Choosing the Correct Boat Propeller

How Propellers Work

Design considerations, how to choose the correct pitch and blade count, choosing the right propeller by crowley marine.

The right prop will get the best performance out of your boat. Matching the propeller to your application, whether cruising, water skiing or performance, maximizes the power from your engine. It also helps with handling and acceleration. Use this guide to learn how different propeller designs affect efficiency, power, and speed and then learn how to choose the correct prop for your boat and application.

The propeller has a hub surrounded by blades of the same length and size. The blades are twisted so that they push water toward the rear as they turn. This pushing is what propels the boat forward in the water. Most blades rotate in a right hand (clockwise) direction when viewed from the rear. Left hand propellers are paired with a right hand propeller in dual-engine installations to keep the boat stable and reduce steering effort.

Pitch is the distance the propeller will move the boat after one revolution (not accounting for slip). A lower pitched propeller will create more power due to more engine RPMs, but the boat will move slower. A higher pitched prop allows the boat to move faster by travelling a farther distance with each rotation. When choosing a propeller, choose a pitch that will keep the engine RPM in its recommended operating range. Going under the range will cause the boat to lug, while going over can cause engine strain.

Blades have other important features built into their design. Rake is the angle between the blade and the hub. The rake angle can be flat, staying the same along the entire blade, or progressive, meaning the angle increases as it approaches the tip. Props have between 0 and 20 degrees rake. The rake angle determines how much the bow lifts out of the water. High rake propellers are ideal for light-weight, high speed boats. Too much rake, however, will strain the engine and reduce overall performance.

Some propellers are cupped, which means they have a lip on the edge of the blades. The cup creates more space between the sides of the blades, reducing ventilation and slippage. If the cup is on the tip of the blade, the blade has an increased rake angle and a higher bow lift. If the cup is on the trailing edge, it effectively increases the pitch size, and the propeller will create more power at the cost of engine speed.

Blades are also designed to prevent ventilation and cavitation. Ventilation is when air is drawn around the blades between the blade surface and the water. Ventilation increases RPM but reduces speed, especially during hard acceleration. The anti-ventilation plate mounted on the outboard helps to prevent this problem. Cavitation is caused by water flow disturbances around the blades. Disturbances cause water bubbles to boil and burst against the blades, which damages the surface and reduces performance.

The fewer number of blades a propeller has, the more efficient it is. However fewer blades will also increase the "vibration" you will feel. That’s why three blade propellers are the most common for general purpose boating. Three blades props provide the best combination of performance, speed, and efficiency. Some manufacturers also create four and five blade propellers to increase acceleration and reduce ventilation. A four blade propeller will improve handling and control for high-performance applications. Five blade propellers are good for rough water conditions and tow sports.

Finally, material is an important consideration for your propeller. Aluminum props are a great balance of cost, performance, and durability. Stainless steel is five times stronger than aluminum, dramatically improving performance and durability. Stainless steel propellers offer better acceleration and are less likely to be damaged from striking objects in the water. Stainless steel props will outlast aluminum multiple times over.

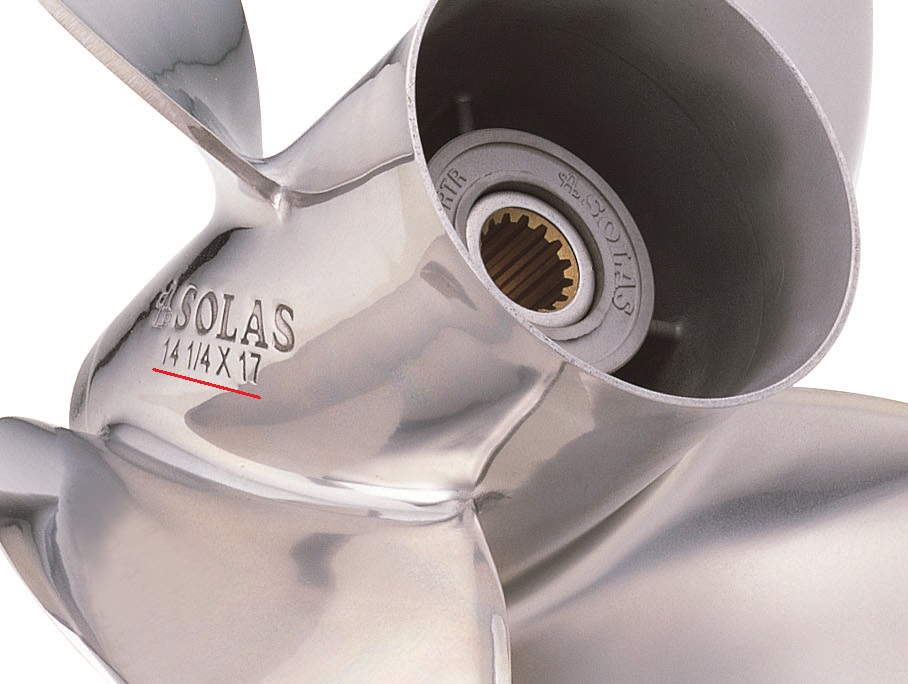

Left: a stainless steel propeller. Right: an aluminum propeller.

Before you dive into choosing a propeller, understand your boat’s intended use. Consider your average speed, load, and boating location. If you will be using the boat for multiple applications, you may need to switch props. The propeller choice directly affects the engine RPM and therefore its performance. Choose a propeller that puts the engine RPM at the midpoint or higher of the wide open throttle (WOT) range with a normal load. This operating range will translate to the highest horsepower available from your outboard. Refer to your engine operating manual for the operating range.

Once you know the operating range, consult the propeller guide for your engine to pick a combination of pitch, blade number, and material. Choose a range of propellers to perform a water test. Test the props under the same conditions that you would typically use the boat—same load, gear, and water. Set the trim angle so the boat has optimum speed on top of the water.

To test the prop, run the boat at WOT and observe the maximum engine RPM on a tachometer. If the RPM is below the recommended operating range, switch to a propeller with lower pitched blades. If the RPM is higher, switch to a propeller with higher pitched blades. Each inch of pitch size will change the RPM by 150-200 RPM. Aim for the midpoint or higher of the recommended operating range. Keep in mind that high altitudes will reduce engine power, so choose a lower pitch to achieve the same RPM as on sea level.

Engine height also affects the performance of the propeller. Once you find the right prop, adjust the engine mounting height to create the best balance between speed, maneuverability, and acceleration. Start with the anti-ventilation plate even with the bottom of the boat. Raise the engine one mounting hole at a time until performance is unacceptable, and then lower the engine one hole down.

Keep a spare prop onboard for emergency situations. One recommendation is to buy a spare propeller that is two inches lower in pitch than your standard propeller. This reduction in pitch is perfect for tow sports, such as water skiing, due to a slower acceleration and higher power.

Back- the low pressure side of the blade closest to the boat Cavitation- vaporized air caused by water flow disturbances Cup (blade)- the lip on the edge of the blade Diameter- width of the circle made by the tips of the blades Face (blade)- the high pressure side of the blade farthest from the boat Leading Edge (blade)- the blade edge closest to the boat Pitch- distance travelled by the propeller in one revolution Rake- angle between the blade and the hub Root (blade)- the edge of the blade attached to the hub RPM- revolutions per minute Slip- distance lost due to inefficiency Surface Area- the total surface of the blades Tip- the point separating the leading edge and trailing edge farthest from the hub Trailing Edge (blade)- the blade edge farthest from the boat Ventilation- air bubbles surrounding the blades WOT- wide open throttle

Propellers For Sale

Evinrude & Johnson

Yamaha Marine

Mercury Marine

Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: c8036741-4b48-11ef-87c5-e32eaeb51372

Powered by PerimeterX , Inc.

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Books & Movies

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← How-To DIY

How to Choose the Right Prop for Your Boat

Advertisement

The goal in propeller selection is to determine what style and size will maximize your boat's performance, while allowing your engine to operate in the recommended r.p.m. range. The correct propeller will prevent the engine from over-revving, yet allow it to reach the minimum r.p.m. where the maximum horsepower is produced, with ideal engine loading.

Using your existing propeller, determine your maximum obtainable r.p.m.. If during this test, you begin to exceed the maximum rated r.p.m. of the engine, reduce the throttle setting. If the engine over-revs beyond the maximum recommended r.p.m., you may need to increase the pitch of the propeller. Increasing the pitch increment by 2" will result in approximately a 200-400 r.p.m. drop. Also, switching from an uncupped to a cupped propeller will reduce your r.p.m (see "Cupping" paragraph below). The cupped propeller of the same pitch and diameter will typically reduce your r.p.m. by approximately 200. If you cannot reach maximum r.p.m., then pitch should be decreased. These recommendations apply to single engine installations only. For most twin engine installations it is necessary to increase pitch by 4".

