This article is an excerpt from NauticEd’s online FREE Basic Sail Trim Course , an interactive online sailing course for beginner to intermediate sailors to learn the basics of sail trim. Or if you want to learn more, upgrade to the Skipper Course Bundle to become a competent sailor!

You can learn to sail and improve your sailing with NauticEd, the international leader in sailing education.

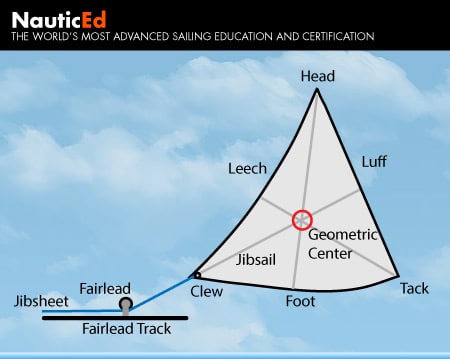

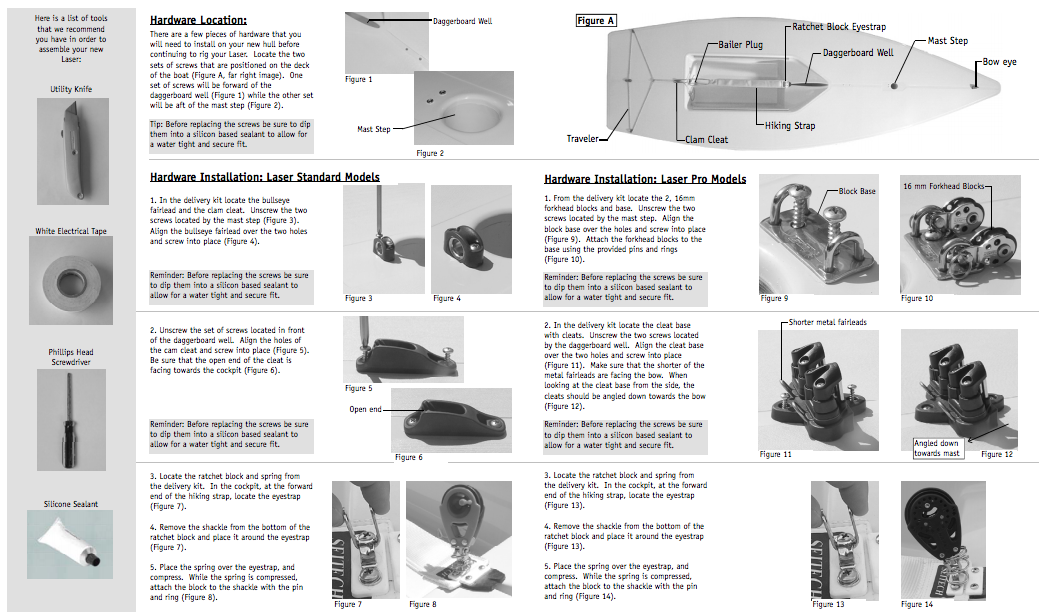

Fairlead Control

The fairlead is the first control device that the jib sheet passes through on its way back to the cockpit. You can move the fairlead forward or backward.

When you move the fairlead all the way forward, the angle that the jibsheet pulls down and back on the jib sail changes so that it is pulling down more down on the leech (back trailing edge) of the sail and less along the foot (bottom) of the sail. Therefore, in the wind, you’d expect that the foot might pooch out more whereas the extra tension on the leech would keep it taut.

Conversely, when you move the fairlead all the way back towards the cockpit, you’re pulling more tension on the foot and less on the leech. In this case, in the wind, the foot would stay taut and not move much but the leech would “twist” out and away downwind. This is especially prevalent at the top of the jib where there is little tension holding it in place.

Obviously, then, there is a balance of where the fairlead should be set depending on sail set, boat heading, wind conditions, and reefing. Here is a really good and rough rule of thumb to use to set the fairlead position. First, imagine the geometric center of the triangular-shaped sail. This is defined by drawing imaginary lines from each corner to the center of each adjacent line. Where they all intersect, this is the geometric center. Now adjust the fairlead forward or back so that an imaginary line extending along the jibsheet would pass through the geometric center of the sail.

That’s a good rule of thumb and will keep you out of trouble. You can also predict from this rule that the fairlead should move forward if the jib sail is reefed. If the jib sheet is eased and the sail goes out and forward then the fairlead should also go forward. But this is a completely fine-tuning adjustment and most people, even racers, tend not to bother with this adjustment.

In the situation of high winds, we want to dump out or spill (not use) the wind at the top of the sail because it creates too much heeling force. Thus it’s easy to imagine that if we moved the fairlead backwards, it would reduce the tension on the leech and allow the leech at the top of the sail to twist out downwind and thus spill the wind at the top.

An example: You’re sailing along at about 60 degrees off the wind on starboard (wind coming over the starboard side of the boat first). You look at the telltales and the bottom ones are flying fine but the top red is flying wildly. What should you do?

Let’s work through the process; Red is on the port side of the sail and in this case, the outer side of the sail. So it needs more wind on it to smooth out its erratic behavior. If we move the fairlead backwards it lessens the tension on the leech and allows the top to twist out a little. When the sail twists out, more wind flows on the outer side of the sail and will thus straighten out the crazy red telltale.

If you’re not getting it – don’t worry. We’ve included an animation of a boat on a port tack here below to help understand. The challenge is to get all the telltales flying back. You’ll need to adjust the headsail and the fairlead control to make this happen. We’ve included two sail set scenarios: Close Reach and Reach. Click and drag on the sheet control and fairlead control to find the perfect combination to make all the telltales fly evenly backward. Then make adjustments to observe and predict the telltales based on the theory above.

Figure 3.2-2 Fairlead Control Animation for a boat on port tack.

Learn Basic Sail Trim for FREE...

A FREE 1-2 hour course that teaches how to work with sails to get your boat moving. The free Basic Sail Trim Course is for any aspiring sailor as well as experienced sailors wanting to learn more. Or, consider upgrading to the Skipper Course Bundle to become a fully competent skipper!

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Pay My Bill

- Customer Service

- Free Newsletter

- Give a Gift

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Open Transom Pros and Cons

Mailport: Charley Morgan, Locker Safety, Fast Bottom Paint

Do-it-yourself Electrical System Survey and Inspection

Install a Standalone Sounder Without Drilling

The Tricked Out Tillerpilot

Resolving Common Steering Problems

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

In Search of the Snag-free Clew

The Cruising Sailor’s Argument for High-tech Fibers

Breaking Point: What Can Go Wrong With Your Yanmar?

Rudder Mods for Low-speed Docking

Using Heat to Bend PVC Pipe

Mildew-resistant Caulks for Boats

Can We Trust Plastic Boat Parts?

Repairing Molded Plastics

Mailport: Marine plywood, fuel additives, through bolt options, winch handle holders

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Rhumb Lines: Livin’ the Wharf Rat Life

Resurrecting Slippery Boat Shoes

Shoe Goo’s Gift to Sailors

PS Advisor: Tank Monitor and Camera Mount Hacks

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

The Ultimate Guide to Caring for Clear Plastic

Preventing Mildew in Marine Fabrics

Gearing Up for Winter Sailing

- Sails, Rigging & Deck Gear

Refining Furling Line Fairleads

Low-friction harken blocks stand out in pss fairlead test field..

