water will also allow the reaction to occur, albeit at a slower pace. Furthermore, while immersion in the electrolyte completes the galvanic cell, it’s not essential; exposure to simple atmospheric humidity, spray or rain will suffice, once again at a slower pace. Galvanic corrosion can be prevented in one of two ways: by isolating aluminum from incompatible metals and/or by the use of sacrificial anodes.

The other malady to which aluminum is susceptible is called poultice corrosion. This is referred to as simple corrosion, in that no other metals are involved. When exposed to air, aluminum almost instantly develops a tough transparent coating that serves as a corrosion inhibitor. Even underwater, provided it’s not stagnant, aluminum is exposed to enough dissolved oxygen for this coating to form. If aluminum is starved of oxygen, however, and it remains exposed to moisture, the environment becomes ideal for the formation of poultice corrosion. Because the oxide coating cannot form without oxygen, the aluminum becomes active; it corrodes, and in the process forms a white byproduct called aluminum hydroxide, which resembles freezer-burned vanilla ice cream.

The most common conditions for poultice corrosion occur when stagnant water is trapped against aluminum, beneath blistered paint, under a gasket or insulator, beneath spreader boots, or even where it comes into contact with wood, which by its porous nature retains water. Other than painting, poultice corrosion is prevented by ensuring aluminum is continually exposed to oxygen.

Steve D’Antonio offers services for boat owners and buyers through Steve D’Antonio Marine Consulting www.stevedmarineconsulting.com.

- More: corrosion , How To , monthly maintenance

- More How To

How to Protect Your Spars from Corrosion

Sailing totem refit series: the forward head makeover, fatty goodlander: dealing with chafe while cruising, how to rig everything in your favor, one mile offshore with christian williams, winds of change.

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

pros-and-cons-of-aluminum-sailboat

I would suggest also to see what is Strongall from Meta, a well known boat maker in France

Mario Jugend

Great article, do you know Lloyds Ship Brisbane, how would you classify them? Thanks

Thanks for a very useful and well done story comparing the two materials. Makes aluminum look more interesting - like Garcia boats. Well done!

Howard Conant

Shawn, Thanks for the good article.More than 30 years ago we embarked on a project to build our 51’ aluminum cutter Holy Grail. Please see www.sail-our-world.com. I still think aluminum is the finest boat building material available for sailboats.

In your first paragraph, “What are the pros and cons of an aluminum sailboat?” what follows in bold might lead to some confusion, as the sentences do not identify which assertions are Pros and which are Cons. Also, on your statemet that aluminum needs painting every 2 or 3 years, that is only, IF YOU PAINT IT. But why would you? Agreed, aluminum does not like paint. And fortunately, it does not NEED paint. Our Holy Grail is only painted under the waterline and on deck to create a nonskid walking surface. Otherwise, paint is not needed. In 29 years of service, the underbody primer coat of paint has remained perfect. It was applied correctly and has served as a barrier coat which has never needed renewing. Further, it is that crucial coat that protects the alu.

Does anyone have any experience with Herley 3400 Solar Power Catamarans? Is the company known for good build quality?

I’m seriously interested in buying one.

https://powercat.herleyboats.com/powercat-3400

You got my attention when you said that aluminum is stronger than fiberglass since fiberglass tends to crack when under stress. This is something that I will share with my husband since he is planning to buy a quintrex boat. He said that he wanted to use the boat every Sunday for his fishing and boating trips, and it makes sense to choose a boat that will last for a long time.

We are looking at a boat made in Italy from Cantieri Navali. I trust made in Italy but does anyone know if it’s a good make? Thank you!

Elina Brooks

It’s good to know that while aluminum might be lighter, it is ten times stronger than fiberglass, so the boat will only dent during a collision. I’ll be settling in a house near the coast starting this summer, so I wanted to get a boat I can use from time to time. I’ll be sure to consider one made of aluminum once I find a boat dealer to contact about my purchase soon. https://www.xtremeboatspc.com/

Leave a comment

Own your first boat within a year on any budget.

A sailboat doesn't have to be expensive if you know what you're doing. If you want to learn how to make your sailing dream reality within a year, leave your email and I'll send you free updates . I don't like spam - I will only send helpful content.

Ready to Own Your First Boat?

Just tell us the best email address to send your tips to:

Navigating the Waves: A Comprehensive Guide to Aluminum Boat Maintenance

Introduction:

Aluminum boats are prized for their durability, versatility, and resistance to corrosion. Whether you’re a seasoned boat owner or a newcomer to the maritime world, proper maintenance is key to ensuring your aluminum vessel remains seaworthy for years to come. In this comprehensive guide, we’ll delve into the intricacies of aluminum boat maintenance, covering everything from routine care to tackling specific issues. So, grab your toolkit and let’s embark on the journey of preserving the longevity and performance of your aluminum boat.

Understanding Aluminum

Before we dive into maintenance tips, it’s crucial to understand the characteristics of aluminum. Aluminum is a lightweight metal known for its resistance to rust and corrosion, making it a popular choice for boat construction. However, it is not entirely immune to environmental factors. Over time, exposure to water, salt, and other elements can take a toll on your boat’s appearance and structural integrity.

Routine Maintenance Practices

- Cleaning and Washing

Regular cleaning is the foundation of effective aluminum boat maintenance. Saltwater, pollutants, and debris can accumulate on the hull, leading to corrosion and reduced performance. Use a mild detergent or boat soap and a soft brush to gently scrub the boat’s surfaces. Rinse thoroughly with freshwater to remove any residue.

- Avoid Harsh Cleaning Agents

While it’s essential to keep your boat clean, avoid using abrasive or harsh cleaning agents. These can damage the protective oxide layer on the aluminum surface. Opt for cleaners specifically designed for aluminum boats, and always follow the manufacturer’s recommendations.

- Polishing for Shine

To maintain the aesthetic appeal of your aluminum boat, consider periodic polishing. Aluminum polishes help remove oxidation and restore the boat’s shine. Apply the polish using a soft cloth or buffer, working in small sections for thorough coverage. Polishing not only enhances the appearance but also contributes to the protective layer.

- Inspecting for Corrosion

Regularly inspect your boat for signs of corrosion, especially in areas prone to water exposure. Check for pitting, discoloration, or any unusual roughness on the aluminum surface. Early detection allows for prompt intervention and prevents corrosion from spreading.

- Anode Check

Aluminum boats often use sacrificial anodes to protect against galvanic corrosion. Inspect these anodes regularly and replace them if more than half of their original size has eroded. Anodes are crucial for diverting corrosive elements away from vital components.

Below-the-Waterline Maintenance

- Anti-Fouling Paint

For boats that spend extended periods in the water, consider applying anti-fouling paint below the waterline. This helps prevent the growth of barnacles, algae, and other marine organisms that can compromise the boat’s performance. Choose a paint compatible with aluminum surfaces.

- Checking Seams and Welds

Examine the seams and welds below the waterline for any signs of stress, cracks, or separation. These vulnerable areas require close attention, and any issues should be addressed promptly to prevent water intrusion and corrosion.

Dealing with Corrosion

- Surface Oxidation Removal

Surface oxidation, often seen as a chalky or white residue, can be removed using a dedicated aluminum cleaner or a mixture of vinegar and water. Gently scrub the affected areas and rinse thoroughly. This step is crucial for maintaining the protective oxide layer.

- Aluminum Brightening

For more stubborn oxidation, consider using aluminum brighteners. These products are designed to restore the luster of the metal. Follow the manufacturer’s instructions and wear protective gear when using brightening agents.

- Pitting and Corrosion Repair

If corrosion has progressed to the point of pitting, repair becomes essential. Sand the affected areas, apply a conversion coating, and use epoxy-based fillers to level the surface. This process helps prevent further corrosion and maintains the structural integrity of the boat.