Once your WOT r.p.m. falls within the recommended range of the engine manufacturer, you have a propeller that is suited to your boat with respect to r.p.m. However, you may not be satisfied with your boat's skiing performance or trolling speed. It may be advisable in these circumstances to have multiple propellers, each to accommodate different boating activities. In all likelihood, more than one propeller will be suitable for your boat and motor combination, depending on your usage. Ski boats need more top end speed, and should choose a prop with a higher pitch. Cruisers and houseboats need more performance at displacement speeds, and should use a prop with a lower pitch to achieve low-end power. It is imperative, however, that the WOT r.p.m. fall within the range specified by your engine manufacturer. If your engine is not able to reach this r.p.m. range, it's operating under an extremely loaded condition and premature failure is highly likely. Our Manager of Technical Services Bob Adriance would like to remind you that the wrong prop can wreck an engine. "I've talked to mechanics that think using the wrong prop is the single greatest cause of premature engine failure," says Bob.

While most of these comments are geared to outboard engines, some also pertain to inboards. There are other factors that can adversely affect the performance of your propeller. One of these is dings on one or more blades. Another would be having the blades out of alignment, as would occur if you hit something. Either of these could cause vibration or undue stress and ultimately damage your transmission, cutlass bearing and other components. Usually the best way to deal with a propeller issue with an outboard is to get a new prop if it's damaged or, if you're not sure you nave the correct prop, try on different ones, with the recommendation of a qualified dealer, until you've got it right. But with inboards typically you'll need to have the propeller(s) pulled and sent to a good prop shop so that they can work their "magic" on your existing prop to repair it or determine that you need another. This includes things such as "swinging it" to determine balance, checking for alignment of the blades, and actually working on blades, such as adding or removing cup and many other adjustments. You would give them all the information about your boat that they'd request and describe fully all the issues you're experiencing.

Selecting the Right Prop

The size of a propeller is defined with two sets of numbers, diameter and pitch, with pitch always following the diameter.

The diameter is two times the distance from the center of the hub to the tip of the blade. It can also be looked at as the distance across the circle that the propeller would make when rotating.

Choose the Right Prop for Your Boat

Pitch, the second number listed in the propeller description, is defined as the theoretical forward movement of a propeller during one revolution. Since there is almost always a small amount of "slip" between the propeller and the water, the actual distance travelled is slightly less.

Many of today's propellers incorporate a cup at the trailing edge of the propeller blade. This curved lip on the propeller allows it to get a better "bite" on the water, resulting in reduced ventilation and slipping, and allows for quicker acceleration, or "hole shot," in many cases. A cupped propeller also works well in applications where the motor can be trimmed so that the propeller is near the surface of the water. The cup will also typically result in a higher top end speed.

Some Problems to Avoid

Ventilation.

Ventilation occurs when surface air or exhaust gasses are drawn into the propeller blades. When this happens, boat speed is lost and engine r.p.m. climbs rapidly. This can result from excessively tight cornering, a motor that is mounted very high on the transom, or by over-trimming the engine.

Cavitation (which is often confused with ventilation) is a phenomenon of water vaporizing or "boiling" due to the extreme reduction of pressure on the back of the propeller blade. Many propellers partially cavitate during normal operation, but excessive cavitation can result in physical damage to the propeller's blade surface due to the collapse of microscopic bubbles on the blade. There may be many causes of cavitation, such as incorrect matching of propeller style to application, incorrect pitch, physical damage to the blade edges, water flow obstruction caused by parts of the boat’s hull or running gear to close to t the propeller and others.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

BoatUS Editors

Contributor, BoatUS Magazine

Award-winning BoatUS Magazine is the official publication of Boat Owners Association of The United States. The magazine provides boating skills, DIY maintenance, safety, news and more from top experts.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

Everything You Need to Know: Boat Propeller Types

Table of Contents

Last Updated on October 12, 2023 by Boatsetter Team

Most boats are driven by propellers and there are many kinds and sizes. The optimal choice of propeller will depend on boat type, length, weight, use, and engine power. The right propeller will enhance efficiency by lowering drag, provide greater torque for faster planing speeds, and optimize performance at top speeds.

Many props are made of aluminum and are lightweight and affordable. These are good for smaller boats and tighter budgets. Stainless steel propellers are better for larger and high-performance boats due to their strength and durability but they’re more expensive. Bronze propellers are strong, rigid, and corrosion-resistant and are the priciest.

Propellers can have anywhere between two to six blades . Two-bladed props are used with smaller engines. They’re highly efficient but tend to produce vibration and aren’t powerful enough for heavier vessels. Sailboats and trolling motors often use two-bladed propellers. The higher the blade count, the more balanced the prop and the greater the thrust but also the greater the drag. Large five and six-bladed propellers are usually used with commercial boats, large yachts and ships.

Let’s go beyond materials and blade count and look at the types of propeller .

Post summary:

- Fixed propellers

- Variable pitch propellers

- Folding propellers

Feathering propellers

- Dual-props

- Surface-piercing propellers

- Specialty propellers

List your boat & start earning an avg. of $20K yearly with Boatsetter

Fixed pitch propellers & controllable pitch propellers

Fixed propellers, commonly referred to as fixed-pitch props, are a fundamental part of a boat’s propulsion system. These propellers have blades with a set angle that cannot be adjusted while the boat is running. Most props are fixed and have a constant blade angle. They’re easy to install and repair and are less expensive than others below.

On the other hand you have controllable Pitch Propeller’s (CPP ), these props are characterized by an adjustable angle. The pitch can be manipulated while the boat is in motion to optimize performance while running at different speeds. They can be more difficult to service and are expensive to purchase and install.

Folding propellers

Folding propellers are a popular choice among boaters looking for enhanced performance and maneuverability, which makes it perfect for sailing . Under sail, you will want to reduce drag as much as possible so they often opt for a folding prop where the blades fold back against the hub when not motoring.

Pro tip : Folding props allow for improved sailing speed and efficiency when the engine is not engaged.

Another way to reduce drag for sailboats is to use a feathering prop. If you’re using feathering propellers, the blades don’t fold but rather angle or rotate the blades to minimize the surface area presented to the water flow when the boat is under sail.

Dual props look as if there are two props in one. These counter-rotating props have several advantages including improved thrust, faster acceleration, better stability and handling even in reverse, and increased efficiency for better fuel economy.

They can be used on smaller boats with outboards or larger boats with stern drives or inboard engines. They can be expensive. Mercury, Suzuki and Volvo offer dual prop solutions.

Surface-piercing propellers

Designed to run partially out of the water (Surface Drive System), these props are often used with high-performance or racing powerboats because they decrease drag through the water. Boaters who crave maximum velocity and agility often opt for surface-piercing propellers, but they may require expert installation and maintenance to ensure safe and effective performance.

Toroid propeller

A new design has been introduced by Sharrow Marine where the prop blades are actually loops rather than flat blades. The purpose is to reduce vibration and increase speed at a given RPM.

Now, for the exception–locomotion through the water can also be achieved via a jet drive that uses forced water rather than a propeller to drive a boat. Jet boats can be small or large and the benefit of jet drives is that they can usually be taken into shallower waters than prop-driven craft.

Knowing which boat propeller is best

The wrong prop can create uncomfortable vibration, limit top speeds regardless of engine RPMs, create sluggish acceleration, and cause cavitation or excessive water aeration.

But, the right propeller will optimize performance including higher top speeds, create a smoother ride, and provide a more fuel-efficient solution. When deciding on a propeller, we recommend seeking a professional to know all your options. In the meanwhile, you can read more about propeller’s right here :

- What Is Propeller Pitch?

- 21-pitch Prop Vs. 19-pitch Prop

- Trimming a Boat in 3 Simple Steps

Boatsetter is the go-to app for boat rentals and on-water experiences. Whatever the adventure, we’ve got a boat for that—Set sail , start the party , go yachting , make your trophy catch , and hone your watersports skills! Download the Boatsetter app ( App Store | Google Play ). Make sure to follow @boatsetter on Instagram, and tag us in all your boat day pictures for the chance to be featured.

List. Rent. Earn—Only at Boatsetter

Zuzana Prochazka is an award-winning freelance journalist and photographer with regular contributions to more than a dozen sailing and powerboating magazines and online publications including Southern Boating, SEA, Latitudes & Attitudes and SAIL. She is SAIL magazines Charter Editor and the Executive Director of Boating Writers International. Zuzana serves as judge for SAIL’s Best Boats awards and for Europe’s Best of Boats in Berlin.

