SV Belle and Beast

Building a Sailboat Trailer

Since Belle did not come with a trailer, much of why she was so inexpensive, we had to source a trailer to put under her to make her useful to us. Buying a custom trailer was going to be in the $3000 range, 10X what we paid for Belle. Adapting a used trailer was going to be the only affordable. So this is how we set about building a sailboat trailer.

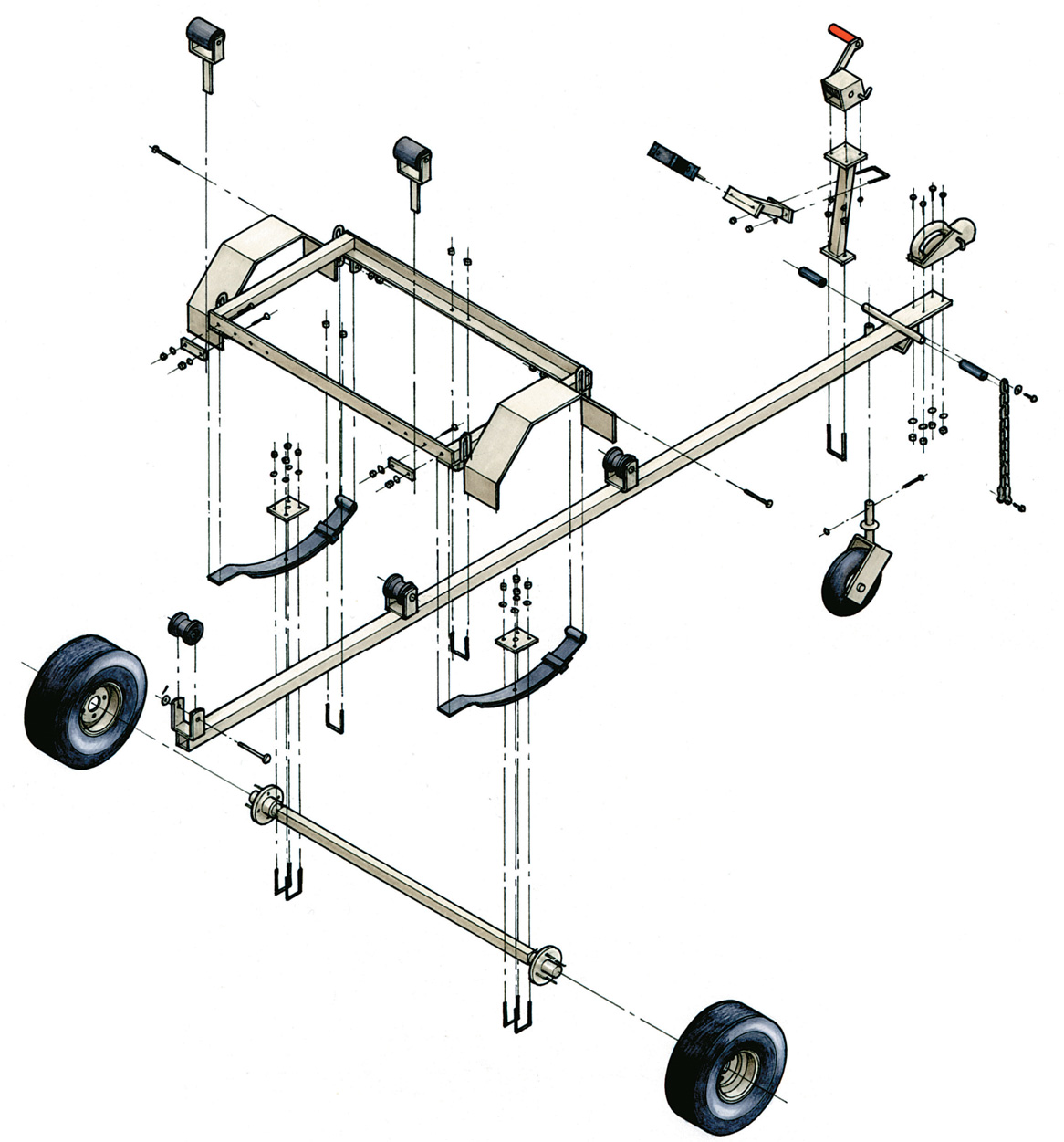

So how does one go about building a sailboat trailer? The easy way is to start with an existing trailer. We need some fairly detailed knowledge about the boat we intend to trailer. We need a trailer that is long enough and strong enough to support the load so we need to know where the center of gravity of the boat is, how far forward and aft the bow and stern are from this point, how much the boat weighs, how far from centerline the reasonably flat/horizontal hull areas extend, and how far these areas are vertically from the bottom of the keel.

Measure It Up

When building a trailer for a sailboat, getting sizes and dimensions right is crucial. I took some critical dimensions during my survey of the boat (yes, I felt comfortable doing my own survey) and while shopping for the trailer. You can see those above. I used these to source my parts for the trailer refit. Our sailboat, an O’Day 23-2 comes in at a max displacement of about 3500lbs. That is equal to the maximum weight of the boat. So I knew I had to find a trailer that could hold 3500lbs. I also knew the shoal keel was going to cause the boat to trailer rather high off the ground and from my father’s experiences I knew I wanted the boat as low as possible and as long a tongue as possible to give us the most flexibility in launch ramp choices. The higher your boat sits on the trailer, the deeper and steeper the ramp you are going to need to launch and recover the boat.

We located our trailer at KM Boat Salvage in Plaistow, NH. Keith had about 30 trailers to choose from. While there were some tandem axle trailers suitable, I decided to go with a heavy single axle Escort brand trailer for a few reasons.

- A single axle is more maneuverable, less tire drag in tight turns.

- This trailer was all galvanized and had hydraulic surge brakes (working or not?)

- The price was half that of the tandem axle trailers ($650)

Looking at the wheels/hubs, I could see they were 6 lugs with 2.5″ caps. And counting the leaf springs, I could see there were 5 leaves. This suggests fairly clearly that the trailer has a ~5000lb class axle. That gives us plenty of room for the weight of the trailer itself once we subtract the weight of the boat. (1500lbs allowance for the weight of the trailer).

Tear It Down, Start With Lights

Once we had the trailer home, we stripped the old bunks and brackets off and removed the broken/old lights. We also removed the bow rest and winch post as they would need to be reconfigured to support the mich higher bow than what the trailer had been set up for.

I made up some new light brackets as the old ones had rusted too much. I found some galvanized tie plates at Lowesdepot and bent them at 90 degrees in my bench vise. I then enlarged two of the holes that lined up with the mounting posts from the trailer lights I bought. These brackets are then secured to the frame by pinching them behind the u-bolts for the rearmost bunk brackets.

The old wiring was stripped off the trailer and the new wiring from the new light kit was strung out on the frame. Rather than use the wire nuts that came with the kit, I preferred to make the connections more permanent and reliable by soldering the wires together and covering the joints with shrink wrap. You can also dab some dielectric grease over the solder joint before you slide the shrink wrap down for even more protection but its the steel in the cheap nuts that rots rather than the copper wire.

The ground wire that comes with these kits is always pathetically short. I’ve never had a vehicle with the trailer plug close enough to the tongue to use such a short wire. So, I harvested some white wire from the “car side” harness and soldered it to the trailer harness. I then used some dielectric grease in an attempt to protect the trailer frame from salt (fool’s errand) and a stainless self -drilling screw to bond it.

New Bunks and Brackets for the Trailer

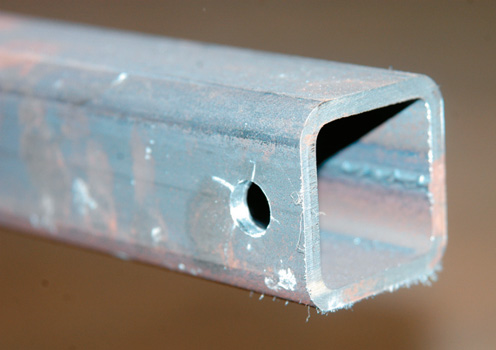

Using the measurements I had taken and the construction of our new trailer, I set about trying to find bunk brackets for adapting the trailer to the sailboat. The dropped axle of the trailer is ideal letting the keel go as low as possible. Measuring up from the keel I needed bunk brackets in the 20-24″ range given we have a 4″ tube section. This tube section, and the lack of horizontal cross members severely limited our choices for off-the-shelf bracketry. Most brackets are designed for 3″X3″ tube cross members. The cross members on the Escort are “L” channel and not suitable for u-bolts. I also refuse to drill new holes in the galvanized trailer frame as these would expose bare steel and rust quickly.