Engine and Mechanical Components

- Flushing the Engine

After every outing, flush the engine with freshwater to remove salt and debris. This is particularly important for boats used in saltwater environments. Follow the manufacturer’s guidelines for the proper flushing procedure.

- Lubricating Moving Parts

Regularly lubricate moving parts, such as steering components, throttle cables, and hinges, to prevent friction-related wear. Use marine-grade lubricants suitable for aluminum components.

- Inspecting Electrical Connections

Check all electrical connections for signs of corrosion. Clean and apply a corrosion inhibitor to terminals and connectors. Proper electrical maintenance ensures the reliability of crucial systems on your boat.

Trailer Maintenance

- Rinsing the Trailer

If your aluminum boat sits on a trailer, make sure to rinse the trailer thoroughly after each launch. Saltwater residue can corrode the trailer, leading to structural issues over time.

- Checking Trailer Components

Regularly inspect the trailer components, including the axles, brakes, and lights. Ensure that the trailer is in good working condition to avoid any complications during transportation.

Storage and Off-Season Care

- Covering the Boat

When not in use, cover your aluminum boat to protect it from the elements. A good-quality boat cover shields the vessel from UV rays, rain, and debris. This is especially crucial during the off-season.

- Proper Storage

If storing your boat for an extended period, choose a location that provides protection from extreme weather conditions. Indoor storage is ideal, but if that’s not possible, use blocks or a cradle to lift the boat off the ground and cover it securely.

- Winterizing the Engine

For boats in regions with freezing temperatures, winterizing the engine is a critical step. This involves draining water from the cooling system, adding antifreeze, and protecting the engine from potential frost damage.

DIY Repairs and Upgrades

- Patch Small Dents and Scratches

Small dents and scratches are inevitable, but they can be addressed with DIY repairs. Use an aluminum-friendly filler to patch minor imperfections. Sand and paint the repaired area to match the boat’s finish.

- Upgrading Hardware

Consider upgrading hardware such as cleats, hinges, or latches if they show signs of wear. Stainless steel or corrosion-resistant alternatives can enhance both functionality and aesthetics.

Conclusion:

Maintaining an aluminum boat is a holistic endeavor that involves a combination of routine care, vigilance, and timely interventions. By incorporating these maintenance practices into your boating routine, you not only preserve the structural integrity and performance of your vessel but also ensure countless hours of enjoyment on the water. Remember, a well-maintained aluminum boat is a testament to your commitment to safe and responsible boating. So, set sail with confidence, knowing that your aluminum companion is ready to navigate the waves for years to come.

- A: Aluminum is favored for its lightweight nature, durability, and resistance to corrosion, making it ideal for boat manufacturing.

- A: Regular cleaning is essential; aim for at least once a month, or more frequently if the boat is exposed to saltwater.

- A: It’s recommended to use cleaners specifically designed for aluminum boats to avoid damaging the protective oxide layer.

- A: Surface oxidation can be removed using a dedicated aluminum cleaner or a mixture of vinegar and water.

- A: Sacrificial anodes protect against galvanic corrosion by diverting corrosive elements away from vital components.

- A: Regularly inspect anodes and replace them if more than half of their original size has eroded.

- A: Anti-fouling paint is used below the waterline to prevent the growth of marine organisms; it’s recommended for boats in the water for extended periods.

- A: Regular inspections are crucial, at least every few months, to catch any signs of stress, cracks, or separation.

- A: Yes, aluminum brighteners are effective for removing stubborn oxidation and restoring the luster of the metal.

- Q: What should I use to lubricate moving parts on my aluminum boat?

- A: Use marine-grade lubricants suitable for aluminum components to prevent friction-related wear.

- Q: How frequently should I flush the engine of my aluminum boat?

- A: After every outing, especially in saltwater, flush the engine with freshwater to remove salt and debris.

- Q: How do I address corrosion on electrical connections?

- A: Clean electrical connections regularly and apply a corrosion inhibitor to terminals and connectors.

- Q: Should I apply wax or polish to my aluminum boat?

- A: Yes, periodic waxing or polishing helps protect the aluminum surface and enhances the boat’s appearance.

- Q: What type of paint should I use for touch-ups on my aluminum boat?

- A: Use marine-grade paints suitable for aluminum surfaces for touch-ups or repairs.

- Q: How do I patch small dents and scratches on my aluminum boat?

- A: Use an aluminum-friendly filler, sand the repaired area, and paint to match the boat’s finish.

- Q: Can I upgrade hardware on my aluminum boat?

- A: Yes, consider upgrading hardware like cleats or hinges with stainless steel or corrosion-resistant alternatives.

- Q: How do I prevent trailer corrosion?

- A: Rinse the trailer thoroughly after each launch, especially if it has been in saltwater.

- Q: What is the purpose of winterizing the engine?

- A: Winterizing protects the engine from potential frost damage in regions with freezing temperatures.

- Q: How should I store my aluminum boat during the off-season?

- A: Store your boat in a covered area if possible, and use blocks or a cradle to lift it off the ground.

- Q: Is it necessary to cover my aluminum boat when not in use?

- A: Yes, covering the boat protects it from UV rays, rain, and debris, especially during the off-season.

- Q: How do I know if my aluminum boat has pitting corrosion?

- A: Pitting appears as small, localized indentations; regularly inspect the boat for signs of corrosion.

- Q: Can I use household vinegar to clean my aluminum boat?

- A: Yes, a mixture of vinegar and water is an effective and environmentally friendly cleaner for aluminum.

- Q: Is it essential to balance the boat on blocks during storage?

- A: Balancing the boat on blocks or a cradle during storage prevents stress on the hull and ensures stability.

- Q: What should I look for when inspecting electrical connections?

- A: Check for signs of corrosion, loose connections, or frayed wires during routine electrical inspections.

- Q: Can I use automotive wax on my aluminum boat?

- A: It’s recommended to use marine-grade wax or polish specifically formulated for aluminum boat surfaces.

- Q: How do I choose the right anti-fouling paint for my aluminum boat?

- A: Choose anti-fouling paint compatible with aluminum and suitable for the boat’s usage (freshwater or saltwater).

- Q: What precautions should I take when applying anti-fouling paint?

- A: Follow the manufacturer’s instructions, wear protective gear, and apply the paint in a well-ventilated area.

- Q: Can I paint my aluminum boat myself, or should I hire a professional?

- A: DIY painting is possible with the right tools and materials, but hiring a professional ensures a high-quality, even finish.

- Q: How do I ensure my boat cover is properly secured?

- A: Use a snug-fitting, reinforced boat cover with secure tie-downs to prevent it from coming loose during storms.

- Q: Are there any eco-friendly options for cleaning my aluminum boat?

- A: Several eco-friendly aluminum cleaners are available, minimizing environmental impact while effectively cleaning the boat.

Maintaining an aluminum boat involves a combination of routine care, timely inspections, and protective measures. By addressing potential issues promptly and following proper maintenance practices, you can ensure the longevity and optimal performance of your aluminum vessel.

Related Posts

Comprehensive aluminum boat buying guide: a navigator’s manual.

Introduction: Navigating the world of aluminum boat purchasing requires a blend of knowledge, research, and a keen understanding of your boating needs. In this comprehensive…

Small Boat Maintenance Tips: Keeping Your Vessel Shipshape

Introduction: Owning a small boat brings a sense of freedom and adventure, but with it comes the responsibility of proper maintenance. Regular upkeep ensures your…

Better Sailing

Sailboat Maintenance Checklist

Whether your sailboat is stationary for a long time, or whether you live and travel with it, there are several key things to keep an eye on. Regular maintenance of your sailboat will ensure more years of use and better performance. Furthermore, your sailboat will be safer and it will keep its value longer. Below you’ll find a checklist for routine mission-critical checks. Some of these checks have to be performed both daily and monthly. Others require monthly and annual checks, but always make sure to inspect everything, thoroughly. Follow the steps of the list and ensure trouble-free sailing.