A USCG 100 Ton Master, Zuzana founded and manages a flotilla charter organization called Zescapes that takes guests adventure sailing at destinations worldwide.

Zuzana has lived in Europe, Africa and the United States and has traveled extensively in South America, the islands of the South Pacific and Mexico.

Browse by experience

Explore articles

10 Best Sailing Gifts

Fort Lauderdale Boating Guide

Sunset Cruises in San Diego: Rentals, Locations & Planning

Running Out of Gas on a Boat: What Now?

The iBoats.com Shop is currently undergoing maintenance. Orders will not be accepted at this time. We apologize for any inconvenience.

- Most Popular Categories

- Boat Covers

Boat Propellers

- Bimini Tops

- Boat Motors & Parts

- Boat Motors

- Boat Seats & Pontoon Furniture

- All Categories »

- Boats for Sale

- Boating Forums

- 1-800-718-2233

- How Do I Check My Order Status?

- How Do I Return a Product?

- Start a Return Online

- How Do I Set Up an Account?

- Our Full FAQs

- Our Return Policies

- Redirect to Cart:

Outboard Propeller Search

Outboard manufacturer, engine hp, year, model, prop rotation, sterndrive propeller search, sterndrive manufacturer, engine model, liters, year, hp, prop rotations, search by prop part #, propeller quick search, where to find your prop pitch, propeller rotation, where to find your propeller part number, about volvo penta duoprops, current propeller specials, why buy boat propellers from iboats.

Easily find a replacement boat propeller for your outboard, sterndrive or outdrive. iboats.com carries marine propellers designed for Mercury, Yamaha, Evinrude, Johnson, Honda, Suzuki, Tohatsu, Mariner, Force, Nissan, and Chrysler outboard motors. We also carry options for Mercruiser, Volvo Penta, OMC Sterndrive Cobra, and Yamaha stern drives.

iboats.com has the largest selection of propellers anywhere. You'll find discount prices on all the top quality brands including Michigan Wheel , Solas , Turning Point , Stiletto Precision Propellers , Quicksilver Props, Volvo Penta QL and Original Factory DuoProps.

These performance brands are available in 3 blade and 4 blade as either value priced aluminum or durable stainless steel props. With the most in-stock props available anywhere, you're sure to find the right size boat prop diameter and pitch, and in standard, right hand rotation or counter, left hand rotation.

Do you know the part number of your old prop? Use the iboats.com Propeller Part Number Search tool for quick exact-matches on any propeller brand, including: Michigan Match, Vortex, Ballistic, Apollo, Hustler, Rascal, Express, Amita, Lexor, Titan, Saturn, Black Diamond, Thunderbolt, Torrent, Silverado, Lightspeed, or Typhoon propellers.

Find blowout pricing on hundreds of discount options using the iboats.com boat prop calculator. As the largest online retailer of boat props, we often have manufacturers give us clearance props, inventory overruns, and other great deals. Shop now to find sales with free shipping and blowout prices up to 70% off.

When switching from 3 to 4-blades, generally a 1" pitch decrease is required. So, a 21" pitch 3-blade is replaced with a 20" pitch 4-blade. Pitch is increased when switching from 4 to 3-blades.

- How do I know which pitch I need?

Unlike every other part on your motor, there is not a single part number that replaces your boat propeller. Three primary performance-changing attributes of the propeller can be changed/modified without preventing the prop from fitting. They are: pitch, blade count, material, and diameter (though after a certain point, diameter can affect fit). Making sure you get a prop that will not only fit the prop shaft but is suited to your application and context (boat style/size/weight, altitude, uses, etc) is a must when it comes to finding a replacement.

If you're looking for a something that will simply replace what you currently have, the easiest way to determine the right prop for your set-up is in two parts: 1) identify the specs of your current propeller and, assuming you're satisfied with the performance, replace it with something with the same pitch, material and blade count. Diameter doesn't need to be identical but should be within 1/4" of the replacement's size. 2) Use our prop finder tool to navigate to a listings of propellers that fit your motor.

So how do you identify your prop's pitch and diameter? Usually either or both will be stamped somewhere on the prop's hub or just behind one of the blades. The standard format of diameter and pitch for props is: pitch x diameter; e.g. a stamp that reads 14x17 would indicate a 14" diameter and a 17" pitch. Alternatively you may only see a number between 5 and 27 followed by a "p", which would be the pitch. Should only the pitch be available, you can easily get the diameter of the prop by measuring from the center of the hub to the tip of one of the blades, then doubling that measurement. If the pitch isn't stamped on the prop but you can find a part number, doing an online search for that part number, especially in conjunction with the prop manufacturers name, may lead you to the specs you need.

Should you be unable to find any information on your current prop's pitch (for example if there were no markings, the prop is sitting at the bottom of the lake, or in the hands of thieves) there are a couple resources that can help you determine what approximate prop specs would serve you best, though none are guaranteed. Mercury Marine's Prop Selector is a tool that will suggest props/specs based on your answers to a series of questions about your boat, motor, boating habbits, and other relevant aspects that would impact optimal prop selection. Another potential resource is a local dealer that services your make of boat. Because altitude is a variable in determining pitch (rule of thumb: drop a pitch for every thousand feet you increase in elevation), it's common for boat manufacturers to leave choosing what pitch goes best with the boat/motor set-up to the dealer. This gives the dealer a solid understanding of the pitch ranges for most boat/motor set-ups in your area, allowing you to pick from that range based on your performance preferences. A third resource is other boaters with your similar set-up and at a similar altitude: what pitch, diameter, and blade count are they using, and what type of performance are they getting from it? If you don't want to spend your time pan-handling for information at the local marina, try our boating forums .

Once you've determined the pitch and diameter you need, you'll need to find prop options that will fit your prop shaft. This is what our Prop Finder was created for: pick your manufacturer, model, pitch, then choose from a variety of props that will fit, using diameter, material, and blade count, and brand preferences to help narrow your selection.

- Prop-Related Over-Revving

Keeping your RPM within the engine manufacturer's suggested wide-open-throttle (WOT) range is a key component in maintaining peak performance of your motor for as many years as possible. While there can be a variety of over-revving causes, the simplest and most common reasons will typically be propeller related, as not everything that fits the motor will work for the boat-motor set up, and propellers naturally lose their bite with the wear and tear accompanying standard use.

For used propellers, there are typically 3 types of damage that can cause over-revving. The amount of over-revving and how quickly it changes from being within the manufacturers WOT ranges to being over can help clue you in to the problem.

If you're over-revving on a brand new propeller, you're likely dealing with a prop with specifications that are not complementive of your motor, such as having too low of a pitch (not enough resistance = over-revving) or too small of a diameter (too much slip = over-revving). This can be a costly mistake since most retailers will not accept returns for props that have been run on the water, making it imperative that you pick the right propeller from the get-go. Alternatively, you could have a factory defect, which is typically a hub related issues, in which case you should contact the retailer or manufacturer for a return or warranty claim.

- Know When To Replace Your Propeller

Props can take a beating in even the best conditions. Churning sand, mud, floating debris, logs and rocks can bend, chip or crack blades. Even minor nicks, dings or scratches that accumulate from normal wear-and-tear can rapidly degrade performance. Running a damaged or bent propeller has the same effect as driving on worn or poorly inflated tires-you have less control, and performance and efficiency suffer.

Worse yet, continuing to use a bent or cracked prop can damage the engine's gearcase. A compromised propeller will not spin true, creating excessive vibration that can have devastating results.

With this in mind, propellers should be inspected regularly for damage. Spring commissioning and fall layup are great times for a close look. Trailered boats can easily be examined prior to each trip.

Signs of severe wear, such as chipping or cracks on the blade tips or cracks along the blade joints are easiest to spot. Another important but less obvious item to inspect is the propeller's pitch, as the blade angles can become bent or offset over time. If propeller blades seem out of alignment, it's best to have them inspected by a local prop specialist.

Apart from regular prop inspections, if while running the boat you hit something or tangle up in thick weeds, examine the prop as soon as possible. If you heard it or felt it, damage is highly likely. This is also why a spare prop should be an essential onboard piece of equipment.

When prop damage occurs, the question is whether to repair or replace. Propeller repair can be expensive, especially on hard-to-weld stainless steel. Blades that are ground down to remove bent or chipped edges create subtle changes in prop pitch, cup and diameter that can degrade performance. And, few prop shops can guarantee same-day service, especially in the heart of boating season. This leaves you off the water.

However, if the damaged prop has a removable hub, the housing can instead be replaced for about the price of a repair. Why repair a prop and contend with performance issues when a brand new one can be installed for a comparable price, putting you back on the water the same day?

