- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

- Best Marine Electronics & Technology

Steel Boats: A Strong Alternative

- By Geoff Payne

- Updated: August 7, 2002

Adventure cruising down Chile’s exciting southern waterway, we chose to make a side trip up one of the many fiords. Like most, this one was uncharted. “Must be as deep as the hills are high around us,” Margaret and I agreed. The crew of an approaching local fishing boat waved enthusiastically as we tacked from shore to shore against a fine breeze.

Those fishermen were really waving their hands in the air at us. “Guess they’ve never seen a sailboat with such good windward ability,” I thought as we left them rapidly astern. If we hadn’t dusted them so completely, perhaps we would have seen their hands go down onto their heads and then over their ears. Full sail and at some seven knots of boat speed, 13 tons of Skookum plowed onto a pile of sharp glacial boulders lurking below the surface.

Was the boat holed due to this colossal blunder? Was the keel parted from the hull? Was the rudder torn off? Was that the end of our cruise? Well, there was a loud bang, we felt the cockpit rapidly rise then suddenly fall, but on we sailed, red-faced and with sails luffing to slow us down. Skookum’s full keel tapers down to a 2 1/2-inch-diameter solid-steel bar. That and the heavier keel plating probably made more impression on the rocks than the rocks did on us. A boat of other material could have sustained trip-terminating damage. Once again, my decision to build in steel had paid off.

Joshua, Williwaw, Damien II: These famous steel cruisers bring to mind high-latitude epic trips, often among ice. But steel is not just for extremist cruisers. As a matter of fact, the finest steel hulls are passing you by, indeed overtaking you under sail. Only you don’t realize they’re made of steel.

On Skookum’s cabin table is a small offcut from the hull plating. It’s often passed around among visitors aboard. “Sure is strong,” folks say, “but isn’t it heavy?” Skookum displaces 28,000 pounds, which is on the heavy side for a 40-footer. But there are respected fiberglass and wood designs of similar size that are heavier still.

They say lighter is faster; it’s true. When it comes to extended cruising, though, the rules are not that simple. A cruising family accumulates literally tons of weight aboard. A serious cruising boat easily could contain over 4,000 pounds of fluids, spares, tools, literature, outboards, and other provisions. That kind of weight stresses and hampers a lightweight craft. The modern steel-hulled cruising boat will be of generous displacement, proportions that will accept a large payload without loss of performance.

Your cruising boat must have good performance. It should tack smartly, carve along to windward at six or seven knots and surge before the trade winds, leaving a straight white wake. Any properly designed, medium- to heavy-displacement sailboat with a big spread of well-cut sails ought to have sparkling performance. (The 1970s saw some successful steel racers.)

Margaret and I have short-tacked slalom courses up narrow buoyed channels, eased sheets to race afternoon sailors, and logged some 180-mile days at sea in Skookum; all this with a displacement/length ratio of 450. That bit of weight in our steel construction equals a lot of comfort on the ocean — especially in rough weather.

No one doubts steel’s strength. It takes over 30,000 psi of force to deform it. Steel is an “orthotropic” material; that means it’s equally strong in all directions. Try to bend or rip a circle of steel any which way you like, it won’t give in any easier. A piece of wood will split down the grain. Wood is thus an “isotropic” material — stronger in one direction. Isotropic materials (including fiberglass, which has extra thickness roving here and there) are very efficient for boatbuilding because their strengths can be aligned to counteract predictable forces of water and wind. This results in a far lighter structure. Even though a piece of deck steel need only support your dainty weight, the minimum practical plating would still take thousands of pounds to pierce.

The end result in steel is an enormously strong structure. Skookum’s mast and rigging loads are so well resisted at deck level that our lee shrouds barely slacken, even under full sail and hard on the wind.

Of major concern to the designer of an all-steel sailboat is the weight of the steel superstructure. Don’t expect to find apartmentlike accommodations inside a steel-decked offshore cruiser, for that would raise the center of gravity unacceptably. The thickness of any framing also represents lost volume inside a steel hull. Used to good effect, it becomes valuable insulation, covered with paneling. Because structural bulkheads are seldom required in steel hulls, cabin layout can be very flexible. Free of constraints inside Skookum, I created a wide-open, bright and light-filled interior. Without fail, newcomers aboard remark upon how roomy the boat feels belowdeck.