Eastern Marine Trailer Parts Super Store had only one solution for our trailer situation. And I could find no solution elsewhere. The Tiedown 24″ bunk bolster brackets would have to do. However, these are set up to have a swivel top bracket bolted directly to the top with a short bolt. If the brackets were attached to cross members, this would be fine as they would allow the bunks to pivot to the slope of the hull. However, we had to attach to the longitudinal frame members so the bunks would want to pivot forward and back rather than side to side. The solution I came up with was to use bunk stiffening bracket weldments that had a tab welded to a tube. By bolting this to the bunk bracket and using two swivel top brackets to either side of the weldment I could change the pivot direction by 90 degrees.

We then had to set about the bunk boards. I had seen a lot of boat trailers with long bunk boards strung between the brackets. It seems to me most of the board area in these cases does nothing but prohibit you from servicing the hull while on the trailer and rubbing bottom paint off. No weight is being carried more than a few inches from the brackets as the boards will simply bend away. I had also seen many trailers using round or square bunks atop the brackets and this seemed more ideal, I originally ordered only four brackets to save money, but once in hand, I realize we had too little margin for error and ordered another two.

I had to replace the wood on the engine mount as well, so I bought a sheet of 3/4″ hardwood plywood. Did not splurge for marine plywood ($$$$) so it has lots of voids in it. I also wanted to reduce the chances of point contact with the hull. The bunk carpet will only disperse a minute amount of load. I chose to cut 1/8″ luan into “inverse circles” to raise the edges of the bunk pads in hopes that they would spread the load more effectively to the edges of the bunk boards. I laminated two layers of 3/4″ plywood and then the 1/8″ luan, sanded edges round, waterproofed with deck and fence sealer (two wet coats) and then Diana stapled bunk carpet to the bunks with stainless steel staples.

Time to Get the Boat on the Trailer

With the bunks fitted to the trailer casually, we were ready to go fetch the boat as they would have to be adjusted for height and angle while setting the boat on the trailer in order to complete building a sailboat trailer. Check out the next post to see the process we came up with for transferring the boat from the jack stands to the new trailer!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Looking to build a trailer

- Thread starter mcurcio1989

- Start date Sep 13, 2010

- Forums for All Owners

- Trailer Sailors

mcurcio1989

I have a 1970 Coronado 25. I got it last year for the right price (next to nothing). I like the boat but I really do not want to pay for storage over the winter. I put it for sale but no one wants to buy a 25 foot sailboat with no trailer or rack in the the fall (obviously). Unfortunately the marina turned the old rack into firewood. I have a good amount of experience behind a welder and I have some friends who build frames for hot rods and such. It would seem that I could find an old dual axle powerboat trailer and convert it over to use on this boat at a reasonable price. You can find them around here for free or very cheap and I can get my hands on good quality scrap steel that would be good for modifying for free or next to free. This boat is a fixed keel so that complicates things in that, from what I understand the boat will have to be lifted out at a marina. That's not a big problem but it would be nice if that wasn't the case. I have a decent amount of questions on this and their seems to be little information about it. I can find info on people who have done it but not on what their design considerations were. Things I am considering. -Supporting the keel: how much should the keel be supported? -Bunks: I have seen front to back and side to side bunks as well as the pads used for sail boats. What should determine which ones I should use. If pads, how many? Also this will be used to store the boat on over the winter. -How does the weight need to be balanced over the axles. I would assume we want basically the keel centered over the axles maybe a little forward to give it some tongue weight. That seems to be the norm of the ones I have looked at. -Where exactly should i locate the supports. . .is their any exact procedure to follow as far as the locations. To my knowledge sailboats do not have stringers like powerboats so its not like I can shoot for that. -What would my best plan of attack be for the height of the pads to account for the keel height and curve of the hull. It is in the water so measurements will be difficult. . . .let me know of other things I should link into. I am new to this forum and I don't know how much this topic has been discussed so If anyone has good information, links, or knowledge from tackling something like this let me know. I think the trailer is the best option because I have free storage for anything on wheel and It will make the boat more sell-able when that time comes.

Charlie13958

google coronado25 you will get some pics and ideas. Here is a mast raising on a 25 on a trailer. http://www.youtube.com/watch?v=5shZq7yIhxM

Google Road King Trailers and link to the sailboat trailer area of the site. That should give you some ideas on what you might need to do to modify a trailer. I have one for my Com-Pac 23 and it's great. Mine has a guide for the shoal keel and bunks on the sides to support the boat. I think you should stay away from rollers as they don't provide the support that bunk board do and could possibly damage the boat. Also, note the tongue extension. This is a must for ramp launching. I actually only need the rear half of my trailer submerged and I can crank the boat all the way onto the trailer with the winch. As for the keel, it should take most of the weight on the trailer, just like it would if the boat was placed on jackstands in a boat yard. My entire keel sits on the bottom support and is centerd by the keel guides.

I modded a bass boat trailer, it works fine. If you don't have to go far I would build a cradle for the trailer from wood to get it home then support the boat with slings or blocks to get it positioned right and get to work. Need help? I could use a working vacation!

Barnacle Bill

Trailer building or modification I have built trailers from scratch and have modified powerboat trailers to accommodate sailboat hulls. First, make sure the powerboat trailer you get has the capacity required to accommodate your boat, with water and fuel in the tanks, outboard and gear. The tires have to be rated accordingly too. Most PB trailers do not have an appropriate keel bed, so that is where you would start. you can weld angle iron in a rectangular pattern on to the thwart members of the trailer down the centerline to that it accommodates a 2x6 or 8 or 10 - whatever seems a good width. The best thing to do would be to lower the boat in slings on to this keel support after you have installed it so that you can determine exactly the location and height of each upright. If you don't have that luxury, or a marina to help, then you have to carefull measure. If you had the old cradle then you could use that as a locator for your fore and aft pads. But, since that ended up in someone's fire place, you either have to find another or start from scratch. Usually your uprights will be welded to the fore and aft members of the trailer, or, perhaps just inside of them attached to a thwart cross member. The location of the cross members will have something to do with the location of the uprights. You can use long boards on each side port and starboard to support the hull, or pads, as you suggested. Pads, if they have threaded rods, like a Brownell boat stand, are adjustable and you can insert them into a square or round tube slightly larger than the threaded rod. Make your tube short enough so you have 6 to 8 inches (whatever works) of adjustment. Depending on the location of the cross members, I would think you would, of course use at least 4 (two in the front and two in the back on each side) as a minimum and maybe 6 if you have a spot to put one in the middle. You can even go 4 on each side, but that might be getting too much for the size boat. With these adjustable pads you have some breathing room if your measurements are suffering some. If you are going to use a board (cheaper approach), then you need to have at least 4 total uprights and possibly 6 or 8. If you can get a perfect measurement (like when the boat is lowered with slings onto the trailer, then you can weld in uprights that are exactly the length you need. Otherwise it might be wise to us an inner and outer tube, whether square or round to adjust. If you are a welder you can drill a hole in the side of the outer tube and weld in a nut to accommodate a bolt which can be used to tighten the inner tube in place. A couple of these nut and bolt arrangements per upright would be better than one. You also need to attach the board with a method that lets it rotate to the right position to sit flat against your hull. You can easily do this by welding a plate with a hole it in to the upper/inner tube so that the plane of that plate runs thwartwise. Then attach an angle iron piece to that with holes in it so that you can screw or bolt it into the board, and also put a bolt through the welded on plate to allow the board to swivel in or out to get the correct angle. The next thing you need to do is probably raise the bow support. The powerboat one will have too short a one and so you have to get creative and add more material (butt weld it in) to raise it so that the winch is in a good place to attach to a bow eye on your stem. The last thing I would consider is keel guides. If you ever were to launch and retrieve your boat - especially retrieve - out of the water, then you want to make sure your keel goes right in the center of the trailer for exact and carefree retrieving. The location of the winch in regards to the bow eye is important to pull the boat up to the perfect towing position. Hope this helps.