There also are good reasons to replace an older propeller that is still in good condition. Changes in hull design and the introduction of high horsepower outboards have led to radical new approaches to propeller design and manufacturing. In addition, computer modeling has resulted in a better understanding of fluid dynamics and high-velocity water flow. Advances such as variable rake and pitch blades, multiple geometries and new barrel designs have rendered older propellers obsolete in terms of hydrodynamic efficiency.

Choosing the appropriate propeller for a particular boat and motor is fairly simple. The most important equation to understand is that less pitch means more rpm and more pitch means less rpm. For peak performance, an engine should run at the upper end of the manufacturer's recommended rpm range at wide open throttle, or WOT. If more speed, handling and lift is desired, particular prop styles come into play. The normal load on the boat, as well as whether the craft is usually used for fishing, watersports or cruising, also factors in prop selection. Turning Point's online Prop Wizard tool helps you select the best prop for your boat/engine set-up.

To help keep your boat running its best, replacing a propeller is quick, easy and inexpensive for models with an interchangeable hub system. Any damaged blade requires only that the housing be replaced, not the entire prop, saving hundreds of dollars over the years.

One question we get all the time is what do I need to do to keep my stainless or aluminum prop in optimum running condition. Other than not hitting something in the water, there is really not much to do. We always recommend removing the prop for overwintering, but that is to protect against theft and from someone hitting their shins on the prop blades when they get too close to your boat! General surface cleaning can be done to stainless if you want to maintain it's like-new shine, but even that is not necessary, A shiny prop is not measurably faster than one a little dulled by use. But it is critical any edge damage, dings, gouges, or bending of the blades be brought to the attention of a local prop repair specialist immediately. They have the tools and expertise to get your prop back in optimal condition. They are not so busy in the off season, so taking that prop for repair after your boat is tucked away is the perfect time to keep a local craftsman busy during the winter.

Ron Bailey is vice president of sales and marketing for Turning Point Propellers. The company has been engineering, manufacturing and marketing high-performance aluminum and stainless steel propellers worldwide for over 15 years. Turning Point Propellers : 11762 Marco Beach Dr., Suite 2, Jacksonville, FL 32224. Phone: 904-900-7739 Email: [email protected] Website: www.turningpointpropellers.com

STAY CONNECTED

Sign up for our Newsletter to Receive the Latest Deals, News and More.

OUR COMPANY

Explore iboats, connect with us.

Where The Power Meets The Water

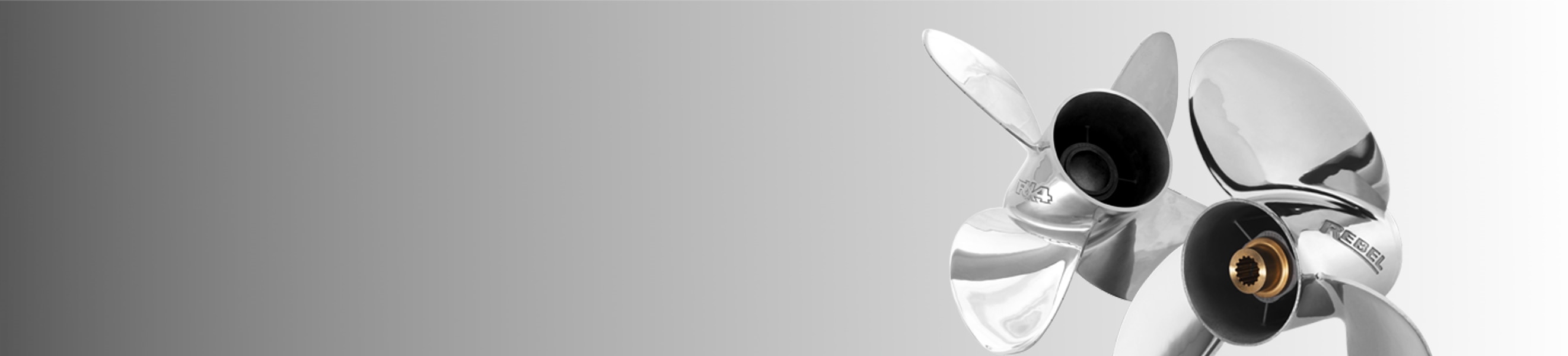

All new rx4 and rx3 propellers.

RX4® FOUR BLADES FOR EFFICIENCY AND TRACTION IN TURBULANT WATER

- Designed for the Evinrude E-TEC G2 engine

- Optimized for traction in turns and any water condition

- Superior bow lift on larger boats

- Variable Vent Port – VVP

Recommended for bass, multi-species, offshore and triple-log pontoon boats Wide range of sizes and rotation to fit Evinrude E-TEC G2 115HO to 300 HP

RX3® THREE BLADES FOR BOAT CONTROL, ACCELERATION AND FUEL ECONOMY

- High Efficiency Cruising and General Operation

- Superior Boat Control and Best for iDock Joystick Applications

Recommended for any boat type and application Wide range of sizes and rotation to fit Evinrude G2 115HO to 300 HP

PROPELLERS' SPECIFIC DESCRIPTIONS

ALUMINUM GENERAL PURPOSE & ECONOMY

- Lowest cost and good value

- Precision casting provides great strength and long life

- Cupped blades

- Recommended for runabout, deck, flats/bay, multi-species, and twin-log pontoon boats

VIPER™ TBX™ RUNABOUTS & GENERAL RECREATION

- V6 – Standard & Counter Rotation

- V4 – Standard Rotation

- Versatile 3-blade performance

- Excellent balance of speed and durability

- Recommended for runabout, deck/flats, multi-species, offshore and pontoon boats

RAKER® H.O. BASS & HIGH PERFORMANCE

- Set the highest stands in top speed performance

- Maximizes the superior power and torque of the Evinrude E-TEC G2 engine

- Superior bow lift

- Vented hub for faster acceleration

- Recommended for multi-species (fiberglass only), bass, and sport runabout

CYCLONE™ TBX™ OFFSHORE CRUISING & RUNABOUTS

- Enhanced performance propeller

- Stays on plane with minimum RPM

- Less vibration and improved fuel economy

- Recommended for runabout, deck, flats/bay, multi-species (Aluminum only), and offshore boats

SSP TBX GENERAL PURPOSE & DURABILITY

- Ideal upgrade from aluminum

- Fast planing 3–blade versatile prop

- Recommended for runabout, and twin-log pontoon boats

HYDRUS™ PONTOON BOATS

ROGUE™ SMALL RUNABOUTS & FLATS BOATS

- Provides extra stern lift

- Stays on plane w/minimum RPM

- Custom high luster finish

REBEL® TBX™ OFFSHORE & CRUISING

- Designed & engineered for efficient midrange cruising hub system

- Use on offshore boats, large runabout, & pontoon boats

All orders have a 2-3 day processing time before shipping. Please note our warehouse is closed Fridays through Sundays.

Propellers Info and Selection Charts

The goal in propeller selection is to determine what propeller style and size will maximize performance for your boat, while allowing the engine to operate in the recommended RPM range (optimized power band). The correct propeller will prevent the engine from over-revving, yet allow it to reach the preferred RPM where maximum horsepower, load carrying capacity and performance is produced. This mix may change depending on the users needs, boat, load, and engine. Elevation and environmental conditions also affect this computation.

When selecting a propeller it is important to first gauge your intended use. If you normally run your boat with a fixed load you should select a propeller that delivers optimum RPM with that load. If you intend to run a heavy load in the fall, it is best to select a smaller pitch propeller or gearing so that you don't loose RPM and drop below your engine's preferred power band. If you intend to run in different climates and different elevations, propeller choices again will vary.

In varying conditions, it is best to invest in a propeller for lighter loads and another for heavy.

Stock motors run best from 3800 to 4000 rpm. Black Death motors run best from 4000 to 4175 rpm, and the BPS mag engines run best in the 4400 to 4600 rpm range. Note: Mag engines are fitted with a 5100 RPM rev limiter and you can run these motors to this limit without question, however, best performance and engine life is achieved by operating the mag engines near 4600.

Many short tail motors like the Mud Buddy series do not have a broad propeller selection, rather they rely on belt sprocket variations.

If you can change drive ratios, it is best to select a propeller and/or sprocket ratio combination that runs a bit slower with a new propeller so that the RPMs can increase as the propeller wears.

A one pitch change will result in a 250 to 350 rpm change.