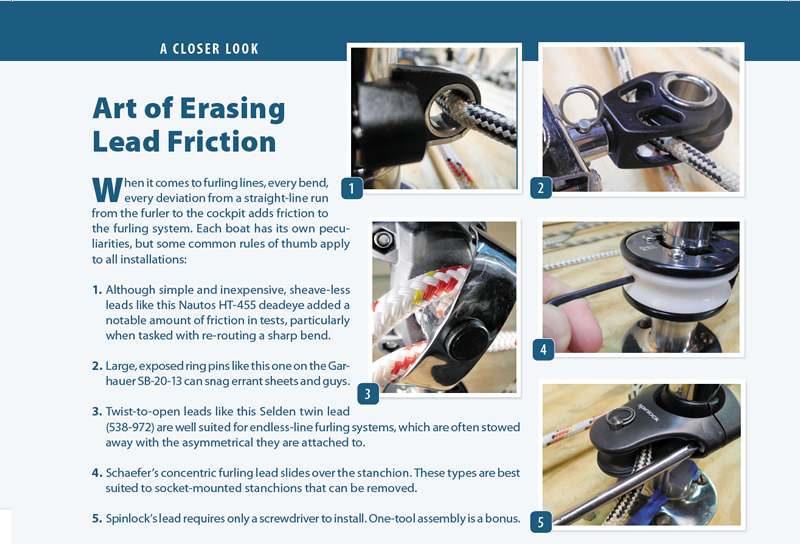

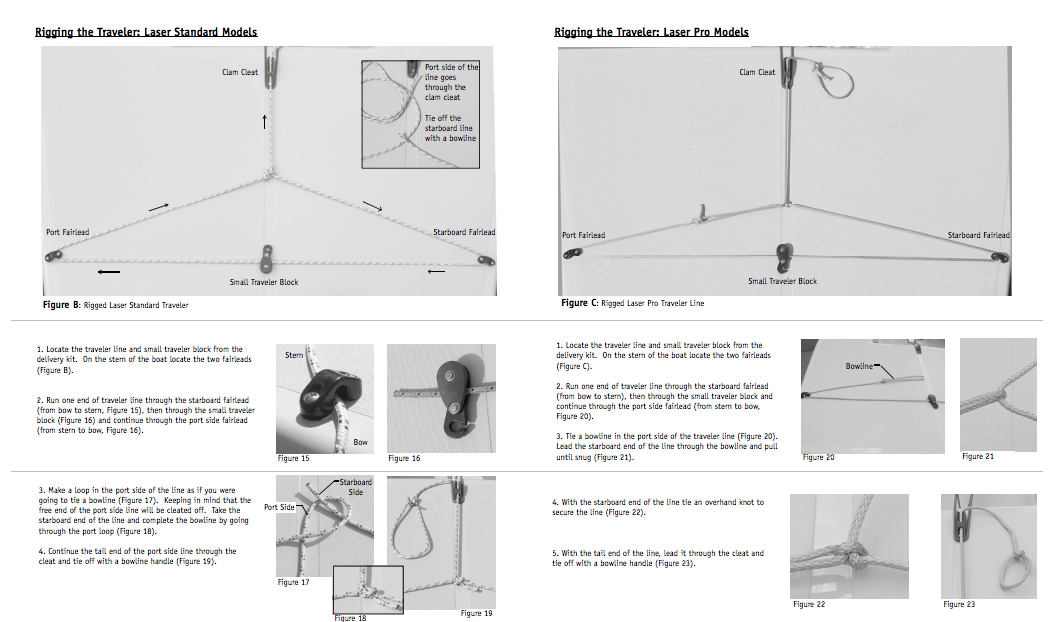

There was a time when headsail handling meant snapping on bronze piston-hanks and hauling on a smooth-running halyard. Times have changed, and now its all about how the furling drum rotates and the headsail wraps around a foil-covered headstay or freewheeling torque rope. (See PS August 2009 for our in-depth jib furler comparison.) Some systems behave more willingly than others, but all benefit from low-friction leads guiding the furling line back to the cockpit. The following report takes a close look at how these fairleads stack up and how much efficiency they add to the furling process.

Every bend and change of direction in a line requires a fairlead or block, and some amount of friction is added at each deflection, increasing the total tension it takes to furl the sail. Interestingly, the ideal number of routing blocks is none; a straight run with no line deflection generates zero friction. But few deck designs and hardware layouts allow for a straight and direct line lead.

On most boats, the furling line is shunted outboard along the stanchions in order to keep the decks uncluttered. Because routing along the stanchions defies the rule of straight-line efficiency, it makes sense to minimize the friction through the use of low-drag blocks for furling-line fairleads. Fortunately, the industry has responded to our headsail furling needs by designing and manufacturing a wide array of stanchion-mounted blocks that pivot, twist, and align with changing angles of pull.

The range of products dedicated for this purpose is surprising. Ultimately, we winnowed the field to 20 different furling line fairleads from six manufacturers. Our assumption going into this test was fairly straightforward: Friction caused by line deflection is an enemy to furling efficiency. Our search focused on finding the blocks that generated the least amount of friction, as measured on our now-familiar test jig , but we also looked at other elements that are critical to this function.

During the course of testing, it became clear that there are different segments of a line lead, each with specific challenges. No single fairlead fit all the demands of running a furling line from the stem to stern. For example, the initial lead from the furling drum to the first fairlead involves multiple constraints. This block not only guides the line; but it keeps it spooling evenly and prevents it from chafing on the drum cover.

Following the all-important lead block is a set of routing fairleads. These keep the furling line following the curve of the lifeline stanchions. Finally, there is the last block, one that must smoothly redirect the furling line to a belay point (jammer, cleat, cam cleat, rope clutch) in the cockpit.

What We Tested

Although you could make your own furling fairleads by pairing a set of specialized blocks or deadeyes with homemade Dyneema loops and shackles (see PS April 2015 online ), this test is limited to pre-fabricated hardware that easily clamps to lifeline stanchions, requiring little time or effort to install.

After some preliminary testing, it became clear that these fairleads fell into five specific categories, based on their purpose or design characteristics. Three sheaveless deadeye fairleads were put in one group; blocks that featured wide-angle, multi-axis articulation were put in another. Fixed, non-articulating blocks had their own category, as did single-axis blocks that articulated in only one plane. Three of the six manufacturers in the test sent a block that led the furling line outboard of the stanchions-these, too, had their own category.

Garhauer, a California-based company known for providing rugged, affordable sailing hardware, submitted four different products to test. Each one clearly reflected the companys highly customizable, machine-shop approach to manufacturing. These mostly metal, clamp-on blocks feature highly polished stainless-steel and anodized aluminum shells and high molecular weight plastic bearings. Three of the Garhauer blocks were clamp-on designs, while one was a dual-sheave fairlead that slipped onto the stanchion, requiring that either the stanchion or the lifelines be removed.

Harken, a long-time leader in sailing hardware and a prominent player in the racing scene, provided several products, each offering an effective way to overcome furling-line friction. Its selection included a set of classic bullet blocks with stainless-steel shells reinforced with stainless-steel straps, a couple of 40-millimeter, lightweight Carbo blocks, and a larger 57-millimeter ratcheting lead block. Four of the five Harken fairleads were injection molded, a process in which nylon resin reinforced with glass fiber is thermo-molded to form the shell and clamp body. More and more products in the Harken lineup are constructed using this process.

Nautos, an international sailing hardware company with manufacturing facilities based in Brazil, also favors an injection-molded body. A clamshell-like clamping arrangement secures its blocks to the stanchions. The four products the company provided included three clamp-on block leads and one deadeye fairlead. As with Harken, Nautos largest swiveling lead block also had a ratchet function. The ratchet, which adds friction to the block when tension is applied in the direction of the drum, helps to reduce the load between pulls and adds some tension to the line as the sail unfurls.

Schaefer, an American company with a long history in the sailing hardware business, remains committed to stainless-steel blocks and clamps. Its blocks incorporate Delrin ball bearings and efficiently designed races to reduce friction. Ring pins and Nylock nuts ensure that fasteners don’t slip. Schaefers outside-the-stanchion clear-step fairlead block is designed to keep decks clear on smaller boats, or on cruising boats with narrow sidedecks that could quickly become cluttered if the lines were routed inboard. Its spring-supported lead block twists to align with challenging furling drum lead angles at the all-important first fairlead on the pulpit.

Selden, the Swedish spar maker that has expanded into the hardware business, sent us four injection-molded, bushing-type, mini-sheave blocks that toggle in one plane. During installation, the owner carefully aligns the blocks according to the optimal furling line run. A set-screw then locks the angle in place. Selden also sent its quick-opening Double Fairlead designed for endless-line furlers. The lead is supposed to be paired with Seldens double cam-cleat, and presumably Seldens endless-line furler, one of the higher-rated products in our endless furler line test. (See PS April 2011 and March 2008 online.) Selden also manufactures a deadeye lead and ratchet block that are worth looking at; we plan to test these for a followup report.

Spinlock, a British company best known for its line of high-performance cam cleats and rope clutches (see PS November 2014 online ), manufactures two compact, lightweight stanchion-mount leads. The larger block incorporates a removable sheave to expedite use with endless-line furlers. It also can be tilted to adapt to minor offsets in lead angles. The smaller unit is an injection-molded, deadeye fairlead with a stainless-steel insert and a split clamp that attaches to the stanchion.

Photos by Ralph Naranjo

How We Tested

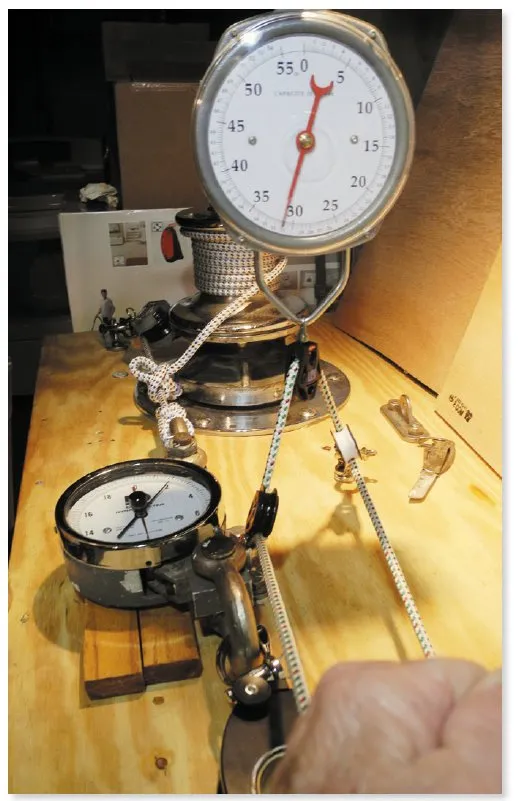

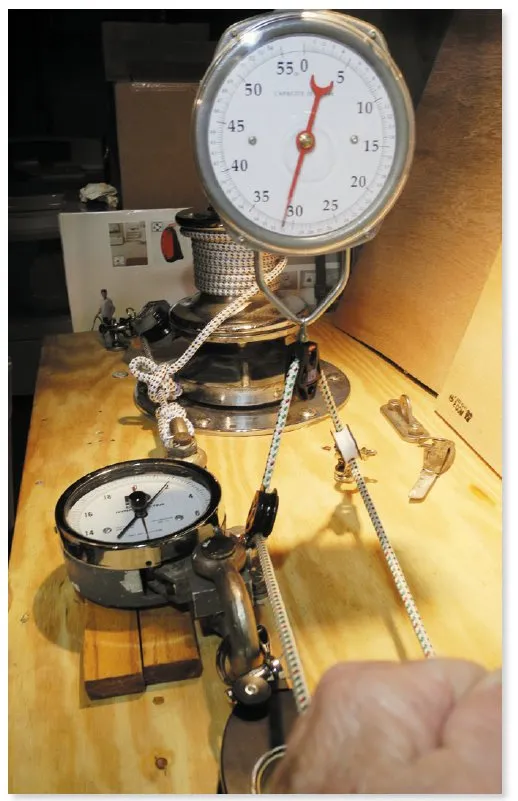

Our initial look focused on characteristics such as design, size, weight, and construction. The focus of our testing, however, was to accurately measure the friction each fairlead added to an evenly tensioned line.