Steel sailboat design has come a long way in recent years. Two aspects of the preceding paragraph have come under rigorous review as designers and manufacturers constantly come up with better steel craft. First, the superstructure need not be made of steel. Secondly, in some cases, the framing can be done away with.

Once upon a time a steel hull might have looked pretty much like a wood one under construction: ribs galore. To support large expanses of steel of minimum thickness and to keep it beautifully smooth and fair, light framing (transverse and longitudinal) is definitely required. Building a fair, curve-plated, round-bilged metal hull is a skill and an art — a task for the professional boatyard. However, if the curved cross section of a sailboat is approximated in straight lines, then the plating of the whole hull is considerably simplified. The fore-and-aft joint lines between plates are called “chines.” The smooth-looking sphere that is a beach ball is actually made up of once-flat tapered strips; each seam is a chine. Done right, a multi-chine steel hull is both easy to build and puts a sweet curve or two along the topsides of that vessel. But it’s a challenge on the drawing board. Done poorly, the chines appear sudden and awkward and make for a boxy looking sailboat.

Chines also introduce lines of strength into the hull (a bit like the way a floppy sheet of paper folds into a sound little aircraft). This has led designers to say, “Aha. Maybe we don’t need the frames!” Indeed it can be done, and there are plenty of such designs available. Chined, frameless hulls do require heavier plating, so there is no great weight savings. “Frameless” construction is a hotly debated topic among metal-boat designers and builders. In fact, Skookum’s chines are strengthened by longitudinal stringers, and floors in the keel provide transverse support. To completely forego all framing yet still adhere to responsible engineering principles would render a small boat heavy indeed.

Having mastered the multi-chine concept, designers and builders saw the opportunity to go one better: eliminate at least those chines visible above the waterline by introducing a “radius chine,” a narrow curved piece of steel that disguises any sudden turns in the plating. So long as that piece of steel can be cut from either a cylinder or a cone, the task is not too hard. In fact, the whole hull can be plated in “conically developed” shapes (frames required though). Steel boats like these are the ones sailing right by you looking like molded fiberglass.

Steel can be worked into nearly any shape imaginable. Clipper bows, canoe sterns, deep fin keels, tumblehome topsides, bowsprits or reverse transoms can all be achieved at commensurate cost. The skeg supporting the steel cruising boat’s rudder can be made so strong that the arrangement could hardly be considered vulnerable to damage by floating objects. Skookum’s stern even incorporates a welded tab and stopper arrangement to support the rudder in the event of the hove-to boat being thrown backward by a big sea.

Welding allows the creation of fabulous custom work on deck. Stainless steel bollards, chain plates, towing eyes, lifting lugs, vents and fillers can all be elegantly incorporated into the deck in an utterly waterproof manner.

Even the thinnest practicable steel plating (about 7/64-inch, or 12-gauge) is too heavy a material for a sailboat much less than 30 feet in length, hence you’ll find few really small steel cruisers. Any thinner plating creates problems with welding, maintaining a fair shape and corrosion tolerance.

Stock plans in steel for popular-size (35-foot to 45-foot) cruising boats generally show a medium- to medium-heavy displacement craft with average internal accommodation. These plans cost from $500 to $1,500, reflecting a wide variation in the amount of information given. Full-size templates for plating are even available with some designs. Very serious consideration should be given to the selection of the design: The one to two percent of the finished value of your project that you invest in plans could be 100 percent responsible for ultimate success…or disappointment. And you won’t find out until the first day’s sail. Designers’ work is best not to be messed with — generally it’s not on the page if it’s not important. A custom design in steel could run to 10 percent of the boat’s value.