When using these charts - select one pitch smaller prop, or one gear ratio smaller when running above 4000 foot elevation or when operating a larger than normal boat and load.

| Short Tail Prop and Sprocket Selection Chart | ||||

| Engine | Propeller | Sprocket Size | Gear Ratio | RPM |

| Mag7000 | 12 X 10 | 40 top / 46 bottom | 1.15:1 | 4400 - 4600 |

| Mag 6000 | 12 X 10 | 38/46 | 1.21:1 | 4400 - 4600 |

| Mag 5500 | 12 X 10 | 38/47 | 1.24:1 | 4400 - 4600 |

| Mag 5000 | 12 X 10 | 38/47 | 1.24:1 | 4400 - 4600 |

| Mag 45 | 12 X 10 | 38/48 | 1.26:1 | 4400 - 4600 |

| Black Death 5500 | 12 X 10 | 40/48 | 1.20:1 | 3900 - 4175 |

| Black Death 4500 | 12 X 10 | 38/46 | 1.21:1 | 3900 - 4175 |

| Stock 35 | 12 X 10 | 38/50 | 1.32:1 | 3800 - 4000 |

| Stock 27 | 12 X 10 | 36/50 | 1.38:1 | 3800 - 4000 |

| Stock 23 | 11X10 or 12X10 | 34/50 | 1.47:1 | 3800 - 4000 |

| Stock 18 | 10 X 8 | 32/50 | 1.56:1 | 3800 - 4000 |

| Stock 14 | 10 X 8 | 32/52 | 1.63:1 | 3800 - 4000 |

| Super Longtail Prop Selection Chart | ||||

| Engine | Propeller | Sprocket Size | Gear Ratio | RPM |

| Black Death 4500 | 9.5 X 9 | 34 top / 54 bottom | 1.59:1 | 3900 - 4175 |

| Stock 35 | 9.5 X 9 | 34/56 | 1.65:1 | 3900 - 4175 |

| Stock 27 | 9.5 X 9 | 32/54 | 1.69:1 | 3800 - 4000 |

| Stock 23 | 9.5 X 9 | 32/56 | 1.75:1 | 3800 - 4000 |

| Long Tail Prop Selection Chart (3800 to 4000 RPM) | |||

| Engine | Propeller | Engine | Propeller |

| Mag45 | 10 X 8 | Stock 18 | 9 X 5 |

| Black Death 4500 | 10 X 8 | Stock 14 | 8 X 4 |

| Stock 35 | 10 X 5 | Stock 12 Gear | 10 X 8 |

| Stock 27 | 9 X 7 | Stock 13 | 8 X 4 |

| Stock 25 | 9 X 7 | Stock 9 | 7 X 4 |

| Stock 24 | 9 X 6 | Stock 6 Gear | 9 X 7 |

| Stock 23 | 9 X 5 | Stock 6 | 6 X 4 |

___________________________________________________________

The BPS Tiger and Big Blade industry leading propellers feature unmatched durability. finish and balance. These time-proven propellers deliver limited slip and provide exceptional hole shots while cranking out amazing top end speeds.

Big Blade is a trademark brand.

- Store Locator

Propellers & Drive Systems

- Tilt & Trim

- Shaft Seals, Couplings, & Parts

- Anodes & Zincs

- Performance Parts

- Bow & Stern Thrusters

- Transmission Parts

- Prop Savers & Skeg Guards

1257 Products

Product type, engine make, manufacturer.

- Johnson / Evinrude / OMC

- Michigan Propeller

- Quicksilver by Mercury

Blade Count

- 3/4" - 16 Thread

- Small 3-3/8"

- Large 4-1/4"

- Spline Drive

Spline Count

- Stainless Steel

Need help finding the right prop? Check out our propeller fit guide. The Solas Propeller Fit Guide will walk you through picking the right propeller for your boat engine's make, model and horse power. You can also select what type of boat configuration you have and the prop fit guide will suggest the appropriate prop. Or if you have the OEM propeller number, you can enter that in and it will give you the Solas cross-reference. If you still aren't sure, give us a call 1-800-998-9508 and one of our techs will help you find the right boat propeller.

Propeller Function

Growth on propellers, metal loss on propellers.

Practical Boat Owner

- Digital edition

Boat propeller: How to choose the right one for your boat

- Tony Davies

- June 5, 2019

For optimum performance and fuel efficiency under engine, it’s important to have the right boat propeller. Tony Davies reports...

Understanding boat propeller design can help solve performance problems that occur when a boat is being driven under power. The wrong prop may be wrong in a number of different ways including diameter, pitch, blade shape or blade area.

Your prop may suffer from cavitation, ventilation or slippage – your boat may be burning too much fuel or lacking acceleration or top speed.

But how can you tell if you have a propeller problem and how do you know which of these issues might be affecting your propulsion?

Boat propeller diameter formula

Line A-B x 2 = propeller diameter

All propellers can be described in basic terms using a set of two numbers: diameter x pitch. Hence a prop with an 18in diameter and 12in pitch is described as 18 x 12.

The diameter of the propeller is the circle which the tip of a single blade describes in a complete rotation.

It is found by measuring from the centre of the propeller boss to the tip of one blade and then doubling the result.

Pitch is the forward distance that a propeller would theoretically travel in a single rotation if there were no slip present – imagine a screw being driven into a piece of wood.

The angle at which the propeller blades are set governs the distance travelled. A fine pitch (meaning little angle on the blades) gives a lesser distance than a coarse pitch (greater blade angle).

How to measure the pitch of a propeller

A boat propeller is usually designed with two to five blades (though sometimes more). In the first instance, the number of blades is decided by the weight of the vessel: the greater the weight, the greater the blade area required to push it through the water with a minimum of slip and cavitation.

To specify the correct type and size of propeller, a standard set of boat, engine and gearbox measurements is required. Designers will use the boat’s length, beam, draught and displacement in combination with the boat’s underwater drag characteristics to calculate hull resistance.

What is Hull Resistance?

Resistance is the hull’s natural tendency to drag through the water. Bare hull resistance is produced by skin friction of the hull’s surface, waves created by the hull running through the water and the shape of the hull below the water.

To the bare hull, the drag of appendages must be added such as rudders, shaft support brackets, shafts, depth sounder transducers, stabiliser fins, etc.

However, the design of the lift surfaces of the hull also have a very significant effect. Designers work to ensure that the lifting characteristics give the hull the least resistance at normal operating speed.

Once this resistance is known, engine and gearbox specifications can be combined with maximum propeller diameter (clearance beneath the boat is typically 12% of the prop’s own diameter) to determine the prop’s minimum requirements. The vessel’s ‘duty cycle’, which is simply a judgement as to whether a boat is to be used for heavy or light commercial or pleasure purposes, then also influences a designer’s final specification.

Propeller diameter is first decided by the type of boat. A large-diameter slow-revving propeller is the most efficient type but this won’t provide the necessary acceleration to get a sports cruiser onto the plane. Acceleration is achieved by increasing the rotation speed, which usually means a smaller diameter propeller. The fact that many modern sports cruisers have limited propeller clearance space is another reason for fitting smaller diameter propellers.

To accommodate the loss of thrust from the smaller diameter, the pitch is increased to give more thrust from the propeller’s movement through the water rather than from the blade area. It is in fact a combination of the three elements: diameter, pitch and rpm that provides the thrust at the given speed of the boat.

The higher the speed of the boat, the higher the pitch should be. Also the higher the pitch, the greater the efficiency of the propeller. Higher pitch can be used by selecting higher gear ratios, but this is not really viable for most outdrive powered craft due to the small choice of ratios available and in this case it is usually necessary to work with the supplied ratio.

Article continues below…

Are folding or feathering propellers worth the extra cost? Ask the experts

Nicko Williams asks: “I wonder what your views are on folding versus feathering boat propellers. “My Jeanneau 379 carries a…

Propeller antifoul: Our expert’s top tips for sticking paint to a prop

Andy Peach writes: “What’s the best preparation and antifouling paint to use on a propeller and P-bracket? “I’d heard that…

Boat propeller cavitation and ventilation

Cavitation is often confused with ventilation as the symptoms are similar: increased shaft revs without any increase in boat speed – or sometimes even a sudden reduction in speed.

Ventilation is caused when air is drawn down into the propeller from the surface. This can be due to the propeller being too near the surface (a design fault) and spinning too fast. The air entering the propeller causes the blades to lose contact with the water and allow it to lose ‘bite’.

Cavitation is totally different and is often caused when a heavy, fast vessel has propellers with too little diameter and blade area. The weight of the boat puts too much load on the propeller blades increasing the pressure on the face side while decreasing the pressure on the backside of the propeller. At very low pressure water starts to vaporize, which causes a vacuum to form on the surface of the blades in the form of tiny bubbles that implode upon themselves. These implosions can damage the surface of the blades with pitting. Over a period of time, these tiny pits, or craters, can seriously weaken the blades and the bubbles can additionally cause erosion on the rudder surface.