The engine of your sailboat is something that requires a lot of care and attention. Inspect regularly the condition of the engine and look for corrosion, as well as make sure that the outboard motor is securely in place. Daily maintenance of the engine consists of:

- Check the engine’s oil level.

- Check the belt tension.

- Transmission fluid level.

- Inspect pulleys as well as the alignment.

- Alternator and water pump belts have to be tight.

And now we’re moving on to the monthly maintenance of the engine which includes:

- Change the oil and filter of the engine.

- Clean the thru-hull.

- Clean the siphon break.

- Fill up coolant and antifreeze if needed.

- Check pump, impeller, and raw water strainer.

Finally, let’s see the annual maintenance of your sailboat’s engine:

- Test the batteries.

- Check the diesel tank for damages.

- Inspect the shaft and propeller.

- Change primary and secondary fuel filters.

- Bleed the fuel system.

Check the Bilge and Bilge Pump

The bilge is situated at the bottom part of the sailboat and collects excess water. The bilge pump is the piece that removes water from the bilge. If the bilge pump is damaged, your sailboat can even be sunk! In order to keep yourself and your boat safe, check the pump hoses for debris that could cause clogs. In case you find a leak, the first thing you should do is to taste the water. Is it freshwater or saltwater? So, every few days survey the bilge for oil, water, or fuel leaks. Moreover, it’s important to lift a central floorboard often just to ensure that the bilge is dry. Leaks can be caused by different areas. For instance, leaks that come from holes in the deck, loose hatch seals, or improperly sealed windows.

>>Also Read: Common Sailboat Problems and How to Fix Them

Always inspect probable damages to your sailboat, even if it’s in a well-maintained condition. It’s recommended to make monthly and yearly checks to make sure it stays in perfect condition. Firstly, inspect the hull, keel, and rudder and look for any damages, cracks, and blisters. Then, make sure that the drain plugs are in place. Apply gel coat restorer or a rust inhibitor to the scratches or to the rusting of your sailboat’s bodywork. Moreover, you will also need to remove your sailboat from the water, once a year. It’s easier to do this during the winter months and although this can be a costly thing to do, is really worth it. Like this, you’ll get a better image of the hull’s condition and fix anything that needs repair. Finally, remember to annually carry out anti-fouling and any re-painting or zinc replacement.

Raw Water Strainers and Freshwater Levels

Don’t forget to check your seas strainers! If you’re running your generator, heat/air conditioning, or anything that requires saltwater or raw cooling system to function, you might want to surveil your strainers. Furthermore, inspect the water flow on all of the raw water cooling systems. You have to see an easy flow of heating, Genset, refrigeration, and aircon cooling water out of the system. If the freshwater system, which is pressurized by an accumulator tank gets too low, then it throws the whole system out and thus it will not be working properly. So, it’s imperative that you never let your water tanks empty.

As for the electrical system it is recommended to check it every month. Check the condition of the wires, if they’re neatly secured, dry, and inspect their casings to see if they are intact. However, there are some sailboats that have their generator running periodically to charge them up. So, keep an eye on your battery’s charge levels. Also, the electrical lines must be in good condition to keep the electrical system on your sailboat up and running. Any damaged lines could provoke a fire hazard. To prevent electrical lines from erosion, remember to keep them clean, and use a digital multimeter to make sure everything’s working properly.

Without the battery, which is the heart of your sailboat, the engine won’t start, nor the electrical components will work. So, take good care of the battery and check it once a year, or more often, i.e. during the boating season. Keep in mind that batteries naturally degrade over time, so this is a must task to perform. You can check the battery’s charge with a digital multimeter, and the connections for corrosion. Moreover, test the batteries and check if they’re clean and dry. There are sailboats that have solar and wind power that continuously tops up the batteries. Other sailboats depend on having the generator running periodically in order to charge them up.

In case you’re running the generator you will need to check its vitals at least once a week. So, check the oil, belt, water level, and inspect for leaks and loose connections. You can see the leaks easier if you keep the Genset clean.

Oil and Filter

Remember to regularly change the oil and oil filter. In case you don’t, then it is possible to provoke damage to the engine parts. In order to change the oil, let the engine run for about seven minutes, then turn it off. Subsequently, place a container under the drain plug. Take out the drain plug and loosen the screw that is located above. Then, let the oil drain out for about 30 minutes. During this process change also the oil filter. After the oil drains out, replace the drain plug and tighten the screw. Finally, fill the engine with the proper oil.

Fridge and Freezer Temperature

The effectiveness of a fridge often depends on the temperature of the sea. Many boat refrigeration systems get a charge over time which makes them less effective. Therefore they slowly reduce the temperature gauge. So, it is recommended to change the temperature gauge at least once a week. The temperature of the fridge has to be below 5 degrees and the freezer below freezing.

Sails and Rigging

Sails and rigging have to be checked at least once a month. Firstly, look out for any chaffing where the headsail sheets attach to the clew, and also to the traveller and boom vang. Secondly, examine thoroughly if there’s any wear on the mainsail. Then, check if the cotter pins and shroud are in place and in good condition. Finally, make sure that the turnbuckles and pelican hooks on the lifeline are in good condition.

Summary- Maintenance List

Your sailboat’s maintenance needs to be taken seriously. When you’re regularly maintaining your sailboat, you also ensure its life spanning. Some basic items that require constant maintenance are the generator, the battery, the plumbing, the bilge, oil, and the fridge and fluid levels, among others. However, there are others that require monthly or yearly maintenance, such as the engine, the electrical system, the sails and rigging, the propeller, zippers, hinges, upholstery, etc. In case you can’t repair or check the condition of these parts, then consider contacting a professional to help you with the maintenance process.

Peter is the editor of Better Sailing. He has sailed for countless hours and has maintained his own boats and sailboats for years. After years of trial and error, he decided to start this website to share the knowledge.

Related Posts

Atlantic vs Pacific: Which is More Dangerous for Sailing?

Why Do Sailboats Lean?

How Does a Boat Sail Upwind? Unveiling the Mechanics of Against the Wind Sailing

How Does Sailing Work? The Physics of Sailing

- Buyer's Guide

- Destinations

- Maintenance

- Sailing Info

Hit enter to search or ESC to close.

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Best Day on the Water

- Books & Movies

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← How-To DIY

Aluminum Care

Advertisement

The best way to maintain the aluminum hardware on your boat is to wash it regularly with soap, and coat it with wax at least twice a year. If you don't do this, oxidation will sooner or later dull and discolor the surface of the aluminum.

While it's easy enough to revive neglected stainless steel, brass, or chrome with a vigorous application of polish, aluminum is more difficult to restore. You can polish it, and there are polish formulations available just for aluminum, but you should use these products with caution. Most aluminum marine hardware is anodized, and polishing can remove this surface coating, leaving the aluminum unprotected. (Read the fine print: most polishes say "Do not use on anodized aluminum.") Instead of polish, try scrubbing the aluminum with fine bronze wool and a powdered cleanser (Ajax, Bar Keeper's Friend). Then give the clean surface a heavy coat of wax. This may not restore the aluminum to like-new luster, but it will retard future oxidation.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Contributor, BoatUS Magazine

Don Casey has been one of the most consulted experts on boat care and upgrades for 30 years, and is one of the BoatUS Magazine's panel of experts. He and his wife cruise aboard their 30-footer part of the year in the eastern Caribbean. His books include Don Casey's Complete Illustrated Sailboat Maintenance Manual, and the recently updated This Old Boat, the bible for do-it-yourself boaters.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

- Boat Accessories

- Where to Buy

Special until April 30th: 30% off Solvent & Cleaner for the month of April. Use Code APR24 at checkout. *restrictions apply

Free ground shipping in the Continental US for any orders over $150!