The jig we used for testing was a variation of the jig we set up to measure friction in snatch blocks. (See PS August 2008 and August 2007 online .) Two large, smooth-running Garhauer snatch blocks were positioned opposite each other, and a continuous loop line was run between them. One block was fixed to a secure base, and the other was led to a Dillon dynamometer connected to an Ideal electric windlass. The windlass was used to tension the continuous loop running between the two blocks. After preliminary testing with line loads ranging from 50 to 500 pounds, testers settled on 200 pounds as the ideal tension for this test.

Testers then mounted a deck socket and lifeline stanchion to the test jig. The stanchion was set off to the side of the continuous loop, so that when the line was run through the fairlead being tested, the angle formed was 152 degrees (a close approximation of the angles formed in actual installations).

Before each test, testers tensioned the two, large ball-bearing snatch blocks to 200 pounds and used a spring scale to measure the force required to move the endless loop. This number, which varied between seven and eight pounds, became the baseline. For the test itself, the fairlead or block being evaluated was fixed on the stanchion and the loop was routed through it. Testers used the spring scale to measure the effort required to move the loop. We tested each block and deadeye fairlead five times. The highest and lowest scores were eliminated, and the middle three were used to determine an average.

In cases when a particular block design required slightly different mounting location on the stanchion (outside versus inside the stanchion, for example), testers could alter the position of the tension-inducing snatch block to ensure that the 152-degree offset angle remained consistent throughout the test.

We also took a close look at chafe points, the ruggedness of the clamp, and ease of inspection-particularly the ability to see how well the fasteners were attached.

The bench testing was supplemented with onboard real-world comparisons. This phase of the testing brought to light several key issues that were not readily apparent during our bench test.

Although our inspection of materials and construction offered insight into the durability of these fairleads, we did not fully explore longevity. A followup report will compare the long-term effects of weathering and exposure to ultra-violet rays, paying particular attention to corrosion resistance.

Observations

During onboard testing, we noted several different fairlead challenges. The first was at the bow, where the furling line leads from the roller drum to the first lead block. This location presented myriad alignment problems, and establishing the optimum lead angle and block twist at the pulpit was often frustrating.

The challenge of fitting the critical first fairlead, of course, will vary from boat to boat. In general, you want to position the lead block as close to the deck as possible; this reduces side loads on the furler and headstay. However, the height of the first block is usually determined by the position of the furling drum. The furling line should lead at a nearly perpendicular angle to the headstay (and thus the drum). In most cases, the first block is positioned on the pulpit rather than on the deck. In some instances, the first lead may have to be placed further aft on the deck.

Key attributes we look for in this first lead block are low friction, an ability to pivot in all planes, and an ability to swivel. A ratchet block can also be helpful here to grip the line between tugs and provide some resistance as the wind catches the sail and unfurls it. (See PS May 2009 online for our last test of ratchet blocks.)

The block used for the primary lead is often the right choice for the last turning point, where the furling line is redirected inboard toward a rope clutch, jammer, or cleat where it can be belayed in the cockpit. Swiveling, pivoting, and minimal friction are essential here, and if you are going to fit just one ratchet block, this is the most logical spot for that block.

Between the first and last blocks are several blocks that serve to maintain a fair lead and keep the decks clear. These tend to be fairly well aligned on a horizontal plane, but the vertical plane bows outward to follow the outline of the deck. Modern boats with narrow decks benefit from fixed leads that hold the furling line close to the stanchion, and many owners even consider investing in a set of outside-the-lifeline leads to keep narrow decks as clear as possible.

One of the key questions we had going into the test was how well the deadeyes, with their low-cost, easy-to-maintain design and no moving parts, compared to conventional blocks. The answer quickly became obvious: In terms of friction, blocks trump deadeyes every time-something sailors have recognized for centuries. In a no-load context, smooth surface, non-sheaved fairleads work just fine, but as soon as load increases, friction takes over and a deadeye delivers more grip than slip. When we finally tallied our test data, fairlead friction was three times greater when a line passed through a deadeye than when it passed over a sheave.

Lead/End Blocks

When it comes to lead blocks best suited to handling the rope-to-drum challenge, we liked Garhauers robust stainless-steel, spring-supported, freely articulating SB-25 and Schaefers 300-35, an elegant, smaller, and lighter rendition of a stainless-steel furling fairlead.

While stainless steel is a sensible material for a furling block, we are not averse to composite construction. Harkens composite 7401 proved to be a light and compact favorite. Its limited range of articulation may not be enough to suit all pulpit-to-drum geometry, but when it fits, its a star performer. Harkens dual-sheave model, the 7405 was a double-barrel rendition of this Harken lead.

Nautos (92088) and Harken (7402) both sent us blocks that featured a useful ratchet option. Both are effective as either the lead or end-point block, and the ratcheting feature helps prevent the furling line from slipping between tugs.

Both designs are slightly hampered by the use of some square-wheel geometry. The circular sheave of a regular block is replaced by an octagonal-shaped sheave that improves the ratchets holding power, but getting the line over the miniature high spots takes just a little extra tugging-as our tension readings revealed.

Bottom line: When the tug of war was over, the Garhauer SB-25 earned our Best Choice for lead furling block. For the cockpit-end lead, we gave the Best Choice to Harkens ratcheting 7402, which featured a secure four-fastener stanchion clamp and ball-joint articulation. It is more expensive, but in our view, its worth the extra cost. Our Budget Buy was the Nautos 92088, which added only minor friction but was significantly less expensive.

Articulating Blocks

All of the blocks in this group adapt to some tilt or angle change, but their flexibility is limited. Spinlocks SPWL-2 utilizes an innovative axial ball-joint that centers on the stanchion, allowing the sheave to can’t into alignment. There is no swivel function, so care must be taken to be sure that the range of tilt allows for a fair lead. This lightweight, small-sheave, bushing-type block (no roller or ball bearings) scored surprisingly well in friction testing-nearly as well as many of the ball-bearing-equipped blocks.

Two Nautos products that we tested, the HT-450A and the 92388, use the same two-bolt clamp. Each offers a single-plane tilting feature combined with a swivel function. These are well suited for stanchion-to-stanchion line guides. Both are bargain-priced, and the small-sheave bushing version (HT-450A) comes with a pull-pin to release the sheave. This feature, which lets you release the line from the block without threading back through it, could come in handy when trying to free a line that is hockled, knotted, or snagged. It will also benefit those who berth at a dock and like to stow the lines forward when alongside to reduce the trip hazard when boarding. The Nautos 92388 features a smooth-spinning, ball bearing race and is reinforced with stainless-steel straps.

The Selden 538-972 is an injection-molded composite lead that easily disassembles into its component parts. Its fiber-reinforced resin composite cage holds a plastic sheave that spins on a bronze shaft. It has a wide toggle range and an effective swivel action.

Bottom line: The Nautos HT-450A generated slightly more friction than the bearing-type blocks, but its attractive pricing and additional features, like swiveling ability and removable sheave, made it our Best Choice in this category.

Limited Articulation

This category features four blocks that spin smoothly but offer even less articulation than the above group. They are best suited to the middle section of a furling line that lacks any sharp angles of deflection. Two standouts were the Harken 168NP and the Garhauer SB 20-13. Each of these blocks features efficient ball bearings, a stainless-steel stanchion clamp, a full swiveling body, and a fixed mount. The chief difference between them is in the mounting. The Harken uses a rubber bushing and ball socket to allow a bit of flex, and this gives it a slight advantage over the smooth-running Garhauer.

Our favorite in this group was the Schaefer 300-34, a no frills, fixed-mount fairlead (no tilt and no swivel) that is carefully engineered to reduce the intrusion of the furling lines on your side-deck. The compact, ball-bearing block mounts on the inboard side of the stanchion, but it achieves almost the same results as an outboard-mounted lead by keeping the furling line close to the stanchion.

Garhauer also sent us a double-sheave furling block, model D, which is designed to accommodate twin leads from an endless furling line. The fairlead offers two bushing surfaces and a central ball-bearing sheave. This design allows you to open the fairlead and quickly insert the endless furling line rather than feed it through each block, one at a time.