The answer to cavitation is to use blades of larger diameter or greater area to increase thrust. This will allow the revs to be reduced by altering the gearbox ratio. However, this is often not possible due to lack of clearance beneath the hull – in which case, the props just have to be replaced more often.

Do I have the wrong size boat propeller?

If the boat is over-propped the engine will not reach maximum rpm and the boat will underperform. Equally, if a boat is under-propped and the engine easily reaches or exceeds maximum rpm, the propeller needs more ‘bite’ to get the boat to maximum performance level.

With outdrives, adjusting the pitch of the prop is often the only option, as the maximum diameter propeller is often already installed. Increasing the pitch will decrease the revs and vice-versa.

If the engine revs seem OK with the current prop, but you want better acceleration, it is often possible to reduce the diameter and increase the pitch by roughly the same amount to give added acceleration without losing the top-end speed.

If you’re still unsure, you can use an online boat propeller calculator like this one from vicprop.com

What is the benefit of new boat propeller blade design?

Blade shape has moved on in the last 15 years or so, thanks partly to computer aided design and a better understanding of what advantages a particular blade shape can offer.

The heavy sectioned blade is no longer the preserve of the plodding working boat, it can also be used to advantage on high-speed vessels where performance and economy are of equal importance.

Take a look at the original propeller on my own boat (below). Not much more than a three-bladed slab of bronze that did its job of pushing the boat through the water.

Three-bladed propeller: a workhorse that served Tony Davies boat well for many years

Now move on ten years and look at the sophisticated four-blade foil design that runs much more quietly, with less vibration and gives increased fuel economy at semi-displacement cruising speed.

A modern four-blade design that is more fuel efficient and more powerful

Brave new boat propeller designs

With modern propeller design and construction methods the three main criteria (diameter, pitch and rpm) are no longer the only governing factors. Increasingly, shape is just as important.

If the diameter needs to be smaller to provide better acceleration then the blade area can be increased by adding more blades. For optimum performance, fuel economy, fast acceleration and smooth vibration-free running, it is the shape and cross section of the blades that make the crucial difference.

For the everyday boat owner blade shape is governed by the boat’s dimensions, its engine specifications and the owner’s choice of propeller manufacturer. High-tech computer-designed and machined propellers only become viable for yachts over 24m (superyachts) where the shape of the blades is tailored to the requirements of the vessel taking into account resistance as well as all the normal information required to build a propeller.

This Sunseeker propeller is a good example of what is required to propel a heavy high-performance craft. The total area is greatly increased by overlapping the leading and trailing edges of the blades. This avoids the problem of cavitation, but the blades are shaped to ensure water flows smoothly through the propeller

Theoretically, fewer blades provide a more efficient propeller. In contrast, more blades make for smoother running and less vibration. With modern propeller design the type of propeller used for any particular purpose is no longer easy to designate as there are often elements of all types incorporated into the design.

The shape of the older equipoise is reminiscent of the latest ‘foil’ design although it has less blade area.

‘Foil’ design propellers are generally used on high performance craft replacing the equipoise style from which they developed. These have finely finished sections and sharp edges for minimum drag and maximum performance.

The round blade turbine propeller is still used on heavy displacement craft including commercial vessels. It has a large blade area and thick sections to resist damage.

The latest incarnation is the surface piercing or cleaving propeller. In theory a single blade propeller would offer the greatest efficiency but this would clearly not work as the imbalance caused by a single blade would be impossible to overcome. The surface piercing propeller does to some extent achieve the impossible by only immersing one blade into the water at a time. While useful on high speed vessels the drawback is less than efficient performance at low speed and the amount of exposed machinery required aft.

Sharrow MX1 toroidal boat propeller

What is a toroidal boat propeller?

Toroidal boat propellers are a new type of propeller with a loop instead of a fin. They are claimed to deliver faster planing, higher top speeds, superior handling and reduced vibration. The drawback is that they are much more expensive to produce.

For more information on toroidal boat propellers, check out this feature from our sister site MBY.com

What paint should I use for boat propeller antifouling?

The right type of bottom paint for your boat propeller antifouling job depends on what your prop is made of. Our expert Vyv Cox has this advice on propeller antifouling , while Richard Jerram has some tips on antifouling bronze brackets .

Originally published in Practical Boat Owner magazine May 2019.

- (678) 322-7877

- 9605 Jot Em Down Rd. Gainesville, GA 30506.

Boat Propeller 101: Frequently asked questions

Is boat propeller selection important .

Yes! After the engine, boat propeller is the essential component that gives your boat connection to the water and creates thrust to propel the boat forward. It is akin to tires on your car. You can feel higher performance handling when you’ve got the right tires.

Similarly, the right propeller gives the perfect balance of acceleration, top-end speed, and smooth ride. In addition, the right size and pitch of the propeller make it, so your engine doesn’t labor and cause unnecessary strain, which damages the engine.

For top-end speed, you want your engine’s maximum recommended rpm’s to be achieved, but not higher.

A propeller shop can make minor adjustments to the pitch and shape characteristics of a propeller to create the perfect balance of performance.

A professional boat shop can help you select the perfect propeller to maximize your boat’s performance.

What is the best metal for a boat propeller?

Boat propellers for recreational boats are made from aluminum, stainless steel, or bronze.

Aluminum is cost-effective. It is easy to repair and is the most common propeller choice. It’s a great choice for areas where your propeller may hit bottom. Aluminum propellers are common on small to medium-sized boats.

Stainless steel is a common propeller material for outboard or I/O motors. Stainless steel propellers are higher performance and priced accordingly. A stainless steel propeller is strong, so it can be machined thinner, so it’s less prop to spin through the water. It is also durable and corrosion-resistant.

Stainless steel propellers can withstand high speeds and may be used on high-performance and heavy boats alike because of its strength, durability, and resistance to harsh environments.

Bronze is a propeller material commonly used with inboard engines. Bronze is strong, has excellent corrosion resistance, and resists flexing and fatigue.

Stainless steel propellers are used on high-performance boats because of their strength and durability.

How many blades are best on a propeller?

From an engineering hypothetical, a single blade propeller is the most efficient, but it would create an enormous amount of vibration and wobble. So a two-blade propeller is the most efficient. This is a common propeller on a small motor.

The more blades on a propeller, the more balanced it is. A three-blade propeller is the most common, offering a combination of performance and balance.

Four or five-blade propellers are useful on heavy boats providing maximum thrust while they also lift the stern. Efficiency and top speed may be decreased with more blades. However, less vibration results in a smooth, fluid ride.

Four and five-blade propellers are also utilized in high-performance applications where the propeller may break the water surface. More blades create an increased blade area to grab into the water to continue to thrust the boat forward.

This cleaver style high-performance racing propeller has five blades. This style grabs the water again quickly after the boat goes airborne.

What do the numbers signify on a propeller?

The numbers on the propeller reflect the diameter and the pitch. The diameter is measured from the center of the propeller to the tip of the blade and is doubled to give the full size of rotation.

The pitch of the propeller refers to how many bites the blades take. It is measured by how much the propeller would move forward if it carved through a soft solid material.

For example, if the propeller was 13 ½ x 21 it has a 13 ½ inch diameter and theoretically would move 21 inches forward with one full revolution.

How much do boat propellers cost?

Aluminum props cost the least compared to other materials. On average, an aluminum propeller costs $160- $220.

Stainless steel propellers cost $400 – $800 depending on characteristics.

Bronze propellers cost $500 and up.

What can a machine shop do for a boat propeller?

A propeller shop can fix small bends, nicks, and properly balance a propeller. They can also add cup to the trailing edge of the propeller to increase pitch slightly and decrease engine RPM’s, while increasing speed.

A trip to the propeller machine shop can run $200 – $400, so sometimes replacement makes more sense. This is especially true of lower-cost aluminum propellers. However, the more expensive the propeller, the more economic sense it makes to use the machine shop.

Propellers last for years if they don’t hit ground. If a propeller has a vibration, a propeller machine shop can bring it back into balance.

What is the optimal max engine RPM’s for a propeller?

An outboard engine will run between 5000-6000 rpms, and sometimes higher. Check the manufacturer’s recommendation.

An inboard engine may run 3400-3800 and sometimes higher. The engine manufacturer gives specific recommendations so you don’t over prop, or conversely, run consistently at too high of RPM’s.

What is cavitation and ventilation?

Cavitation is the formation of air bubbles on the propeller, often caused by damage to the propeller-like dings or a slight bend. It causes vibrations and reduces the propeller’s ability to bite. A telltale sign are pits in the propeller from burns.

An interesting phenomenon is that water can actually boil at a low temperature if air pressure is reduced enough. This occurs during propeller cavitation and is what causes burns and pitting on a propeller.