The Ultimate Sailboat Maintenance Checklist...

The ultimate sailboat maintenance checklist.

Pop quiz: when are you finished with maintenance on your sailboat? It’s a trick question. The real answer is “never,” because a sailboat needs regular care and attention if it’s going to perform at its best. And that care and attention won’t help if it isn’t comprehensive. That’s why we’ve put together this ultimate sailboat maintenance checklist to help keep your ship in top condition:

- Inspect the boat. Survey the bilge, for example. Test the bilge pump and make sure it runs smoothly. Visually inspect the hull. Look for leaks. Check the raw water sea strainers and look at your battery levels on a regular basis. The key word here is “comprehensive.” Remember, without a comprehensive inspection, you won’t know which issues need addressing.

- Inspect your anchorage. Keeping an anchor in proper condition is essential. You don’t want to head out on a journey and find out that your anchor is suddenly flawed. Some experts recommend waiting for clear waters and weather and diving down to check the anchor itself.

- When in doubt, get a second opinion. If you’re not sure about the quality of a particular system, you should bring in an extra pair of eyes—preferably an expert’s pair of eyes. It’s better to know that your sailboat doesn’t have a problem than to wonder.

- Write down your regular maintenance habits. Add a date next to your notes so you know what needs to be done first. You’d be amazed at how much time can pass since you inspect a critical system if you don’t track it. By tracking it, you’ll know which spots on your sailboat deserve the most attention next time around.

- Look at the quality of your sailboat’s wood. A sailboat’s wood is comparable to its lifeblood. You don’t want dry rot to set in and completely change its quality. We recommend a range of Wood Restorers that can help you out here if a total replacement is not needed. Our Git-Rot Kit is particularly helpful. It uses capillary action to penetrate through wood rot and strengthen the wood to make it both sandable and paintable.

- Keep it clean! If there’s one thing inexperienced boat owners often forget, it’s that keeping a clean boat can work wonders. Keeping your sailboat clean will help prevent mildew from developing, which in turn ensures that you don’t end up with a lot of strange odors that become hard to eradicate. We have a full range of Boat Cleaning Products here at BoatLIFE for you to peruse.

- Address maintenance issues as soon as they arise. Don’t put a new issue, such as a strange noise, on the back-burner. You don’t want to find out about a new problem when you’re out on the water. You want to know everything there is to know when you’re safe at home.

Stock Up On Boat Maintenance Products

There is a lot you can do to maintain a high-quality, sea-worthy sailboat—and you’ve read a lot of it here. Make sure to expand your boat maintenance toolkit with our boating products here at BoatLIFE.

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

Featured Products

Liquid LifeSeal® Sealant 5.2 fl. oz. Clear

Stainless Steel Cleaner 16 fl. oz.

Related blogs, thanksgiving trivia.

Thanksgiving is one of America’s oldest and most loved holidays. Even though the story is steeped in a dark history […]

Detailing Your Boat

There’s nothing better than hitting the water in a beautiful boat. A warm summer day with the sun shining, there’s […]

How To Properly Clean Your Boat Trailer

We all know that cleaning your boat is important to not only keep it looking great, but to also ensure […]

All products proudly made in the usa

Attainable Adventure Cruising

The Offshore Voyaging Reference Site

Articles in this topic:

29 aluminum boat care tips—part 1, 29 aluminum boat care tips—part 2, 29 aluminum boat care tips—part 3.

A quarter century of caring for an aluminum boat has taught John a lot and he is sharing it all.

What started as a simple list post is now a care manual for aluminum boat owners. If you are an aluminum boat owner or are considering buying an aluminum boat, don’t miss this series, it could save you tens of thousands of dollars and untold heartache.

The final chapter in John’s magnum opus on aluminum boat care. Includes some good news about how durable the material really is and some thoughts on why you might want to buy a boat built of it.

- Clutches, Clam & Cam Cleats

- Deck Organizers

- Genoa Leads & Track

- Jib Reefing, Furling, Headfoils

- Lifeline Hardware

- Mainsail Travelers & Accessories

- Rigging Hardware

- Rope & Accessories

- Tillers & Tiller Extensions

- Whisker Poles & Accessories

- Winches, Parts & Accessories

- Emergency Gear

- Harnesses & Tethers

- Man Overboard

- EPIRBs, AIS, PLBs

- Electric Pumps

- Fresh Water

- Manual Pumps

- Seacocks & Valves

- Bags & Luggage

- BBQ Grills & Accessories

- Umbrella & Awning

- Waterproof Cases

- Audio & Video

- Charts & Cruising Guides

- Navigation Tools

- Books & Publications

- Clocks & Barometers

- Propane System

- Stoves & Cooktops

- Teak Accessories

- Ventilation

- DC Electrical

- Generators & Power Equipment

- Shore Power

- Accessories

- Foul Weather Gear

- Sailing Gloves

- Outboard Motor Parts

- Spark Plugs

- Boat & Motor Accessories

- Boat Letters & Numbers

- Highfield Boats

- Boat Maintenance

- Engine Maintenance

- Anchor Rodes & Chain

- Inflatable Boat Maintenance & Repair

- Outboard Motors Servicing

- 303 Products

- Adventure Medical

- Alexander Roberts

- Apex Inflatable Boats

- Aqua Signal

- Bete-Fleming

- Blue Sea Systems

- Boat Bright

- Bristol Finish

- Buck Algonquin

- Captains Choice

- Chesapeake Bay Magazine

- Chesapeake Marine Fasteners

- Cole Hersee

- Consolidated Thread

- CrewWatcher

- Cruise Products

- Ebinger Leather

- Fell Marine

- Gam Electronics

- GMCO Maps & Charts

- Gorilla Glue

- Green Mountain

- GSI Outdoors

- Handi-Man Marine

- HarperCollins

- Helly Hansen

- Henri Lloyd

- Honda Outboard Motors

- Inland Marine

- Johnson Marine

- Johnson Pumps

- Just Marine

- Kotap America

- Lord & Hodge

- Lunar Marine

- Master Lock

- McGraw Hill

- Moby Dick Specialties

- Nautic Sport

- New England Ropes

- Paradise Cay

- Poly-Planar

- PSS Shaft Seal

- Quicksilver

- Redtree Industries

- Rudder Craft

- Sailing Specialties

- SamplexSolar

- Sea-Dog Line

- Seattle Sports

- Sesamee Padlocks

- Shaft Shark

- Shakespeare

- Signal Mate

- Snappy Teak

- Standard Horizon

- Taylor Made

- Teknor Apex

- Teak Wonder

- Tip Top Teak

- Torqeedo Outboard Motors

- Trac Ecological

- Treadmaster

- Ultra Safety Systems

- Viking Life Rafts

- Waterway Guide

- Weems & Plath

- West System

- Western Pacific Trading

- Williams & Heintz Map

- Yale Cordage

June 6, 2023

How to Clean an Aluminum Boat

Are you the proud owner of an aluminum boat? Aluminum is a great material for boats because it's highly resistant to rust, making it suitable for both salt and fresh water. As with any type of boat, cleaning is an essential part of aluminum boat maintenance .

Cleaning an aluminum boat involves three steps — washing it with soap and water, cleaning it with an aluminum boat cleaner and buffing it with aluminum polish to protect it and make it shiny. We'll dive into the details of each step below so you can learn how to clean your aluminum boat properly.