Ideally, this block should be located on the stanchion so that the sheave that handles the inhauling line, which imposes the most load on the block and stanchion, is below the outhauling line. Poor alignment of this block can cause the line to rub on the stainless-steel side plates or bushing surfaces, causing a significant increase in friction.

Bottom line: The Schaefer 300-34 was our Best Choice in this category; its especially well-suited for those looking to maximize sidedeck space.

Deadeye Fairleads

The term deadeye is ancient mariner speak for a fairlead that has no rolling sheave or other mechanical means of reducing fiction. Shape, smoothness, lubrication, and material choice are the key variables. The fact that there are no moving parts to break hardly makes up for the increase in friction such engineering delivers.

Spinlocks SPWL1 and the Nautos HT-455 both feature injection-molded parts with a stainless-steel sleeve. Split clamps are used for mounting. Both are nicely crafted, but the lighter, slightly more compact Spinlock keeps the furling line a little closer to the stanchion. More importantly, the curved inside surface of the Spinlocks line-lead ferrule imparted far less friction that the flatter inside surface of the Nautos. The more rugged clamp body and visible hex nut on the Nautos will appeal to cruisers, but the slipperier Spinlock was still the testers favorite in this group.

Seldens easy-opening, twin-line guide is designed to accommodate lines led inboard of the stanchion. The Double Fairlead is not intended to be a lead or end block, only for the intermediate points. Interestingly, in our testing, it produced less friction and imparted less stress on the pivot spindle when mounted outboard.

Bottom line: Were not big fans of deadeyes, even for this application. If you do prefer the simplicity of going bearing-less, the Spinlock SPWL1 earned our Best Choice for conventional furling line while Seldens Double Fairlead earned a Recommended rating.

Outside the Stanchion Fairleads

Routing furling lines outboard of the stanchions can add more space to narrow, line-cluttered decks. Several hardware makers have blocks designed to surround a stanchion and lead lines outside just above well-secured bases.

Schaefers clear-step (506-44) is slipped over (or under) the stanchion and secured in place with a single se-screw. The blocks large-radius hub and ball-bearing system delivers a superior, friction-free spin. Harkens 7403 tandem sheave rendition clamps onto a stanchion without having to pull the stanchion from its socket or remove lifelines to install. Garhauers tandem, stainless-steel outside-the-stanchion lead can also be slotted right onto a stanchion and locked in place with just one cap screw.

Bottom line: It was tough to pick a winner in this group. All are in the $40 range and all scored well in our pull test. If you can pull your stanchions from their bases, or easily remove your lifelines, we like the Schaefer blocks. However, if the Schaefers are too much hassle for you to fit, either the Harken or Garhauer are a good choice for anyone looking to route their furling lines outboard. In the end, we picked the Harken 7403 as our Best Choice because of its slightly better friction rating.

We kicked off this round of testing with some preconceived notions-some held and some didnt. The most obvious assumption that stuck was that blocks trump deadeye fairleads, especially as loads escalate. What fell apart was the idea that one specific fairlead should be used at all deflection points along the furling line run. In order to get the most efficiency and reliability out of your furling fairleads, youll want to select the specific type block for the specific job. Thus, we have our various categories, arranged by design and function.

Among the most important lessons we learned was to make sure stanchions are well secured-especially when fairleads and tension loads are well above deck level. Keep fairleads as low as possible in order to lessen the leverage associated with side loading. And finally, give extra thought to the line lead angles at the rope drum and where the reefing line is finally tensioned by hand or by using a winch.

The bottom line is that friction adds up, and stringing together a series of inefficient line-deflection hardware makes little sense. Keep in mind that a clear, straight run always delivers less drag than a deflected line running through the best of blocks. So when engineering a route for your furling lines, try to minimize the turning points. This is easier said than done, so the next best thing is to choose blocks that score well in tension testing, not simply sound like a roulette wheel when you spin them with your finger.

Our final task was to pick a block from each category to suit the needs of a crew aboard a 35- to 40-foot cruising sailboat. In some cases, there were several options in a near dead heat, but after considerable debate, heres how the chips fell: The Garhauer SB-25 was our top articulating lead block; the ratcheting Harken 7402 was a favorite for the cockpit-end; the Nautos HT-450A was our favored limited articulating block (middle section); the Schaefer 300-34 was our favorite low-profile, inside-the-stanchion block; the Spinlock SPWL1 was our top deadeye-style block; and the Harken 7403 was our best product for use outside of the stanchion.

- Untangling Furling-line Fairlead Logistics

RELATED ARTICLES MORE FROM AUTHOR

Nice article, but you only show solutions for 1″ post. That is useful for most; however, I have larger diameter and difficulty finding anything for 1.25″ posts other than the larger Schaefer blocks which unfortunately tend to deform when tightened sufficiently (there is only one set screw) creating resistance.

Well, I was hoping Myles would get a response. There are more vessels (including mine)now have 1.25”. As has been stated, there are not many options. Any response or assistance would be helpful

Regards, Cristian

LEAVE A REPLY Cancel reply

Log in to leave a comment

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Cleats and fairleads

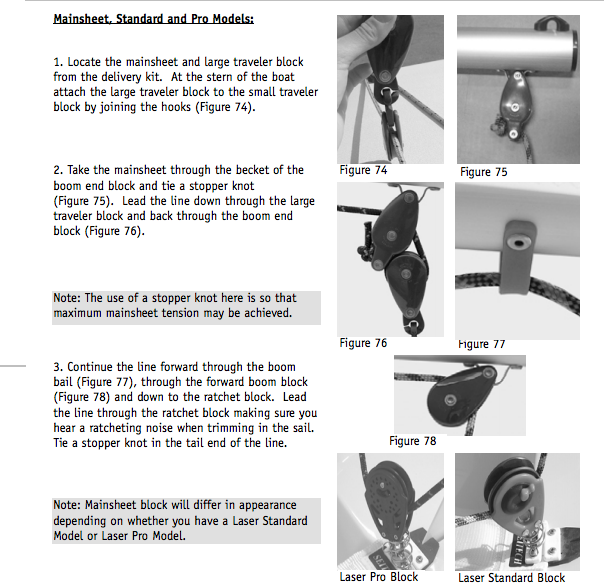

Cleats can be bought in a variety of shapes and sizes. In general the larger a cleat, the less the wear on lines and the easier it will be to make up a line on it. There should be no sharp edges anywhere on the cleat. Every boat should be equipped with at least four deck cleats for mooring and larger boats should have more. A Samson post or central bollard, which provides a stronger point at which to secure lines and the anchor chain, is often fitted on the foredeck and sometimes at the stern as well. Fairleads located at the bow and stern of a boat are used to guide lines onto the boat and prevent them from becoming entangled in the lifelines and rigging. Fairleads can be open at the top or closed. The latter are generally preferable as the line cannot slip out. Sometimes they are set into the raised edge around the foredeck. like cleats, fairleads should have no sharp edges which could cause excessive chafe on your lines. A method of protecting against chafe is described, above right.

The layout of a foredeck with a central bollard, showing the cleats and fairleads.

CRUISING/Preparation for docking

Preparation for docking

When coming in and out of congested harbors and marinas, if you have an engine, you should always use it. This does not mean, however, that you should not bother to learn how to handle your boat under sail in such situations. Inevitably, there will come a time when, owing to engine failure, you will have to maneuver under sail and you must be prepared for such an eventuality. This means that you should practice regularly, preferably at times when you have room to make a mistake. Because of the risk of engine failure when motoring, you should always have at least one sail ready for hoisting and an anchor ready to be dropped in case of need. It is bad practice to leave from or return to a berth under power with the mainsail cover on, the headsails bagged in the fore cabin and the anchor stowed. Should the engine fail, it would take some time for the sails to be hoisted or the anchor dropped —by which time you could have drifted into another boat, causing considerable damage.

Continue reading here: Effects of wind and tide

Was this article helpful?

Related Posts

- Getting in and out - Sailing Procedures

- Boat Parts For Beginners Sailing Cleats Shackles

- Changing course - Sailing Procedures

- Ketch Schooner Yawl Cutter

- Reefing - Sailing Procedures

- Catamarans - Sailing Procedures

Readers' Questions

How to run lines through a fairleads to a mooring cleat?

To run lines through a fairlead to a mooring cleat, follow these steps: Determine the direction of the desired line from the fairlead to the mooring cleat. Start by passing the line through the fairlead, which is a device that guides the line and prevents chafing. Pull the line firmly through the fairlead until there is enough slack to reach the mooring cleat. Thread the line over the top of the mooring cleat, making sure it is positioned correctly to ensure a secure hold. Wrap the line around the base of the mooring cleat, moving in a figure-8 pattern. After a few wraps, create a half-hitch by passing the line under itself and then over the cleat's top horn or through a locking mechanism if present. Continue forming half-hitches until the line is secure. Ensure the line is tight and the knots are secure by pulling on it gently. To untie the line, simply remove the half-hitches and unwrap the line from the base of the mooring cleat. Pay attention to any specific instructions or guidelines provided by the manufacturer or harbor/marina regulations regarding proper line handling and cleat usage.

Practical Boat Owner

- Digital edition

- Ben Meakins

- September 22, 2009

A device made to lead a rope smoothly or fairly. May be made of plastic or wood or metal, and in a variety of forms. Some fairleads are open, for example those mounted on side-decks to prevent chafe of mooring lines, and others are closed as is the case with the Bullseye sheet lead. A fair lead is fixed to the boat, whereas a Dead-eye is usually free to move: for example a dead-eye may be attached to a sail.