Chined construction, a method that greatly simplifies hull plating, is an attractive option for amateur builders. With little more than a welding machine and good cutting and handling equipment, a steel hull can be backyard built. Once I had learned how to handle the long pieces of steel properly, I found the hull construction to be most rewarding. Sparks flew, there was smoke and grit, but in essence it was a bit like sewing: I made Masonite patterns for each strake, traced around them and cut the material to shape, tacked it onto the upside down temporary frame, then finally seamed it all together. Welding is so immensely and immediately strong that I was as convinced then of the boat’s colossal strength as I am now, 50,000 miles later. Full-strength welding meant I could carry out 100 percent corrections of occasional cutting errors.

What About Corrosion?** Talk of steel and the word “rust” comes up straightaway. Rust is a chemical reaction and salt water speeds it up, but not as much as you would think. Ice scraped the paint off Skookum’s waterline about a meter back from the bow. Although I didn’t get around to touching it up until nearly a year later, no major harm was done to the plating. What worried me more was rust inside the hull, in the hidden corners of the bilges. Only after four years of hard sailing did we remove the cabin sole (wisely, I made it all demountable) and after a thorough scrub, we found areas of scratched paintwork. Nothing serious, nor structural — just awkward to sand and touch up.

The steel deck, unlike the hull, is not only continually doused in salt water, but also trafficked and abraded. Anchors, chain, winch handles, harbormasters’ boots — they inevitably knock off paint. Very soon, out weeps a trickle of brown. But at least you can see it! Unlike rot or ultraviolet deterioration or osmosis, rust gives itself away practically the day it starts. It’s not difficult to remedy, just tedious.

On Skookum we have some nuisance rust spots that repeatedly need rubbing back and touching up. Repainting means a full four or five coats of touch up, so the process is a protracted one. In every case, these bits of rust around hatches, coamings, stanchions and winches could have been avoided had I done things differently in the first place. Companies well experienced in steel boat production have developed excellent detailing on deck.

Given that recurring rust problems occur on deck, and that a boat doesn’t sail upside down, why then not construct the deck of something else? It’s called composite construction and it’s commonplace. Strong plywood decks and cabins can be built over steel framing. Epoxy and fiberglass take care of the sealing and finish. Aluminum decks can be married to steel hulls. Composite construction has other merits, such as less weight and less magnetic interference. (Tons and tons of steel certainly have an effect on a compass. Our classic five-inch-diameter steering compass stands on its own binnacle and was some 20 degrees off upon installation. Standard correctors inside the unit reduced this to a known five degrees on east and west headings. Electronic compasses can have sensors placed inside the mast or on a radar post and thus removed from steel’s magnetic clutches.)

Corrosion comes in another and more wicked form: electrolysis. Put nearly any other common metal underwater near steel and a battery current flows. More often than not it is steel that loses the electrons. Little volcanoes of corrosion erupt on unprotected steel, and these inflict damage much faster than rust. Electrolysis is a threat to any kind of boat, but especially to metal-hulled ones.

All steel craft sport little zinc pads on the keel, rudder and propeller shaft. These “sacrificial anodes” corrode instead of the hull, so must be maintained. Corrosion vigilance is the price one must pay for the reassuring strength of steel.

The corrosion specter heavily devalues older steel boats, especially if a bit of the brown stuff is visible. Boats that have not had the protection of modern paint systems might be picked up, for a “steel.” If you’re planning to recondition an older steel craft, first establish if you can gain access to all the steel surfaces. Even then the cost of dismantling, preparation and recoating will be considerable.

Coatings Offer Excellent Protection** Rust and electrolysis can only get a grip on bare steel. Coatings have advanced in recent decades and offer excellent protection. One system coats the sandblasted steel with coal tar combined with epoxy. Another paint is substantially zinc. Or, the whole boat can be “flame sprayed” with aluminum or zinc — the ultimate treatment (see the “Save The Steel” sidebar, following). Most seagoing steel is protected mainly by epoxy paint. As many as nine coats go on — primer, high builds, hard and gloss coats (polyurethane). It’s a significant investment in paint, but very effective and attractive.

That little piece of plating that we keep by the cabin table to show visitors was cut out of the finished transom. The thickness of paint buildup seen in the cross section is impressive. In fact, we’ve taken to saying we’re sailing around the world in an epoxy boat lined with steel. These paints ought to last a very long time. As long as the steel remains coated, our boat is going to be around longer than we are.