What Makes an Aluminum Boat Unique?

Many boat owners think of aluminum as just another boat material. With its smooth appearance, they might assume regular soap and water are all that's necessary to clean it. However, aluminum has unique properties, which is why dedicated aluminum boat cleaners are best to extend its life and keep it looking great.

Keep the following characteristics in mind when planning your aluminum boat cleaning regimen:

- Aluminum reacts to air exposure: The oxidation process begins when aluminum is exposed to air. Aluminum's tendency to oxidize means you'll need to follow a special cleaning process, even if you keep it in excellent condition.

- Aluminum's signature sheen is its natural state before reaction: If you want shiny aluminum, you’ll need to adopt a regular cleaning regimen. While aluminum is rust-resistant, its reactive nature means it will become lackluster without regular cleaning and polishing.

- Aluminum tends to take on a layer of oxidation: Cleaning products specially made for aluminum will cut through the oxidized layer so you're cleaning the actual aluminum, not just the coating.

What You Need to Clean an Aluminum Boat

Taking good care of your aluminum boat means you'll need a few essential cleaning supplies. Use the list below to shop for aluminum boat cleaning products , so you're well-stocked on cleaning day:

- A large sponge

- A scrubbing brush

- A water hose

- A five-gallon bucket

- Aluminum boat cleaner

- Aluminum polish

- Buffing cloth or machine

- A buffing rake

You'll use regular soap to give your boat a preliminary washing before following up with a dedicated aluminum boat cleaner. In addition to being washed, aluminum must be polished and brightened to bring out its signature shine and protect it from the elements. While regular soap and water might clean the surface, they'll do little to restore or protect it.

You may also want to wear protective goggles and gloves when you clean your boat. These can prevent soap and aluminum cleaner from getting into your eyes and drying out your hands.

How to Clean Aluminum on a Boat

Plan to clean your aluminum boat on a day that isn't too hot. Direct sunlight can heat aluminum so much that it may become too hot to touch.

Place the boat on its trailer and park it in a shady spot that offers plenty of room for you to work. Then, follow the steps below to clean an aluminum boat hull.

Give Your Boat an Initial Wash

A basic washing will remove loose or bulky dirt and debris that have gathered on the aluminum. This step is important because aluminum must be free of buildup before you apply an aluminum cleaning product. Doing so results in much clearer aluminum and makes the cleaning process easier.

Here's how to wash your aluminum boat:

- Spray down the aluminum surfaces on your boat to help loosen dirt and grime.

- Fill the bucket with hot water and add some of the car soap.

- Soak the sponge in the soapy water and scrub the boat.

- Hose off the soap.

If you have problem areas that won't come clean despite vigorous scrubbing, try scouring them with steel wool. If they still appear dirty, let the aluminum cleaning solution tackle them in the next step.

Apply the Aluminum Boat Cleaning Solution

Most aluminum boat cleaning products are concentrates that you must dilute with water before applying to your boat. When selecting an aluminum cleaner, make sure it's safe to use on boat hulls. Carefully read the directions on the bottle before diluting the concentrate as directed.

Once the cleaning solution is ready for use, soak the scrubbing brush in it and get to work cleaning the aluminum surfaces. Make sure to dedicate time to scrubbing any areas that didn't come clean during the first wash.

After you’ve thoroughly scrubbed every inch of aluminum, check the directions on the cleaning product to determine whether it needs time to set into the metal or whether you can rinse it off immediately.

Buff the Aluminum to a High Shine

Once you've rinsed away any residual cleaning solution, the next step is to buff the aluminum to bring out its shine. If your boat is small, only has light oxidation or you simply don't mind the labor involved, you may decide to hand-buff your boat. But if you want to make quick work of it, a buffing machine is your best option.

If you're buffing by hand, start by applying aluminum polish to a buffing cloth or pad. Press it to the boat's surface and start buffing in a circular pattern until you've covered the aluminum. Add more aluminum polish to the buffing pad as needed. Remember that buffing by hand can be time- and labor-intensive, especially if the aluminum is heavily oxidized.

If you're using a buffing machine, start by applying aluminum polish to the buffing pad while it's in motion. Press the pad into the aluminum and buff, moving slowly from side to side until you've covered all of the aluminum. It's important to be thorough here — one pass will be enough if you buff slowly and deliberately.

You'll need to add more aluminum polish to the buffing pad as you work. Keep in mind that the edge of the buffing pad may collect polish buildup or aluminum particles, so inspect it every so often and remove any debris. You can use a buffing rake to clear the pad, which is a hard, metal comb that cleans the surface of the buffing pad to prepare it for fresh polish.

Find Aluminum Boat Cleaning Products at Fawcett Boat Supplies

Fawcett Boat Supplies is your resource for all things boating. We offer an expansive inventory of boating supplies to assist you in any and all of your boat projects. We also provide service , warranty repair, winterization, storage and repower at our Annapolis location.

If you need aluminum boat cleaning products or anything else related to boats, reach out to Fawcett Boat Supplies today. Our knowledgeable staff looks forward to assisting you!

Additional Boat Cleaning Resources

If you're planning to clean your aluminum boat or stocking up on cleaning supplies, we recommend viewing our other guides to ensure you're fully prepared!

- How to Clean and Wax Your Non-Skid Deck

- A Step-By-Step Guide to Cleaning Your Boat's Interior

- How to Clean Boat Carpet

- How to Clean Your Boat Bilge

- How to Clean Your Boat Hull

- Choosing a selection results in a full page refresh.

- Press the space key then arrow keys to make a selection.

- Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device

Net Orders Checkout

Shipping address, shipping methods.

How to Maintain Your Aluminum Boat Properly

Aluminum boats are an excellent choice for many anglers thanks to their durability, reliability, and ease of maintenance. Owning a vessel made with aluminum material offers you many benefits. Whether you want to enjoy fishing, cruising, or spending long weekends on the water with family & friends, different types of aluminum boats are available. However, like any other vessel, they require regular maintenance to keep them in good condition for extended periods, especially when you usually go in saltwater conditions. We’ve tried to cover some valuable tips from marine experts to maintain your aluminum boat. Let’s have a look.

1. Keep Your Vessel Dry

Many boaters think that boats are made for the marine environment. Hence, keeping them dry is optional. However, it’s not correct. When you do not keep your boat dry, it can create issues like mould, rusting, odour, and more. Remember that when the boat is made with different metals, like primary material aluminum and some copper or other metal, it can corrode in saltwater faster than pure aluminum or fibreglass boats . The corrosion rate depends on how sensitive the material is when you use it in salt water for a longer time.

The corrosion rate depends on how sensitive the material is when you use it in salt water for a longer time. Experts recommend to washing your aluminum vessel with fresh water after every saltwater use with the help of a pressure washer. It will help remove any salt built-ups and prevent galvanic corrosion.

• Drain the water completely from the vessel. Marine mechanics recommend keeping the outboard attached when you follow a proper drainage process by holding the vessel at an angle. • Chances are there that debris, sand, and other particles can get in the way of drainage. Ensure you inspect the drainage process properly and remove any such obstacles immediately.

2. Clean Your Boat Thoroughly

Drying the vessel is not enough. Your high-quality outboards , bot hull, and other components need timely cleaning to operate appropriately. Regularly clean the vessel’s exterior using a mild boat soap or a mixture of water and vinegar. It will remove salt residue. It will also help prevent corrosion. Avoid using harsh chemicals that could damage the boat’s finish. We recommend using Captain Phab Aluminum Hull Cleaner, an all-in-one solution for brightening, polishing, and providing long-term protection to the aluminum parts.