^That is basically exactly what I have been planning in my head so far. Wow great information guys. I wasn't sure how much support their would be for a diy trailer but this seems to be fairly common. I am really excited to get started now. I am definitely going to go with a double axle trailer because they tow so much better and just about any reasonably sized double axle trailer should support the 4,500lbs this boat weighs. I think the bunks are where I am going to go with this. It seems that it will be more cost efficient, provide better support, more capable of being reinforced, and would be easier for use at a ramp. I like the idea of using the bolts threaded in to adjust height and I also like the idea of swiveling bunks. I was basically planning exactly what you described as far as the keel and using guides etc. My dad has big sheets of the plastic that is used on toilet partitions so that would work great to put on above the wood to help the keel slide on easily. This boat doesn't have a bow eye so I am going to have to figure something out with that. Either install one or use kleets. For the measurements I think I will try the coronado forum to ask those guys what their measurements are. My other option is to bring it up to the very lightly sloped shore just until the keel touches at 3.5 feet and the take measurements from the boat to the river bottom. You guys that are using these trailers to launch from a shore, how much draft do you require? With this boat requiring 3.5 feet I will need at least 4.5 feet of depth at the ramp. I am going to get some measurements from the ramps in my area. I'm hoping that it will be doable to ramp this and not have to take it to the marina. Those guys are hurting and they are making prices ridiculous instead of making them less. With this boat being 25 feet long I will basically have 13 feet from right in between the two axles to where the front of the boat will be on the trailer. With that said and taking my depth into consideration where about would a good range be for the length of the tongue. Ie from the front of the boat forward what range of feet should I look for. Just trying to get a feel for what is commonly done. Thanks for all the help so far I think I am getting a pretty good grasp on this!

Before you get to ambitious put together a mterials list including Iron, springs, wheels, tires, bearing buddies, hubs, winch, bunks, etcs. Compare what the raw materials will run as to what factory stock trailer made to fit your boat will cost. You might be surprised as I was when considering building a trailer. I think Coronado was bought out by Catalina? Fair Winds...

Well I'm not actually building the trailer. I am going to modify a powerboat trailer to fit this boat. Anyone have any experience pulling out a boat with a 3.5 foot draft at a ramp? I went down their yesterday and took some measurements. Based off what I have found, provided I have a long enough trailer, this ramp could definitely accommodate this. It is fairly steep, very deep and has concrete 30 feet out on a low day. I found a section view of the coronado hull/keel and scaled it up with a sketch of the measurements of this ramp. I was having a hard time visualizing the different dimension i would need to account for. based off of this it looks like if i can find a trailer with 18 feet from the hitch to in between the axles and 1 foot of ground clearance to the cross members this will surely work!

My Com-Pac has only 27 inches of draft and it sits about 15 inches above ground on the trailer so I know it's a bit less than your Coronado. As i stated before, you don't necessarily need the entire trailer submerged in order to get your boat fully on the trailer. The stern will float the whole time and allow you to winch the boat up. As long as the rear end of the bunks or the rear stand pads are submerged enough you should have no problems. If you have thirty feet of ramp at low water you should have no problem. Steep and deep are good too. I have a tongue extension that adds 4 feet of length to the trailer. I have seen some extensions that add more. If you are modifying a trailer this should be one area that you should focus on. It makes launching and retrieving dramatically easier.

^Thats some good info for me. I was sort of unsure about the dynamics of loading the boat on the trailer, as far as how much of the trailer would need submerged. Like I said earlier I ended up making a cross sectional view of the ramp I use on some graph paper then scaled a cross section of my boat and cut that out. So I was moving the boat around and measuring the clearances out. I had a 17 foot tongue with the hitch a foot from the water and the keel sitting one foot off the road. With those dimensions I was able to get the front of the bunks in the water. Based off what you are saying that should be more than enough clearance. That is great news because the 1 foot of clearance would be a little tricky and I would rather not have to have the rear tires of the tow vehicle in the water. I am focusing on finding something with a low v in the middle and around 18 feet of distance from the tongue to in between the axles. based off what your saying I should have plenty off wiggle room for loading if I can get close to those dimensions. Thanks that is really what I was looking for as I have never seen a sail boat loaded on the ramp before. I've done plenty of power boats just not sailboats.

I have a retractable tongue, shutup with the comments, on my V25 trailer because in some places you nee to sink the trailer to get the boat off. It slide in and out of the socket with varying positions to lock it in place. Fair winds...

Look For My Post Under Ask All Sailors About Launching A Sailboat. It's A True Story. Fair Winds...

Here's a few before/after pics to wet your appetite for a major DIY project. This was a CB boat so yours will be a couple feet taller. Make no mistake it'll take far more time, effort, brain power and cash than you are figuring but it can be done. If I wasn't hauling it far it'd be best to locate screw jacks at the lift zones and a bow roller with a stop and a stout bow eye/hook. Otherwise build bunks to saddle the curves exactly so you don't have hot spots wearing away while you truck it down the road. You're sure the boat is worth the effort, right? Good luck. Mike

Attachments

Keel guides are definitely a good idea (as per the centerboard boat trailer photos). Rollers are easier than bunks for launch / retrieval, but apply more force to the hull. Keep the structure of the boat in mind when locating rollers / bunk supports so that the bulkheads take the load as much as possible. Be sure to have a platform under the keel as for a keelboat the keel will take most of the weight.

You don't want to use cleats for a couple of reasons. First you most likely will tear them out of your deck and secondly they will be in the wrong location. A properly placed bow eye will put the boat right where you want it when retrieving the vessel out with the use of the winch.

soling42 said: Here's a few pics to wet your appetite for a major DIY project. This was a CB boat so yours will be a couple feet taller. Make no mistake it'll take far more time, effort, brain power and cash than you are figuring but it can be done. If I wasn't hauling it far it'd be best to locate screw jacks at the lift zones and a bow roller with a stop and a stout bow eye/hook. Otherwise build bunks to saddle the curves exactly so you don't have hot spots wearing away while you truck it down the road. You're sure the boat is worth the effort, right? Good luck. Mike Click to expand

I'd cut my loss and donate it to the local youth sailing group immediately. You'll feel better about helping an enthusiastic group with deeper pockets and plenty of volunteer help. Your time is worth something, added to your cash outlay it sounds like a break even trial to still end up with a boat that you'll inevitably have to deal with next spring again. Let it go...life is too short to mess with a beater boat you don't absolutely love. Mike

I bought a trailer yesterday. I really couldn't find any tandem axle trailers for under 400. The single axles are everywhere and crazy cheap but bigger tandems start getting expensive! I ended up heading over to a marine salvage yard 30 min from my house to see what they had. With 500 junk boats their they had a very good selection of old trailers for cheap. I made a deposit on a tandem axle trailer that has a 24 foot powerboat on it. If anything this will be to big. . .not a problem! From in between the axles to the tongue is 21 feet so it will easily launch the boat from the ramp. He is charging me $400 for it which i thought was a good deal. They just have to scrap and move the boat that is on it before I can go pick it up. I should be starting this project pretty soon! I have about $700 into this and I will have about $1200 once it is on the trailer. I am sure I can get it sold in the spring and not lose anything. I don;t have to pay anything for storage and I can keep it their as long as I want so It is not costing me any money to not sell it. I would think I have deeper pockets than any local sailing organization I just want to be able to get out what I have in the boat. I love fabricating so I will enjoy this project and hopefully I will be able to sell this boat in the spring. Plus after spring I will have some very fat checks heading my way so I will be more likely to buy another sailboat that I can actually keep at my dock.

So i got the trailer built this weekend and gave it a test. I'll summarize To modify the trailer I used a section of old scaffold which basically emulated to the t what the boat jacks do. same material and everything. Tripod with a vertical tube and adjustable pads. For the keel support i got a set of pallet rack cross members which were rated at 5k lbs. everything was very solid. So we pulled the boat out. Ramp worked out great and the truck had no problem. The boat practically floated on. We pulled it out and had to adjust the pads a couple times. Once we got it pulled out we then realized that it was sitting a good two feet to far back. negative tongue weight and the trailer was deflecting as a result. So We were going to back it in and re adjust but my dad and i had a mutual feeling of terror looking at that huge boat up in the air like that. It was getting late so we backed the boat back in and called it quits. I am really scared of trailering that thing it is just so big and high. There were some things with the design that I don't like. I separated my pads by about 11 feet centered over the axles.I just put them on the cross members. That was to far and I think the load would be more steady if i move those closer to the axles. I am a little concerned with the weight. The trailer had a 24 foot powerboat on it so i think weight would be comparable. However with my boat on their the suspension seemed to be bottomed out. The tires are good for 6k lbs though. Is this crazy? I am starting to contemplate just taking this to a marina and using my trailer as a rack. It just seems so terrifying to trailer a sail boat of that size on the road the boat is so tall. Just looking up and seeing the rub rail way up at the top of my reach is scary. I try to tell myself that the weight is all way down low on the keel but it still seems creepy. I am not concerned with my supports and welds. That is all very capable of supporting the applied loads. What scares me is the trailer itself failing at some point. with a 25 foot trailer and that much weight an uneven load can cause some crazy bending moments.