One other coating proven on steel hulls is sprayed polyurethane foam insulation. About 1 1/2 to two inches of this closed-cell substance, sprayed inside from the turn of the bilge up and over the deckhead, transforms a clammy, tinny chamber into a quiet refuge, cozy or cool as required. It’s superb insulation that retains or repels heat, eliminates condensation, dampens deck noises and sticks tenaciously to (lightly painted) steel, keeping air and water from ever initiating interior rust.

There’s an image of steel boats being dank and clammy belowdeck. Perhaps those that are uninsulated are that way. In fact, the coziest and sweetest smelling cabins I’ve experienced have been aboard steel craft. The Mexican “lancha” drivers used to think we were “locos” to live inside a black steel hull…until they came below and found it to be airy and cool. Spray foam has kept Skookum comfortable to live in at all latitudes.

The Security Issue** Steel sailboats are over-engineered — for wind and water forces, that is. Can the vessel to which you entrust your family’s life be too strong? What if on a calm and sunny day you tied up, went into town, and returned to find the local ferry had T-boned your boat into a concrete wharf? It happened. That metal sailboat completed its circumnavigation — a bit dented, that’s all.

In or out of the water an all-steel sailboat with polycarbonate hatches also will be a formidable barrier to burglars, even bullets. If seacocks connect to metal standpipes extending above the waterline and shafts have metal stuffing boxes, then a steel craft might survive an internal explosion or fire. Charred, but still floating.

Our boat’s nearly invincible strength had to become our insurance policy in far southern latitudes — no underwriter would cover us. So why are we shopping around for coverage now that we’re back in busier, foggier waters? Afraid of being run down? On the contrary — with 13 tons of momentum, our pointy-ended boat could sink something 10 times its size. We need liability insurance.

With such strength and so solid a feel, by providing so smooth a ride, the well-appointed steel sailboat is a Mercedes Benz of ocean cruisers. Cost is not in the upper luxury level, especially if you are home-building, for which steel is well suited. Extra expenses for the rig and proper sail area to drive such a sturdy craft is why a performance, steel sailboat is not going to be the cheapest option. In value, appearance and performance steel cruisers are right in there with equivalent-size boats made of other materials. And if it comes to the c-r-u-n-c-h, they’re incomparably stronger.

Before next you stroll the marinas, put a fridge magnet in your pocket. Slide it on to some really pretty boats — you might just get a surprise. Marine steel craft have come a long way in recent years.

———————————————————————— After taking a couple of years off from cruising to build a house, to research a biography of yacht designer (and uncle) Alan Payne and to fill the cruising kitty, Australians Geoff Payne and Margaret Hough are planning to take Skookum next summer for a tour of the Canadian Maritimes and beyond.

- More: sailboat , Sailboats

- More Sailboats

New to the Fleet: Pegasus Yachts 50

Balance 442 “Lasai” Set to Debut

Sailboat Review: Tartan 455

Meet the Bali 5.8

Cruising the Northwest Passage

A Legendary Sail

10 Best Sailing Movies of All Time

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

GETTING THE JOB DONE

- Power Boats For Sale

- Yachts For Sale

Sorry, this listing is no longer available....

BUSINESS HOURS

- Mon – Fri, 9:00 AM – 5:00 PM

- Sat, 9:00 AM – 2:00 PM

- All other times by appointment

Sandy Bay Office Derwent Sailing Squadron 23 Marieville Esp John - 0459 322 862 [email protected] Jo - 0432 031 100

Kettering Office Oyster Cove Marina Ferry Rd Kettering [email protected] Jo - 0432 031 100

©2024 Derwent Boat Sales

Log in with your credentials

Forgot your details.

- 125212, Moscow, Leningradskoye Highway, 39 p. 6 Royal Yacht Club

- Miami +1 786 233 7721 London +44 203 807 94 54 Moscow +7 495 215 19 11

- [email protected]

Alan Payne Skookum 40ft Steel Cruising Yacht CAPABLE BLUEWATER CRUISER/COMFORTABLE LIVEABOARD! ** NOW SOLD **

Used Yachts For Sale

Sail monohulls 40ft > 50ft, alan payne boats for sale, alan payne skookum 40ft steel cruising yacht boats for sale.