3. Take Care of Fuel Tanks

Remember that even if your boat is not made with aluminum, it can have aluminum fuel tanks. They are one of the safest, without any doubt. However, sometimes leaks can occur. You can contact any boat repair services providers and ask them the reason for tank failures. Almost all of them will blame corrosion. Follow the below tips for the longevity of aluminum fuel tanks:

• If you paint the tanks, apply them properly and thoroughly. You should regularly check & remove if there is any moisture under the paint. • Try using stainless steel washers or adapters in the boat fuel system fittings to prevent moisture and galvanic corrosion. • Drain water from all sides of the tank when you move your vessel out of the water. Keep the tank at least a quarter-inch above your boat hull for proper air circulation and out of the reach of bilge water. • Use neoprene, Teflon, or any other high-density plastic for the tank’s support system.

4. Paint the Bottom

One of the beneficial ways to keep the rust & corrosion from the aluminum fishing boats in BC is to apply paint on the hull. You can take the help of your boat dealer in Canada to paint the vessel. They will ensure the application up to the water line, patching nicks and chips. Inspect the boat paint after every few outings. Touch up if you identify any scratches or dings.

5. Outboard & Trailer Maintenance

Don’t forget the boat trailer and the outboard. The trailer components, like brakes, springs, hubs, etc., require regular checks and maintenance recommended by the boat manufacturer. Pay attention to the outboard inspections and repairs. After each use, flush the boat motor with fresh water to remove salt buildup and prevent corrosion.

You can protect your vessel from the corrosive effects of saltwater and ensure it remains in excellent condition for years by following the tips mentioned above. Regularly & correctly maintained aluminum boats like the Pacific North West Editions of a Thunder Jet boat model empower you to explore the open waters in BC and indulge in exciting saltwater adventures – long term.

If you are searching for a boat dealer in BC, Canada or suitable boat engines for sale , connect with Alberni Power & Marine. Our team will help you gear up for the season and enjoy the endless possibilities that await you on your next boating & fishing trips!

- Marine Electronics (3)

- Parts & Accessories (11)

- Marine Services (30)

- Mercury Outboards (17)

- Boat Engines (11)

- Propellers (2)

Boat Reviews

- Aquila Boat Reviews

- Aspen Boat Reviews

- Avalon Boat Reviews

- Aviara Boat Reviews

- Axopar Boat Reviews

- Barletta Boat Reviews

- Bayliner Boat Reviews

- Centurion Boat Reviews

- Charger Boat Reviews

- Cruiser Yachts Reviews

- Formula Boat Reviews

- Fountaine Pajot Reviews

- Freeman Boatworks Reviews

- Galeon Luxury Yachts Reviews

- Intrepid Boat Reviews

- Jupiter Marine Reviews

- Manitou Boat Reviews

- Native Watercraft Reviews

- Phenom Yacht Reviews

- Pursuit Boat Reviews

- Sailfish Boat Reviews

- Sea Ray Boat Reviews

- Sea-Doo Watercraft Reviews

- SeaVee Boat Reviews

- Solace Boat Reviews

- Windy Boat Reviews

- X Shore Boat Reviews

- Yamaha Boat Reviews

- Boats Specs

- Marine Pros

- Boat Insurance

- Boat Warranties

- Boat Transport

- Boat Towing

- Marine Forecasts

Your Ultimate Boating Resource

2024 Pursuit OS 445: An Overview

Boat safety 101: exploring the serenity and adventure of boating, the moment of truth – 6 signs you need a new boat, is it possible to wakesurf on a pontoon boat, 2024 aquila 47 molokai review, 2024 sea-doo switch 13 sport review, 2024 aspen c120 review, what is the maintenance like on an aluminum sailboat.

Owning an aluminum sailboat is a fantastic experience. These strong and durable boats can last for decades, offering the perfect vessel for all your boating needs. However, like any other boat, aluminum sailboats require regular maintenance to stay in tip-top shape. Proper maintenance is essential to keep your boat safe, seaworthy, and looking great.

One of the primary benefits of owning an aluminum sailboat is that it is incredibly easy to maintain. The rugged and robust construction of these boats makes them resistant to scratches and other forms of damage, which means you won’t have to worry too much about keeping its exterior in top shape.

However, this does not mean that aluminum boats do not require regular upkeep. Here are some maintenance tips that can help you keep your aluminum sailboat in good condition for many years to come.

Exterior Cleaning and Maintenance

To keep your aluminum sailboat looking like new, wash it regularly with clean water and mild soap. Avoid using abrasive cleaners, scratchy sponges, or hard-bristled brushes as they can damage the aluminum surface. A gentle cleaner like dish soap mixed with fresh water should be all you need to get the job done.

Regular Waxing

Aluminum boats can be susceptible to corrosion if they are not well-maintained. Regular waxing can help protect your boat’s aluminum surface and prevent build-up of salt stains and other contaminants.

Routine Mechanical Checkups

Regular mechanical checkups can help ensure that your boat’s engine and other systems are running correctly. Check the oil levels, fuel levels, and other fluids regularly. Any leaks or unusual noises should be addressed immediately to avoid significant problems.

Maintaining Your Sails

Inspect your sails regularly for wear and tear. Making repairs to tears or holes as soon as you notice them can prevent the damage from getting worse, ultimately extending the lifespan of your sail. Keep your sails covered and out of sunlight when you are not using them.

Winter Maintenance

During the offseason, store your boat in a dry, covered area. Be sure to winterize your boat’s engine, draining any excess water to avoid freezing and cracking. You should also remove any food, liquids, and other items that could attract pests or rodents.

Owning an aluminum sailboat is an investment that requires regular maintenance to ensure it remains seaworthy and in excellent condition. By following the above tips, you’ll not only keep your boat running smoothly but also extend its life, ensuring you get the most out of your aluminum sailboat.

Related Questions

What type of wood is used for pier pilings, what is the difference between a dock and a floating pier, what is the proper technique for pulling a beginner wakeboarder, what does ‘no wake’ mean on a lake, what is the difference between wash and wake, is wakesurfing possible in the sea, why don’t wooden piers rot, what size wakeboard is needed, how to achieve more pop on a wakeboard, does wake surfing translate to ocean surfing, latest posts, the top 9 reasons to maintain a meticulous boat log, don't miss, our newsletter.

Get the latest boating tips, fishing resources and featured products in your email from BoatingWorld.com!

Eco-Savvy Sailing: Expert Tips for Reducing Fuel Costs and Enhancing Your Boating Experience

Sea safety blueprint: constructing the perfect float plan for your boating adventures, 10 essential tips for fishing near private property, the benefits of using a drift sock: guidance for anglers, lure fishing: secrets for imitating live bait and attracting fish, explore the untapped depths of america’s best bass fishing spots, tackle your catch-and-release adventures with these 6 tips, outboard motor maintenance: tips for keeping your engine in top shape, the essential boat tool kit: tools every boater needs, diy boat building: 8 tips and tricks for building your own vessel, the art of miniature maritime craftsmanship: ship in a bottle, antifouling paints: a guide to keeping your boat shipshape, beginner’s guide to standup paddle boarding: tips and techniques, boating for fitness: how to stay active on the water, kayak safety: how to stay safe on the water, anchoring in a kayak or canoe: how to secure your small boat, 2024 yamaha 222xd review, 2024 sailfish 316 dc review, 2023 seavee 340z review, 2023 centurion fi23 review, gear reviews, megabass oneten max lbo jerkbait review, fortress anchors fx-7 anchoring system review, fortress anchors fx-11 anchoring system review, fortress anchors commando anchor kit review, fortress anchors aluminum anchors review, stay in touch.

To be updated with all the latest news, offers and special announcements.

- Privacy Policy

How To Clean An Aluminum Boat

A step-by-step guide on how to effectively clean an aluminum boat.