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

This page is currently unavailable

How to build a sailboat trailer extension

This is the remarkable true story about how I built a sturdy trailer extension and got 27 stitches in the process. I recommend the former, though I included instructions on how I got the latter just in case you’re interested.

The previous owner of my Catalina 270 took her in and out of the water with a crane. Unfortunately on my lake, there are no cranes, so we have to launch the boat by backing the trailer into the lake. When the lake is low or the ramps shallow, it is necessary to extend the trailer out further into the water than the tow vehicle can go. One way to accomplish this task is by building an extension to go between the trailer and tow vehicle, which allows the trailer to be let down further out into the water.

On my prior boat, I used a strap and rolling wheel on the front of the trailer to lower the boat in. The problem with the strap (or rope, or cable) method is that you can’t push the trailer further into the water. Often times there are large ruts or pits in the dirt beneath the ramp caused by power boaters gunning their engines to push boats on and off trailers. To pass over these ruts using a strap, you have to let the boat back quickly down the ramp to build up enough momentum to roll through the ruts, and I always worried that a deep rut on one side or the other would tip the trailer to the side. It never did, but I always imagined it happening.

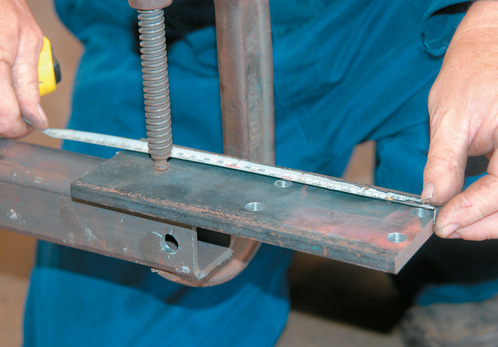

So this time I wanted more control over the boat, and decided to build a solid bar extension. I looked at several designs on various websites and decided I wanted one that was heavy duty enough to support the weight without needing a dolly wheel under the front of the trailer. I wanted about 15 feet of extension, and it needed to be easily installed, removed, and stowed on the trailer.

First, off to the local metal shop, where I purchased 15 feet of galvanized steel, in the same dimension as the steel on the trailer’s tongue (3″x5″). I think it’s possible to go with something smaller, but not knowing how it would handle the load I decided to stay with the original dimensions.

Next, I ordered a 2-5/8″ hitch coupler from Amazon on the front of the hitch extension, which would connect to the tow vehicle’s ball without having to switch ball sizes.

Then, I had the terrible idea of simply bolting the hitch extension alongside the trailer’s tongue. Two large bolts, spaced about 2 feet apart, seemed like they would do the trick. However, the weight of the trailer bent the bolts and the extension sagged to about 2 inches off the ground. It was enough to launch it the first year, but I knew I’d need a sturdier connection between extension bar and trailer by the time we hauled out in fall.

I ordered a 2- 5/8″ trailer ball to mount on the top of the extension bar. This ball would lock into the trailer hitch. At the back end of the bar, I planned to have two bars welded on that would hug the sides of the trailer tongue and be secured on top with a hitch pin.

The bars I chose were half inch thick steel. This is how I ended up with 27 stitches. My battery powered drill would never make it through, so I ran to the hardware store to pick up a corded drill. The drill I’d planned to buy was good, but when I got there I found a higher amperage drill on sale for less. More power for less money? Yes, please. So I walked out of the store with a 9 amp Hitachi drill.

I lifted my 25 lbs vice off the workbench and set it on the garage floor for safety. I locked the steel in the vice and started drilling, stopping every 30 seconds or so to add some oil into the hole. The whole operation felt pretty safe until the drillbit punched through the back side of the steel. That’s when the full fury of all 9 amps was unleashed. That monster drill grabbed the steel bar and 25 pound vice and spun them in circles so fast that by the time I let go of the trigger it had spun around 2 full times. I felt something had hit the back of my leg, and glancing down, realized I was in trouble. The half inch bar traveling at 9 amps had laid open the back of my calf. It was going to need stitches. And not a few, because as it turns out, half inch steel is not a very precise cutting implement.

On the drive over to the hospital, I used Intermountain Healthcare’s “ConnectCare” telehealth app on my phone. It was amazing, I could actually show the doctor a video of the wound from the car so she could tell me if I needed to go straight to the emergency department, or just a clinic. One emergency department visit and 27 stitches later, I was good to go. And I only had one more bar to drill through. It took me two weeks to get the courage to do it.

But the end result was a great trailer extension. It’s very sturdy, able to hold the front of the trailer at the same height over the full length of the bar. It also has enough ground clearance that I can attach it on flat pavement and drive it over the edge of the road onto the ramp without bottoming out. This makes work on the ramp much safer, because the trailer is never unhitched from the tow vehicle while on the incline. I also have an impressive scar on the back of my leg which I refer to proudly as “a sailing injury.”

Recent Posts

Key Lime Sailing Day 5 - After Thoughts

Checkout was simple. I asked what we needed to do, and was told "Just leave us a good review if we earned it!" And yes, they did. A few observations for a next trip here: It's a quick trip from...

Key Lime Sailing Day 4 - Key West

We got up early this morning and headed down to Islamorada for a dive. It was a successful trip, seeing moray eels, nurse sharks, and some lionfish. Then off for the drive to Key West. It's...

DIY Boat Building Plans

How to Build a Boat Trailer

Download over 500 Boat Plans. Click on the link below.

-->click here<--.

Table of Contents

Key Takeaways – How to Build a Boat Trailer

⛵ Building a boat trailer allows for customization of size, shape, material, color, and features.

🔧 Building a boat trailer can save money, and using recycled materials can further reduce costs.

🛠 Building a boat trailer is an opportunity to learn new skills such as design, welding, woodworking, and more.

😄 Building a boat trailer can be a fun and enjoyable hobby that allows for creative expression.

🤔 Consider factors like time, space, skills, and resources before deciding to build a boat trailer.

🧰 Essential tools for building a boat trailer include saws, drills, sanders, hammers, wrenches, pliers, welders, multimeters, levels, and tape measures.

🌲 Common materials for boat trailers include wood, metal, and plastic, and you can mix and match them as needed.

⚙️ Safety tips include wearing protective gear, working in a well-ventilated area, using proper tools , following instructions, securing workpieces, keeping the work area clean, being cautious with electricity, and seeking help when needed.

📐 Design your boat trailer by determining size and weight capacity, selecting materials, and creating a plan.

✂️ Preparing materials involves cutting them to size using appropriate tools for wood, metal, or plastic.

🪚 Sanding materials smooth is necessary to remove rough edges and achieve an even finish, with different tools for wood, metal, and plastic.

🚢 Assemble the Boat Trailer Frame involves joining wood, metal, or plastic parts using various tools and methods like screws, bolts, nails, rivets, and welds.

📏 When assembling the frame, follow your plan carefully, check measurements, use a level for squareness, and secure connections with washers and lock nuts for stability and safety.

👷 Wear protective gear such as gloves, goggles, and masks to prevent injuries while assembling the boat trailer frame.

🪚 Assemble different types of frames based on the material used (wood, metal, or plastic) with corresponding fasteners.

🚤 Finish your boat trailer by attaching the axle, wheels, tires, hitch, and other features.

✅ When finishing, follow your plan, check measurements, use a level for stability, and secure connections firmly.

⚙️ Attach the axle, wheels, tires, hitch, and any additional features to make your boat trailer functional and safe.

🏋️♂️ Make sure your boat trailer is strong enough by choosing the right materials, fasteners, and joints.