- My Searches

- Watch List (0)

- Sign In

ALAN PAYNE SKOOKUM 40FT STEEL CRUISING YACHT CAPABLE BLUEWATER CRUISER/COMFORTABLE LIVEABOARD! SOLD

Used Yachts For Sale

Sail monohulls 40ft > 50ft, alan payne boats for sale, alan payne skookum 40ft steel cruising yacht boats for sale.

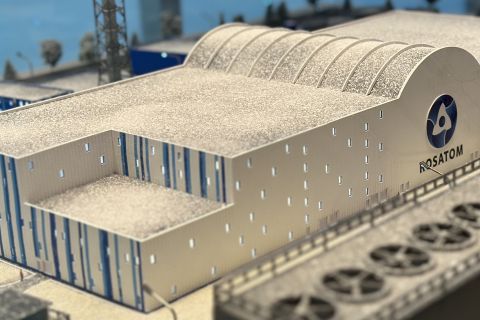

For the first time Rosatom Fuel Division supplied fresh nuclear fuel to the world’s only floating nuclear cogeneration plant in the Arctic

The fuel was supplied to the northernmost town of Russia along the Northern Sea Route.

The first in the history of the power plant refueling, that is, the replacement of spent nuclear fuel with fresh one, is planned to begin before 2024. The manufacturer of nuclear fuel for all Russian nuclear icebreakers, as well as the Akademik Lomonosov FNPP, is Machinery Manufacturing Plant, Joint-Stock Company (MSZ JSC), a company of Rosatom Fuel Company TVEL that is based in Elektrostal, Moscow Region.

The FNPP includes two KLT-40S reactors of the icebreaking type. Unlike convenient ground-based large reactors (that require partial replacement of fuel rods once every 12-18 months), in the case of these reactors, the refueling takes place once every few years and includes unloading of the entire reactor core and loading of fresh fuel into the reactor.

The cores of KLT-40 reactors of the Akademik Lomonosov floating power unit have a number of advantages compared to the reference ones: a cassette core was used for the first time in the history of the unit, which made it possible to increase the fuel energy resource to 3-3.5 years between refuelings, and also reduce the fuel component of the electricity cost by one and a half times. The FNPP operating experience formed the basis for the designs of reactors for nuclear icebreakers of the newest series 22220. Three such icebreakers have been launched by now.

For the first time the power units of the Akademik Lomonosov floating nuclear power plant were connected to the grid in December 2019, and put into commercial operation in May 2020. The supply of nuclear fuel from Elektrostal to Pevek and its loading into the second reactor is planned for 2024. The total power of the Akademik Lomonosov FNPP, supplied to the coastal grid of Pevek without thermal energy consumption on shore, is about 76 MW, being about 44 MW in the maximum thermal power supply mode. The FNPP generated 194 million kWh according to the results of 2023. The population of Pevek is just a little more than 4 thousand, while the FNPP has a potential for supplying electricity to a city with a population of up to 100 thousand people. After the FNPP commissioning two goals were achieved. These include first of all the replacement of the retiring capacities of the Bilibino NPP, which has been operating since 1974, as well as the Chaunskaya TPP, which has already been operating for more than 70 years. Secondly, energy is supplied to the main mining companies in western Chukotka in the Chaun-Bilibino energy hub a large ore and metal cluster, including gold mining companies and projects related to the development of the Baimsk ore zone. In September 2023, a 110 kilovolt power transmission line with a length of 490 kilometers was put into operation, connecting the towns of Pevek and Bilibino. The line increased the reliability of energy supply from the FNPP to both Bilibino consumers and mining companies, the largest of which is the Baimsky GOK. The comprehensive development of the Russian Arctic is a national strategic priority. To increase the NSR traffic is of paramount importance for accomplishment of the tasks set in the field of cargo shipping. This logistics corridor is being developed due regular freight voyages, construction of new nuclear-powered icebreakers and modernization of the relevant infrastructure. Rosatom companies are actively involved in this work. Rosatom Fuel Company TVEL (Rosatom Fuel Division) includes companies fabricating nuclear fuel, converting and enriching uranium, manufacturing gas centrifuges, conducting researches and producing designs. As the only nuclear fuel supplier to Russian NPPs, TVEL supplies fuel for a total of 75 power reactors in 15 countries, for research reactors in nine countries, as well as for propulsion reactors of the Russian nuclear fleet. Every sixth power reactor in the world runs on TVEL fuel. Rosatom Fuel Division is the world’s largest producer of enriched uranium and the leader on the global stable isotope market. The Fuel Division is actively developing new businesses in chemistry, metallurgy, energy storage technologies, 3D printing, digital products, and decommissioning of nuclear facilities. TVEL also includes Rosatom integrators for additive technologies and electricity storage systems. Rosenergoatom, Joint-Stock Company is part of Rosatom Electric Power Division and one of the largest companies in the industry acting as an operator of nuclear power plants. It includes, as its branches, 11 operating NPPs, including the FNPP, the Scientific and Technical Center for Emergency Operations at NPPs, Design and Engineering as well as Technological companies. In total, 37 power units with a total installed capacity of over 29.5 GW are in operation at 11 nuclear power plants in Russia. Machinery Manufacturing Plant, Joint-Stock Company (MSZ JSC, Elektrostal) is one of the world’s largest manufacturers of fuel for nuclear power plants. The company produces fuel assemblies for VVER-440, VVER-1000, RBMK-1000, BN-600,800, VK-50, EGP-6; powders and fuel pellets intended for supply to foreign customers. It also produces nuclear fuel for research reactors. The plant belongs to the TVEL Fuel Company of Rosatom.