One of the most commonly asked questions is how to clean an aluminum boat. From the smallest aluminum dinghy up to large pontoon boats and bowriders. The boating world is full of aluminum boats of all shapes and sizes.

In the following article, we’ll take an in-depth look at how to clean an aluminum boat with our easy step-by-step guide. For more information about aluminum boats, check out our Easy Guide to Aluminum Boat Maintenance .

Table of Contents

One. The Importance of Cleaning your Aluminum Boat

All boats, especially aluminum ones, need to be cared for. Sure, they’ll last a while without a lot of regular maintenance. However, with a little bit of regular maintenance, your aluminum boat could last much longer. Not only that, but it’ll help to retain its value if you have cared for your boat.

Think about what your aluminum boat is exposed to regularly. Things like air and water pollution, saltwater, freshwater, marine life, algae, wind, dirt, oil, grease, and fuel. These pollutants can leave your aluminum boat hull looking a little worse for wear. So often, aluminum boat owners are left scratching their heads, wondering how to clean an aluminum boat effectively.

While it can sound like a big job, regular cleaning and maintenance of your aluminum boat will actually make it easier. The more often you clean your boat, the less time it’ll take. Besides that, the benefits of having a clean hull include the following:

- A clean hull free of debris will move through the water easier and reduce drag. This will save you money on fuel, increasing your fuel efficiency.

- Your boat will move through the water easier which will improve handling.

- When it comes time to sell your boat, it’ll be in much better condition. This means you’ll get a better sale price and have more money to invest in your next boat.

- A clean hull and boat are easier to work or fish in and let’s face it, it just looks better!

Let’s check out the steps to cleaning your aluminum boat effectively.

Two. Boat Wash – The Easiest and Cheapest Method

If your boat doesn’t spend much time on the water, it will not need intense cleaning all the time. However, a premium boat wash like this 303 Marine Boat Wash with UV Protection is a great product for general boat washes. Used in combination with a Boat Scrubbing Brush , you’ll be able to reach all those hard places comfortably.

For your basic wash, you’ll need access to fresh water, a scrubbing brush, your boat wash, and a bucket. Pretty simple stuff. It’s no different than what you would need to wash your car. Before you start washing, be sure to remove anything which could be damaged by water, such as electronics.

- Start by finding somewhere out of the direct sun. If you live in a hot climate, the sun can heat the aluminum, making it difficult to clean. So instead, start by rinsing the boat with your hose to get it nice and wet and remove any loose dirt or debris. I like to start on the outside first in case anything gets washed into the interior.

- Fill your bucket with water and the correct amount of boat wash. Don’t go crazy with the boat wash. It doesn’t need to have soap overflowing out of the bucket!

- Now take your scrubbing brush and give the entire hull of your aluminum boat a good scrub down with the boat wash.

- The final step is to take your hose and rinse off all the soap from the outside. If you think it still needs another clean, then repeat the outside steps before you move to the interior.

- When you’re washing the interior, try to remove any electronics or accessories, such as radio, radar, fish finders, seats, upholstery, etc., that might get too wet.

Three. Deep Cleans – Using A Pressure Washer

A pressure washer is a great investment for any boat owner spending a lot of time on the water. It’s especially useful if you do a lot of fishing and need to remove blood, slime, or scales from the interior of your boat. The RowRyte Electric Pressure is well worth the investment if you’re going to be spending a lot of time washing and cleaning your aluminum boat.

- Once you get back home, get out of the pressure washer and add your boat wash. Be sure to remove or cover anything such as electrical components or upholstery and covers which could be damaged by water or high-pressure water.

- Give the entire interior and exterior a good spray with the boat wash first. Please leave it to soak for about five minutes. If you can find somewhere out of direct sunlight, it’ll be better for this stage.

- Now it’s time to rinse it all! Starting from the top, be sure to rinse off all the soap. Next, move to the interior, being sure to rinse all the water and soap out of the boat through the bung.

Four. Follow Up with Aluminum Boat Polish

If you want your aluminum hull or interior to stay looking bright and clean, then you need to follow up with an aluminum boat cleaner and polish, such as the 3M Marine Aluminum Restorer and Polish .

You don’t have to use aluminum boat polish and restorer every time you wash your boat. Depending on your use and where you’re using your boat, you should be using this every 3-6 months. Carefully follow the instructions on the boat polish, and be sure to carefully read the safety guide on what safety gear you need to use.

- Read the instructions carefully. Be sure to check the recommended safety instructions and also application instructions. All products are different, and some aluminum boat polish and cleaner may need to be diluted.

- Dip your application pad or scrubber in the solution and apply it to your boat hull as per instructions. A scrubbing brush is good for any stains, watermarks, or blemishes.

- Take note of any cracks, deep scratches, or areas that are exhibiting signs of corrosion. You may need to have a qualified boat repairer further examine these. Small cracks in the aluminum can quickly become big cracks when exposed to stress.

- Rinse or remove any boat polish as per the instructions in the product. Some products need to be buffed out straight away, while others need to be left in place for several minutes.

Five. It’s Time to Shine!

Not all boat owners are satisfied with just a wash. Some boat owners, especially those selling their aluminum boats, want them to shine. A good polish of your aluminum hull is a great way to finish off your deep clean. If you’re getting ready to sell your aluminum boat, then a deep clean with a pressure washer followed up by a polish will have it look fantastic. It’s well worth the investment of time and energy.

How To Clean An Aluminum Boat – Conclusion

Not only does a clean boat look better and hold its value better, but it also performs better. A clean hull leads to better maneuverability, increased fuel efficiency, and better performance. So not only will your boat last longer, but it’ll also hold its value better. Even if you’re not planning on selling your boat anytime soon, regular maintenance and cleaning is a great habit to get into.

There’s nothing better than putting a clean boat out on the water for a day of fishing or fun with the family. An hour at the end of the day isn’t much of a price to pay for great fishing in a great-looking boat!

If you have any questions about aluminum boats or want to learn more about aluminum boat maintenance, please don’t hesitate to reach out and contact us directly! Also, don’t forget to bookmark the page. That way, you don’t miss out on all our exciting upcoming blogs. While you’re there, be sure to read this article, How Much is a Bass Boat ? It contains some great tips on bass boats and how aluminum bass boats stack up against fiberglass boats.

- Recent Posts

- How To Clean An Aluminum Boat - January 14, 2023

- Easy Guide to Aluminum Boat Maintenance - January 13, 2023

- How To Fish & Boat

- Register Your Boat

- Get Your Fishing License

- Places To Boat And Fish

- Connecticut

- District Of Columbia

- Massachusetts

- Mississippi

- New Hampshire

- North Carolina

- North Dakota

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- West Virginia

- How to Catch Fish

- How to Tie Fishing Knots

- Fishing Gear and Tackle

- How to Fish with Lures

- How to Fish with Live Bait

- Fishing Safety

- Fishing Tips

- When to Fish

- Types of Fishing

- Fishing Terms

- Fishing and Conservation

- Fishing Resources

- When to Saltwater Fish

- Saltwater Bait and Lures

- Saltwater Fishing Tackle

- Types of Saltwater Fishing

- Saltwater Fishing Gear

- Saltwater Fish Species

- Saltwater Fishing FAQ

- Types of Freshwater Fishing

- When to Freshwater Fish

- Freshwater Bait and Lures

- Freshwater Fish Species

- Best Freshwater Fishing Gear

- Freshwater Fishing FAQ

- Fly Fishing Basics

- Fly Fishing Flies

- Fly Fishing Gear

- Fly Casting

- Ice Fishing Basics

- Ice Fishing Gear

- Ice Fishing Techniques

- Boating Basics

- How to Boat

- Boating and Water Safety

- Choose Your Boat

- Use Our Boat Explorer Tool

- Get on the Water

5 Tips for Aluminum Boat Treatment & Maintenance

By Tom Keer

Apr 26, 2017

A little preventative maintenance on aluminum fishing boats saves time later on. Take care of your skiff and you'll spend more time fishing and less time repairing.