🌧️ To watertight your boat trailer, seal any gaps, cracks, or holes in the frame, and protect materials and parts from water exposure and moisture.

🛠️ Maintain your boat trailer by cleaning, lubricating, inspecting, and storing it properly.

🚢 Choose the material for your boat trailer (wood, metal, or plastic) based on your budget, preference, availability, and purpose.

🎨 Building a custom boat trailer: Define its purpose, get inspired, be creative with materials and design, and thoroughly test it.

🏁 Building a boat trailer is a rewarding DIY project, offering cost savings, customization, and skill development. Enjoy the process!

Do you love boating but hate the hassle of renting or buying a boat trailer? Do you want to save money and customize your own boat trailer to suit your needs? Do you enjoy DIY projects and learning new skills? If you answered yes to any of these questions, then this article is for you.

In this article, we will show you how to build a boat trailer from scratch. We will cover everything you need to know, from the tools and materials you need, to the step-by-step instructions on how to design, assemble, and finish your boat trailer. We will also answer some frequently asked questions and provide some resources for getting help with your boat trailer building project.

By the end of this article, you will have a clear idea of how to build a boat trailer that is strong, durable, and safe. You will also have the satisfaction of creating something with your own hands and saving money on the cost of a new trailer. So, let’s get started!

What is a Boat Trailer?

A boat trailer is a vehicle that is used to transport a boat from one place to another. It consists of a frame that supports the boat, an axle that connects the wheels and tires, a hitch that attaches the trailer to the towing vehicle, and other features such as a winch, a lighting system, and a storage compartment.

A boat trailer can be either single-axle or tandem-axle, depending on the size and weight of the boat. A single-axle trailer has one axle and two wheels, while a tandem-axle trailer has two axles and four wheels. A tandem-axle trailer can carry heavier loads and provide more stability, but it is also more expensive and harder to maneuver.

A boat trailer can also be either open or enclosed, depending on the type of boat and the level of protection required. An open trailer has no roof or walls, while an enclosed trailer has a roof and walls that protect the boat from the weather and theft. An enclosed trailer can also offer more storage space and comfort, but it is also more costly and heavier.

Why Build a Boat Trailer?

Building a boat trailer can be a rewarding and fun project for anyone who loves boating and DIY. There are many reasons why you might want to build your own boat trailer instead of buying or renting one. Here are some of the benefits of building a boat trailer:

- Save money . Building a boat trailer can be much cheaper than buying or renting one. Depending on the size and quality of the trailer, you can save hundreds or even thousands of dollars by building your own. You can also use recycled or salvaged materials to reduce the cost even further.

- Customize . Building a boat trailer allows you to customize it to your specific needs and preferences. You can choose the size, shape, material, color, and features of your trailer according to your boat and your personal taste. You can also add or modify any features as you go along or as your needs change.

- Learn . Building a boat trailer can help you learn new skills and improve your existing ones. You can learn how to design, measure, cut, drill, sand, paint, weld, bolt, wire, and more. You can also learn about the physics and mechanics of towing, such as weight distribution, balance, alignment, friction, etc.

- Enjoy . Building a boat trailer can be a fun and enjoyable hobby that you can do alone or with your friends or family. You can express your creativity and personality through your trailer design. You can also take pride in your workmanship and show off your finished product to others.

When to Build a Boat Trailer?

Building a boat trailer is not for everyone or for every situation. There are some factors that you need to consider before deciding to build your own boat trailer. Here are some questions that you need to ask yourself:

- Do you have enough time? Building a boat trailer can take anywhere from a few days to several weeks or even months, depending on the complexity of the project. You need to have enough time to plan, prepare, assemble, and finish your trailer without rushing or compromising on quality.

- Do you have enough space? Building a boat trailer requires a large and flat area where you can work safely and comfortably. You need to have enough space to store your tools and materials, lay out your frame and parts, move around freely, and test your trailer.

- Do you have enough skills? Building a boat trailer requires some basic skills in carpentry, metalwork, electrical work, etc. You need to know how to use various tools such as saws, drills, sanders, hammers, wrenches, etc. You also need to know how to read plans and diagrams, follow instructions, measure accurately, etc.

- Do you have enough resources? Building a boat trailer requires some investment in tools and materials. You need to have access to or purchase the essential tools and materials for your project. You also need to have access to or purchase any additional features or accessories that you want to add to your trailer.

If you answered yes to all of these questions, then you are ready to build your own boat trailer. If you answered no to any of these questions, then you might want to reconsider your decision or seek some help from others.

What are the Essential Tools and Materials for Building a Boat Trailer?

The tools and materials that you need for building a boat trailer depend on the size, type, and design of your trailer. However, there are some common tools and materials that you will need for any boat trailer project. Here is a list of the essential tools and materials for building a boat trailer:

- Saw . A saw is used to cut wood, metal, or plastic materials to size. You can use a hand saw, a circular saw, a jigsaw, a hacksaw, or a band saw, depending on the material and the shape that you want to cut.

- Drill . A drill is used to make holes in wood, metal, or plastic materials. You can use a hand drill, a power drill, or a drill press, depending on the size and depth of the hole that you want to make. You also need various drill bits for different materials and diameters.

- Sander . A sander is used to smooth the edges and surfaces of wood, metal, or plastic materials. You can use a hand sander, a belt sander, an orbital sander, or a disc sander, depending on the material and the area that you want to sand.

- Hammer . A hammer is used to drive nails, screws, bolts, or other fasteners into wood, metal, or plastic materials. You can use a claw hammer, a ball-peen hammer, a sledgehammer, or a rubber mallet, depending on the type and size of the fastener that you want to use.

- Wrench . A wrench is used to tighten or loosen nuts, bolts, or other fasteners on wood, metal, or plastic materials. You can use an adjustable wrench, a socket wrench, a combination wrench, or a torque wrench, depending on the type and size of the fastener that you want to adjust.

- Screwdriver . A screwdriver is used to turn screws or other fasteners on wood, metal, or plastic materials. You can use a flathead screwdriver, a Phillips screwdriver, a hex screwdriver, or a star screwdriver, depending on the type and size of the fastener that you want to turn.

- Pliers . Pliers are used to grip, twist, bend, cut, or crimp wires or other materials. You can use needle-nose pliers, slip-joint pliers, wire cutters, wire strippers, or crimping pliers, depending on the type and size of the material that you want to manipulate.

- Welder . A welder is used to join metal parts together by melting and fusing them with an electric arc or a gas flame. You can use a stick welder, a MIG welder, a TIG welder, or a gas welder, depending on the type and thickness of the metal that you want to weld.

- Multimeter . A multimeter is used to measure voltage, current, resistance, or continuity of electrical circuits or components. You can use a digital multimeter or an analog multimeter, depending on the accuracy and readability that you prefer.

- Level . A level is used to check if a surface or an object is horizontal or vertical. You can use a spirit level, a laser level, or a digital level, depending on the precision and convenience that you need.

- Tape measure . A tape measure is used to measure length, width, height, or diameter of objects or materials. You can use a retractable tape measure, a steel tape measure, or a cloth tape measure, depending on the flexibility and durability that you want.

- Square . A square is used to check if an angle is 90 degrees or if two surfaces are perpendicular. You can use a carpenter’s square, a combination square, or a speed square, depending on the versatility and portability that you need.

- Wood . Wood is one of the most common and versatile materials for building a boat trailer. It is easy to work with, relatively cheap, and widely available. You can use various types of wood such as pine, oak, cedar, or plywood , depending on the strength and appearance that you want.

- Metal . Metal is another common and durable material for building a boat trailer. It is strong, rigid, and resistant to corrosion and wear. You can use various types of metal such as steel, aluminum , or galvanized metal, depending on the weight and cost that you want.

- Plastic . Plastic is a lightweight and flexible material for building a boat trailer. It is easy to mold, cut, and join, and it can withstand water and weather exposure. You can use various types of plastic such as PVC pipe, HDPE sheet, or ABS plastic, depending on the shape and function that you want.

- Fasteners . Fasteners are used to join two or more parts together securely. You can use various types of fasteners such as nails, screws, bolts, nuts, washers, rivets, etc., depending on the material and the strength that you need.

- Axle . An axle is a metal rod that connects the wheels and tires of the boat trailer. You can use a straight axle or a torsion axle, depending on the suspension and clearance that you want.