The Worldwide Leader in Sailmaking

- Sail Care & Repair

- Sailing Gear

- Sail Finder

- Custom Sails

- One Design Sails

- Flying Sails

- New Sail Quote

- 3Di Technology

- Helix Technology

- Sail Design

- NPL RENEW Sustainable Sailcloth

- Sailcloth & Material Guide

- Polo Shirts

- Sweaters & Cardigans

- Sweatshirts & Hoodies

- Accessories

- Mid & Baselayers

- Luggage & Accessories

- Spring Summer '24

- Sailor Jackets

- NS x Slowear

- Sailor Jacket

- Sustainability

- North Sails Blog

- Icon Sailor Jacket

- Our Locations

- North SUP Boards

- North Foils

- North Kiteboarding

- North Windsurfing

SAIL FINDER

SAILING GEAR

COLLECTIONS & COLLAB

COLLECTIONS

WE ARE NORTH SAILS

ACTION SPORTS

Popular Search Terms

Collections

Sorry, no results for ""

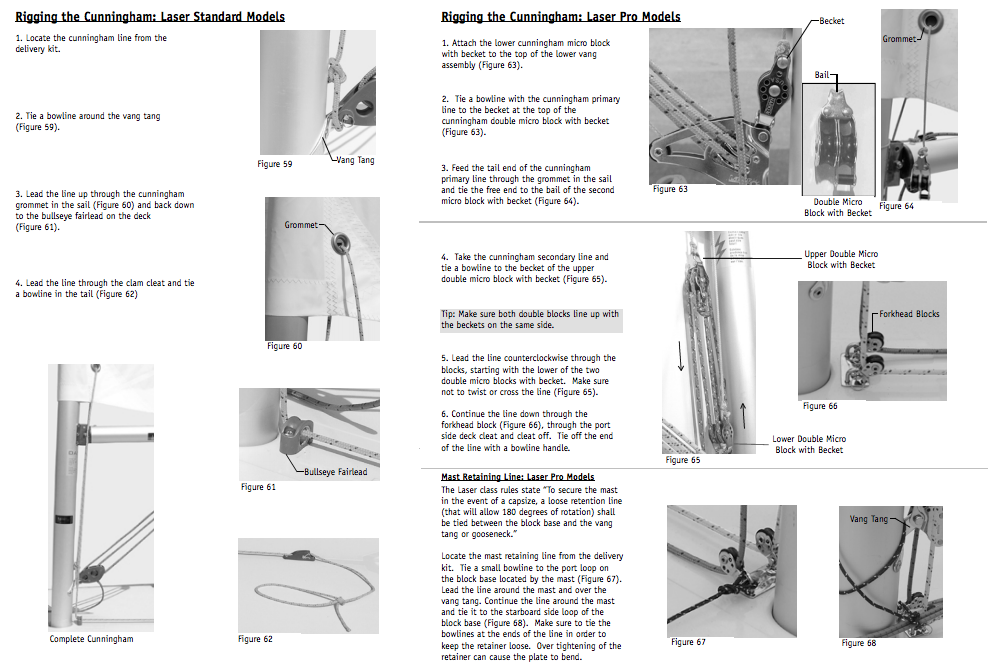

i420: Controlling the Jib Leech Tension

Controlling jib leech tension, how to effectively finetune your fairleads with fixed positions.

Sailing dinghies are all unique. It is always fun to go from one one-design class to another and check out what makes them different, what controls they have, and in this case, what they might not have available for the crew to use to adjust and tune.

One very important tuning device for jib trim is the fairlead position. Fairlead position defines sheeting angle for the jib, and many classes of course have adjustable fairleads; that is, the position can be moved fore and aft (or in some cases up and down, and in and out). When it gets windy, it’s often nice to be able to open the leech of the jib a little bit, and this can be achieved by moving the fairlead position aft. Conversely, moving it forward can create a more powerful shape.

The 420 was designed, for better or worse, without adjustable fairleads; it is, as they say, where it is. How do you effectively move the fairlead fore and aft in a boat with fixed fairlead positions? The answer on the i420 is jib height. To achieve this, i420 sailors can raise and/or lower the height of the jib on the luff wire to achieve proper leech tension on the jib for given conditions and mast rake.

You may notice boats in-between races that are capsized on their coach boat; often this is done to change jib height to match expected conditions for the next race. The peak rope fixed (and adjustable) at the head of the jib controls jib height. The boat also has an adjustable jib tack control to accommodate changes at the peak. Normally the jib should be fixed by having a proper deck sweeping effect. However, for the i420 class it is important to know the height should be adjusted to provide the optimum jib lead angle. Since, as we said, the sheeting point is fixed, you should adjust the peak rope to move the jib clew up or down to achieve the desired sheeting angle.

In short, lower the jib down a bit to open the leech and ease power when the winds are up; in light winds, raise the jib for more power and jib leech return. It is also imperative to remember that mast rake also has a significant effect on jib leech tension. Raking back effectively opens the jib leech, and conversely, raking forward closes it. Don’t forget this when you tune the boat.

Adding jib height to your tuning regimen can make a performance difference. Experiment, find the right balance, mark your settings, and go faster!

For more information and questions on how to match your North i420 sails perfectly, please contact North Sails clas expert Tom Sitzmann.

FEATURED STORIES

Npl renew faq, flying sails 101.

21 December

CAPE 31 TUNING GUIDE

- Refresh page

Types of Cleats On A Sailboat

- July 18, 2023

Table of Contents

Cleats are essential fixtures on a sailboat used to secure lines (ropes) and control sail trim. They come in various designs and are strategically placed throughout the boat to provide convenient and secure attachment points. Here, I will describe the different types of cleats found on a sailboat in detail:

Sailboat Cleat Types

The horn cleat is the most common and recognizable type of cleat. It features one or more protruding horns or arms that provide multiple options for securing lines. The line is wrapped around the horns in a figure-eight pattern to create a secure hold. Horn cleats come in different sizes and are used for various applications throughout the boat, including halyards, sheets, and control lines.

Recommended Horn Cleats:

Ronstan Horn Cleat Nylon 76MM (3″)

Schaefer Mid-Rail Chock and Cleat Mounts on 1-1/4 x 3/16-Inch T-Track fits Up to 5/8-Inch/16mm Line

Cam cleats are designed with a spring-loaded cam mechanism that clamps down on the line when it is under tension. The cam grips the line securely and holds it in place until released. Cam cleats are popular for applications where quick and easy adjustment is required, such as controlling jib or spinnaker sheets. They are commonly found on sailboats with high-performance or racing-oriented setups.

Recommended Cam Cleats:

Jam cleats, also known as jamming cleats or rope clutches, are designed to hold a line firmly under load. They feature a set of ridges or teeth that grip the line when it is tensioned. Jam cleats provide a secure hold and are often used for halyards, control lines, and other high-load applications. To release the line, it needs to be pulled at a specific angle to disengage the teeth.

Recommended Jam Cleats:

Clam cleats consist of two interlocking jaws that close around the line. As the line is pulled, the jaws grip it tightly, creating a secure hold. Clam cleats are often used for smaller lines, such as control lines on dinghies or small sailboats. They provide quick and easy adjustment and are commonly found on boats where weight and simplicity are crucial.

Recommended Clam Cleats:

Osculati Clamcleat

V cleats, as the name suggests, have a V-shaped groove that runs along the top surface of the cleat. The line is inserted into the groove, and the V-shaped design holds it securely in place. V cleats are primarily used for smaller-diameter lines or control lines. They are commonly found on dinghies and small sailboats where space and weight are at a premium.

Recommended V Cleats:

Nautos 91061 – V Jam Cleat – Sailboat Hardware

Jammers are similar to jam cleats but offer a more sophisticated and mechanical gripping mechanism. They consist of one or more jaws that grip the line under tension using a cam or lever system. Jammers provide a strong and secure hold and are commonly used for halyards, control lines, and sheets on larger sailboats or racing-oriented setups.

Recommended Jammers:

Spinlock Mobile Jammer for securing Loaded Lines 10-14mm

Rope Clutch

Rope clutches are heavy-duty cleats often used on larger sailboats. They consist of multiple jaws or disks that can be engaged or disengaged to secure or release a line. Rope clutches are designed to handle high loads and are commonly used for controlling halyards, sheets, and other lines that require precise adjustment and secure holding power.

Recommended Rope Clutches:

Deck cleats, also known as mooring cleats, are larger cleats that are permanently mounted to the deck or cockpit of a sailboat. They provide a secure attachment point for dock lines, fenders, and other lines used for docking or securing the boat. Deck cleats are usually made of durable materials such as stainless steel or aluminum and are designed to handle significant loads.

Recommended Deck Cleats:

Fairlead Cleat

Fairlead cleats combine the functionality of a cleat with that of a fairlead, which helps guide lines to the appropriate cleating position. They feature an integrated fairlead or a combination of a fairlead and a cleat. Fairlead cleats are commonly used for jib or genoa sheet control lines, where it is important to guide the line for optimal sail trim and secure it quickly.