A stitch in time saves nine goes the adage, and its spot on for aluminum boat corrosion treatment. Here are 5 tips for keeping your tin skiff in the water instead of in the workshop.

1. Keep them dry

Half of the battle of stopping corrosion on an aluminum boat is not getting any in the first place. Water plus metal equals corrosion, and that means you have to do more than just pull the plugs after you haul. Store frequently used boats in a sunny area. If you leave your outboard attached then tilt them so the water drains. If the boats are small enough flip them over.

2. Chart your course

Knowledge of your terrain is important to avoid collisions with rocks. Dents, particularly at the direct point of impact, weaken metal. Also, carefully pound out dents as a hammer blow can create more problems. Rubber mallets work best, and start from the outside and work in. Avoiding collisions and pounding out dents can lessen the need for aluminum boat corrosion treatment later on.

3. Don't stop the drainage

I remember pulling a skiff off a beach. Sand from the haul blocked the rib drainage, and I created my own headache. The treatment for this corrosion in my aluminum boat was an entire rib replacement. It's far easier to inspect the ribs to make sure they're not full of sand or weeds and that the water drains properly.

4. Ditch the carpet on your bunks

Carpets hold water that, over time, can cause hull pitting. Remove the carpet and cover with plastic which makes for easier launches anyway.

5. Paint the hull

The best way for stopping corrosion on an aluminum boat is to paint the hull. Bottom paint prevents fouling. Be sure to paint up to the water line, and patch nicks or chips as soon as possible.

Aluminum fishing boats require more maintenance than fiberglass boats, so keeping ahead of the curve saves big overhaul projects. Keep in mind also registering your boat!

NEWSWAVES SIGNUP

Stay up-to-date on RBFF’s fishing and boating programs and initiatives with the monthly NewsWaves newsletter. Read about relevant stories on the fishing and boating industry, RBFF’s work to and increase participation, the latest research and trends on fishing and boating audiences and participation and marketing insights, tips and content.

Please complete the following fields to subscribe to our newsletter.

Download this Resource

To download this free resource, please fill out the form below:

Aluminum Boat Maintenance: Get Your Aluminum Boat Ready for Spring

By Tami Holly

Spring lets you live life to the fullest! Conquering the waters with your boat is just another blessing of spring. But after sitting idle throughout the long winter, your boat demands some attention, especially if the boat is made of aluminum. Aluminum boat maintenance is a bit different. The amount of yearly upkeep tasks depends on your ongoing aluminum boat maintenance, which may include welding or brazing the boat itself.

This article can work as a complete guide for you to get your aluminum boat ready to rock after a long winter. We have included some crucial tips on de-winterizing your aluminum boat in the latter part of the article.

How to Perform Aluminum Boat Maintenance for Spring?

Getting your aluminum boat ready for spring involves proper attention, meticulous inspection, and some hard work. If you are confident, you can do it alone, or you can do it with some assistance from a maintenance professional.

Check the Hull

Since your boat was covered for months, anything could have happened to it by this period. The most vulnerable part of your boat is the hull. Your boat’s ability to float on water mostly depends on the well-being of the hull. So, the first step in checking your boat after the winter should be inspecting the hull thoroughly.

During the inspection, look for any cracks, moisture accumulation, or damage to the hull of your boat. If you find water in the hull, it may indicate cracks. Identify the need for painting. Replace the zincs if more than half of it is gone. Carefully check the hull for any need for repair of dings, dents, or any damaged seams.

Repair the Hull

If you find any damage to the dings, dents, or seams of the hull, do not hesitate to repair them immediately. Aluminum boat repair is a bit different than the maintenance of other boats, due to the difficulty in welding large masses of aluminum. Make sure to follow the correct procedure to ensure the safety of your water adventures.

You should always use quality materials to repair the hull of the aluminum boat. For that, you can rely on Super Alloy 5 Aluminum Repair Rods , produced by Muggy Weld LLC. You can weld, solder, or braze any damage to your boat with them. These aluminum rods can work with any torch, including oxyacetylene, MAPP gas, natural gas, or propane.

Inspect the Engine

Like any motorized vehicle, your aluminum boat’s performance heavily depends on the engine. After a long rest, the engine can grow any type of problem that is out of your imagination. First of all, check the status of the engine oil. We hope you changed the engine oil and filter before putting your boat to rest at the beginning of the winter. That is the standard maintenance procedure.

If the engine oil has grown a frothy texture, there might be water in it. It may indicate a serious engine problem. We suggest consulting a professional in that situation. You should also reinstall the engine battery and check all the electrical connections.

Paint the Boat

To prevent any growth at the bottom and on the sides of your aluminum boats, you should paint it properly. It is very important to ensure a long life for your boat when you need to keep it in the water for a long time.

However, any type of paint will not be able to save your aluminum boat. You must use anti-fouling paint to confirm the boat’s durability.

Get a Professional Check-Up

It doesn’t matter if you have prepared your aluminum boat for the spring all by yourself or with someone else’s help. You must check every safety issue of the vehicle by a maintenance professional expert before taking the boat into the water.

You can be as confident about your repair job as you please. But it is the job of a professional to duly follow the standard procedures and check if the vehicle is ready for water or not.

7 Tips to De-Winterize Aluminum Boats

Here we have listed 7 tips about de-winterizing your aluminum boat. We think they can be very helpful to track yearly aluminum boat maintenance tasks:

- Change the Safety Gears: The life jackets, fire extinguishers, flares, and other safety gears have been there untouched and unused for months. It is wise to change them all no matter how new they look. After all, it is a matter of your life!

- Follow State Regulations: Make sure to comply with all the rules and regulations of federal and state governments on plying water vehicles. For example, all children need to wear floating gear which is approved by the U.S. Coast Guard.

- Use Corrosion Inhibitors: At all the joints of all the metal parts of your aluminum boat, apply corrosion-inhibitor agents. It will ensure a longer life for the boat.

- Carry Extra Fuel Filter: Carrying an extra fuel filter can save you from many awkward situations in the water. Also, you should inspect the fuel filter before every journey.

- Mind the Cushions: The cushions of your boat can also work as flotation devices in a time of emergency. So, do not forget to make sure they are in good condition before sailing the boat.

- Duct Tapes & Garbage Bags: You should always be prepared for the worst scenario. Big garbage bags along with duct tape can save your life by stopping water leaks. You should always take them in the water.

- White Vinegar: You will be surprised to know the versatile use of white vinegar. Apart from being a good ingredient in your foods, they can save you from uncomfortable itchiness if you get in contact with a jellyfish or pesky mosquitoes.

Repair Any Dents, Dings And Damaged Seams With Muggy Weld

Aluminum boat repair is essential before you set out on the spring waters. No matter how good you are at aluminum boat maintenance, rust and defects do occur over the winter. So, proper checking and repair is a must.

But you are going to need high-quality supplies for the repair as only that can ensure the highest longevity of your boat. We at Muggy Weld provide only the most pristine maintenance welding supplies that you can use to get your boat back into tip-top shape. So, take a look at our welding supply collection and order what you need to begin your aluminum boat maintenance process.

The time of year is here for you to get the most use out of your aluminum boat, but it’s still important to keep up with regular maintenance. This ensures you can keep your boat in top shape. The easiest and best ways to do this are to remember to make sure you keep your boat dry and your aluminum clean each time you take it out of the water.

Keep Your Boat Dry