Ventilation is the sucking in of surface air, commonly from jumping the boat out of the water, or trimming the motor too high. Ventilation can cause the engine to over-rev. Special propeller characteristics may be utilized to minimize the effects of ventilation.

What are the signs I need a different boat propeller?

- There’s undesirable vibration

- Can’t reach a reasonable top speed

- Improper acceleration

- Cavitation causes the propeller not to bite properly

- Your RPM’s don’t reach the recommended max engine speed

- Your top-end RPM’s exceed the recommended max engine speed

- There is physical propeller damage from hitting bottom

Lakeside Marine is voted Best Boat Repair Shop on Lake Lanier and can assist you with all of your high performance boat needs, including propellers.

Conclusion:

Propellers have many characteristics that can be engineered into them. It is amazing science behind them. If you believe you need a new propeller for any of the above reasons, consult a professional shop like Lakeside Marine.

Lakeside Marine’s performance professionals can research your boat’s engine and model specs. We will assist you in choosing the perfect propeller that gives you acceleration, top-speed, and a smooth ride. Then, call Lakeside Marine today for all of your boat repairs and upgrades at (678) 322-7877.

Contact Us for Boat Propeller Service

NEVER MISS A POST

Sign up for free and be the first to get notified about updates

Advantages of a Center Console Boat

May 26, 2022

Center console boats are akin to the SUV's of boats. You sit up high, they're sturdy, utilitarian, and a blast to drive. The primary advantages of a center console boat are ease of operation, superior view from the center helm, clear access to all sides of the boat,...

How Does Marine Audio Equipment Differ?

Apr 7, 2022

Marine Audio equipment is specially designed and manufactured to perform in the harsh conditions of the marine environment: sun, rain, spray, salt, and the shock of pounding waves. Marine audio equipment is either waterproof or highly water-resistant. The internal...

25 Advantages of Outboard Motors

Jan 16, 2022

There are many advantages to outboard motors. The primary benefits are lower up-front cost, lower weight, higher speed, and ease of maintenance. To be sure, there are also advantages to inboard motors and stern drives, and we will explore these. In this easy-to-follow...

Submit a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Submit Comment

- Salary & Income Tax Calculators

- Mortgage Calculators

- Retirement Calculators

- Depreciation Calculators

- Statistics and Analysis Calculators

- Date and Time Calculators

- Contractor Calculators

- Budget & Savings Calculators

- Loan Calculators

- Forex Calculators

- Real Function Calculators

- Engineering Calculators

- Tax Calculators

- Volume Calculators

- 2D Shape Calculators

- 3D Shape Calculators

- Logistics Calculators

- HRM Calculators

- Sales & Investments Calculators

- Grade & GPA Calculators

- Conversion Calculators

- Ratio Calculators

- Sports & Health Calculators

- Other Calculators

Boat Propeller Calculator

You can use this boat propeller calculator to determine one of five variables: boat speed, propeller slip, propeller pitch, engine gear ratio, or engine revs.

To use the calculator, input four of the five variables. The calculator will automatically compute the 5 th variable.

Boat Speed mph kts kph

Engine Revs RPM RPS

Gear Ratio : 1

Propeller Pitch inch cm mm

Propeller Slip %

Propeller slip provides an indication of the efficiency with which a boat is traveling through the water. However, it is not to be confused with propeller efficiency.

If there was an absence of slip as the propeller circulates through the water, the boat will, theoretically, move forward at a distance that matches the propeller pitch.

A propeller pitch can be understood by considering the action of a screw. The pitch indicates the distance that each rotation contributes to the extent to which the boat moves forward on each rotation. For instance, if the propeller moves forward 15 inches every time it completes a full turn, the nominal propeller pitch is 15 inches.

The propeller revolution rate is determined by dividing the engine rpm by the gear ratio. The propeller rpm multiplied by the propeller pitch indicates the distance forward a boat will move forward every minute.

However, as a result of propeller slip, there is a difference between actual and theoretical speed. Specifically, the actual speed is typically 10-20% slower than the propeller than the theoretical speed when the boat is traveling at its top speed.

The slip can be much higher at lower speeds, often above 50%. Typically, the slip reduces as the speed increases, generally diminishing to under 10%.

'Gear ratio' defines the number of drive shaft revolutions per propeller revolution. As such, if an engine has a gear ratio of 2:1, the engine drive shaft will turn twice for every propeller revolution. It is common for 200-HP engines to have a ratio of 1.86:1. Engines that have a smaller horsepower will have a higher ratio in the region of 2.33:1.

Calculator Equations

The following equations are used within this calculator:

V = [RPM × PP × (1 − (PS/100))] / [GR × C]

RPM = [V × GR × C] / [PP × (1 − (PS/100))]

GR = [RPM × PP × (1 − (PS/100))] / [V × C]

PP = [V × GR × C] / [RPM × (1 − (PS/100))]

PS = [1 − (V × GR × C) / (RPM × PP)] × 100

V is the speed at which the boat is traveling,

RPM is the crankcase speed (rpm),

GR is the number of revolutions the crankshaft needs to produce one revolution of the prop shaft,

PP is the blade pitch of propeller (inches),

PS is the index of propeller performance (as a percentage),

C is the constant to convert inches-per-minute of revolution to boat speed V ;

V (in mph), C = 1056 ;

V (in knots), C = 1215.2 ;

V (in kph), C = 656 .

- Currently 4.68/5

Rating: 4.7 /5 (357 votes)

- My account Close My account Log out

- Compare products list

You have no items in your shopping cart.

- Inboard Propellers

- Outboard Propellers

- Stern drive boat props

- PWC Impellers

- Ski Wake Boat Props

- Volvo Duo Props

- Prop Pullers

- Prop Guide & Sizings

- Brass cutless bearings

- Non Metallic

- Flanged bearings

- Stave bearings

- Shaft Zincs for sale

- Rudder Boat Zincs

- Plate Zincs

- Stainless Steel Shafts

- Shaft Seals

- Packing Boxes

- Shaft Accessories

- Deck Hardware

- Drivetrain Hardware

- Exhaust Fittings

- Hose and Clamps

- Steering Hardware

- Plumbing Fittings

- Shafting Accessories

- Miscellaneous Hardware

- Michigan Wheel

- Zimar Zinc Anodes

- Tides Marine

- SOLAS boat propellers

- ACME Marine

- Volvo Penta Duo Props

- Buck Algonquin Marine Hardware

- Boat Props /

- Outboard Propellers /

Boat props by outboard marine engine

Propeller Depot is the ultimate source for replacing your outboard boat prop, you will find the best prices on all of the best aluminum and stainless boat propellers.

We have cross-referenced all of our online boat propellers and hub kits with the corresponding engines, making it easier for you to find the right propeller. By clicking on the appropriate engine, you will be presented a list of all models that we currently support for a particular engine, and the boat propellers that fit that model. Propeller Depot is your best source for all outboard marine engine boat props, save big today!

- Evinrude Propellers

- Johnson Propellers

- Mercury Propellers

- Mariner and Sea Ray Propellers

- Honda Propellers

- US Marine Propellers

- Suzuki boat props

- Yamaha boat props

- Nissan boat props

- Tohatsu boat props

- Chrysler Propellers

- Force boat props

| Product(s) | Diameter | Pitch | Rotation | # Blades | Engine Type | Material | # Splines | Hub Kit | Price | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| : 15-1/2 inch : 25.50 : Left Hand (LH) : 3 : Suzuki : Stainless Steel : 25 Tooth Spline : Not Required (rubber pressed in hub) | 15-1/2 inch | 25.50 | Left Hand (LH) | 3 | Suzuki | Stainless Steel | 25 Tooth Spline | Not Required (rubber pressed in hub) | $754.99 | |||||

| : 15-1/2 inch : 24 : Left Hand (LH) : 3 : Suzuki : Stainless Steel : 25 Tooth Spline : Not Required (rubber pressed in hub) | 15-1/2 inch | 24 | Left Hand (LH) | 3 | Suzuki | Stainless Steel | 25 Tooth Spline | Not Required (rubber pressed in hub) | $754.99 | |||||

| : 15-1/2 inch : 22.50 : Left Hand (LH) : 3 : Suzuki : Stainless Steel : 25 Tooth Spline : Not Required (rubber pressed in hub) | 15-1/2 inch | 22.50 | Left Hand (LH) | 3 | Suzuki | Stainless Steel | 25 Tooth Spline | Not Required (rubber pressed in hub) | $754.99 | |||||

| : 15-1/2 inch : 21 : Left Hand (LH) : 3 : Suzuki : Stainless Steel : 25 Tooth Spline : Not Required (rubber pressed in hub) | 15-1/2 inch | 21 | Left Hand (LH) | 3 | Suzuki | Stainless Steel | 25 Tooth Spline | Not Required (rubber pressed in hub) | $754.99 | |||||