- Wheels and tires . Wheels and tires are the parts that allow the boat trailer to roll on the ground. You can use various sizes and types of wheels and tires, depending on the load and terrain that you expect.

- Hitch . A hitch is a metal device that attaches the boat trailer to the towing vehicle. You can use a ball hitch, a pintle hitch, or a gooseneck hitch, depending on the weight and angle of the trailer.

- Winch . A winch is a mechanical device that helps you load and unload your boat from the trailer. It consists of a cable, a drum, and a handle or a motor. You can use a manual winch or an electric winch, depending on the power and convenience that you want.

- Lighting system . A lighting system is a set of lights that make your boat trailer visible and safe on the road. It includes brake lights, turn signals, tail lights, license plate lights, etc. You can use LED lights or incandescent lights, depending on the brightness and efficiency that you want.

- Storage compartment . A storage compartment is an optional feature that provides extra space for storing tools and supplies on your boat trailer. It can be a box, a bag, a rack, or a basket, depending on the size and shape that you want.

Safety Tips for Building a Boat Trailer

Building a boat trailer can be a fun and rewarding project, but it also involves some risks and hazards. You need to follow some safety tips to avoid injuries and accidents while working on your boat trailer. Here are some safety tips for building a boat trailer:

- Wear protective gear . You should wear gloves, goggles, ear plugs, masks, boots, etc., to protect yourself from cuts, burns, sparks, dust, noise, etc., while using tools and materials.

- Work in a well-ventilated area . You should work in an open or airy space to avoid inhaling fumes, smoke, or dust from welding, cutting, sanding, painting, etc.

- Use proper tools . You should use tools that are suitable for the task and material that you are working on. You should also check if the tools are in good condition and have no defects or damages.

- Follow instructions . You should follow the instructions and guidelines that come with your tools, materials, plans, etc., to ensure that you use them correctly and safely.

- Secure your workpiece . You should clamp or fasten your workpiece to a stable surface or support to prevent it from moving or falling while you work on it.

- Keep your work area clean . You should keep your work area tidy and organized to avoid tripping over wires, cords, hoses, etc., or knocking over tools, materials, parts, etc. You should also dispose of any waste or scrap materials properly and safely.

- Be careful with electricity . You should be careful when working with electrical tools or components, such as welders, drills, multimeters, lighting systems, etc. You should make sure that the power source is off before connecting or disconnecting any wires or cables. You should also avoid touching any exposed wires or metal parts with your bare hands or wet skin.

- Ask for help . You should not hesitate to ask for help from someone who has more experience or knowledge in building a boat trailer. You can also consult online forums, blogs, videos, etc., for tips and advice from other boat trailer builders.

These are some of the safety tips that you need to follow while building a boat trailer. By following these tips, you can reduce the risk of injuries and accidents and enjoy your boat trailer building project.

Building a Boat Trailer Step-by-Step

Now that you have learned the basics of what a boat trailer is, why you might want to build one, and what tools and materials you need, it is time to get to the fun part: building your boat trailer.

In this part, we will show you how to build a boat trailer from scratch, following a simple and effective process. We will divide the process into four main steps:

- Design your boat trailer

- Prepare the materials

- Assemble the boat trailer frame

- Finish the boat trailer

For each step, we will provide detailed instructions, diagrams, tips, and examples to help you complete your boat trailer project successfully. We will also assume that you are building a single-axle open boat trailer made of wood and steel, but you can adjust the steps according to your own preferences and needs.

Let’s begin!

Step 1: Design Your Boat Trailer

The first step in building a boat trailer is to design it. Designing your boat trailer involves determining the size and weight capacity of your trailer, choosing the type of material you want to use, and creating a plan for your trailer.

Determine the Size and Weight Capacity of Your Boat Trailer

The size and weight capacity of your boat trailer depend on the size and weight of your boat. You need to measure the length, width, height, and weight of your boat accurately before designing your trailer. You can use a tape measure, a scale, or a calculator to do this.

The length of your boat trailer should be slightly longer than the length of your boat, to allow some space for the hitch and the winch. The width of your boat trailer should be slightly wider than the width of your boat, to allow some clearance for the wheels and tires. The height of your boat trailer should be as low as possible, to reduce wind resistance and improve stability.

The weight capacity of your boat trailer should be greater than the weight of your boat, plus any additional load that you might carry on your trailer, such as fuel, water, equipment, etc. You can use this formula to calculate the weight capacity of your boat trailer:

WeightCapacity=BoatWeight+AdditionalLoad+SafetyFactor

The safety factor is a percentage that accounts for any possible variations or errors in your measurements or calculations. You can use a safety factor of 10% to 20%, depending on how confident you are in your data.

For example, if your boat weighs 1,000 pounds and you plan to carry 200 pounds of additional load on your trailer, you can use a safety factor of 15% and calculate the weight capacity of your boat trailer as follows:

WeightCapacity=1,000+200+(1,000+200)×0.15

WeightCapacity=1,380pounds

Choose the Type of Material You Want to Use

The type of material you want to use for your boat trailer depends on your budget, preference, and availability. You can use wood, metal, plastic, or a combination of these materials for different parts of your trailer.

Wood is a common and versatile material for building a boat trailer. It is easy to work with, relatively cheap, and widely available. You can use various types of wood such as pine, oak, cedar, or plywood, depending on the strength and appearance that you want. You can use wood for the frame, the deck , or the storage compartment of your boat trailer.

Metal is another common and durable material for building a boat trailer. It is strong, rigid, and resistant to corrosion and wear. You can use various types of metal such as steel, aluminum, or galvanized metal, depending on the weight and cost that you want. You can use metal for the axle, the wheels, the tires, the hitch, or the winch of your boat trailer.

Plastic is a lightweight and flexible material for building a boat trailer. It is easy to mold, cut, and join, and it can withstand water and weather exposure. You can use various types of plastic such as PVC pipe, HDPE sheet, or ABS plastic, depending on the shape and function that you want. You can use plastic for the lighting system or the fenders of your boat trailer.

You can also mix and match different materials for different parts of your boat trailer, as long as they are compatible and secure. For example, you can use a wood frame with a metal axle and wheels, or a metal frame with a plastic deck and lighting system.

Create a Plan for Your Boat Trailer

The final step in designing your boat trailer is to create a plan for it. A plan is a detailed diagram that shows the dimensions, shapes, positions, and connections of all the parts of your boat trailer. A plan helps you visualize your boat trailer design and guides you through the building process.

You can create a plan for your boat trailer using various methods such as sketching on paper, drawing on a computer program, or purchasing a pre-made plan online or offline. You can also modify an existing plan to suit your needs and preferences.

A good plan for your boat trailer should include:

- A scale that shows the ratio between the actual size and the drawn size of your boat trailer

- A legend that explains the symbols, colors, and labels used in your plan

- A front view that shows the length and height of your boat trailer

- A side view that shows the width and height of your boat trailer

- A top view that shows the length and width of your boat trailer

- A cross-section view that shows the internal structure of your boat trailer

- A detail view that shows any specific or complex part of your boat trailer

- A list of materials that shows the type, quantity, size, and cost of each material used in your boat trailer

- A list of tools that shows the type and function of each tool used in your boat trailer

- A list of steps that shows the order and procedure of each task involved in building your boat trailer

This is how you design your boat trailer. By following these steps, you can create a custom boat trailer design that meets your needs and preferences.

Step 2: Prepare the Materials for Building Your Boat Trailer

The second step in building a boat trailer is to prepare the materials. Preparing the materials involves cutting the materials to size, sanding the materials smooth, and marking the materials for assembly.

Cut the Materials to Size

The first task in preparing the materials is to cut them to size. Cutting the materials to size means trimming them according to the dimensions and shapes that you have specified in your plan. You can use various tools such as saws, drills, or welders to cut your materials.

You should follow these tips when cutting your materials:

- Measure twice, cut once . You should measure your materials carefully and accurately before cutting them, to avoid wasting material or making mistakes. You can use a tape measure, a ruler, or a square to measure your materials.

- Use a guide or a template . You should use a guide or a template to help you cut your materials in a straight or curved line, depending on the shape that you want. You can use a piece of wood, metal, or plastic as a guide or a template, or you can draw a line on your material with a pencil or a marker.