Recommended Fairlead Cleats:

HARKEN Micro Carbo-Cam Cleat Kit w/Wire Fairlead

Jamming Block with Cleat

This type of cleat is a combination of a jammer or a cam cleat with a pulley or block. It allows the line to be redirected and creates a mechanical advantage when trimming sails. Jamming blocks with cleats are commonly used for applications that require increased purchase or control, such as mainsheet systems or complex control line setups.

Recommended Jamming Block Cleats:

It’s important to note that the specific cleat types and their placement on a sailboat can vary depending on the boat’s design, rigging setup, and intended use. Sailboat owners and manufacturers may also develop unique variations or combinations of cleats to suit their specific needs. Proper installation, sizing, and maintenance of cleats are essential for safe and efficient sail handling.

The Sailor’s Marketplace for Sailboats and Sails.

Sell Your Sailboat

Sailboats for sale.

- New Sailboats

- Used Sailboats

- Cruising Sailboats

- Racing Sailboats

Sell Your Sails

Sails for sail, sail manufacturers.

- North Sails

- Quantum Sails

- Doyle Sails

- UK Sailmakers

Sailing Reviews

- Sailing Line

- Safety Equipment

- Sailing Accesories

As an Amazon Associate SailTrader earns from qualifying purchases.

This website uses cookies to ensure you get the best experience possible.

Fairlead Sailing: A Comprehensive Guide to Mastering the Technique

by Emma Sullivan | Aug 10, 2023 | Sailboat Gear and Equipment

Short answer fairlead sailing:

Fairlead sailing refers to the practice of positioning a line or rope through a device called a fairlead, which is typically used to guide the line in a desired direction. This technique is commonly employed in sailing to ensure efficient and effective handling of ropes and rigging on boats and ships.

The Basics of Fairlead Sailing: A Comprehensive Guide for Beginners

Sailing is a thrilling adventure that allows you to harness the power of the wind and explore the vastness of the open water. Whether you are a complete novice or have some experience under your belt, understanding the fundamentals is essential to ensure a safe and enjoyable journey. In this comprehensive guide, we will dive into the world of fairlead sailing – an important technique that every sailor should master.

What is Fairlead Sailing?

Fairlead sailing refers to a method used by sailors to direct their lines while adjusting sail trim and controlling the boat’s performance. The fairlead itself is essentially a pulley system or ring that guides ropes or sheets along specific paths on a sailboat, allowing for efficient maneuvering and sail adjustments.

Selecting Your Fairleads

Before diving straight into practicing fairlead sailing, it’s crucial to choose the right equipment for your boat . The selection process involves considering several factors such as line diameter, load capacity, material (typically stainless steel or high-quality composite), and compatibility with your boat’s deck layout. Consulting with experienced sailors or professionals can provide valuable guidance in making an informed decision tailored to your specific needs.

Understanding Line Angle

An indispensable aspect of fairlead sailing is achieving optimal line angles. When adjusting your sails, it’s important to assess how the lines run through each fairlead position relative to their effect on sail shape and overall boat performance. As a beginner, experimenting with different line angles can help you develop an intuitive feel for what works best in various wind conditions.

Sheeting Angles and Sail Trim

Once you grasp the concept of fairleads and line angles, mastering sheeting angles becomes paramount in maximizing your sail efficiency. Sheeting angle refers to how closely aligned your lines are with the centerline of your boat when pulling them towards yourself while trimming sails close-hauled or partially unfurled.

To achieve ideal sheeting angles, you must balance the tension on both sides of the sail while ensuring it maintains an efficient shape based on prevailing wind conditions. It’s crucial to fine-tune your sail trim by adjusting the fairlead positions accordingly, allowing for precise control and efficiency in harnessing the winds.

Maintenance and Care

To ensure your fairleads function optimally, regular maintenance is vital. Inspect all fairlead components for signs of wear or damage, such as fraying lines, loose fasteners, or degraded materials. Lubrication is essential to prevent any hitches or snags along the lines’ path while maintaining smooth movement through the fairleads.

Furthermore, routine cleaning of fairleads helps remove dirt, salt accumulation, or any debris that may impede performance. Maintaining clean and well-functioning fairleads ensures their longevity and consistent performance when you need them most.

Mastering Fairlead Sailing: Practice Makes Perfect

Like any skill in sailing, mastering fairlead sailing requires practice and patience. Finding opportunities to apply this technique during various sailing conditions will greatly enhance your understanding of its nuances and effectiveness. Consider joining a local sailing club or participating in regattas where experienced sailors can offer valuable guidance tailored to your specific needs.

Sailing with Confidence

Now armed with a comprehensive understanding of fairlead sailing basics, you can confidently take on new adventures as a sailor. By continuously honing your skills through practice and seeking knowledge from seasoned sailors, you’ll soon be effortlessly maneuvering your boat using this invaluable technique .

So grab those binoculars and set sail into the world of fairlead sailing – a realm filled with endless possibilities for exploration and unforgettable experiences on the open water!

Exploring the Benefits and Techniques of Fairlead Sailing

Title: Exploring the Benefits and Techniques of Fairlead Sailing: Reimagining Efficiency and Precision at Sea

Introduction:

Sailing has forever been synonymous with adventurous spirits, a harmonious dance between wind, water, and the human conquest of distant horizons. As technology continues to evolve, one fundamental aspect of sailing – fairleads – has caught the attention of seafarers seeking enhanced performance, efficiency, and control on the open seas . In this blog post, we will delve into the world of fairlead sailing to uncover its numerous benefits, as well as explore various techniques that enable sailors to push their vessels to new limits while harnessing the power of wind.

1. Deconstructing Fairleads: Fairleads are an integral part of a sailboat ‘s rigging system that facilitates optimal distribution of forces along individual lines or ropes. These purpose-built fittings act as guides or pulleys for ropes to pass through smoothly, redirecting them in desired directions while minimizing friction and wear. By carefully positioning fairleads throughout the rigging system, mariners can ensure maximum efficiency in controlling sails and maneuvering their vessels.

2. Unveiling the Benefits: a) Enhanced Sail Control: With strategically positioned fairleads, sailors achieve better control over sails by effectively managing loads exerted on different parts of their rigging systems. This increased control directly translates into improved boat balance and responsiveness – critical factors when it comes to maximizing speed and maneuverability.

b) Reduced Friction & Wear: Whether racing against competitors or embarking on a leisurely cruise, excessive friction can be your silent adversary at sea. Fairleads play a vital role in diminishing friction by minimizing any sharp bends or rough contact points between ropes and other structure components. By ensuring smooth passage for lines through these fittings, seafarers reap the rewards of reduced wear on rigging elements while maintaining optimal performance .

c) Optimized Sail Trim: Achieving ideal sail trim can make all the difference in your sailing experience. By incorporating fairleads into your rigging system, you gain newfound control and precision in adjusting the shape of sails according to changing wind conditions. This enables sailors to harness maximum power from their sails, translating into improved speed, efficiency, and overall performance under various weather circumstances.

3. Techniques for Mastering Fairlead Sailing: a) Strategic Positioning: Determining the optimal placement of fairleads throughout your rigging system is a crucial step towards unlocking the benefits they offer. Assessing load distribution and identifying areas where ropes are subject to excessive stress or friction allows sailors to position fairleads strategically. Experimentation with different placements based on boat size, mast height, and intended purpose empowers mariners to establish a perfect balance between performance and adaptability.

b) Rope Selection & Maintenance: When venturing into fairlead sailing, selecting high-quality ropes specifically designed for reduced friction should be at the top of your priority list. Regular inspections for signs of wear or strain ensure that proper maintenance measures are taken promptly. By doing so, you not only prolong the lifespan of your rigging elements but also guarantee optimal functioning of fairleads.

c) Continuous Learning & Adaptation: Fairlead sailing demands constant learning through practical experiences and sharing knowledge within the sailing community. Attending workshops, engaging with fellow sailors online or offline, and exploring new techniques solidify skills in harnessing the full potential of fairleads aboard different types of vessels under diverse sailing conditions.

Conclusion:

Fairlead sailing offers an array of benefits that elevate a sailor’s experience on the water by way of enhanced control, reduced friction and wear, as well as optimized sail trim. Mastering this technique requires strategic positioning of fairleads while incorporating high-quality ropes paired with diligent maintenance practices. As seafarers continually learn from one another and adapt their skills over time – embracing innovation without forsaking tradition – we witness the marriage of professionalism, wit, and cleverness that leads us to new heights in sailing efficiency and precision on the open seas .

Step-by-Step Instructions for Mastering Fairlead Sailing

Fairlead sailing is a technique that every sailor should master . It involves using the fairlead, which is a small, metal or plastic device through which the sheets (lines) are run to guide them properly . By understanding how to utilize this nifty contraption effectively, you can enhance your sail control skills and optimize your boat ‘s performance on the water. In this blog post, we will provide you with detailed instructions on how to become a true master of fairlead sailing.

1. Familiarize yourself with the fairleads: Before delving into fairlead sailing, it’s crucial to understand the fundamentals of these little wonders. Take some time to examine your boat’s fairleads closely and get acquainted with their various types and positions. Different boats may have different setups, so it’s essential to know what you’re working with.

2. Choose the right line: Selecting the appropriate sheet or line for each fairlead is vital for optimal control while sailing . The size, material, and flexibility of the line can significantly impact its efficiency in running through the fairlead smoothly without hindrance.