Rosatom obtained a license for the first land-based SMR in Russia

On April 21, Rosenergoatom obtained a license issued by Rostekhnadzor to construct the Yakutsk land-based SMR in the Ust-Yansky District of the Republic of Sakha (Yakutia).

ROSATOM and FEDC agree to cooperate in the construction of Russia's first onshore SNPP

ROSATOM and FEDC have signed a cooperation agreement to build Russia's first onshore SNPP in Yakutia.

Rosatom develops nuclear fuel for modernized floating power units

Rosatom has completed the development of nuclear fuel for the RITM-200S small modular reactor designed for the upgraded floating power units.

IMAGES

COMMENTS

Alan Payne's Skookum design is renowned for its exceptional sailing abilities in even the most challenging conditions. One spent many years in the Southern high latitudes including multiple seasons exploring Antarctica, the Chilean Fjords and South Georgia!

Alan Payne Skookum 40ft Steel Cruising Yacht CAPABLE BLUEWATER CRUISER/COMFORTABLE LIVEABOARD! ** NOW SOLD ** This listing is no longer available. You can however view similar listings using one of the four links below. Used Yachts For Sale → Sail Monohulls 40ft > 50ft

First, beware resale on a plywood yacht. Second, Alan Payne designs are eminently seaworthy but wet, cramped and hobbled by the rule of the day (long overhangs to work around the RORC rule). I cruised thousands of miles around Australia in a 34' Robert Clark design modified by AP, which was a great sailing boat, but with only 8'6" beam had less room than the heads on my current yacht.

Model: Used Alan Payne Skookum 40ft Steel Cruising Yacht Capable Bluewater Cruiser/comfortable Liveaboard!, Hull:Steel Steel 6mm Steel Hull, Category: Sailing Boats | Boats Online, State: Tasmania (Tas), Description: Alan Payne's Skookum design is renowned for its exceptional sailing abilities in even the most challenging conditions. One

Alan Payne was born in London, England in 1921, but moved to Australia in 1925 where he spent his childhood in Brisbane and then Sydney. ... Alan Payne continued with cruising yacht design, mainly deep keeled steel yachts. His nephew Geoff Payne built one of these, the SKOOKUM, which earned a reputation through Cruising World magazine as a ...

Full sail and at some seven knots of boat speed, 13 tons of Skookum plowed onto a pile of sharp glacial boulders lurking below the surface. ... After taking a couple of years off from cruising to build a house, to research a biography of yacht designer (and uncle) Alan Payne and to fill the cruising kitty, Australians Geoff Payne and Margaret ...