| : 15-1/2 inch : 19.50 : Left Hand (LH) : 3 : Suzuki : Stainless Steel : 25 Tooth Spline : Not Required (rubber pressed in hub) | 15-1/2 inch | 19.50 | Left Hand (LH) | 3 | Suzuki | Stainless Steel | 25 Tooth Spline | Not Required (rubber pressed in hub) | $754.99 | |||||

| : 14-1/8 inch : 25.50 : Right Hand (RH) : 4 : Suzuki : Stainless Steel : 15 Tooth Spline : Not Required (rubber pressed in hub) | 14-1/8 inch | 25.50 | Right Hand (RH) | 4 | Suzuki | Stainless Steel | 15 Tooth Spline | Not Required (rubber pressed in hub) | $799.00 | |||||

| : 14-1/8 inch : 24 : Right Hand (RH) : 4 : Suzuki : Stainless Steel : 15 Tooth Spline : Not Required (rubber pressed in hub) | 14-1/8 inch | 24 | Right Hand (RH) | 4 | Suzuki | Stainless Steel | 15 Tooth Spline | Not Required (rubber pressed in hub) | $799.00 | |||||

| : 14-1/8 inch : 22.50 : Right Hand (RH) : 4 : Suzuki : Stainless Steel : 15 Tooth Spline : Not Required (rubber pressed in hub) | 14-1/8 inch | 22.50 | Right Hand (RH) | 4 | Suzuki | Stainless Steel | 15 Tooth Spline | Not Required (rubber pressed in hub) | $799.00 | |||||

| : 14-1/8 inch : 21 : Right Hand (RH) : 4 : Suzuki : Stainless Steel : 15 Tooth Spline : Not Required (rubber pressed in hub) | 14-1/8 inch | 21 | Right Hand (RH) | 4 | Suzuki | Stainless Steel | 15 Tooth Spline | Not Required (rubber pressed in hub) | $799.00 | |||||

| : 14-1/8 inch : 19.50 : Right Hand (RH) : 4 : Suzuki : Stainless Steel : 15 Tooth Spline : Not Required (rubber pressed in hub) | 14-1/8 inch | 19.50 | Right Hand (RH) | 4 | Suzuki | Stainless Steel | 15 Tooth Spline | Not Required (rubber pressed in hub) | $799.00 | |||||

| : 15 inch : 14 : Left Hand (LH) : 3 : Various Engine Types - Please verify : Stainless Steel : Determined by Hub Kit : Required | 15 inch | 14 | Left Hand (LH) | 3 | Various Engine Types - Please verify | Stainless Steel | Determined by Hub Kit | Required | $578.99 | |||||

| : 14-4/5 inch : 20 : Left Hand (LH) : 3 : Various Engine Types - Please verify : Stainless Steel : Determined by Hub Kit : Required | 14-4/5 inch | 20 | Left Hand (LH) | 3 | Various Engine Types - Please verify | Stainless Steel | Determined by Hub Kit | Required | $578.99 | |||||

| : 14-4/5 inch : 19 : Left Hand (LH) : 3 : Various Engine Types - Please verify : Stainless Steel : Determined by Hub Kit : Required | 14-4/5 inch | 19 | Left Hand (LH) | 3 | Various Engine Types - Please verify | Stainless Steel | Determined by Hub Kit | Required | $578.99 | |||||

| : 14-4/5 inch : 18 : Left Hand (LH) : 3 : Various Engine Types - Please verify : Stainless Steel : Determined by Hub Kit : Required | 14-4/5 inch | 18 | Left Hand (LH) | 3 | Various Engine Types - Please verify | Stainless Steel | Determined by Hub Kit | Required | $578.99 | |||||

| : 14-4/5 inch : 17 : Left Hand (LH) : 3 : Various Engine Types - Please verify : Stainless Steel : Determined by Hub Kit : Required | 14-4/5 inch | 17 | Left Hand (LH) | 3 | Various Engine Types - Please verify | Stainless Steel | Determined by Hub Kit | Required | $578.99 | |||||

| : 14-4/5 inch : 16 : Left Hand (LH) : 3 : Various Engine Types - Please verify : Stainless Steel : Determined by Hub Kit : Required | 14-4/5 inch | 16 | Left Hand (LH) | 3 | Various Engine Types - Please verify | Stainless Steel | Determined by Hub Kit | Required | $578.99 | |||||

| : 14-1/2 inch : 21 : Left Hand (LH) : 3 : Various Engine Types - Please verify : Stainless Steel : Determined by Hub Kit : Required | 14-1/2 inch | 21 | Left Hand (LH) | 3 | Various Engine Types - Please verify | Stainless Steel | Determined by Hub Kit | Required | $578.99 | |||||

| : 14-1/4 inch : 22 : Left Hand (LH) : 3 : Various Engine Types - Please verify : Stainless Steel : Determined by Hub Kit : Required | 14-1/4 inch | 22 | Left Hand (LH) | 3 | Various Engine Types - Please verify | Stainless Steel | Determined by Hub Kit | Required | $578.99 | |||||

| : 14 inch : 24 : Left Hand (LH) : 3 : Various Engine Types - Please verify : Stainless Steel : Determined by Hub Kit : Required | 14 inch | 24 | Left Hand (LH) | 3 | Various Engine Types - Please verify | Stainless Steel | Determined by Hub Kit | Required | $578.99 | |||||

| : 15 inch : 14 : Right Hand (RH) : 3 : Various Engine Types - Please verify : Stainless Steel : Determined by Hub Kit : Required | 15 inch | 14 | Right Hand (RH) | 3 | Various Engine Types - Please verify | Stainless Steel | Determined by Hub Kit | Required | $578.99 | |||||

| : 14-4/5 inch : 20 : Right Hand (RH) : 3 : Various Engine Types - Please verify : Stainless Steel : Determined by Hub Kit : Required | 14-4/5 inch | 20 | Right Hand (RH) | 3 | Various Engine Types - Please verify | Stainless Steel | Determined by Hub Kit | Required | $578.99 |

- Outboard props by brand

- Outboard propellers by Material

- Propeller Cases

- Cutless Bearings

- Shafts & Seals

- Boat Hardware

- 48-13702A46

- 48-16314A46

- 48-16316A46

- 48-16318A46

- 48-832828A45

- 48-832830A45

- Get in Touch

- Shipping and Return Policy

- Privacy Notice

- Conditions of Use

- Customer info

- Shopping cart

Payment options

Simple Flying

Explained: the main differences between turboprops & piston engines.

Your changes have been saved

Email Is sent

Please verify your email address.

You’ve reached your account maximum for followed topics.

- Piston engines are less powerful but more cost-effective to purchase, maintain and operate, and are ideal for shorter flights at lower altitudes.

- Turboprop engines offer significant performance benefits such as cruising speed, climb rate, and maximum altitude and are favored by regional airlines.

- Piston engines are used in aircraft like the Cirrus SR22, while turboprops power a range of aircraft from the Pilatus PC-12 to the ATR-72.

To a casual observer, the world of aviation is divided into jet and propeller aircraft, and the latter are all variations of the same theme. However, the engines of propeller aircraft can vary significantly from one another, depending on whether it is a turboprop or a piston engine. But what are the differences between these two types of propellor engines?

Piston Engines

Piston engines, also known as reciprocating engines, have existed since the birth of flight. The Wright Flyer was the first successful powered aircraft in 1903 and the first to use a piston engine. It was powered by a 12-horsepower gas engine with a basic mechanical design similar to a modern four-stroke, four-cylinder automobile engine. From that point until the late 1930s, a reciprocating internal combustion engine with a propeller was the only means to propel aircraft.

How they work

A piston engine operates simply by converting energy from burning fuel into mechanical energy using a repetitive piston movement cycle. They operate through four to six fixed cylinders arranged horizontally opposed, are commonly air-cooled, and rely on magnetos for ignition. The four-stroke cycle (see diagram below) has the following operations:

- Intake Stroke: The piston moves downward inside the cylinder, creating a low-pressure area that draws air and fuel into the combustion chamber through an open intake valve.

- Compression Stroke: The piston moves upward within the cylinder and compresses the air-fuel mix within the combustion chamber.

- Power Stroke : A spark plug ignites the compressed air-fuel mix, causing an explosion that forces the piston downward and creates the power that eventually turns the propeller.

- Exhaust Stroke: After the power stroke, the piston moves back upward, pushing the burned gases (exhaust) out of an open exhaust valve and resets the chamber for the next intake stroke.

|

| |

|---|---|

|

|

|