3. Adjust fairleads’ position: Based on factors such as wind direction and desired sail trim angles, adjust the positioning of your boat’s fairleads accordingly. This step requires careful consideration as even slight changes in placement could lead to dramatic differences in performance.

4. Respect line friction: Effective fairlead sailing ensures minimal friction between lines and their respective devices. Friction hinders smooth movement and negatively affects your boat ‘s overall performance. Always check for potential friction points along the lines’ path—keep an eye out for rubbing against edges or other objects.

5. Moderate tension application: Remember that applying excessive tension while running lines through a fairlead system can be counterproductive; it risks creating unnecessary strain on sheets and decrease overall responsiveness during maneuvers such as tacking or jibing. Find an optimal balance, applying enough tension to maintain control without compromising flexibility.

6. Use proper fairlead angle: Another crucial aspect of mastering fairlead sailing is understanding the significance of the angle at which lines pass through the fairleads. Ideally, aim for a narrower angle since it reduces friction and enables smoother line movement. Experiment with various angles to discover what works best for your boat and sailing conditions.

7. Employ fairleads for precise trim: Fairlead sailing plays a pivotal role in achieving precise sail trim on your boat. By properly utilizing these devices, you can effectively adjust the angle and shape of your sails to capture maximum wind power and optimize speed . Remember that small adjustments can significantly impact your boat ‘s performance.

8. Mindfully handle line load: As you manipulate sail trim using fairleads, be mindful of how the lines distribute load across the boat. Properly balancing loads helps maintain stability and prevents excessive strain on individual components or rigging elements.

9. Continuously learn and adapt: The key to truly mastering any skill is a relentless thirst for knowledge and a willingness to adapt and experiment as you become more experienced with fairlead sailing techniques. Observe seasoned sailors, engage in discussions within sailing communities, or consult professional resources to expand your understanding further.

10. Practice, practice, practice: Lastly, no amount of theory can replace practical experience when it comes to mastering fairlead sailing fully. Get out on the water as often as possible; experiment with different settings, scenarios, wind conditions—immerse yourself in hands-on learning that will accelerate your progress.

By following these step-by-step instructions diligently, you will gradually unlock the secrets of fairlead sailing prowess—a highly sought-after skill that distinguishes skilled sailors from amateur enthusiasts. Remember that true mastery takes time and dedication—so be patient with yourself but never shy away from honing this artful technique !

Frequently Asked Questions About Fairlead Sailing: All You Need to Know

Welcome aboard, sailor! If you’ve found yourself here, chances are you’re curious about fairlead sailing and eager to learn more. Well, you’re in luck because we have all the answers to those burning questions that have been bobbing around in your head. So grab a cup of coffee, settle into your comfiest deck chair, and let’s dive into the world of fairlead sailing!

1. What exactly is fairlead sailing? Fairlead sailing refers to a technique utilized in sailboat racing where teams strategically position crew members to manipulate the sails using primary and secondary winches. By adjusting the angle and tension on lines guiding the sails through various fairleads (pulley systems), sailors can optimize their boat’s performance.

2. How does fairlead sailing differ from traditional sailing? Fairlead sailing takes traditional sailing techniques to new heights by focusing on fine-tuning sail control for max speed potential. While classic sailors rely on intuition and experience, fairlead sailors employ systematic manipulation of different controls, constantly fine-tuning their rigging setups.

3. Why should I bother with fairlead sailing? Think of it this way: if traditional sailing is like driving a car with a manual transmission, fairlead sailing is like having a perfectly synchronized Formula 1 gearbox! It allows for precise control over each sail position, leading to faster speeds and improved efficiency – every sailor’s dream!

4. Are there any downsides to fairlead sailing? Like any technique worth mastering, there may be a slight learning curve associated with fairlead sailing. However, once you get the hang of it (and trust us, you will), it becomes second nature – just like tying your shoelaces!

5. Do I need specialized equipment for fairlead sailing? Fear not! You don’t need an arsenal of expensive gadgets or futuristic contraptions to begin your journey as a fairlead sailor. Most modern sailboats are equipped with a standard set of winches and fairleads necessary for this technique. That’s the beauty of fairlead sailing – it’s accessible to everyone!

6. Can fairlead sailing be applied to everyday cruising? Absolutely! While fairlead sailing initially gained popularity in competitive racing circles, its benefits can be enjoyed by any sailor willing to explore new techniques. By harnessing the power of fairlead systems, you can enhance your overall sailing experience, regardless of whether you’re racing or enjoying a leisurely sail.

7. Will fairlead sailing make me a better sailor? Short answer: absolutely! Fairlead sailing allows sailors to gain a deeper understanding of wind dynamics, sail trim, and boat performance – all skills that will undoubtedly take your sailing expertise to new horizons. Plus, mastering this technique will undoubtedly impress your fellow seafarers!

So there you have it – the lowdown on fairlead sailing! We hope these answers have satisfied your curiosity and fueled your passion for this exciting technique . Whether you plan on hoisting the mainsail in friendly competition or simply want to optimize your cruising adventures, fairlead sailing is without a doubt worth exploring. So unfurl those sails, embrace the wind, and embark on an exhilarating journey towards becoming a masterful fairlead sailor!

How Fairlead Sailing Can Improve Your Yacht’s Performance: Tips and Tricks

Fairlead sailing, a technique that involves utilizing fairleads on your yacht’s deck, can significantly enhance your vessel’s performance on the water. By properly understanding and implementing fairlead sailing, you can achieve greater control, increased speed, and improved maneuverability – all factors that make for an exceptional yachting experience . In this blog post, we will delve into the various ways fairlead sailing can elevate your yacht’s performance while offering valuable tips and tricks along the way.

Firstly, let’s establish what fairleads are and their purpose. Fairleads are essentially simple yet essential fitting devices found on the deck of a yacht. They serve as guiding tools for lines – ropes or cables used to control sails, rigging, and other components of a sailboat. Through these fairleads, lines smoothly traverse across the deck and successfully reach their intended destinations while minimizing friction.

Now let’s explore the ways in which incorporating fairlead sailing techniques can optimize your yacht’s performance:

1. Minimized Friction: One of the primary benefits of using fairleads is reducing friction between control lines and other objects on deck. This lower resistance allows for smoother movement of lines during maneuvers such as tacking or gybing. Enhanced line movement contributes to efficient adjustments of sails and rigging systems without unnecessary energy loss.

Pro Tip: Choosing high-quality fairleads made from low-friction materials like stainless steel or composite materials helps maximize their beneficial effects on overall yacht performance.

2. Improved Sail Control: Fairleads enable precise control over sail trim by ensuring that control lines have an optimal lead angle from mast-mounted winches or cleats to specific areas like jib sheets or mainsail controls. Proper lead angles ensure minimal deflection between the point of force application (winch/cleat) and where it connects with sails or rigging elements.

Tip: Experimenting with fairlead positions could help fine-tune sail controls according to wind conditions – allowing you to find the sweet spot for maximum sail efficiency.

3. Enhanced Maneuverability: When it comes to sailing maneuvers, fairlead placement plays a crucial role in achieving nimble maneuverability. By positioning fairleads strategically and in consideration of various forces at play, such as wind direction, tacking or gybing becomes smoother and more precise. This improved maneuverability translates into quicker response times, reducing the risk of collisions and increasing overall safety.

Tip: Understanding the principles of true lead angle – where the fairlead aligns with incoming forces on control lines during various sailing scenarios – can empower you to optimize your yacht ‘s maneuvering capabilities.

4. Increased Speed: The reduction of friction achieved through proper fairlead utilization directly affects your yacht’s speed potential. Better line movement means less energy dissipated as heat due to friction, allowing more power from wind or propulsion mechanisms to translate into increased forward momentum. Consequently, this can result in improved upwind performance or even boost your competitive edge during regattas.

Pro Tip: Conduct regular checks and maintenance of fairleads to ensure smooth operation and avoid any potential wear that could compromise performance gains.

Incorporating these tips and tricks based on an understanding of fairlead sailing will undoubtedly elevate your yachting experience. However, it is essential to note that each yacht may require different fairlead setups depending on design factors like winch locations, deck layouts, and rigging configurations . Consultation with professional yacht designers or experienced sailors can provide valuable insights tailored specifically for your vessel.

To conclude, embracing the world of fairlead sailing offers remarkable advantages for improving your yacht’s performance across multiple fronts – from minimizing friction and optimizing sail controls to enhancing maneuverability and achieving higher speeds. By integrating these techniques into your sailing repertoire, you’ll find yourself at the helm of a remarkably efficient vessel that effortlessly glides through serene waters or conquers fierce regatta competition – all while enjoying the thrill of the open sea . So, set your fairleads in place and embark on a transformative journey towards unlocking your yacht’s true potential!

Advanced Tips and Tricks for Fine-tuning Fairlead Sail Settings

In the exhilarating world of sailing, every sailor dreams of achieving optimal speed and control on the water. Mastering the art of fine-tuning fairlead sail settings is a crucial step towards gaining a competitive edge. With this in mind, we’re here to provide you with advanced tips and tricks that will take your sailing skills to new heights.

Fairlead sail settings refer to the position of the foredeck blocks that guide your sails’ sheets or control lines. Proper adjustment of these fairleads allows you to optimize sail shape, angle of attack, and leech tension – all critical factors influencing your boat’s performance. So without further ado, let’s dive into some expert insights for fine-tuning fairlead sail settings .