Find a full range of Used Alan Payne skookum 40ft steel cruising yacht Boats For Sale in Australia. Sell My Boat My Searches My WatchList SignIn. Toggle navigation. Home; Boats For Sale. New Boats For Sale; ... Alan Payne's Skookum design is renowned for its exceptional sailing abilities in even the ... LOCATION: Hobart TAS, Tasmania 40' 6 ...

1921 - 1995. Alan Payne was a yacht designer who was born in Great Britain but spent his career in Australia. He is probably best known as the designer of the 12 meter 'Gretel II', that very nearly took away the America's cup in 1970. In 1993, he was honored as a Member of the Order of Australia (AM) for his contribution to Australian yachting.

Alan Payne (right) and Bryce Mortlock (next left) constructing a Payne-Mortlock sailing canoe, late 1940s.. Alan Newbury Payne AM (11 December 1921, London - 20 June 1995, Sydney) was a naval architect born in England but who worked in Australia.His yacht designs were readily built by both professionals and amateurs, and remain well represented in the ocean-going and coastal yacht fleet.

Derwent Sailing Squadron 23 Marieville Esp. John - 0459 322 862. [email protected]. Jo - 0432 031 100. Kettering Office. Oyster Cove Marina Ferry Rd Kettering. [email protected].

Tasman Seabird Alan Payne Design. Expressions of interest are being sought for; Danu is an 11m sailing vessel designed by ... South Coast Callala Bay, New South Wales. 37' 0". 11.28m. 1962. AU $80,000. Find a full range of Alan Payne Boats For Sale in Australia. New and Used boats for sale.

Radio Moscow: circa 1968. February 11, 2014. Many thanks to David Firth, who is kindly sharing shortwave radio recordings he made on his reel-to-reel recording equipment in the late 1960's. Firth is uncovering and digitizing these recordings as time allows. We are grateful for this recording of Radio Moscow, which Firth recorded in 1968.

Royal Yacht Club ; Miami +1 786 233 7721. London +44 203 807 94 54. Moscow +7 495 215 19 11. [email protected]; Miami +1 786 233 7721. London +44 203 807 94 54. Moscow +7 495 215 19 11. [email protected]. Main menu. Services; Sale; New yachts; Charter; News; Contacts; Service. Buy boat; Sell boat; Evaluation boat; Registration boat;

Alan Payne Skookum 40ft Steel Cruising Yacht Capable Bluewater Cruiser/comfortable Liveaboard!. Alan Payne's Skookum design is renowned for its exceptional sailing abilities in even the most challenging conditions.

Russia Yacht Charter, Moscow, Russia. 120 likes. Организация отдыха, обучения на парусных яхтах. Семейные ...

Model: Used Alan Payne Skookum 40ft Steel Cruising Yacht Capable Bluewater Cruiser/comfortable Liveaboard!, Hull:Steel 6mm Steel Hull, Category: Sailing Boats | Boats Online, State: Tasmania (Tas), Description: Alan Payne's Skookum design is renowned for its exceptional sailing abilities in even the most challenging conditions. One

Alan Payne worked at Cockatoo Dock during the 2nd World War and trained as a naval architect at Sydney Technical College at the same time, becoming their first graduate in 1945 with a diploma, the highest level available at that time. He set up private practice immediately after the war, initially designing yachts and launches, then later some ...

21 April 2023 Rosatom obtained a license for the first land-based SMR in Russia. On April 21, Rosenergoatom obtained a license issued by Rostekhnadzor to construct the Yakutsk land-based SMR in the Ust-Yansky District of the Republic of Sakha (Yakutia).

Alan Payne was born in London, England in 1921, but moved to Australia in 1925 where he spent his childhood in Brisbane and then Sydney. His father Sidney Payne had a ship's masters ticket, but after a period at sea he moved to shore based activities and then emigrated with the family to Brisbane to work for Dalgety's on the Brisbane waterfront. When they moved to Sydney where he attended ...

Alan Payne was born in London, England in 1921, but moved to Australia in 1925 where he spent his childhood in Brisbane and then Sydney. His father Sidney Payne had a …