- Secure your material . You should secure your material to a stable surface or support, such as a workbench, a table, or a sawhorse, to prevent it from moving or falling while you cut it. You can use clamps, screws, bolts, or nails to secure your material.

- Wear protective gear . You should wear gloves, goggles, ear plugs, masks, boots, etc., to protect yourself from cuts, burns, sparks, dust, noise, etc., while cutting your materials.

Here are some examples of how to cut different types of materials:

- Wood . To cut wood, you can use a hand saw, a circular saw, a jigsaw, or a band saw. You should choose the type of saw that matches the thickness and shape of the wood that you want to cut. For example, you can use a hand saw for thin and straight cuts, a circular saw for thick and straight cuts, a jigsaw for thin and curved cuts, and a band saw for thick and curved cuts.

- Metal . To cut metal, you can use a hacksaw, a metal shear, a plasma cutter, or a welder. You should choose the type of tool that matches the thickness and shape of the metal that you want to cut. For example, you can use a hacksaw for thin and straight cuts, a metal shear for thin and curved cuts, a plasma cutter for thick and straight cuts, and a welder for thick and curved cuts.

- Plastic . To cut plastic, you can use a knife, a scissors, a saw, or a drill. You should choose the type of tool that matches the thickness and shape of the plastic that you want to cut. For example, you can use a knife for thin and straight cuts, a scissors for thin and curved cuts, a saw for thick and straight cuts, and a drill for thick and curved cuts.

These are some examples of how to cut different types of materials for your boat trailer. You should follow your plan and mark your materials before cutting them, to ensure accuracy and consistency.

Sand the Materials Smooth for Building Your Boat Trailer

The second task in preparing the materials is to sand them smooth. Sanding the materials smooth means removing any rough edges, splinters, burrs, or rust from the surfaces of your materials. You can use various tools such as sanders, files, or sandpaper to sand your materials.

You should follow these tips when sanding your materials:

- Choose the right grit . You should choose the right grit of sandpaper or sander for your material and your desired smoothness. The grit is the number that indicates how coarse or fine the abrasive particles are on the sandpaper or sander. The lower the number, the coarser the grit; the higher the number, the finer the grit. You should start with a coarser grit and gradually move to a finer grit, to achieve a smooth and even finish.

- Use a steady motion . You should use a steady and consistent motion when sanding your materials, to avoid creating uneven or scratched surfaces. You should move the sandpaper or sander along the grain of the wood or metal, not against it. You should also apply a moderate pressure, not too hard or too soft, to avoid damaging or burning your material.

- Wear protective gear . You should wear gloves, goggles, masks, etc., to protect yourself from dust, debris, sparks, etc., while sanding your materials.

Here are some examples of how to sand different types of materials:

- Wood . To sand wood, you can use a hand sander, a belt sander, an orbital sander, or a disc sander. You should choose the type of sander that matches the size and shape of the wood that you want to sand. For example, you can use a hand sander for small and detailed areas, a belt sander for large and flat areas, an orbital sander for curved and irregular areas, and a disc sander for round and angled areas.

- Metal . To sand metal, you can use a file, a grinder, or a sandpaper. You should choose the type of tool that matches the size and shape of the metal that you want to sand. For example, you can use a file for small and detailed areas, a grinder for large and rough areas, and a sandpaper for fine and smooth areas.

- Plastic . To sand plastic, you can use a sandpaper or a sander. You should choose the type of sandpaper or sander that matches the thickness and shape of the plastic that you want to sand. For example, you can use a coarse sandpaper for thick and hard plastic, and a fine sandpaper or sander for thin and soft plastic.

These are some examples of how to sand different types of materials for your boat trailer. You should follow your plan and check your materials after sanding them, to ensure smoothness and quality.

Step 3: Assemble the Boat Trailer Frame for Building Your Boat Trailer

The third step in building a boat trailer is to assemble the boat trailer frame. Assembling the boat trailer frame involves joining the wood, metal, or plastic parts together to form the structure of your boat trailer. You can use various tools and methods such as screws, bolts, nails, rivets, welds, etc., to assemble your boat trailer frame.

You should follow these tips when assembling your boat trailer frame:

- Follow your plan . You should follow your plan and instructions carefully and accurately when assembling your boat trailer frame, to ensure that all the parts are in the right place and position. You should also check your measurements and alignments frequently, to avoid any errors or mistakes.

- Use a level . You should use a level to check if your boat trailer frame is square and level, to ensure stability and safety. You should also adjust your boat trailer frame as needed, to make it horizontal or vertical.

- Secure your connections . You should secure your connections firmly and tightly, to ensure strength and durability. You should also use washers, lock nuts, lock washers, or locking compounds, to prevent your connections from loosening or coming apart.

- Wear protective gear . You should wear gloves, goggles, masks, etc., to protect yourself from injuries or accidents while assembling your boat trailer frame.

Here are some examples of how to assemble different types of boat trailer frames:

- Wood . To assemble a wood boat trailer frame, you can use screws, bolts, nails, or wood glue. You should choose the type of fastener or adhesive that matches the thickness and strength of the wood that you are using. For example, you can use screws or bolts for thick and hard wood, nails or wood glue for thin and soft wood.

- Metal . To assemble a metal boat trailer frame, you can use bolts, rivets, or welds. You should choose the type of fastener or joint that matches the thickness and shape of the metal that you are using. For example, you can use bolts or rivets for thin and flat metal, welds for thick and curved metal.

- Plastic . To assemble a plastic boat trailer frame, you can use screws, bolts, or plastic welds. You should choose the type of fastener or joint that matches the thickness and shape of the plastic that you are using. For example, you can use screws or bolts for thick and flat plastic, plastic welds for thin and curved plastic.

These are some examples of how to assemble different types of boat trailer frames. You should follow your plan and check your boat trailer frame after assembling it, to ensure that it is strong and stable.

Step 4: Finish Your Boat Trailer by Attaching the Axle, Wheels, Tires, Hitch, and Other Features

The fourth and final step in building a boat trailer is to finish it by attaching the axle, wheels, tires, hitch, and other features. Finishing your boat trailer involves adding the parts that make your boat trailer functional and safe. You can use various tools and methods such as screws, bolts, nuts, washers, etc., to attach these parts to your boat trailer frame.

You should follow these tips when finishing your boat trailer:

- Follow your plan . You should follow your plan and instructions carefully and accurately when finishing your boat trailer, to ensure that all the parts are in the right place and position. You should also check your measurements and alignments frequently, to avoid any errors or mistakes.

- Use a level . You should use a level to check if your boat trailer is square and level, to ensure stability and safety. You should also adjust your boat trailer as needed, to make it horizontal or vertical.

- Wear protective gear . You should wear gloves, goggles, masks, etc., to protect yourself from injuries or accidents while finishing your boat trailer.

Here are some examples of how to finish different types of boat trailers:

- Attach the axle . To attach the axle to your boat trailer frame, you can use bolts, nuts, washers, and brackets. You should choose the type and size of the axle that matches the weight capacity and clearance of your boat trailer. You should also make sure that the axle is properly aligned and leveled with the frame.

- Attach the wheels and tires . To attach the wheels and tires to your axle, you can use lug nuts, wheel spacers, and valve stems. You should choose the type and size of the wheels and tires that match the load and terrain of your boat trailer. You should also make sure that the wheels and tires are properly balanced and inflated.

- Attach the hitch . To attach the hitch to your boat trailer frame, you can use bolts, nuts, washers, and couplers. You should choose the type and size of the hitch that match the weight and angle of your boat trailer. You should also make sure that the hitch is properly aligned and leveled with the towing vehicle.

- Add any other desired features . To add any other desired features to your boat trailer, such as a winch, a lighting system, or a storage compartment, you can use various tools and methods such as screws, bolts, wires, etc. You should follow the instructions and guidelines that come with your features or accessories, to ensure that they are installed correctly and safely.

- Finish the boat trailer . To finish your boat trailer, you can sand it smooth, apply a sealant or paint to protect it from the elements, and add any decals or stickers to personalize it.

These are some examples of how to finish different types of boat trailers. You should follow your plan and check your boat trailer after finishing it, to ensure that it is functional and safe.

Congratulations! You have successfully built your own boat trailer. Now you can enjoy boating with your own custom-made boat trailer.

FAQs – How to Build a Boat Trailer

In this part, we will answer some frequently asked questions on building a boat trailer. These questions are based on the common queries and issues that boat trailer builders face. We hope that these answers will help you solve your problems and improve your boat trailer building skills.