1. Understand Your Sailing Rig: Before venturing into adjusting your fairleads, it’s essential to have a strong understanding of your boat ‘s rigging and how it impacts sail shape. Familiarize yourself with concepts like mast rake, forestay tension, and diamond spreader placement as these elements play a crucial role in sail control.

2. The Quest for Optimal Sail Shape: One key aspect of fine-tuning fairlead settings is ensuring an ideal sail shape. Depending on wind conditions and points of sail, adjust your fairleads accordingly to achieve optimum camber along the length and depth of the sail. Experimenting with different positions will allow you to find the sweet spot where fullness distributes evenly across the entire cloth.

3. Perfecting Angle of Attack: Adjusting your fairleads also affects the angle at which wind interacts with your sails – known as “angle of attack.” For upwind sailing, move your jib sheet cars slightly aft from their default position to increase power by tightening windward shrouds simultaneously.

4. Balancing Leech Tension: Leech tension plays a significant role in maintaining optimum airflow across each sail section while minimizing drag-inducing turbulence near trailing edges. Experiment with fairlead positions to find the ideal balance between fully powered-up sails and excessive leech flutter, ultimately maximizing speed.

5. Utilizing Telltales: Mounting telltales on your sails provides invaluable feedback in determining whether your sail settings are dialed-in perfectly. These small ribbons or strings should flow smoothly when sailing upwind – if any fluttering or stalling occurs, adjust your fairleads accordingly until a steady flow is achieved.

6. The Art of Fine-Tuning: Sailing conditions can change rapidly, demanding continuous adjustments to maintain peak performance. Ensure that you regularly monitor wind shifts, waves, and other factors influencing sail dynamics, allowing you to make informed decisions regarding adjusting your fairleads for optimal control at all times.

7. Video Analysis: Recording your sailing sessions and analyzing the footage later can be incredibly enlightening. Observe how changes in fairlead positions manifest on the water – noting differences in boat speed , pointing ability, and overall balance – enabling you to refine and perfect your techniques over time.

While these advanced tips may take time and practice to master, embracing the art of fine-tuning fairlead sail settings will undoubtedly give you a competitive edge in any race or regatta. Remember that there is no “one-size-fits-all” approach; each boat responds uniquely to various adjustments. By combining technical expertise with intuition honed through experience, you’ll unlock a world of high-performance sailing that turns heads on the water.

So set sail confidently armed with these advanced tips and tricks for fine-tuning fairlead sail settings, fierce competitors on every racecourse await you!

Recent Posts

- Approaching a Mooring Buoy: Essential Tips for Safe Navigation

- Best Tiller Autopilot: Enhance Your Sailing Experience

- Nautical Navigator: Essential Tools and Techniques for Seamanship

- Sail Making Material: A Comprehensive Guide

- 2 Person Dinghy: The Ultimate Guide to Choosing the Perfect Boat

- Sailboat Gear and Equipment

- Sailboat Lifestyle

- Sailboat Maintenance

- Sailboat Racing

- Sailboat Tips and Tricks

- Sailboat Types

- Sailing Adventures

- Sailing Destinations

- Sailing Safety

- Sailing Techniques

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Jib Fairleads Adjustment

- Thread starter Don Guillette

- Start date Jun 6, 2013

- Featured Contributors

- Sail Trim with Don Guillette

Don Guillette

Our good friend Shermandr has provided us with a topic. He made two statements. The first one was "plenty of cruising sailors rarely if ever adjust their jib leads" and 'he has been on many racing boats, who win, that set their jib leads for a leg of the race and don't micro adjust unless conditions change". At first I was going to jump all over this UNTIL I re-read the statements - I though he was saying something different that could be misunderstood by newbies. Let me explain. Most boats that I've been invited on to help the boat improve sail trim have the fairleads rusted in place. Fairleads are the first thing I look at because it tells me 2 things -- one is they don't use them and two is I wonder if they know how to use them. By not adjusting the fairleads, they're like the broken clock. The adjustment is right for one point of sail and wind condition and wrong for all others. This is especially a problem on a masthead rig boat where the engine is the jib. If the boat has pin type adjustors I can understand the problem. Sailors and all humans will do what is easy and not what is hard. It's hard to adjust pin type fairleads under load so they "set it and forget it". They may as well be sailing a 55 gal drum with a broom stick for a mast and a bed sheeet for a sail. At minimum, a cruiser or a racer should check their fairlead adjustment during each tack and this is how it's done. Just before the boat comes head to wind the jib will "break". Either the top or bottom will break first. It's the responsibility of the trimmer on the loaded sheet to call the "break' to the trimmer on the lazy sheet so he can make the fairlead adjustment on his side before the sail comes over to his side. If the sail breaks evenly from top to bottom, no adjustment is necessary. At first I thought he was telling me that race boats he's been on don't adjust their fairleads and win races, which is silly, but he 's not saying that. There's nothing wrong with adjusting your fairleads as you sail along. If you have a Garhauer adjustable system, such as I have, the system adjusts itself. When you tack it finds it's own position -- almost. I found I needed to pull the car aft a tiny bit and set up the system so it looked like a minny traveler -- I can move the cars back and forward. As far as the halyard is concerned, here's how I set mine. I go to full hoist and then back off slightly. I never adjust the mainsail or jib using the halyard -- I use a cunningham for the main and jib. What do you guys think about this topic??

My pxr cleats don't hold the halyard well enough to tension the main, so I use the Cunningham until we have to reef. I'm replacing the cleats with clutches in a week or so, which I hope will help. Should resolve the issue of someone bumping them with a hand and having the cleat pop open and the sail come down on our heads, too. Genoa track is garhauer, though not self adjusting. All I have to do is pull on a line to move them under way, so we do use them. Maybe not on every tack, but I'll tweak 'em if I'm in a performance mood instead of relaxation mood. Cabin-top jib track has pins and they're not adjustable under load. They only get adjusted if conditions change dramatically. Bigger issue is the permanent twist in my tuff luff foil. Pretty sure the PO stored it curved on deck instead of rolled up or flat. On port tack a 3-4 foot section near the top is twisted too far off the wind at the luff. While it's not a huge deal with the genoa, it's hard to keep the blade from flapping up there. Shaeffer says it can't be fixed, but I'm thinking a bit of time and careful application of a heat gun might let me reduce the twist.

Let's get this back on the new posts. We're trying to have a perfectly good donnybrook here and no one is helping. What I am saying is that for all the talk about adjusting jib leads, in practice it is done a whole lot less than it's talked about. I can't tell you how many racing boats I've been on that when someone begins to adjust the fairlead the skipper is screaming to leave them alone. That is, I think, because the skipper probably had a good race with them adjusted where they are and doesn't want to change them. In Don's parlance the skipper doesn't really understand how to adjust them. Also there are a lot of drivers who like to leave the trim alone. They would rather find a groove and not have changes to the trim to make it more difficult. I'm not saying that is correct. I'm just saying in the real world of club level racing where this is common. On other boats the skipper doesn't want someone on the lee side - unfortunately almost never me. My other point about the halyard wasn't that it is the most important. But I think it is the most overlooked. It is the first sail control employed - raising the sail. And, it's proper adjustment seems like the first thing to do. Most boats are not even set up to get proper tension on; and, a lot of casual sailors don't realize that if the halyard is 100' long and they have 1 to 2 percent stretch (Low Stretch) they will have 1 to 2 feet of stretch. Try lowering your halyard 2 feet on an upwind let and see how it goes. The cunningham is good for maybe a few inches. That was my point.

The halyards are perhaps 'the' most important sail control ... as they control the point along the horizontal cord/plane of the sail which develops its point of maximum draft. Ignore this 'sail shaping control' and youll be forever fighting adverse helm. With adverse helm all the other sail shape and trim considerations simply 'go out the window' ... until the boat is sooner or later corrected, by helm balance (easiest corrected by halyard adjustment) ......... to stop dragging the rudder partly sideways through the water. If youre dragging your rudder, you will need a powered-up shape ... a shape thats 'slow', a shape that causes excess heel, a shape that disturbs the air flow way out in front of the boat. Good trim requires 'helm balance'; you will be cross-controlled to solve the problems of 'helm unbalance' until you get that helm balance correctly set ---- halyard tension. If you prefer to sail a 'slow' boat, simply tow a bucket ... but after you set up for a very slight 'weather helm'. ;-)

I have been sailing as crew on a Catalina 22 and we move the genoa track fairleads often, but not while under a load. I am in the process of doing several upgrades to my Catalina 25 and one of them is installing a Barber Hauler type system to the genoa sheets to pull them forward and leave the fairleads aft. I solo sail on a small lake and tack quite often so moving them from the cockpit will be helpful. I have not seen this done yet but I think I am going to try it. Your thoughts?

25yearslater

I recognize the comment from shemandr and now I understand the process of setting the jib cars and what to look for. The break of the luff being top to bottom as a basic setting will be put in practice tomorrow. Can't wait for the book. Thanks Don.

Sailing Vermont

Okay, I've been thinking about ordering Don's book. I just did when I realized I didn't understand which way to move the cars if the jib luff break was too high or too low. I'm guessing if it's too high, I'd pull them aft to bring the break down. Can you tell me if I'm correct, or do I have to wait until the book arrives?