How do I make sure my boat trailer is strong enough?

One of the most important factors to consider when building a boat trailer is its strength. You want your boat trailer to be able to support the weight of your boat and any additional load without breaking or bending. You also want your boat trailer to be able to withstand the stress and strain of towing, loading, and unloading.

To make sure your boat trailer is strong enough, you need to choose the right materials, fasteners, and joints for your boat trailer frame and parts. You also need to follow the proper design and assembly techniques for your boat trailer.

Here are some tips on how to make sure your boat trailer is strong enough:

- Choose the right materials . You should choose materials that have high tensile strength, compressive strength, and shear strength for your boat trailer. Tensile strength is the ability of a material to resist being pulled apart, compressive strength is the ability of a material to resist being crushed, and shear strength is the ability of a material to resist being cut or sliced. You should also choose materials that have high stiffness, toughness, and ductility for your boat trailer. Stiffness is the resistance of a material to bending or deformation, toughness is the ability of a material to absorb energy without breaking, and ductility is the ability of a material to stretch or bend without cracking.

- Choose the right fasteners . You should choose fasteners that have high tensile strength, shear strength, and torque resistance for your boat trailer. Tensile strength is the ability of a fastener to resist being pulled apart, shear strength is the ability of a fastener to resist being cut or sliced, and torque resistance is the ability of a fastener to resist being twisted or turned. You should also choose fasteners that have high corrosion resistance, wear resistance, and vibration resistance for your boat trailer. Corrosion resistance is the ability of a fastener to resist rusting or deteriorating, wear resistance is the ability of a fastener to resist abrasion or friction, and vibration resistance is the ability of a fastener to resist loosening or coming apart due to movement or shaking.

- Choose the right joints . You should choose joints that have high tensile strength, shear strength, and fatigue resistance for your boat trailer. Tensile strength is the ability of a joint to resist being pulled apart, shear strength is the ability of a joint to resist being cut or sliced, and fatigue resistance is the ability of a joint to resist weakening or failing due to repeated stress or strain. You should also choose joints that have high stiffness, rigidity, and flexibility for your boat trailer. Stiffness is the resistance of a joint to bending or deformation, rigidity is the resistance of a joint to twisting or turning, and flexibility is the ability of a joint to adapt or adjust to changes in load or movement.

- Follow the proper design and assembly techniques . You should follow the proper design and assembly techniques for your boat trailer, to ensure that it is strong and stable. You should use the right size and number of fasteners and joints for each part of your boat trailer. You should also use the right angle and direction for each fastener and joint. You should also use washers, spacers, brackets, or braces to reinforce your connections and prevent stress concentration.

These are some tips on how to make sure your boat trailer is strong enough. You should also test your boat trailer regularly and inspect it for any signs of damage or wear.

How do I watertight my boat trailer?

Another important factor to consider when building a boat trailer is its watertightness. You want your boat trailer to be able to resist water penetration and leakage, especially when you submerge it in water to load or unload your boat. You also want your boat trailer to be able to prevent water damage and corrosion to your materials and parts.

To watertight your boat trailer, you need to seal any gaps, cracks, or holes in your boat trailer frame and parts. You also need to protect your materials and parts from water exposure and moisture.

Here are some tips on how to watertight your boat trailer:

- Seal any gaps, cracks, or holes . You should seal any gaps, cracks, or holes in your boat trailer frame and parts, using various sealants or adhesives such as silicone, epoxy, polyurethane, etc. You should choose the type of sealant or adhesive that matches the material and function of your boat trailer part. For example, you can use silicone for flexible and waterproof seals, epoxy for rigid and durable seals, polyurethane for elastic and abrasion-resistant seals.

- Protect your materials and parts from water exposure and moisture . You should protect your materials and parts from water exposure and moisture, using various coatings or treatments such as paint, varnish, galvanizing, anodizing, etc. You should choose the type of coating or treatment that matches the material and function of your boat trailer part. For example, you can use paint or varnish for wood, galvanizing or anodizing for metal, etc.

These are some tips on how to watertight your boat trailer. You should also check your boat trailer regularly and repair any leaks or damages as soon as possible.

How do I maintain my boat trailer?

The last factor to consider when building a boat trailer is its maintenance. You want your boat trailer to last long and perform well, without requiring too much time or money for repairs or replacements. You also want your boat trailer to be safe and reliable, without causing any problems or accidents.

To maintain your boat trailer, you need to clean it, lubricate it, inspect it, and store it properly. You also need to follow the manufacturer’s recommendations and instructions for your boat trailer parts and accessories.

Here are some tips on how to maintain your boat trailer:

- Clean your boat trailer . You should clean your boat trailer after every use, especially if you use it in saltwater or muddy conditions. You should rinse your boat trailer with fresh water to remove any dirt, salt, sand, or debris from the frame and parts. You should also use a mild soap or detergent to wash your boat trailer with a sponge or a brush. You should avoid using any harsh chemicals or abrasives that might damage your materials or parts. You should also dry your boat trailer thoroughly with a cloth or a towel, or let it air dry in a shaded area.

- Lubricate your boat trailer . You should lubricate your boat trailer regularly, especially the moving parts such as the axle, the wheels, the tires, the hitch, the winch, etc. You should use a suitable lubricant such as grease, oil, or spray for each part of your boat trailer. You should apply the lubricant generously and evenly to prevent friction, wear, rust, or corrosion. You should also wipe off any excess lubricant with a cloth or a paper towel.

- Inspect your boat trailer . You should inspect your boat trailer before and after every use, to check for any signs of damage, wear, or malfunction. You should look for any cracks, dents, bends, or breaks in the frame and parts. You should also check if all the fasteners and joints are tight and secure. You should also test if all the lights, brakes, and signals are working properly. You should also measure if the tire pressure and the hitch height are correct. You should also weigh your boat trailer to make sure it is not overloaded or unbalanced. You should also listen for any unusual noises or vibrations while towing your boat trailer. If you find any problems or issues with your boat trailer, you should fix them as soon as possible or seek professional help.

- Store your boat trailer properly . You should store your boat trailer properly when not in use, to protect it from theft, vandalism, or damage. You should park your boat trailer in a safe and secure location, such as a garage, a shed, or a fenced area. You should also lock your boat trailer with a hitch lock, a wheel lock, or a chain lock. You should also cover your boat trailer with a tarp or a cover to shield it from dust, dirt, sun, rain, snow, etc. You should also lift your boat trailer off the ground with jacks or blocks to prevent flat spots on the tires or rust on the axle.

These are some tips on how to maintain your boat trailer. You should also follow the manufacturer’s recommendations and instructions for your boat trailer parts and accessories.

What is the best type of material to use for a boat trailer?

There is no definitive answer to this question, as different types of materials have different advantages and disadvantages for building a boat trailer. The best type of material to use depends on your budget, preference, availability, and purpose.

However, here are some general guidelines that you can follow when choosing the type of material for your boat trailer:

- Wood . Wood is a good choice for building a boat trailer if you want a cheap, easy, and versatile material. Wood is widely available and can be cut, shaped, and joined in various ways. Wood is also lightweight and can float on water. However, wood is also prone to rotting, warping, cracking, and splintering, especially when exposed to water and weather. Wood also requires regular maintenance and protection, such as sanding, sealing, or painting.

- Metal . Metal is a good choice for building a boat trailer if you want a strong, durable, and rigid material. Metal can withstand heavy loads and resist corrosion and wear. Metal can also be welded, bolted, or riveted in various ways. However, metal is also expensive, heavy, and hard to work with. Metal also requires special tools and skills, such as welding or cutting. Metal also conducts heat and electricity, which can be dangerous or uncomfortable.

- Plastic . Plastic is a good choice for building a boat trailer if you want a lightweight, flexible, and waterproof material. Plastic can be molded, cut, and joined in various ways. Plastic can also withstand water and weather exposure without rusting or rotting. However, plastic is also weak, brittle, and prone to cracking, breaking, or melting, especially when exposed to heat or pressure. Plastic also requires special adhesives or welds to join it securely.

These are some general guidelines that you can follow when choosing the type of material for your boat trailer. You should also consider the availability, cost, and environmental impact of each material before making your final decision.

What are some tips for building a custom boat trailer?